Article contents

Anisotropic surface stability of TiB2: A theoretical explanation for the easy grain coarsening

Published online by Cambridge University Press: 25 April 2017

Abstract

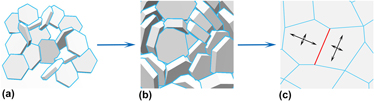

The exaggerated grain growth, anisotropic crystallite morphology, and thermal expansion are the main reasons for the microcracking of sintered TiB2, wherein grain coarsening and anisotropic crystallite morphology are believed to be controlled by the surface stabilities of TiB2. To deeply understand the grain growth mechanism, the anisotropic stability and bonding features of TiB2 surfaces, including

$\left( {11\bar 20} \right)$

, two types of (0001), and three types of

$\left( {11\bar 20} \right)$

, two types of (0001), and three types of

$\left( {10\bar 10} \right)$

, are investigated by first-principles calculations. By employing the two-region modeling method, surface energies are calculated and the

$\left( {10\bar 10} \right)$

, are investigated by first-principles calculations. By employing the two-region modeling method, surface energies are calculated and the

$\left( {11\bar 20} \right)$

surface is found to be more stable than (0001) and

$\left( {11\bar 20} \right)$

surface is found to be more stable than (0001) and

$\left( {10\bar 10} \right)$

surfaces. Hexagonal plate-like grain morphology is predicted. The different bonding conditions of surface Ti and B atoms contribute to the difference of surface structure relaxation between surfaces with Ti- and B-termination, which lead the B-terminated ones to be more stable. It is also found that the surface energies of TiB2 are much higher than those of ZrB2 with a similar structure, which may be responsible for the easy coarsening of TiB2.

$\left( {10\bar 10} \right)$

surfaces. Hexagonal plate-like grain morphology is predicted. The different bonding conditions of surface Ti and B atoms contribute to the difference of surface structure relaxation between surfaces with Ti- and B-termination, which lead the B-terminated ones to be more stable. It is also found that the surface energies of TiB2 are much higher than those of ZrB2 with a similar structure, which may be responsible for the easy coarsening of TiB2.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Sung-Yoon Chung

References

REFERENCES

- 5

- Cited by