Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Leineweber, A.

2012.

Anisotropic microstrain broadening in cementite, Fe3C, caused by thermal microstress: comparison between prediction and results from diffraction-line profile analysis.

Journal of Applied Crystallography,

Vol. 45,

Issue. 5,

p.

944.

Laschet, G.

Fayek, P.

Henke, T.

Quade, H.

and

Prahl, U.

2013.

Derivation of anisotropic flow curves of ferrite–pearlite pipeline steel via a two-level homogenisation scheme.

Materials Science and Engineering: A,

Vol. 566,

Issue. ,

p.

143.

Jiang, Chao

and

Srinivasan, Srivilliputhur G.

2013.

Unexpected strain-stiffening in crystalline solids.

Nature,

Vol. 496,

Issue. 7445,

p.

339.

Tacq, Jeroen

Kriška, Martin

and

Seefeldt, Marc

2013.

Synchrotron Diffraction Study of the Cementite Phase in Cold Drawn Pearlitic Steel Wires.

Materials Science Forum,

Vol. 768-769,

Issue. ,

p.

380.

Laschet, Gottfried

Shukla, Mohit

Henke, Thomas

Fayek, Patrick

Bambach, Markus

and

Prahl, Ulrich

2014.

Impact of the Microstructure on the U–O Forming Simulations of a Ferrite–Pearlite Pipeline Tube.

steel research international,

Vol. 85,

Issue. 6,

p.

1083.

Tacq, J.

Kriška, M.

and

Seefeldt, M.

2014.

Residual Stress in the Cementite Phase of Cold Drawn Pearlite*.

HTM Journal of Heat Treatment and Materials,

Vol. 69,

Issue. 2,

p.

64.

Leineweber, A.

Shang, S.L.

and

Liu, Z.K.

2015.

Elastic anisotropy of iron carbides with trigonal-prismatic coordination of C by Fe.

Journal of Alloys and Compounds,

Vol. 633,

Issue. ,

p.

390.

Weisser, M.A.

Van Petegem, S.

Cervellino, A.

and

Van Swygenhoven, H.

2015.

On the origin of cementite diffraction peak broadening during tensile deformation at ambient temperatures.

International Journal of Plasticity,

Vol. 66,

Issue. ,

p.

138.

Leineweber, Andreas

2016.

Thermal expansion anisotropy as source for microstrain broadening of polycrystalline cementite, Fe3C.

Journal of Applied Crystallography,

Vol. 49,

Issue. 5,

p.

1632.

Borchers, Christine

and

Kirchheim, Reiner

2016.

Cold-drawn pearlitic steel wires.

Progress in Materials Science,

Vol. 82,

Issue. ,

p.

405.

Mauger, L.

Herriman, J. E.

Hellman, O.

Tracy, S. J.

Lucas, M. S.

Muñoz, J. A.

Xiao, Yuming

Li, J.

and

Fultz, B.

2017.

Phonons and elasticity of cementite through the Curie temperature.

Physical Review B,

Vol. 95,

Issue. 2,

Taniyama, Akira

Takayama, Toru

Arai, Masahiro

and

Hamada, Takanari

2017.

Deformation Behavior of Cementite in Deformed High Carbon Steel Observed by X-ray Diffraction with Synchrotron Radiation.

Metallurgical and Materials Transactions A,

Vol. 48,

Issue. 10,

p.

4821.

Huang, Linghui

Tu, Yiyou

Zhang, Qi

Zhou, Xuefeng

and

Jiang, Jianqing

2018.

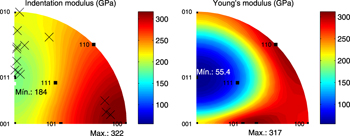

Unobvious elastic anisotropy of measured single–crystal cementite.

Materials Research Express,

Vol. 6,

Issue. 1,

p.

016531.

Umemoto, Minoru

Kruger, Silvio E.

and

Ohtsuka, Hideyuki

2019.

Ultrasonic study on the change in elastic properties of cementite with temperature and Mn content using nearly full density polycrystalline bulk samples.

Materials Science and Engineering: A,

Vol. 742,

Issue. ,

p.

162.

Guelton, Nicolas

and

François, Marc

2020.

Microstructure–Property Relationship in Cold-Drawn Pearlitic Steel Wires.

Metallurgical and Materials Transactions A,

Vol. 51,

Issue. 4,

p.

1543.

Bhadeshia, H. K. D. H.

2020.

Cementite.

International Materials Reviews,

Vol. 65,

Issue. 1,

p.

1.

Ohmura, Takahito

and

Wakeda, Masato

2021.

Pop-In Phenomenon as a Fundamental Plasticity Probed by Nanoindentation Technique.

Materials,

Vol. 14,

Issue. 8,

p.

1879.

Umemoto, Minoru

and

Ohtsuka, Hideyuki

2021.

Mechanical Properties of Cementite.

Tetsu-to-Hagane,

Vol. 107,

Issue. 4,

p.

269.

Umemoto, Minoru

and

Ohtsuka, Hideyuki

2022.

Mechanical Properties of Cementite.

ISIJ International,

Vol. 62,

Issue. 7,

p.

1313.

Tsybenko, Hanna

Tian, Chunhua

Rau, Julia

Breitbach, Benjamin

Schreiber, Paul

Greiner, Christian

Dehm, Gerhard

and

Brinckmann, Steffen

2022.

Deformation and phase transformation in polycrystalline cementite (Fe3C) during single- and multi-pass sliding wear.

Acta Materialia,

Vol. 227,

Issue. ,

p.

117694.