Article contents

Analyzing mechanical properties of a nanocrystalline Fe–Ni coating by nanoindentation

Published online by Cambridge University Press: 19 September 2011

Abstract

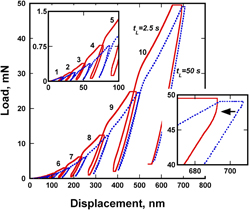

Systematic nanoindentation experiments have been carried out to study the mechanical properties of a nanocrystalline Fe–51Ni coating exhibiting anelastic and creep characteristics. An analytical method based on the correspondence principle for linear viscoelasticity was developed. The holding displacement–time data obtained in indentation creep tests at a high loading rate of 20 mN/s were analyzed, and material parameters related to the elastic, anelastic, and creep characteristics were derived using a model containing one Maxwell unit and two Kelvin units. The anelastic deformation thus contains at least two relaxation processes having relaxation times of 0.37 and 6.8 s, respectively, and the creep deformation is described by a viscosity value of 4.2 × 104 GPa·s for the alloy in an as-deposited state. The anelastic and creep characteristics descend associated with increases of the elastic modulus and hardness values after the alloy was annealed at 673 K.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2011

References

REFERENCES

- 3

- Cited by