Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Poplawsky, Jonathan D.

Milligan, Brian K.

Allard, Lawrence F.

Shin, Dongwon

Shower, Patrick

Chisholm, Matthew F.

and

Shyam, Amit

2020.

The synergistic role of Mn and Zr/Ti in producing θ′/L12 co-precipitates in Al-Cu alloys.

Acta Materialia,

Vol. 194,

Issue. ,

p.

577.

Seikh, Ziyauddin

Huraira Biswas, Abu

Kamaruzzaman, Md

Haque, Rafiqul

Kibria, Golam

Haidar, Shamim

and

Sekh, Mukandar

2021.

Density, hardness and wear responses of aluminium-copper-magnesium alloys.

Materials Today: Proceedings,

Vol. 47,

Issue. ,

p.

2358.

Pan, Yong

and

Yu, Ende

2021.

First-principles investigation of structural stability, mechanical and thermodynamic properties of Pt3Zr5 compounds.

Physica B: Condensed Matter,

Vol. 611,

Issue. ,

p.

412936.

Tao, Chengchuang

Huang, Hongjun

Yuan, Xiaoguang

Yue, Chunyu

Su, Ming

and

Zuo, Xiaojiao

2022.

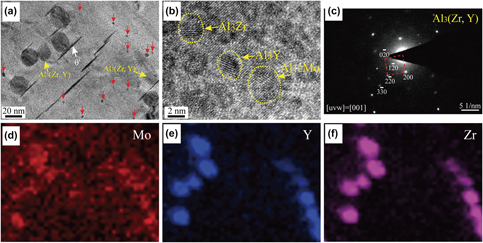

Effect of Y Element on Microstructure and Hot Tearing Sensitivity of As-Cast Al–4.4Cu–1.5Mg–0.15Zr Alloy.

International Journal of Metalcasting,

Vol. 16,

Issue. 2,

p.

1010.

Mondol, Sukla

Bansal, Ujjval

Singh, Mahander Pratap

Dixit, Saurabh

Mandal, Animesh

Paul, Aloke

and

Chattopadhyay, Kamanio

2022.

Microstructure-Strength Correlations in Al-Si-Cu Alloys Micro-Alloyed with Zr.

SSRN Electronic Journal ,

Mondol, Sukla

Bansal, Ujjval

Singh, Mahander Pratap

Dixit, Saurabh

Mandal, Animesh

Paul, Aloke

and

Chattopadhyay, Kamanio

2022.

Microstructure-strength correlations in Al-Si-Cu alloys micro-alloyed with Zr.

Materialia,

Vol. 23,

Issue. ,

p.

101449.

Poplawsky, Jonathan D.

Michi, Richard

Allard, Lawrence

Bahl, Sumit

Plotkowski, Alex

and

Shyam, Amit

2022.

Using Θ' Interfaces as Templates for Planar L12 Precipitation in Alcumnzr Alloys.

SSRN Electronic Journal ,

Yang, Yuping

Su, Ruiming

Ma, Siyi

Li, Guanglong

Qu, Yingdong

and

Li, Rongde

2022.

Effect of Zr Content on the Microstructure and Corrosion Resistance of Al–Cu–Mn Alloy.

Russian Journal of Non-Ferrous Metals,

Vol. 63,

Issue. 6,

p.

681.

Bansal, Ujjval

and

Chattopadhyay, Kamanio

2022.

Newer Developments in Aluminium Alloys Through Ordered Precipitates and Segregation of Transition Elements.

Transactions of the Indian Institute of Metals,

Vol. 75,

Issue. 4,

p.

1015.

Poplawsky, Jonathan D.

Michi, Richard A.

Allard, Lawrence F.

Bahl, Sumit

Plotkowski, Alex J.

and

Shyam, Amit

2022.

Using θ′ interfaces as templates for planar L12 precipitation in AlCuMnZr alloys.

Additive Manufacturing Letters,

Vol. 3,

Issue. ,

p.

100086.

Dai, Jun-Nan

Kou, Shu-Qing

Yang, Hong-Yu

Xu, Zheng-Bo

Shu, Shi-Li

Qiu, Feng

Jiang, Qi-Chuan

and

Zhang, Lai-Chang

2022.

High-content continuous carbon fibers reinforced PEEK matrix composite with ultra-high mechanical and wear performance at elevated temperature.

Composite Structures,

Vol. 295,

Issue. ,

p.

115837.

Zhang, Han

Hao, Qitang

Li, Xinlei

Yu, Wentao

and

Xue, Yanqing

2023.

Coupled Precipitation of Dual-Nanoprecipitates to Optimize Microstructural and Mechanical Properties of Cast Al–Cu–Mg–Mn Alloys via Modulating the Mn Contents.

Nanomaterials,

Vol. 13,

Issue. 23,

p.

3038.

Hu, Te

Ruan, Zixiong

Fan, Touwen

Chen, Dongchu

Wu, Yuanzhi

and

Tang, Pingying

2023.

First-principles calculations to investigate stability, mechanical and thermo-dynamic properties of AlxTMy intermetallics in aluminum alloys.

Solid State Communications,

Vol. 376,

Issue. ,

p.

115361.

Dai, Hongbin

Wang, Lang

Dong, Bolun

Miao, Jian

Lin, Sanbao

and

Chen, Hongtao

2023.

Microstructure and high-temperature mechanical properties of new-type heat-resisting aluminum alloy Al6.5Cu2Ni0.5Zr0.3Ti0.25V under the T7 condition.

Materials Letters,

Vol. 332,

Issue. ,

p.

133503.

Liu, Kun

Wang, Shuai

Hu, Peng

Pan, Lei

and

Chen, X.-Grant

2023.

Improved Thermo-Mechanical Fatigue Resistance of Al-Si-Cu 319 Alloys by Microalloying with Mo.

Materials,

Vol. 16,

Issue. 9,

p.

3515.

Cai, Zhiyong

Liu, Haijiang

Wang, Richu

Peng, Chaoqun

Feng, Yan

and

Wang, Xiaofeng

2023.

Microstructure and Mechanical Properties of the Extruded Al-Cu-Mn-Sc-Zr Alloy during Single-Stage and Two-Stage Aging.

Journal of Materials Engineering and Performance,

Vol. 32,

Issue. 1,

p.

185.

Hu, Kuishen

Zou, Chunming

Wang, Hongwei

and

Wei, Zunjie

2023.

Influence of Ti elements on the evolution of microstructure, mechanical properties and thermal stability of Al-Cu alloy.

Journal of Alloys and Compounds,

Vol. 952,

Issue. ,

p.

169860.

Cui, Junge

Zeng, Guangkai

Gupta, Nikhil

Luo, Yue

Fu, Xiangzhou

Yang, Hailong

Li, Anmin

and

Pan, Liwen

2023.

Microstructure and Tensile Property of Al3Zr/Al-Cu-Ni-V Composite Prepared by In Situ Reaction.

Journal of Materials Engineering and Performance,

Tang, Pang

Yu, Kailai

Qin, Luman

and

Huang, Saisha

2023.

Effect Mechanism of Sc Addition and T6 Heat Treatment on Precipitated Phase and Mechanical Properties of Al‐Cu‐Mn Alloy.

physica status solidi (a),

Vol. 220,

Issue. 15,

Liu, Jingbin

Hu, Jingyi

Li, Mengyu

Liu, Guiliang

Wu, Yuying

Gao, Tong

Liu, Shushuai

and

Liu, Xiangfa

2024.

Influence of Zr Microalloying on the Microstructure and Room-/High-Temperature Mechanical Properties of an Al–Cu–Mn–Fe Alloy.

Materials,

Vol. 17,

Issue. 9,

p.

2022.