Article contents

Development of ultrafine grained Al 7075 by cryogenic temperature large strain extrusion machining

Published online by Cambridge University Press: 20 September 2018

Abstract

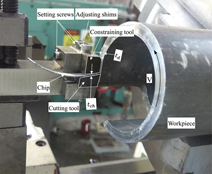

Large strain extrusion machining (LSEM) emerges as an innovative severe plastic deformation method of fabricating ultrafine grained materials. However, substantial heat generated during LSEM would sacrifice the mechanical properties of materials. Cryogenic temperature (CT) LSEM is put forward to overcome this shortcoming. The Al 7075 was processed by cryogenic and room temperature (RT) LSEM to investigate their comparative effects on mechanical and microstructural properties. Results indicate that the chip morphology of CT LSEM is featured with better integrity. Grains are refined to less than 200 nm by CT LSEM. A more complicated microstructure with high dislocation density is observed in the CT LSEM specimens. The hardness of cryogenic and RT LSEM specimens increases with the compression ratio and reaches the highest values of 187HV and 170HV, respectively. Dislocation strengthening is the main contributor, accounting for the higher hardness of CT LSEM specimens.

Keywords

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

Footnotes

This article has been updated since original publication. A notice detailing this change has also been published at https://doi.org/10.1557/jmr.2018.383.

References

REFERENCES

A correction has been issued for this article:

- 9

- Cited by

Linked content

Please note a has been issued for this article.