Article contents

Effects of austenitic and duplex electrodes on microstructure, mechanical properties, pitting, and galvanic corrosion resistance of ferritic and dual-phase stainless steel dissimilar joints

Published online by Cambridge University Press: 25 July 2017

Abstract

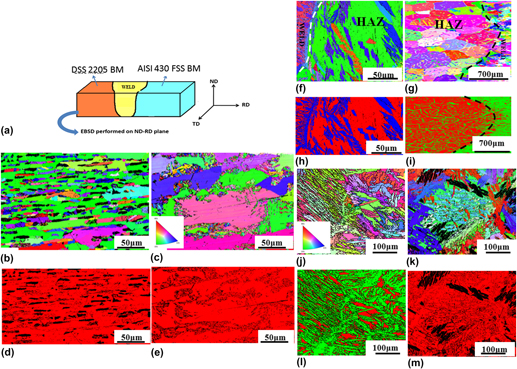

In this work, examination of joint properties of ferritic and dual-phase stainless steel dissimilar welds was carried out by using E2209 duplex and E309LMo austenitic electrodes. The results of E2209 weld showed dual-phase microstructure of ferrite and austenite in the form of grain boundary austenite, Widmanstatten and intragranular austenite, whereas E309LMo weld showed acicular ferrite in the cores of subgrain of austenite. Electron backscatter diffraction was used to study the evolution of the microstructure and micro-texture. The significant variations in the feature of weldments illustrated the presence of a very strong texture. Ferritoscope measurement revealed higher ferrite content in the E2209 weld. Tensile strength, hardness, and absorbed energy of weld metal were dominated by E2209 weld. The modified Strauss test indicated intergranular corrosion attack in the AISI 430 ferritic side heat affected zone. Higher pitting resistance showed by E2209 weld than E309LMo weld. While higher galvanic corrosion observed in the E309LMo weld and AISI 430 ferritic base metal couple.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 6

- Cited by