Article contents

Dislocation dynamics modeling of precipitation strengthening in Fe–Ni–Al–Cr ferritic superalloys

Published online by Cambridge University Press: 26 September 2017

Abstract

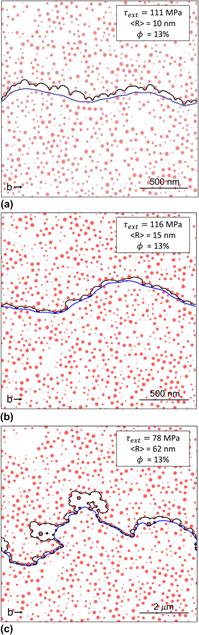

Two-dimensional dislocation dynamics (DD) simulations are performed to simulate the increase in strength of ferritic superalloys strengthened by ordered β′(B2)–NiAl precipitates. Parametric studies for three precipitate volume fractions (10, 13, and 20%) and various radii (from 1 to 75 nm) predict strengthening via a mixture of precipitate bypassing and shearing by single- and super-dislocations of edge or screw character. DD strength contributions for various precipitate radii (for a 13% volume fraction) are compared to analytical models for ordered precipitate strengthening: good agreement exists in the overaged state, but not in the peak-aged and underaged states for either dislocation configurations. DD strength contributions, converted to hardness values, are compared to experimental hardness values from previously reported literature on a ferritic superalloy [Fe–10Cr–10Ni–6.5Al–3.4Mo–0.25Zr–0.005B (wt%)] aged at various temperatures and times. DD hardness values from the single-edge dislocation simulations accurately predict the experimental peak hardness, but not the under- and over-aged hardness values or trends. By incorporating the effect of secondary NiAl nanoprecipitates formed on cooling and solid solution strengthening of Fe in the primary precipitates, reasonable agreement is achieved in the overaged condition.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 9

- Cited by