Article contents

Balancing processing ease with combustion performance in aluminum/PVDF energetic filaments

Published online by Cambridge University Press: 01 September 2020

Abstract

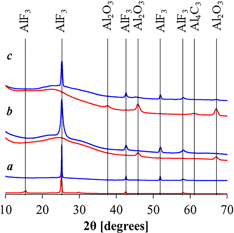

Molecular weight (Mw) effects in poly(vinylidene fluoride) (PVDF) influence both processability and combustion behavior in energetic Al–PVDF filaments. Results show decreased viscosity in unloaded and fuel-lean (i.e., 15 wt% Al) filaments. In highly loaded filaments (i.e., 30 wt% Al), reduced viscosity is minimal due to higher electrostatic interaction between Al particles and low Mw chains as confirmed by Fourier-transform infrared spectroscopy. Thermal and combustion analysis further corroborates this story as exothermic activity decreases in PVDF with smaller Mw chains. Differential scanning calorimetry and Thermogravimetric analysis show reduced reaction enthalpy and lower char yield in low Mw PVDF. Enthalpy reduction trends continued in nonequilibrium burn rate studies, which confirm that burn rate decreases in the presence of low Mw PVDF. Furthermore, powder X-ray patterns of post-burn products suggest that low Mw PVDF decomposition creates a diffusion barrier near the Al particle surface resulting in negligible AlF3 formation in fuel-rich filaments.

- Type

- Invited Feature Paper

- Information

- Copyright

- Copyright © Materials Research Society 2020

Footnotes

Contributing Editor: Sarah Morgan

References

- 7

- Cited by