1. Introduction

Premixed flame propagation is a rich problem that has been fruitfully addressed for many years by the scientific community. Numerous technological applications rely on the fundamental understanding of the physical processes that take part in the aerothermochemistry of reacting fronts. In particular, knowledge of the coupling between flames and acoustic waves is essential for an adequate design and operation of most burners and combustion chambers in favour of safety and efficiency. Thermoacoustic coupling in tubes has been a field of intense study since the original reports by Sondhauss (Reference Sondhauss1850), which dealt with external heating of pipes with a closed end, and by Rijke (Reference Rijke1859) that covered heated tubes with two open ends. Regardless of the heat release source, this interaction was first explained by Rayleigh (Reference Rayleigh1878) through his thermoacoustic growth criterion: heat promotes acoustic waves if released at the compression stage or if extracted during rarefaction. This behaviour was detected early on burners by Mallard & Le Chatelier (Reference Mallard and Le Chatelier1881) and later addressed experimentally (Mason & Wheeler Reference Mason and Wheeler1920; Coward, Hartwell & Georgeson Reference Coward, Hartwell and Georgeson1937), where the marked behaviour of oscillating flames under smooth and violent regimes was directly related to acoustic coupling.

First theoretical models to explain thermoacoustic instabilities with flames appeared in the context of project SQUID after World War II (Markstein Reference Markstein1950), which proposed the so-called parametric instability. The latter is defined as the coupling driven by an imposed oscillating-pressure flow interacting with a flame (Markstein Reference Markstein1953; Markstein & Squire Reference Markstein and Squire1955). These analyses led to Mathieu's equation that was able to provide a description of the flame response to the acoustic field given the amplitude and frequency of the oscillatory velocity and the wavelength of the perturbed reacting front. The stability problem was later revisited by other authors (Searby & Rochwerger Reference Searby and Rochwerger1991; Aldredge & Killingsworth Reference Aldredge and Killingsworth2004; Yañez, Kuznetsov & Grune Reference Yañez, Kuznetsov and Grune2015) under the assumption of a fixed acoustic field. However, the extended theoretical analyses of the flame response to self-excited parametric acoustic oscillations have only been offered recently (Wu & Law Reference Wu and Law2009; Assier & Wu Reference Assier and Wu2014). Other oscillatory regimes have been found in stabilized premixed flames in tubes (Richecoeur & Kyritsis Reference Richecoeur and Kyritsis2005), which are related to extinction–reignition cycles for diameters of the tube comparable to the quenching distance and are strongly influenced by the temperature and thermal properties of the tube material (Evans & Kyritsis Reference Evans and Kyritsis2009).

Markstein also reported the arising acoustic harmonics, their position along the tube upon flame coupling, and smooth-to-strong excitation events found for hydrogen, methane and higher hydrocarbons at either rich or lean mixtures with air (Markstein Reference Markstein1951). This change in behaviour was later defined as the development of primary and secondary acoustic instabilities, reported in propane flames travelling downwards towards a closed end of a tube with the ignition end open to the atmosphere (Searby Reference Searby1992). Primary acoustic instabilities are characterized by a small pulsation amplitude and smooth variations of the flame surface. However, secondary acoustic instabilities involve large-amplitude oscillations and pressure variations at least one order of magnitude greater than in the former case. In addition, the flame front is typically corrugated and disordered, producing a large increase in burning area and overall reaction rate. However, accurate modelling and explanations of the mechanisms controlling this kind of transition remain under discussion. Nevertheless, similar transitions were also found for downward propagating methane flames in a periodic Taylor–Couette burner (Aldredge & Killingsworth Reference Aldredge and Killingsworth2004), where rich flames showed a more stable behaviour than lean flames. Experiments in narrow tubes open at both ends show equivalent trends for propane flames, which propagate with large- and small-amplitude oscillations depending on the stoichiometry of the mixture (Connelly & Kyritsis Reference Connelly and Kyritsis2014; Yang et al. Reference Yang, Mossa, Huang, Wang, Woolley and Zhang2015). Furthermore, experiments in Hele–Shaw burners have reproduced the transition from primary to secondary instabilities for different fuels, which seem to take place for richer mixtures in the case of propane and dimethyl ether (DME), but for leaner mixtures in hydrogen and methane premixed flames (Martínez-Ruiz, Veiga-López & Sánchez-Sanz Reference Martínez-Ruiz, Veiga-López and Sánchez-Sanz2019; Veiga-López et al. Reference Veiga-López, Martínez-Ruiz, Fernández-Tarrazo and Sánchez-Sanz2019, Reference Veiga-López, Martínez-Ruiz, Kuznetsov and Sánchez-Sanz2020), ruling out simplified explanations based on flame temperature and flame propagation velocity criteria alone.

Numerical studies have also provided detailed information on the onset and transition between the two different oscillatory regimes for a flame propagating towards the closed end of narrow domains. Acoustic oscillations have been shown to produce an acceleration field at the flame front leading to intense Rayleigh–Taylor instabilities that wrinkle the flame-front in sufficiently wide regions (Petchenko et al. Reference Petchenko, Bychkov, Akkerman and Eriksson2006). However, small-amplitude flame oscillations are preserved in domains where the channel height ![]() $h$ and the flame thickness

$h$ and the flame thickness ![]() $\delta _T$ hold a moderate scale relation

$\delta _T$ hold a moderate scale relation ![]() $h/\delta _T \simeq 10$ (Petchenko et al. Reference Petchenko, Bychkov, Akkerman and Eriksson2007). This effect, directly related to viscous damping, has been reported for thermoacoustic instabilities of lean hydrogen–air mixtures in Hele–Shaw cells (Veiga-López et al. Reference Veiga-López, Martínez-Ruiz, Kuznetsov and Sánchez-Sanz2020), where thinner channels drastically reduce the acoustic coupling. In turn, small-diameter tubes show the same behaviour in suppressing and extinguishing premixed flames under parametric instabilities (Dubey et al. Reference Dubey, Koyama, Hashimoto and Fujita2021).

$h/\delta _T \simeq 10$ (Petchenko et al. Reference Petchenko, Bychkov, Akkerman and Eriksson2007). This effect, directly related to viscous damping, has been reported for thermoacoustic instabilities of lean hydrogen–air mixtures in Hele–Shaw cells (Veiga-López et al. Reference Veiga-López, Martínez-Ruiz, Kuznetsov and Sánchez-Sanz2020), where thinner channels drastically reduce the acoustic coupling. In turn, small-diameter tubes show the same behaviour in suppressing and extinguishing premixed flames under parametric instabilities (Dubey et al. Reference Dubey, Koyama, Hashimoto and Fujita2021).

In addition, simulations of axisymmetric flames propagating upwards exhibit the same oscillating quasi-stationary response to acoustic perturbations as in the experiments, until wrinkles arise in the reacting front (Higuera Reference Higuera2019). Other numerical studies conclude that symmetric and non-symmetric flames propagating in tubes in the absence of gravity present different gain to acoustic wave perturbations and varying onset of the instability with non-negligible dependence on the channel length, thickness and on the chemical kinetics modelling (Jiménez, Fernández-Galisteo & Kurdyumov Reference Jiménez, Fernández-Galisteo and Kurdyumov2021).

All things considered, secondary acoustic instabilities seem to require the previous development of primary acoustic oscillations to take place. Therefore, numerous works have proposed fundamental explanations to the origin of the finite-amplitude initial coupling (Clavin, Pelcé & He Reference Clavin, Pelcé and He1990; Clanet, Searby & Clavin Reference Clanet, Searby and Clavin1999), with two mechanisms considered to this end. First is the modification of the internal structure of the flame front owing to the sensitivity of the chemical kinetics to temperature variations. This mechanism was addressed through a correlation between the product ![]() $\beta M$, where

$\beta M$, where ![]() $\beta$ and

$\beta$ and ![]() $M$ are the Zel'dovich and the Mach numbers, respectively, and the acoustic pressure by Yoon, Noh & Fujita (Reference Yoon, Noh and Fujita2016). This suggested a non-negligible sensitivity of the reaction rate to acoustic pressure variations through temperature. Nevertheless, it was theorized by Clavin et al. (Reference Clavin, Pelcé and He1990) that this amplification arising from acoustic temperature fluctuations was relevant only in marginal cases. Second is the geometry variation of the flame related to the sensitiveness of the curved flame front to the presence of an acceleration, as given by the acoustic field. A theoretical analysis of this velocity coupling in the limit of weakly wrinkled flames was carried out by Pelcé & Rochwerger (Reference Pelcé and Rochwerger1992), with predicted growth rates two orders of magnitude greater than the pressure-coupling feedback. In spite of this, both analyses provide a common first-order prediction of the coupling frequencies given by the outer flow field, independent of the considered transfer mechanism at the flame inner region.

$M$ are the Zel'dovich and the Mach numbers, respectively, and the acoustic pressure by Yoon, Noh & Fujita (Reference Yoon, Noh and Fujita2016). This suggested a non-negligible sensitivity of the reaction rate to acoustic pressure variations through temperature. Nevertheless, it was theorized by Clavin et al. (Reference Clavin, Pelcé and He1990) that this amplification arising from acoustic temperature fluctuations was relevant only in marginal cases. Second is the geometry variation of the flame related to the sensitiveness of the curved flame front to the presence of an acceleration, as given by the acoustic field. A theoretical analysis of this velocity coupling in the limit of weakly wrinkled flames was carried out by Pelcé & Rochwerger (Reference Pelcé and Rochwerger1992), with predicted growth rates two orders of magnitude greater than the pressure-coupling feedback. In spite of this, both analyses provide a common first-order prediction of the coupling frequencies given by the outer flow field, independent of the considered transfer mechanism at the flame inner region.

These theoretical studies on the initiation mechanisms have produced detailed predictions of the modification of the flame structure, transfer function and oscillating frequency along the tube. Although very useful in the comparison of thermoacoustic simulations with adiabatic boundaries (Jiménez et al. Reference Jiménez, Fernández-Galisteo and Kurdyumov2021), the oscillation frequency is not accurately described when heat losses are not negligible. For this reason, introduction of conductive heat-transfer processes through the walls of the system is mandatory to represent real scenarios. For instance, Rijke-type devices, related to generic heat sources in open tubes (Raun et al. Reference Raun, Beckstead, Finlinson and Brooks1993), have been recently proposed as a benchmark to control acoustic oscillations through heat transfer from secondary sources (Jamieson & Juniper Reference Jamieson and Juniper2017). An adequate comprehension of the non-adiabatic effects is thus needed to progress in the description and understanding of premixed-flame thermoacoustic instabilities. The outer-flow acoustic model of Clavin et al. (Reference Clavin, Pelcé and He1990) and Pelcé & Rochwerger (Reference Pelcé and Rochwerger1992) is here addressed to propose an extension to non-adiabatic thermal effects that yields adequate theoretical results for the flame oscillation frequency, which is in close agreement with that obtained from experiments.

Most canonical experimental studies found in the literature focused their attention on flames propagating in vertical tubes under the effect of gravity. In this paper, a non-adiabatic extension to the one-dimensional coupling frequency model is offered to accurately predict the oscillations of premixed flames in very slender configurations. Later, a horizontal tube of inner diameter ![]() $D$, such that the Froude number is

$D$, such that the Froude number is ![]() $Fr\simeq 1$ and transverse buoyancy effects are non-dominant, is used together with a circulating thermal bath to capture the controlling effects of the oscillating frequency. This frequency value, which sustains first-order modifications, plays a major role in the initiation of thermoacoustic instabilities. Furthermore, the selection of a moderate diameter aims to avoid complex aerodynamic structures that can take part in the fast wrinkling of the flame by setting the experimental cases in the near-viscous limit. Finally, a moveable piston allows modifications to the tube length

$Fr\simeq 1$ and transverse buoyancy effects are non-dominant, is used together with a circulating thermal bath to capture the controlling effects of the oscillating frequency. This frequency value, which sustains first-order modifications, plays a major role in the initiation of thermoacoustic instabilities. Furthermore, the selection of a moderate diameter aims to avoid complex aerodynamic structures that can take part in the fast wrinkling of the flame by setting the experimental cases in the near-viscous limit. Finally, a moveable piston allows modifications to the tube length ![]() $L$, measured from the piston to the open end of the tube, which controls the main acoustic frequency. The latter also depends on the varying position of the flame

$L$, measured from the piston to the open end of the tube, which controls the main acoustic frequency. The latter also depends on the varying position of the flame ![]() $r$ along the tube, which provides the evolution of the oscillation frequency during flame propagation. The experimental set-up is, thus, envisioned to validate the extended model proposed here, to simplify the analysis and to facilitate the understanding of thermoacoustic coupling initiation mechanisms.

$r$ along the tube, which provides the evolution of the oscillation frequency during flame propagation. The experimental set-up is, thus, envisioned to validate the extended model proposed here, to simplify the analysis and to facilitate the understanding of thermoacoustic coupling initiation mechanisms.

Additional results of this study include the modification of primary-to-secondary instability transition owing to mixture temperature variation. In particular, slightly preheated mixtures are increasingly driven to stabilization in primary acoustic oscillations by thermal suppression of transition to secondary instability regimes. Experimental evidence of this feature is offered in the final section of the manuscript.

2. Background and theoretical modelling

2.1. Primary acoustic instabilities

The existing theoretical predictions of the coupling and amplification of primary thermoacoustic modes follow the seminal works of Clavin et al. (Reference Clavin, Pelcé and He1990) and Pelcé & Rochwerger (Reference Pelcé and Rochwerger1992), which provide a method to compute the acoustic frequencies of a one-dimensional flame propagating from the open to the closed end of a tube. From the perspective of the fluid dynamics acoustic problem, the flame front is seen as a discontinuity surface separating the unburnt and the burnt gases when the dimensionless activation energy is a large parameter, with the Zel'dovich number ![]() $\beta \gg 1$.

$\beta \gg 1$.

A sketch of the gas properties distribution applicable to this model is presented in figure 1(a) along with the associated pressure and velocity modes. The dimensionless axial coordinate ![]() $\xi = x/L$ measures the distance to the closed end of the tube and the flame sheet is located at

$\xi = x/L$ measures the distance to the closed end of the tube and the flame sheet is located at ![]() $\xi = r$. Therefore, in region

$\xi = r$. Therefore, in region ![]() $0<\xi < r$, the properties of the gas are those of the quiescent unburnt mixture, that is, density

$0<\xi < r$, the properties of the gas are those of the quiescent unburnt mixture, that is, density ![]() $\rho _u$ and temperature

$\rho _u$ and temperature ![]() $T_u$, and the region with

$T_u$, and the region with ![]() $r<\xi <1$ exhibits burnt gas properties,

$r<\xi <1$ exhibits burnt gas properties, ![]() $\rho _b$ and

$\rho _b$ and ![]() $T_b$, where

$T_b$, where ![]() $T_b = \epsilon T_u$ is the adiabatic flame temperature. Owing to the dependence of the speed of sound on fluid temperature,

$T_b = \epsilon T_u$ is the adiabatic flame temperature. Owing to the dependence of the speed of sound on fluid temperature, ![]() $c=\sqrt {\gamma \mathcal {R}_gT}$, acoustic waves propagate at different velocities in the unburnt,

$c=\sqrt {\gamma \mathcal {R}_gT}$, acoustic waves propagate at different velocities in the unburnt, ![]() $c_u$, and burnt,

$c_u$, and burnt, ![]() $c_b$, gas sections. For this reason, as the flame propagates along the tube at velocity

$c_b$, gas sections. For this reason, as the flame propagates along the tube at velocity ![]() $S_u\ll c_u$, the length of the region occupied by combustion products increases and a variation of the natural frequency of the tube is obtained.

$S_u\ll c_u$, the length of the region occupied by combustion products increases and a variation of the natural frequency of the tube is obtained.

Figure 1. Sketch of adiabatic and non-adiabatic conditions of flame propagation in a tube: (a) adiabatic and (b) non-adiabatic.

The linearized analysis is performed over the perturbation of base-flow variables denoted by superscript ![]() $0$, through small acoustic variations denoted by superscript

$0$, through small acoustic variations denoted by superscript ![]() $1$, e.g.

$1$, e.g. ![]() $u=u^0(\xi ) + u^1(\tau,\xi )$, and is applied at both sides of the flame. The dimensionless momentum and mass governing equations for the perturbations read

$u=u^0(\xi ) + u^1(\tau,\xi )$, and is applied at both sides of the flame. The dimensionless momentum and mass governing equations for the perturbations read

\begin{equation} \frac{\rho^0}{\rho_u}\frac{\partial \hat{u}}{\partial \tau} ={-} \frac{\partial {\rm \pi}}{\partial \xi}, \quad \frac{\partial {\rm \pi}}{\partial \tau} ={-} \frac{\rho^0}{\rho_u}\left(\frac{c^0}{c_u}\right)^2 \frac{\partial \hat{u}}{\partial \xi}, \end{equation}

\begin{equation} \frac{\rho^0}{\rho_u}\frac{\partial \hat{u}}{\partial \tau} ={-} \frac{\partial {\rm \pi}}{\partial \xi}, \quad \frac{\partial {\rm \pi}}{\partial \tau} ={-} \frac{\rho^0}{\rho_u}\left(\frac{c^0}{c_u}\right)^2 \frac{\partial \hat{u}}{\partial \xi}, \end{equation}

where ![]() $\hat {u}=u^1/S_u, {\rm \pi}= p^1 /(\rho _u S_u c_u)$ and

$\hat {u}=u^1/S_u, {\rm \pi}= p^1 /(\rho _u S_u c_u)$ and ![]() $\tau = tc_u/L$. Combination of both expressions allows to write the problem in the wave equation form,

$\tau = tc_u/L$. Combination of both expressions allows to write the problem in the wave equation form,

where ![]() $\rho ^0T^0 = p^0/\mathcal {R}_g = \mathrm {const.}$, in the framework of the acoustic analysis. Moreover, for the sake of generality and as an extension to Clavin et al. (Reference Clavin, Pelcé and He1990) and Pelcé & Rochwerger (Reference Pelcé and Rochwerger1992), the temperature ratio

$\rho ^0T^0 = p^0/\mathcal {R}_g = \mathrm {const.}$, in the framework of the acoustic analysis. Moreover, for the sake of generality and as an extension to Clavin et al. (Reference Clavin, Pelcé and He1990) and Pelcé & Rochwerger (Reference Pelcé and Rochwerger1992), the temperature ratio ![]() $\varDelta (\xi ) = T^0/T_u$ is here allowed to follow a non-uniform distribution as sketched in figure 1(b). An equation for the natural frequencies of the tube with two regions of different properties can be derived by solving (2.2a,b) with the appropriate boundary conditions at both ends of the tube for acoustic velocity and pressure perturbations,

$\varDelta (\xi ) = T^0/T_u$ is here allowed to follow a non-uniform distribution as sketched in figure 1(b). An equation for the natural frequencies of the tube with two regions of different properties can be derived by solving (2.2a,b) with the appropriate boundary conditions at both ends of the tube for acoustic velocity and pressure perturbations,

In addition, jump conditions across the flame sheet must be provided for adequate problem closure. Typical low-Mach flame propagation produces pressure variations across the discontinuity of order ![]() $\sim \rho _u S_u^2$, much smaller than acoustic pressure variations of order

$\sim \rho _u S_u^2$, much smaller than acoustic pressure variations of order ![]() $\sim \rho _u S_u c$, which yields

$\sim \rho _u S_u c$, which yields

Furthermore, first-order solution assumes the flame front to behave as a passive interface, such that

The solution to the one-dimensional acoustic perturbation problem can be analytically derived for constant temperature of the burnt gases ![]() $\varDelta = T_b/T_u = \epsilon$ and

$\varDelta = T_b/T_u = \epsilon$ and ![]() $\varDelta = 1$ in the unburnt mixture,

$\varDelta = 1$ in the unburnt mixture,

\begin{gather} \left. \begin{gathered} \hat{u}_u = {\rm e}^{{\rm i}\varOmega\tau}[A_u \,{\rm e}^{{\rm i}\varOmega\xi} + B_u \,{\rm e}^{-{\rm i}\varOmega\xi}],\quad {\rm \pi}_u ={-}{\rm e}^{{\rm i}\varOmega\tau}[A_u \,{\rm e}^{{\rm i}\varOmega\xi} - B_u \,{\rm e}^{-{\rm i}\varOmega\xi}]\\ \hat{u}_b = {\rm e}^{{\rm i}\varOmega\tau}[A_b \,{\rm e}^{{\rm i}\varOmega\xi/{\sqrt{\epsilon}}} + B_b \,{\rm e}^{-{\rm i}\varOmega\xi/{\sqrt{\epsilon}}}], \quad {\rm \pi}_b ={-}\dfrac{{\rm e}^{{\rm i}\varOmega\tau}}{\sqrt{\epsilon}}[A_b \,{\rm e}^{{\rm i} {\varOmega}\xi/{\sqrt{\epsilon}}} - B_b \,{\rm e}^{-{\rm i}{\varOmega}\xi/{\sqrt{\epsilon}}}] \end{gathered} \right\}. \end{gather}

\begin{gather} \left. \begin{gathered} \hat{u}_u = {\rm e}^{{\rm i}\varOmega\tau}[A_u \,{\rm e}^{{\rm i}\varOmega\xi} + B_u \,{\rm e}^{-{\rm i}\varOmega\xi}],\quad {\rm \pi}_u ={-}{\rm e}^{{\rm i}\varOmega\tau}[A_u \,{\rm e}^{{\rm i}\varOmega\xi} - B_u \,{\rm e}^{-{\rm i}\varOmega\xi}]\\ \hat{u}_b = {\rm e}^{{\rm i}\varOmega\tau}[A_b \,{\rm e}^{{\rm i}\varOmega\xi/{\sqrt{\epsilon}}} + B_b \,{\rm e}^{-{\rm i}\varOmega\xi/{\sqrt{\epsilon}}}], \quad {\rm \pi}_b ={-}\dfrac{{\rm e}^{{\rm i}\varOmega\tau}}{\sqrt{\epsilon}}[A_b \,{\rm e}^{{\rm i} {\varOmega}\xi/{\sqrt{\epsilon}}} - B_b \,{\rm e}^{-{\rm i}{\varOmega}\xi/{\sqrt{\epsilon}}}] \end{gathered} \right\}. \end{gather}

The equation for the dimensionless acoustic frequencies ![]() $\varOmega = \omega t_a$, where

$\varOmega = \omega t_a$, where ![]() $t_a = L/c_u$ is the acoustic time, is prescribed after imposing boundary (2.3) and jump conditions (2.4) and (2.5) to the linear system (2.6) for the non-trivial value of constants

$t_a = L/c_u$ is the acoustic time, is prescribed after imposing boundary (2.3) and jump conditions (2.4) and (2.5) to the linear system (2.6) for the non-trivial value of constants ![]() $A_u, B_u, A_b$ and

$A_u, B_u, A_b$ and ![]() $B_b$. Namely, the adiabatic problem yields the analytic expression for the acoustic frequency eigenvalues,

$B_b$. Namely, the adiabatic problem yields the analytic expression for the acoustic frequency eigenvalues,

Unfortunately, this simplified analysis does not adequately predict the evolution of the natural frequencies of the tube with the varying flame position ![]() $r$ in the experimental set-up, as will be shown below. Further efforts have introduced acoustic and radiative losses as main deviations from the theoretical predictions of stability (Clavin et al. Reference Clavin, Pelcé and He1990; Schuller, Poinsot & Candel Reference Schuller, Poinsot and Candel2020). However, additional thermal effects in non-adiabatic long and thin tubes at constant wall temperature may substantially modify the burnt-region isothermal picture presented above, causing major variations in the acoustic coupling of the system upon introduction of non-constant distributions

$r$ in the experimental set-up, as will be shown below. Further efforts have introduced acoustic and radiative losses as main deviations from the theoretical predictions of stability (Clavin et al. Reference Clavin, Pelcé and He1990; Schuller, Poinsot & Candel Reference Schuller, Poinsot and Candel2020). However, additional thermal effects in non-adiabatic long and thin tubes at constant wall temperature may substantially modify the burnt-region isothermal picture presented above, causing major variations in the acoustic coupling of the system upon introduction of non-constant distributions ![]() $\varDelta (\xi )$ in (2.2a,b).

$\varDelta (\xi )$ in (2.2a,b).

2.2. Heat-loss estimates, cooling length

Heat losses influence thermoacoustic instabilities of flames in two significant ways. On the one hand, they affect the inner reaction region by extracting part of the energy of the combustion process and reducing the local temperature. In sufficiently thin tubes, heat losses can even disable self-sustained combustion processes, restraining the propagation of premixed laminar flames and even induce extinction–reignition oscillations (Richecoeur & Kyritsis Reference Richecoeur and Kyritsis2005). Conversely, in wide tubes where the surface to volume ratio is small enough, heat-loss effects are confined to a very thin region close to the tube wall. The present study focuses on intermediate scenarios, moderate tube diameters that prevent the growth of large-scale dynamic instabilities of the flow, and which characteristically sit far from negligible heat losses in the averaged section. In this context, heat losses affect the flame inducing the curvature of the front and being responsible for deviations from simplified one-dimensional reactions. On the other hand and most importantly, the decrease of burnt gas temperature along the tube owing to conductive heat losses produces a first-order modification in the velocity at which acoustic waves propagate in this media, which changes the coupling frequency. In particular, the variation of the speed of sound with the distance to the flame front can significantly modify the eigenvalues of the acoustic problem, as depicted in figure 1. Therefore, the temperature decay behind the flame requires the characterization underneath.

The infinitely thin flame approximation that propagates with velocity ![]() $S_u$ remains valid here for the estimate of the streamwise cooling distance

$S_u$ remains valid here for the estimate of the streamwise cooling distance ![]() $l_c$, in which the average burnt gas temperature decreases to reach values of the order of the ambient temperature

$l_c$, in which the average burnt gas temperature decreases to reach values of the order of the ambient temperature ![]() $T_u$. On the moving frame of reference, burnt gas temperature equals the adiabatic flame temperature immediately downstream from the flame, such that

$T_u$. On the moving frame of reference, burnt gas temperature equals the adiabatic flame temperature immediately downstream from the flame, such that ![]() ${T_b}/{T_u} ={\rho _u}/{\rho _b} = {S_b}/{S_u} = \epsilon$ owing to mass conservation and the gas equation of state. However, heat losses through the wall cause the temperature of the products to decrease with distance measured from the flame front. The region near the wall affected by conduction grows accordingly until, at some point, it is comparable to the tube radius

${T_b}/{T_u} ={\rho _u}/{\rho _b} = {S_b}/{S_u} = \epsilon$ owing to mass conservation and the gas equation of state. However, heat losses through the wall cause the temperature of the products to decrease with distance measured from the flame front. The region near the wall affected by conduction grows accordingly until, at some point, it is comparable to the tube radius ![]() $R$, which defines the cooling distance from the flame

$R$, which defines the cooling distance from the flame ![]() $l_c$. Although exact calculation of temperature profiles is a complex task, some assumptions can be made to obtain a valuable approximation.

$l_c$. Although exact calculation of temperature profiles is a complex task, some assumptions can be made to obtain a valuable approximation.

The lack of chemical reaction in the burnt region enables a straight-forward balance between the convective transport and the radial conduction terms in the energy conservation equation, as the longitudinal conduction term is neglected in slender configurations (Hicks, Montgomery & Wasserman Reference Hicks, Montgomery and Wasserman1947). Integration of the equation of energy in the cross-sectional area is performed to enable a suitable introduction of the heat transfer problem solution in the one-dimensional acoustic analysis, with use made of the averaged value of temperature at each section,

\begin{equation} T_b^0(x) = \frac{\displaystyle \int_0^R 2{\rm \pi} y \rho u T {{\rm d} y}}{\rho_b^0 u_b^0 {\rm \pi}R^2}, \end{equation}

\begin{equation} T_b^0(x) = \frac{\displaystyle \int_0^R 2{\rm \pi} y \rho u T {{\rm d} y}}{\rho_b^0 u_b^0 {\rm \pi}R^2}, \end{equation}

where ![]() $y$ is the radial coordinate of the tube and

$y$ is the radial coordinate of the tube and ![]() $\rho _b^0 u_b^0 = \int _0^R 2 {\rm \pi}y\rho u {{\rm d} y}/{\rm \pi} R^2$ is the analogous averaged momentum. Finally, heat flux per unit area at the wall is assumed to be proportional to the temperature jump between the outer bath temperature and the section-averaged temperature of the gases

$\rho _b^0 u_b^0 = \int _0^R 2 {\rm \pi}y\rho u {{\rm d} y}/{\rm \pi} R^2$ is the analogous averaged momentum. Finally, heat flux per unit area at the wall is assumed to be proportional to the temperature jump between the outer bath temperature and the section-averaged temperature of the gases ![]() $T_{ext} - T_b^0(x)$. Therefore, radial conduction terms can be approximated as

$T_{ext} - T_b^0(x)$. Therefore, radial conduction terms can be approximated as ![]() $\sim {Nu} k_b(T_u-T_b^0)/R^2$, where the temperature at the wall equals the unburnt gas temperature

$\sim {Nu} k_b(T_u-T_b^0)/R^2$, where the temperature at the wall equals the unburnt gas temperature ![]() $T_u, k_b$ is the thermal conductivity of the burnt gases and

$T_u, k_b$ is the thermal conductivity of the burnt gases and ![]() $Nu$ is the Nusselt number. The equation that describes the evolution of

$Nu$ is the Nusselt number. The equation that describes the evolution of ![]() $T_b^0$ under the presented assumptions is

$T_b^0$ under the presented assumptions is

with ![]() $c_{pb}$ the specific heat evaluated at the burnt-side temperature

$c_{pb}$ the specific heat evaluated at the burnt-side temperature ![]() $T_b$. In particular, averaged values of transport coefficients

$T_b$. In particular, averaged values of transport coefficients ![]() $\overline {k_{b}}$ and

$\overline {k_{b}}$ and ![]() $\overline {c_{pb}}$ are selected to represent the simplified problem over a range of burnt gas temperatures

$\overline {c_{pb}}$ are selected to represent the simplified problem over a range of burnt gas temperatures ![]() $500< T_b<1900$ K. The non-dimensional form of this equation,

$500< T_b<1900$ K. The non-dimensional form of this equation,

with ![]() $\theta = (T_u-T_b^0)/(T_u-T_b)$, introduces the cooling parameter

$\theta = (T_u-T_b^0)/(T_u-T_b)$, introduces the cooling parameter ![]() $\sigma = L/l_c$, defined as the ratio between the length of the tube and the cooling length

$\sigma = L/l_c$, defined as the ratio between the length of the tube and the cooling length

Therefore, the parameter ![]() $\sigma$ is a function of the Péclet number

$\sigma$ is a function of the Péclet number ![]() ${Pe}$, the Nusselt number

${Pe}$, the Nusselt number ![]() $Nu$ and the aspect ratio of the tube. To evaluate the cooling length, the value for the Nusselt number following Kays & Crawford (Reference Kays and Crawford1993, Chapter 9) for laminar flows with constant wall temperature is selected to be

$Nu$ and the aspect ratio of the tube. To evaluate the cooling length, the value for the Nusselt number following Kays & Crawford (Reference Kays and Crawford1993, Chapter 9) for laminar flows with constant wall temperature is selected to be ![]() $Nu=3.66$, accordingly with the present thermally controlled slender tube used in this work. The Péclet number is in turn evaluated using the values of the different physical quantities provided in table 1. All things considered, the numerical evaluation of (2.11) gives a cooling distance

$Nu=3.66$, accordingly with the present thermally controlled slender tube used in this work. The Péclet number is in turn evaluated using the values of the different physical quantities provided in table 1. All things considered, the numerical evaluation of (2.11) gives a cooling distance ![]() $l_c \simeq 0.05$ m, which will be used in the rest of the document to characterize the exponential temperature decay for our set of experiments in tubes of

$l_c \simeq 0.05$ m, which will be used in the rest of the document to characterize the exponential temperature decay for our set of experiments in tubes of ![]() $R=5$ mm. Consequently, the cooling parameter

$R=5$ mm. Consequently, the cooling parameter ![]() $\sigma = L/l_c$ only changes when the length of the tube

$\sigma = L/l_c$ only changes when the length of the tube ![]() $L$ is modified.

$L$ is modified.

Table 1. Values used to evaluate ![]() $l_c$ for methane–air flames throughout the present document.

$l_c$ for methane–air flames throughout the present document.

2.3. Non-adiabatic acoustics

In sufficiently long tubes, ![]() $\sigma \gg 1$, experimental observations are in disagreement with predictions given by (2.7) for the evolution of acoustic frequencies along the tube. Longer tubes and greater surface-to-volume ratios, for decreasing diameters, increase the impact of heat losses that produce decreasing temperature profiles in the burnt gas

$\sigma \gg 1$, experimental observations are in disagreement with predictions given by (2.7) for the evolution of acoustic frequencies along the tube. Longer tubes and greater surface-to-volume ratios, for decreasing diameters, increase the impact of heat losses that produce decreasing temperature profiles in the burnt gas ![]() $T_b^0(\xi )$. This variation of burnt gas temperature with the longitudinal coordinate causes the acoustic waves propagation velocity

$T_b^0(\xi )$. This variation of burnt gas temperature with the longitudinal coordinate causes the acoustic waves propagation velocity ![]() $c_b$ to change with

$c_b$ to change with ![]() $\xi$ in the burnt gases region

$\xi$ in the burnt gases region ![]() $r<\xi <1$, an important point that has been recurrently disregarded in the interpretation of experimental measurements.

$r<\xi <1$, an important point that has been recurrently disregarded in the interpretation of experimental measurements.

Straightforward integration of (2.10) from a moving reference frame fixed on a steady planar flame front propagating at velocity ![]() $S_u$, provides the temperature profiles

$S_u$, provides the temperature profiles ![]() $\theta ({\xi }) = \exp (-\sigma (\xi -r))$. Hereafter, the dimensionless base temperature distribution in the burnt gases can be rewritten as

$\theta ({\xi }) = \exp (-\sigma (\xi -r))$. Hereafter, the dimensionless base temperature distribution in the burnt gases can be rewritten as

Introduction of burnt gas temperature distribution into (2.2a,b) defines a non-isothermal acoustics problem. In particular, some analytic solutions exist for exponential temperature variation laws ![]() $\varDelta (\xi )$ (Musielak, Musielak & Mobashi Reference Musielak, Musielak and Mobashi2006). Nevertheless, for each

$\varDelta (\xi )$ (Musielak, Musielak & Mobashi Reference Musielak, Musielak and Mobashi2006). Nevertheless, for each ![]() $0< r<1$ flame position, the eigenvalues of the system of partial differential equations, with open and closed end boundary conditions (2.3), and jump conditions at the flame (2.4) and (2.5) can be numerically computed to offer a more accurate description of the oscillation frequency than (2.7). The resulting evolution with

$0< r<1$ flame position, the eigenvalues of the system of partial differential equations, with open and closed end boundary conditions (2.3), and jump conditions at the flame (2.4) and (2.5) can be numerically computed to offer a more accurate description of the oscillation frequency than (2.7). The resulting evolution with ![]() $r$ of the acoustic coupling frequencies of the tube

$r$ of the acoustic coupling frequencies of the tube ![]() $\varOmega$ depends on both the temperature ratio

$\varOmega$ depends on both the temperature ratio ![]() $\epsilon$ and the cooling parameter

$\epsilon$ and the cooling parameter ![]() $\sigma$. Figure 2 shows the evolution of the dimensionless acoustic frequency

$\sigma$. Figure 2 shows the evolution of the dimensionless acoustic frequency ![]() $\varOmega$ with

$\varOmega$ with ![]() $r$ for

$r$ for ![]() $\epsilon =5$ and different values of

$\epsilon =5$ and different values of ![]() $\sigma$ in the fundamental mode and first harmonic. The original adiabatic solution

$\sigma$ in the fundamental mode and first harmonic. The original adiabatic solution ![]() $\sigma =0$, depicted by solid lines, can be compared to long temperature decay distances

$\sigma =0$, depicted by solid lines, can be compared to long temperature decay distances ![]() $l_c \gg L$. Oppositely, increasing the heat-loss effect flattens the distribution by providing a burnt-side temperature that is rapidly cooled down to the wall temperature

$l_c \gg L$. Oppositely, increasing the heat-loss effect flattens the distribution by providing a burnt-side temperature that is rapidly cooled down to the wall temperature ![]() $T_{ext} = T_u$ and, thus, an isothermal gas condition is approached for

$T_{ext} = T_u$ and, thus, an isothermal gas condition is approached for ![]() $\sigma \gg 1$.

$\sigma \gg 1$.

Figure 2. Non-adiabatic predictions of the dimensionless coupling frequency distributions with flame position for fundamental and first harmonic acoustic modes. The curves for ![]() $\sigma =0$ correspond to (2.7).

$\sigma =0$ correspond to (2.7).

To compare the new non-isothermal acoustics model with experimental data, a flame tube is placed in a thermal bath that maintains the wall temperature to a fixed value by means of a recirculating water flow. Temperature control is key to the non-adiabatic validation and will be shown to play a major role in controlling the transitions between primary and secondary thermoacoustic instabilities.

3. Experimental set-up and procedure

A simplified scheme of the experimental set-up, which consists of two concentric horizontal tubes of lengths ![]() $150$ cm, is presented in figure 3. Combustion takes place inside the inner tube, which is made of borosilicate glass, has an inner diameter

$150$ cm, is presented in figure 3. Combustion takes place inside the inner tube, which is made of borosilicate glass, has an inner diameter ![]() $D=10$ mm and a wall thickness of 2 mm. The outer tube is made of acrylic glass, has an outer diameter of 30 mm and a wall thickness of 3 mm. In the space between the two tubes, a constant flow of a mixture of ethylene glycol and water is established. Its temperature,

$D=10$ mm and a wall thickness of 2 mm. The outer tube is made of acrylic glass, has an outer diameter of 30 mm and a wall thickness of 3 mm. In the space between the two tubes, a constant flow of a mixture of ethylene glycol and water is established. Its temperature, ![]() $T_{ext}$, is controlled by means of a Fisher Scientific Isotemp 4100 R20 refrigerated circulating bath. This temperature is varied between

$T_{ext}$, is controlled by means of a Fisher Scientific Isotemp 4100 R20 refrigerated circulating bath. This temperature is varied between ![]() $273$ and

$273$ and ![]() $343$ K, where the upper value is limited by the structural integrity of the outer tube.

$343$ K, where the upper value is limited by the structural integrity of the outer tube.

Figure 3. Schematic representation of the experimental apparatus. During the feeding phase, piston is in position ![]() $(1)$. Upon complete charge, the piston is moved to position

$(1)$. Upon complete charge, the piston is moved to position ![]() $(2)$ enclosing an effective distance

$(2)$ enclosing an effective distance ![]() $L$.

$L$.

In the following experiments, a flame propagates from one end of the tube, which is maintained open to the atmosphere, to the other, which is kept closed. The flammable mixture is prepared using air and ![]() $99.5\,\%$ purity methane. The equivalence ratio is controlled by adjusting the mass flow rates of air and reactant with two EL-Flow Bronkhorst mass flow controllers. The ignition device is situated at the open end and consists of a piezoelectric spark generator which is connected to two electrodes facing each other diametrically inside the tube. When the spark gap is driven, the electric arc between the two electrodes supplies the required energy to ignite the mixture. Finally, the opposite end of the tube is closed with a moveable piston that allows testing different effective tube lengths

$99.5\,\%$ purity methane. The equivalence ratio is controlled by adjusting the mass flow rates of air and reactant with two EL-Flow Bronkhorst mass flow controllers. The ignition device is situated at the open end and consists of a piezoelectric spark generator which is connected to two electrodes facing each other diametrically inside the tube. When the spark gap is driven, the electric arc between the two electrodes supplies the required energy to ignite the mixture. Finally, the opposite end of the tube is closed with a moveable piston that allows testing different effective tube lengths ![]() $L$. Taking all this into account, the described set-up can be used to study the behaviour of thermoacoustic instabilities of the flame under variations of three parameters: equivalence ratio

$L$. Taking all this into account, the described set-up can be used to study the behaviour of thermoacoustic instabilities of the flame under variations of three parameters: equivalence ratio ![]() $\phi$, wall temperature

$\phi$, wall temperature ![]() $T_{ext}$ and length of the tube

$T_{ext}$ and length of the tube ![]() $L$.

$L$.

The propagation of the flame inside the tube is recorded from the orthogonal direction to the tube axis by means of a Phantom VEO 710 high-speed camera with a resolution of ![]() $1280\times 800\ \mathrm {pixels}$. A frame rate of 2000 fps is chosen for most of the experiments to provide a good compromise between sufficient time resolution and image brightness. The images are used to obtain the position and velocity of the flame. Each frame of the recorded video registers the instantaneous luminosity of the flame which gives its position inside the frame. The displacement between subsequent frames and the camera frame rate enable the computation of the instantaneous velocity of the front. Owing to the slenderness of the combustion chamber and the need for spatial resolution across the flame front, only partial longitudinal visualization of the set-up is possible during each experiment. A field of view of approximately

$1280\times 800\ \mathrm {pixels}$. A frame rate of 2000 fps is chosen for most of the experiments to provide a good compromise between sufficient time resolution and image brightness. The images are used to obtain the position and velocity of the flame. Each frame of the recorded video registers the instantaneous luminosity of the flame which gives its position inside the frame. The displacement between subsequent frames and the camera frame rate enable the computation of the instantaneous velocity of the front. Owing to the slenderness of the combustion chamber and the need for spatial resolution across the flame front, only partial longitudinal visualization of the set-up is possible during each experiment. A field of view of approximately ![]() $200\ \mathrm {mm}$ has been selected to provide a good compromise between resolution and observational length.

$200\ \mathrm {mm}$ has been selected to provide a good compromise between resolution and observational length.

Images of the flame front propagation are post-processed using an in-house Python code. Therefore, flames are discretized in the transverse direction by the pixel-row resolution of the image. Typically, a number of ![]() $64$ rows fall within the horizontal band described by the flame in its movement. The axial displacement of every point of the flame front is computed by using the cross-correlation of every pixel row between consecutive frames. In particular, the cross-correlation is performed over the derived image intensity values with respect to

$64$ rows fall within the horizontal band described by the flame in its movement. The axial displacement of every point of the flame front is computed by using the cross-correlation of every pixel row between consecutive frames. In particular, the cross-correlation is performed over the derived image intensity values with respect to ![]() $x$ to prevent the flame tail from introducing a bias in the correlation and therefore a drift in flame position tracking, see Appendix A. The position of the maximum value of the cross-correlation is the most probable displacement of the flame in the selected row. The accuracy of the method is improved by using a parabolic subpixel interpolation. This process is repeated for every row that contains the flame and for every pair of frames. The calculated displacement of the flame front is averaged in the vertical direction and is divided by the time lapse between two frames, which is kept constant for every video. Therefore, the velocity of the averaged flame front is obtained as a function of time. Finally, the frequency components of this signal are obtained by applying Fourier analysis.

$x$ to prevent the flame tail from introducing a bias in the correlation and therefore a drift in flame position tracking, see Appendix A. The position of the maximum value of the cross-correlation is the most probable displacement of the flame in the selected row. The accuracy of the method is improved by using a parabolic subpixel interpolation. This process is repeated for every row that contains the flame and for every pair of frames. The calculated displacement of the flame front is averaged in the vertical direction and is divided by the time lapse between two frames, which is kept constant for every video. Therefore, the velocity of the averaged flame front is obtained as a function of time. Finally, the frequency components of this signal are obtained by applying Fourier analysis.

Additional instrumentation includes a microphone to capture the acoustic emission of the flame during its propagation. The microphone is placed at a fixed position at the outlet of the combustion chamber and samples pressure oscillations at a ![]() $44.1\ \mathrm {kHz}$ frequency with a

$44.1\ \mathrm {kHz}$ frequency with a ![]() $16$ bit depth. Although audio signals do not allow us to determine the absolute magnitude of pressure, they offer qualitative information about the amplitude of pressure variations and are suitable for time-frequency analysis.

$16$ bit depth. Although audio signals do not allow us to determine the absolute magnitude of pressure, they offer qualitative information about the amplitude of pressure variations and are suitable for time-frequency analysis.

Finally, the operation procedure is always performed as follows. Prior to each experiment, the piston at the closed end is moved backwards allowing the mixture to enter the tube. During the feeding phase, combustion products from previous runs are replaced with fresh gases. The venting occurs at the open end of the tube. Once the tube is filled with fresh mixture, the gas feeding system is cut off by closing the valve at the inlet of the tube. To prevent the diffusion of the reactive mixture, which would cause problems of ignition, the open end is blocked. The effective chamber length is then adjusted by placing the piston at a distance ![]() $L$ from the open end. Upon completion of the filling process, the mixture is allowed to settle for approximately one minute to ensure that the temperature of the reactants mixture equals the refrigerated bath circulator's temperature,

$L$ from the open end. Upon completion of the filling process, the mixture is allowed to settle for approximately one minute to ensure that the temperature of the reactants mixture equals the refrigerated bath circulator's temperature, ![]() $T_{ext} = T_u$. Then, the blockage of the ignition end is removed and the mixture is ignited manually, with a delay of the order of 3 s.

$T_{ext} = T_u$. Then, the blockage of the ignition end is removed and the mixture is ignited manually, with a delay of the order of 3 s.

It should be emphasized that the experimental set-up enables the control of thermal boundary conditions and the unburnt gas temperature ![]() $T_u$. Therefore, the evolution of temperature downstream of the flame can be predicted from the heat-transfer analysis presented above. This is of uttermost importance in the experimental validation of thermoacoustic frequency analysis with heat losses presented next.

$T_u$. Therefore, the evolution of temperature downstream of the flame can be predicted from the heat-transfer analysis presented above. This is of uttermost importance in the experimental validation of thermoacoustic frequency analysis with heat losses presented next.

4. Experimental results

In this section, the experimental data of premixed flames undergoing thermoacoustic instabilities in horizontal tubes of different lengths ![]() $L$, and thermal bath temperatures

$L$, and thermal bath temperatures ![]() $T_{ext} = T_u$, are presented and discussed. Under these conditions, the computed thickness of methane flames is

$T_{ext} = T_u$, are presented and discussed. Under these conditions, the computed thickness of methane flames is ![]() $\delta _T= k /(\rho c_p S_u) \simeq 5\times 10^{-2}\ \mathrm {mm}$. Therefore, the different tested tube lengths expressed in terms of flame thickness are approximately

$\delta _T= k /(\rho c_p S_u) \simeq 5\times 10^{-2}\ \mathrm {mm}$. Therefore, the different tested tube lengths expressed in terms of flame thickness are approximately ![]() $L/\delta _T \sim {O}(10^4)$, considering the ranges of

$L/\delta _T \sim {O}(10^4)$, considering the ranges of ![]() $L=30\text {--}150$ cm, so that the acoustic wavelengths are indeed much larger than the reacting sheet thickness.

$L=30\text {--}150$ cm, so that the acoustic wavelengths are indeed much larger than the reacting sheet thickness.

4.1. Phenomenology

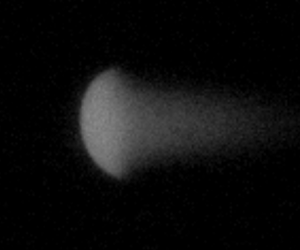

Three main propagation regimes have been identified in the experiments through high-speed video recording. Figure 4 summarizes the features of each regime in terms of front shape and displacement. The first regime is characterized by the absence of thermoacoustic instabilities, where a steady propagation of the flame front is observed for equispaced snapshots every ![]() $0.06$ s on the top row, propagating from right (open end) to left (closed end). The steady propagation velocity is higher than the planar flame velocity

$0.06$ s on the top row, propagating from right (open end) to left (closed end). The steady propagation velocity is higher than the planar flame velocity ![]() $S_L$, as expected from curved fronts far from the quenching limit. Moreover, the pulsating flame regime shown in the middle row of figure 4 is associated to primary instabilities. In this regime, flames are known to oscillate with a rather constant amplitude and with significant front curvature reduction, which can be noted as the flattening of the flame. Finally, the snapshot composition in the bottom row of figure 4 depicts the flame motion under secondary instabilities. Under certain conditions, the flame front transitions from primary to secondary instabilities. First, the previous nearly planar front is perturbed with a smooth wrinkling of the surface. Then, the amplitude of this corrugation grows fast and soon the flame becomes a folded and stretched disordered surface. During this phase, the front loses its coherence and propagates faster owing to the large increase in burning area. The absence of a well-defined flame surface complicates the tracking of its position and the measurement of the propagation velocity during this phase. Thus, once the secondary instability is fully developed, only a qualitative description of flame front propagation is possible from recorded images. In particular, various transitions between regimes can take place in the same tube during the complete propagation of the flame.

$S_L$, as expected from curved fronts far from the quenching limit. Moreover, the pulsating flame regime shown in the middle row of figure 4 is associated to primary instabilities. In this regime, flames are known to oscillate with a rather constant amplitude and with significant front curvature reduction, which can be noted as the flattening of the flame. Finally, the snapshot composition in the bottom row of figure 4 depicts the flame motion under secondary instabilities. Under certain conditions, the flame front transitions from primary to secondary instabilities. First, the previous nearly planar front is perturbed with a smooth wrinkling of the surface. Then, the amplitude of this corrugation grows fast and soon the flame becomes a folded and stretched disordered surface. During this phase, the front loses its coherence and propagates faster owing to the large increase in burning area. The absence of a well-defined flame surface complicates the tracking of its position and the measurement of the propagation velocity during this phase. Thus, once the secondary instability is fully developed, only a qualitative description of flame front propagation is possible from recorded images. In particular, various transitions between regimes can take place in the same tube during the complete propagation of the flame.

Figure 4. Flame-front propagation snapshots along the experimental tube for three regimes: steady propagation (top row); primary instabilities (middle row) and secondary instabilities (bottom row).

It should be pointed out that the flame velocity in the laboratory fixed reference frame, ![]() $u_f$, differs a small amount from the flame propagation velocity

$u_f$, differs a small amount from the flame propagation velocity ![]() $S_u$ because of the nearly stagnant flow condition found in the mixture of reactants before the flame front. Nevertheless, acoustic oscillations trigger a small amplitude motion in the fluid that needs to be accounted for if specific values of flame propagation velocities are required.

$S_u$ because of the nearly stagnant flow condition found in the mixture of reactants before the flame front. Nevertheless, acoustic oscillations trigger a small amplitude motion in the fluid that needs to be accounted for if specific values of flame propagation velocities are required.

Experimental results of flame position and velocity with time in a ![]() $L=150$ cm tube, for a rich methane–air mixture of equivalence ratio

$L=150$ cm tube, for a rich methane–air mixture of equivalence ratio ![]() $\phi = 1.3$ and wall temperature

$\phi = 1.3$ and wall temperature ![]() $T_u = 323$ K are presented in figure 5. An initial constant-speed motion is captured after ignition, followed by the initiation of smooth oscillations that are representative of primary thermoacoustic instabilities, which develop through an exponential growth of pressure and velocity oscillations, following unstable linear-system behaviour. At some point, nonlinear effects and damping mechanisms become important, which causes the exponential growth to decay and oscillation amplitude saturation around a fixed value. Differences in terms of flame velocity between steady propagation and averaged primary oscillations are noticeable. Specifically, the averaged flame velocity during the pulsating flame regime, where the flame surface and curvature are reduced, is very similar to the theoretical planar flame velocity

$T_u = 323$ K are presented in figure 5. An initial constant-speed motion is captured after ignition, followed by the initiation of smooth oscillations that are representative of primary thermoacoustic instabilities, which develop through an exponential growth of pressure and velocity oscillations, following unstable linear-system behaviour. At some point, nonlinear effects and damping mechanisms become important, which causes the exponential growth to decay and oscillation amplitude saturation around a fixed value. Differences in terms of flame velocity between steady propagation and averaged primary oscillations are noticeable. Specifically, the averaged flame velocity during the pulsating flame regime, where the flame surface and curvature are reduced, is very similar to the theoretical planar flame velocity ![]() $S_L = 0.273$ m s

$S_L = 0.273$ m s![]() $^{-1}$ in this experiment, and lower than the steady propagation speed under the initial curved front. Flame flattening precedes the appearance of small corrugations at the front, which then grow fast increasing the reacting surface area. This gives rise to the large-amplitude secondary instabilities that rapidly produce complex reacting-front surfaces, which become difficult to track through the high-speed video images and develop at

$^{-1}$ in this experiment, and lower than the steady propagation speed under the initial curved front. Flame flattening precedes the appearance of small corrugations at the front, which then grow fast increasing the reacting surface area. This gives rise to the large-amplitude secondary instabilities that rapidly produce complex reacting-front surfaces, which become difficult to track through the high-speed video images and develop at ![]() $t>0.55$ s in figure 5.

$t>0.55$ s in figure 5.

Figure 5. Position and velocity of the flame front against time obtained from video recording of a methane–air mixture with ![]() $\phi =1.3, L=150$ cm and

$\phi =1.3, L=150$ cm and ![]() $T_u = 323\ \mathrm {K}$.

$T_u = 323\ \mathrm {K}$.

Nonetheless, the audio signal provides extra quantitative information when the video processing fails upon the presence of secondary oscillations. In particular, the acoustic oscillation frequency can be measured during the secondary instability regime and along the whole length of the tube for each run, which becomes a difficult task for imaging methods in such slender configurations. Figure 6 shows the complete audio signal in time for ![]() $L = 150$ cm,

$L = 150$ cm, ![]() $\phi = 0.95$ and

$\phi = 0.95$ and ![]() $T_u =313$ K. This measurement is proportional to acoustic pressure, which allows to link propagation regimes to the order of magnitude of pressure oscillations in the tube with a common reference pressure

$T_u =313$ K. This measurement is proportional to acoustic pressure, which allows to link propagation regimes to the order of magnitude of pressure oscillations in the tube with a common reference pressure ![]() $p_{ref}$ fixed through the microphone set-up. In this particular experiment, the flame experiences the evolution from steady propagation to primary instability close to the open-end ignition event. Soon, transition from primary to secondary instability occurs and the flame front becomes strongly corrugated, where the amplitude of pressure oscillations shoots up. Later, re-stabilization occurs in the middle region of the tube, flame front coherence is recovered, and propagation remains stable and steady. Finally, as the flame approaches the closed end, a second appearance of primary instabilities occurs. This time, no secondary instability develops and, after a series of cycles, the flame front re-stabilizes.

$p_{ref}$ fixed through the microphone set-up. In this particular experiment, the flame experiences the evolution from steady propagation to primary instability close to the open-end ignition event. Soon, transition from primary to secondary instability occurs and the flame front becomes strongly corrugated, where the amplitude of pressure oscillations shoots up. Later, re-stabilization occurs in the middle region of the tube, flame front coherence is recovered, and propagation remains stable and steady. Finally, as the flame approaches the closed end, a second appearance of primary instabilities occurs. This time, no secondary instability develops and, after a series of cycles, the flame front re-stabilizes.

Figure 6. Audio signal recorded for ![]() $L =150$ cm,

$L =150$ cm, ![]() $T_u=313$ K and

$T_u=313$ K and ![]() $\phi =0.95$. The propagating flame undergoes primary oscillations and transitions to the secondary regime at distance

$\phi =0.95$. The propagating flame undergoes primary oscillations and transitions to the secondary regime at distance ![]() $L_{o.e}$ before restabilizing at the mid part of the tube, to finally excite primary instabilities near the closed end at distance

$L_{o.e}$ before restabilizing at the mid part of the tube, to finally excite primary instabilities near the closed end at distance ![]() $L_{c.e.}$.

$L_{c.e.}$.

This rich variety of phenomena is affected by modifications in tube length, bath temperature and equivalence ratio. In particular, it will be shown that typical transitions in far-from-stoichiometric mixtures produce flame extinction, while reactions of nearly stoichiometric mixtures can withstand the strain produced by high-pressure oscillations and recover the steady propagation regime after developing disordered patterns. Furthermore, flames do not transit from primary to secondary instabilities under certain combinations of the controlling parameters, for particularly long tubes and increasing temperatures.

4.2. Acoustic mode variation with tube length

A variation of the length of the combustion volume is offered through progressive displacement of the piston at the closed end of the tube. This allows modifying the acoustic time involved in the wave displacement along a distance ![]() $L$. Furthermore, the extended frequency analysis for non-adiabatic tubes is controlled by the relation of tube length to cooling distance

$L$. Furthermore, the extended frequency analysis for non-adiabatic tubes is controlled by the relation of tube length to cooling distance ![]() $\sigma = L/l_c$, which renders nearly isothermal solutions in long tubes

$\sigma = L/l_c$, which renders nearly isothermal solutions in long tubes ![]() $L\gg l_c$, and nearly adiabatic solutions in the short-tube limit

$L\gg l_c$, and nearly adiabatic solutions in the short-tube limit ![]() $L\ll l_c$.

$L\ll l_c$.

First results of the experimental tests can be extracted from figure 7, which shows the measured acoustic emission for decreasing tube lengths with stoichiometric mixtures, ![]() $\phi = 1$, and bath temperature equal to the unburnt gases temperature,

$\phi = 1$, and bath temperature equal to the unburnt gases temperature, ![]() $T_u = 303$ K. Acoustic pressure variations are referred to a reference amplitude value

$T_u = 303$ K. Acoustic pressure variations are referred to a reference amplitude value ![]() $p_{ref}$, which is chosen in such a way that secondary instabilities are of order unity and primary oscillations one order of magnitude smaller. In every panel showing audio signals, microphone position and gain are equal so that the pressure scale is common and therefore amplitudes can be compared noting the span of the vertical axes.

$p_{ref}$, which is chosen in such a way that secondary instabilities are of order unity and primary oscillations one order of magnitude smaller. In every panel showing audio signals, microphone position and gain are equal so that the pressure scale is common and therefore amplitudes can be compared noting the span of the vertical axes.

Figure 7. Audio signals from experiments with different tube lengths ![]() $L$, with

$L$, with ![]() $T_u = 303$ K and

$T_u = 303$ K and ![]() $\phi = 1$, and constant amplitude reference measurement

$\phi = 1$, and constant amplitude reference measurement ![]() $p_{ref}$. First emerging oscillations correspond to the

$p_{ref}$. First emerging oscillations correspond to the ![]() $L_{o.e}$ region, followed by a second stage of oscillations in the

$L_{o.e}$ region, followed by a second stage of oscillations in the ![]() $L_{c.e.}$ region, except in the

$L_{c.e.}$ region, except in the ![]() $L=30$ cm case.

$L=30$ cm case.

In very long tubes, ![]() $L = 150$ cm, two excited regions undergoing primary instabilities exist around certain sections of distances

$L = 150$ cm, two excited regions undergoing primary instabilities exist around certain sections of distances ![]() $L_{o.e.}$ and

$L_{o.e.}$ and ![]() $L_{c.e.}$ measured from the closed end, where o.e. and c.e. stand for open and closed end, respectively, and indicate the nearest end of the tube to the corresponding instability. Depending on the experimental conditions, the distance of the section near the open end

$L_{c.e.}$ measured from the closed end, where o.e. and c.e. stand for open and closed end, respectively, and indicate the nearest end of the tube to the corresponding instability. Depending on the experimental conditions, the distance of the section near the open end ![]() $L_{o.e.}$ ranges from

$L_{o.e.}$ ranges from ![]() $3L/4$ to

$3L/4$ to ![]() $4L/5$, and the one next to the closed end

$4L/5$, and the one next to the closed end ![]() $L_{c.e.}$ is approximately between

$L_{c.e.}$ is approximately between ![]() $L/4$ and

$L/4$ and ![]() $L/5$. Later on, it will be shown that these oscillations correspond to the destabilization of the first harmonic mode and that other regions are of interest when considering the excitation of the fundamental mode.

$L/5$. Later on, it will be shown that these oscillations correspond to the destabilization of the first harmonic mode and that other regions are of interest when considering the excitation of the fundamental mode.

Furthermore, the amplitude of pressure oscillations displays a growing trend with length reduction from ![]() $150$ cm to

$150$ cm to ![]() $100$ cm. Tubes of

$100$ cm. Tubes of ![]() $L=125$ cm show double development of secondary thermoacoustic instabilities at both coupling regions. These lead to pressure oscillations whose amplitude is typically an order of magnitude higher than those observed for primary instabilities, easily identified in the

$L=125$ cm show double development of secondary thermoacoustic instabilities at both coupling regions. These lead to pressure oscillations whose amplitude is typically an order of magnitude higher than those observed for primary instabilities, easily identified in the ![]() $L=100$ cm and

$L=100$ cm and ![]() $L=90$ cm panels of figure 7. As the tube length is reduced to

$L=90$ cm panels of figure 7. As the tube length is reduced to ![]() $L=100$ cm, the second transition is eliminated and weak oscillations of a lower frequency appear in between these two coupling regions. This new mid-tube regime is in turn associated with the fundamental mode.

$L=100$ cm, the second transition is eliminated and weak oscillations of a lower frequency appear in between these two coupling regions. This new mid-tube regime is in turn associated with the fundamental mode.

Further reduction to ![]() $L = 70$ cm displays a change in the unstable behaviour of acoustic modes. The oscillatory motion of the flame presents here two differentiated frequency components associated with the fundamental and first harmonic modes. Broadly speaking, fundamental mode instability seems to be more intense in the central region while first harmonic destabilization seems to be preferential around

$L = 70$ cm displays a change in the unstable behaviour of acoustic modes. The oscillatory motion of the flame presents here two differentiated frequency components associated with the fundamental and first harmonic modes. Broadly speaking, fundamental mode instability seems to be more intense in the central region while first harmonic destabilization seems to be preferential around ![]() $L_{o.e.}$ and

$L_{o.e.}$ and ![]() $L_{c.e.}$ regions. Finally, in shorter tubes,

$L_{c.e.}$ regions. Finally, in shorter tubes, ![]() $L<60$ cm, a sole unstable region exists. The oscillations observed in shorter tubes correspond to the destabilization of the fundamental mode, which always leads to secondary instabilities under these temperature, diameter and equivalence ratio conditions.

$L<60$ cm, a sole unstable region exists. The oscillations observed in shorter tubes correspond to the destabilization of the fundamental mode, which always leads to secondary instabilities under these temperature, diameter and equivalence ratio conditions.

For the sake of completeness, video processing of the flame front can provide here key information regarding the base frequency of the thermoacoustic dynamics in different regions of the tube. In particular, figure 8 shows the comparison between the theoretical frequencies obtained by the adiabatic prediction (dashed curves), extended non-adiabatic model (solid curves) and experimental flame image oscillation frequencies (symbols). There, fundamental mode (red) and first harmonic frequencies (blue) are identified. Moreover, the use of dimensionless frequency, ![]() $\varOmega = \omega t_a$, enables the collapse of predictions for variable temperature conditions, as the reference acoustic time,

$\varOmega = \omega t_a$, enables the collapse of predictions for variable temperature conditions, as the reference acoustic time, ![]() $t_a =L/c_u$, is modified through the main sound speed of the mixture. Empty circles correspond to experiments with

$t_a =L/c_u$, is modified through the main sound speed of the mixture. Empty circles correspond to experiments with ![]() $T_u= 303$ K and filled squares are experimental data with

$T_u= 303$ K and filled squares are experimental data with ![]() $T_u = 333$ K, where the error bars represent the experimental uncertainty, as detailed in Appendix A.

$T_u = 333$ K, where the error bars represent the experimental uncertainty, as detailed in Appendix A.

Figure 8. Theoretical predictions of the dimensionless coupling frequency (solid lines) for the fundamental (red) and first harmonic (blue) modes along the tube using the extended non-adiabatic model, and experimental data (symbols) at ![]() $303$ K (empty circles) and

$303$ K (empty circles) and ![]() $333$ K (solid squares). Dashed lines correspond to the one-dimensional adiabatic model of (2.7).

$333$ K (solid squares). Dashed lines correspond to the one-dimensional adiabatic model of (2.7).

It is now recalled that video recording in such slender configurations implies numerous tests to cover the imaging of the tube by composition of short longitudinal sections of approximately ![]() $20$ cm, depicted by the collection of symbols. However, good agreement of the frequency theoretical prediction and experiments is also obtained when considering the audio signals that provide a continuous frequency description along the whole tube and of the same value of image oscillation frequencies.

$20$ cm, depicted by the collection of symbols. However, good agreement of the frequency theoretical prediction and experiments is also obtained when considering the audio signals that provide a continuous frequency description along the whole tube and of the same value of image oscillation frequencies.

First, it is clear that increasing tube lengths provide greater values of ![]() $\sigma =L/l_c$ with constant cooling length and, therefore, more pronounced modifications to the adiabatic predictions given by (2.7). Specifically, theoretical estimation of the cooling length

$\sigma =L/l_c$ with constant cooling length and, therefore, more pronounced modifications to the adiabatic predictions given by (2.7). Specifically, theoretical estimation of the cooling length ![]() $l_c$ is recalled here to yield a value of

$l_c$ is recalled here to yield a value of ![]() $5$ cm. This estimation has been used throughout the whole document to compare experimental results and theoretical predictions in the

$5$ cm. This estimation has been used throughout the whole document to compare experimental results and theoretical predictions in the ![]() $10$ mm diameter tube used here. The experimental results are in good agreement with the heat-loss model presented here, which allows identification of which acoustic modes are involved in the oscillation. The fundamental mode (red) is shown to dominate for shorter tube lengths, contrarily to the first harmonics (blue), which become more important with increasing lengths. Although first harmonics near the closed end of the tube (

$10$ mm diameter tube used here. The experimental results are in good agreement with the heat-loss model presented here, which allows identification of which acoustic modes are involved in the oscillation. The fundamental mode (red) is shown to dominate for shorter tube lengths, contrarily to the first harmonics (blue), which become more important with increasing lengths. Although first harmonics near the closed end of the tube (![]() $r\simeq 0.1$) could be mistaken for adiabatic fundamental modes (red dashed curve) if taken separately from the experiments, the rest of the measurements providing the frequency distribution along the tube should then be identified as inconsistent with the adiabatic model.

$r\simeq 0.1$) could be mistaken for adiabatic fundamental modes (red dashed curve) if taken separately from the experiments, the rest of the measurements providing the frequency distribution along the tube should then be identified as inconsistent with the adiabatic model.

4.3. Bath temperature effects

A secondary validation of the heat transfer problem can be achieved by systematic modification of the temperature of the working liquid, which sets the wall temperature and the quiescent mixture to a nearly constant value ![]() $T_u$ previous to ignition. Figure 9 shows the audio signals and their time-frequency transform for a higher temperature of

$T_u$ previous to ignition. Figure 9 shows the audio signals and their time-frequency transform for a higher temperature of ![]() $T_u = 333$ K and tube lengths

$T_u = 333$ K and tube lengths ![]() $L=150$ cm (a),

$L=150$ cm (a), ![]() $L=100$ cm (b),

$L=100$ cm (b), ![]() $L=90$ cm (c),

$L=90$ cm (c), ![]() $L=70$ cm (d),

$L=70$ cm (d), ![]() $L=50$ cm (e) and

$L=50$ cm (e) and ![]() $L=30$ cm (f). Together with each spectrogram, theoretical dimensional frequency predictions have been plotted for the sake of comparison with

$L=30$ cm (f). Together with each spectrogram, theoretical dimensional frequency predictions have been plotted for the sake of comparison with ![]() $\sigma = 30, 20, 18, 14, 10$ and

$\sigma = 30, 20, 18, 14, 10$ and ![]() $6$, respectively, with the same value of

$6$, respectively, with the same value of ![]() $l_c =5$ cm. This comparison requires an additional reconstruction of the temporal domain from the spatial one used in the theoretical prediction. For simplicity, it has been assumed that flames propagate at constant velocity

$l_c =5$ cm. This comparison requires an additional reconstruction of the temporal domain from the spatial one used in the theoretical prediction. For simplicity, it has been assumed that flames propagate at constant velocity ![]() $\bar {u}_f$, averaged in each case to match the approximate duration of the audio signal and the length of the tube. Average flame propagation speed is

$\bar {u}_f$, averaged in each case to match the approximate duration of the audio signal and the length of the tube. Average flame propagation speed is ![]() $\bar {u}_f = 1.3S_L$ for

$\bar {u}_f = 1.3S_L$ for ![]() $L = 150$ cm,

$L = 150$ cm, ![]() $\bar {u}_f =1.2S_L$ for

$\bar {u}_f =1.2S_L$ for ![]() $L =100, 90$ and

$L =100, 90$ and ![]() $70$ cm, and

$70$ cm, and ![]() $\bar {u}_f =1.7S_L$ for

$\bar {u}_f =1.7S_L$ for ![]() $L = 50$ and

$L = 50$ and ![]() $30$ cm, with the theoretical planar flame velocity

$30$ cm, with the theoretical planar flame velocity ![]() $S_L\simeq 0.45\ \mathrm {m\ s^{-1}}$. However, as has been mentioned above, front velocity depends strongly on the propagation regime. For instance, flames undergoing primary instabilities see their average speed reduced with respect to the steady propagation velocity. Consequently, horizontal shifting between the model and the experimental results is expected at some sections owing to small errors in the temporal reconstruction. The horizontal shifting may become more relevant in shorter tubes