Article contents

Effect of rolling reductions on microstructure and properties of 2Cr13/316L multi-layered steel composite plate by accumulative roll-bonding

Published online by Cambridge University Press: 08 November 2018

Abstract

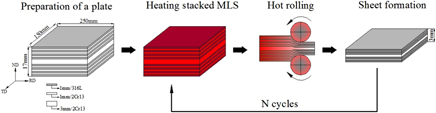

The 2Cr13/316L multilayered composite plates were fabricated by hot rolling with recycle heating step. The effect of rolling reductions on microstructure and properties was investigated. The 2Cr13 layer consists of martensite and lath ferrite, but the middle layer has less ferrite than both sides. The content and grains of ferrite increase with the increase of the reduction and number of reheating, which leads to a decrease in the hardness of the 2Cr13 layer. The hardness of the 2Cr13 layer is determined by the volume ratio of martensite and ferrite. Tensile strength of the specimens with the rolling reduction of 72% and 82% reached 815.8 MPa and 763.4 MPa, while elongations were 20% and 20.8%, respectively. With the increase of the rolling reduction, the fracture mode also changed from cleavage fracture to dimple fracture. There were no cracks and delamination when the 2Cr13/316L composite plate bent to 130° and 180°, which indicated better interfacial bonding.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

REFERENCES

- 7

- Cited by