1. Introduction

Microfluidic channels are widely used to produce droplets with controlled size and low polydispersity index, which are important in applications such as emulsification, inkjet printing, cosmetics and healthcare (Lawrence & Rees Reference Lawrence and Rees2000; Yang et al. Reference Yang, Kapur, Wang, Fiesser, Bierbrauer, Wilson, Sabey and Bain2018; Park, Kim & Kim Reference Park, Kim and Kim2021). Surfactants are commonly added during drop formation to modify the interfacial properties and improve the stability of the emulsions. The presence of surfactant molecules significantly affects the nonlinear drop formation process and thus the final size (Chen, Xu & Luo Reference Chen, Xu and Luo2015). In the common dripping regime, drop formation depends on the balance between the interfacial tension and the drag forces, with the latter being the combination of shear and pressure forces (Xu et al. Reference Xu, Luo, Li and Chen2006). As a result, a lower interfacial tension caused by surfactant addition will result in smaller and more rapidly forming drops. As seen in previous work, the small characteristic time scales that are present in microfluidics can lead to interfacial tension values different from the equilibrium ones, which are often used in the calculation of capillary numbers ![]() $Ca$ (Kalli & Angeli Reference Kalli and Angeli2022) and in predictive equations for drop size. Additionally, shear stresses from high continuous phase velocities can redistribute surfactant molecules at the interface, which will cause interfacial tension gradients and thus Marangoni stresses (Kovalchuk & Simmons Reference Kovalchuk and Simmons2021). For surfactants that result in a large decrease in interfacial tension, the effect of interface retardation at low surfactant concentrations can be sufficiently large to change the velocity fields close to the interface and inside the drop, due to Marangoni stresses in the opposite direction to the flow. At high concentrations, surfactant exchange between the bulk and the interface is fast and interface remobilisation is seen at high velocities (Martin & Hudson Reference Martin and Hudson2009). Since both observations will greatly impact the final surfactant transport, it is important to study the behaviour of such surfactants at different concentrations, below and above the critical micelle concentration (CMC).

$Ca$ (Kalli & Angeli Reference Kalli and Angeli2022) and in predictive equations for drop size. Additionally, shear stresses from high continuous phase velocities can redistribute surfactant molecules at the interface, which will cause interfacial tension gradients and thus Marangoni stresses (Kovalchuk & Simmons Reference Kovalchuk and Simmons2021). For surfactants that result in a large decrease in interfacial tension, the effect of interface retardation at low surfactant concentrations can be sufficiently large to change the velocity fields close to the interface and inside the drop, due to Marangoni stresses in the opposite direction to the flow. At high concentrations, surfactant exchange between the bulk and the interface is fast and interface remobilisation is seen at high velocities (Martin & Hudson Reference Martin and Hudson2009). Since both observations will greatly impact the final surfactant transport, it is important to study the behaviour of such surfactants at different concentrations, below and above the critical micelle concentration (CMC).

As first reported by Garstecki, Stone & Whitesides (Reference Garstecki, Stone and Whitesides2005), drop formation in the dripping regime is typically divided into three stages called expansion, necking and pinch-off. Following drop detachment, the interface pulls towards the inlet before recoiling in the downstream direction. At this stage, drop growth is mainly in the streamwise direction forming a parabolic interface profile and is dominated by interfacial tension. Once the pressure builds up due to restriction of the inlet from the forming drop, the drag force overcomes the interfacial tension force and a reversal of the interface curvature is observed, which indicates the beginning of the necking stage. The neck width decreases until the drag force is large enough to cause drop detachment and thus pinch-off. In recent studies (Wang et al. Reference Wang, Lu, Xu and Luo2009; Xu et al. Reference Xu, Dong, Zhao, Tostado and Luo2012), it was found that high dispersed phase flow rates enhance convection and surfactant mass transfer from the continuous phase to the interface, which explain the reduced interfacial tension values at short formation times. Furthermore, it was found that absorption and mass transfer rates can compete with drop formation times (Kalli, Chagot & Angeli Reference Kalli, Chagot and Angeli2022). Investigating the transport of surfactants during each phase of the drop formation process is vital in understanding the impact on the final drop size.

Improvements in experimental techniques allow the accurate visualisation of flows inside microchannels, which can be used to explore the effects of surfactant transport. Kiratzis et al. (Reference Kiratzis, Kovalchuk, Simmons and Vigolo2022) used ghost particle velocimetry to study the effect of surfactant concentration, continuous phase velocity and viscosity on drop formation in rectangular channels. Results revealed smaller velocities at the interface when a surfactant of the same family but with a slower adsorption rate (lower CMC) was present, suggesting the presence of Marangoni stresses. In addition, larger internal circulation inside the drops was seen at higher continuous phase viscosity during the expansion stage. Roumpea et al. (Reference Roumpea, Kovalchuk, Chinaud, Nowak, Simmons and Angeli2019) used an innovative two-colour micro-particle image velocimetry (![]() $\mu$PIV) technique to study velocity fields in a flow-focusing microchannel in the presence of two cationic surfactants of the same family but different adsorption kinetics (C

$\mu$PIV) technique to study velocity fields in a flow-focusing microchannel in the presence of two cationic surfactants of the same family but different adsorption kinetics (C![]() $_{12}$TAB, dodecyltrimethylammonium bromide and C

$_{12}$TAB, dodecyltrimethylammonium bromide and C![]() $_{16}$TAB, hexadecyltrimethylammonium bromide). Addition of surfactant in the dispersed phase resulted in higher velocities at the tip and more uniform velocity fields inside the drop, which was attributed to surfactant accumulation at the tip that increases the interface rigidity in that area. A second observation was the decrease in the circulation inside the drop, which was again attributed to Marangoni effects that caused the interface to move in the opposite direction to the flow and opposed circulation. Similar effects were seen when a non-ionic surfactant (Span80) was added in the continuous oil phase, in a T-junction channel (Riaud et al. Reference Riaud, Zhang, Wang, Wang and Luo2018). A stagnant cap was observed in this case near the drop tip that split the forming drop interface into a mobile and a rigid region. The resulting Marangoni force in the opposite direction of the forming drop resisted the flow circulation. Studies on drop formation in a flow-focusing microchannel by Carrier et al. (Reference Carrier, Ergin, Li, Watz and Funfschilling2015) revealed a flow inversion during pinch-off and weaker recirculation at the base of the drop compared with its front, upon addition of SDS (sodium dodecylsulphate) surfactant. Changes in circulation within surfactant-laden drops using

$_{16}$TAB, hexadecyltrimethylammonium bromide). Addition of surfactant in the dispersed phase resulted in higher velocities at the tip and more uniform velocity fields inside the drop, which was attributed to surfactant accumulation at the tip that increases the interface rigidity in that area. A second observation was the decrease in the circulation inside the drop, which was again attributed to Marangoni effects that caused the interface to move in the opposite direction to the flow and opposed circulation. Similar effects were seen when a non-ionic surfactant (Span80) was added in the continuous oil phase, in a T-junction channel (Riaud et al. Reference Riaud, Zhang, Wang, Wang and Luo2018). A stagnant cap was observed in this case near the drop tip that split the forming drop interface into a mobile and a rigid region. The resulting Marangoni force in the opposite direction of the forming drop resisted the flow circulation. Studies on drop formation in a flow-focusing microchannel by Carrier et al. (Reference Carrier, Ergin, Li, Watz and Funfschilling2015) revealed a flow inversion during pinch-off and weaker recirculation at the base of the drop compared with its front, upon addition of SDS (sodium dodecylsulphate) surfactant. Changes in circulation within surfactant-laden drops using ![]() $\mu$PIV were investigated in emulsions produced in a tapered microchannel leading to a geometrical constriction (Leong, Gai & Tang Reference Leong, Gai and Tang2018). It was found that vortical structures forming when the drops passed the constriction, increase circulation up to 2.5 times compared with droplet mixing at the channel constriction.

$\mu$PIV were investigated in emulsions produced in a tapered microchannel leading to a geometrical constriction (Leong, Gai & Tang Reference Leong, Gai and Tang2018). It was found that vortical structures forming when the drops passed the constriction, increase circulation up to 2.5 times compared with droplet mixing at the channel constriction.

Despite the work reviewed above, there are still important limitations to be addressed in order to fully understand the effect of surfactant on the drop formation process. As previously mentioned, it is essential to know the surfactant distribution at the interface as it can accumulate at the tip and cause Marangoni flows as the drop forms. The surfactant concentration at the interface is very challenging to obtain experimentally (Dussaud, Matar & Troian Reference Dussaud, Matar and Troian2005), especially during flow. Even if a fluorescent surfactant is used, the powerful intensity of the laser needed for visualisation can cause photobleaching (Eggeling et al. Reference Eggeling, Widengren, Rigler and Seidel1998), which is non-reversible. Another issue is self-quenching (Aicolina, Leaver & Stapleton Reference Aicolina, Leaver and Stapleton1989; Li et al. Reference Li, Zhou, Yu, Pu, Sun, Zhou and Zhang2022), where the total emitted intensity can change upon temperature, pressure or pH fluctuations. Additionally, most fluorescent surfactants are soluble in solvents such as chloroform and dimethylformamide, which can be toxic. Since most fluorescently tagged surfactants are synthesised by adding a fluorescent group to the amphiphilic structure of the surfactant, they usually result in heavier molecules that exhibit low interfacial activity (i.e. small reduction in interfacial tension with concentration) or slow adsorption kinetics, especially when compared with the fast drop formation process. Dong, Weheliye & Angeli (Reference Dong, Weheliye and Angeli2019) used planar laser induced fluorescence to capture the spatio-temporal distribution of a fluorescent surfactant during the coalescence of a mm size drop with a flat surface, using a laser sheet with 1 mm thickness. This dimension is an order of magnitude larger than typical microchannel length scales. On the other hand, the volume illumination used for microchannel laser induced fluorescence studies is not ideal when tracing molecules at a three-dimensional interface.

The complex phenomena of drop formation in microchannels have also been investigated through numerical approaches. Computational fluid dynamics (CFD) simulations in particular are a powerful tool to overcome most of the above-mentioned experimental limitations and extract useful information related to the dynamics of the flow. Numerous CFD investigations based on volume-of-fluid and level-set methods have been conducted to determine the role of operating conditions on the drop formation process in surfactant-free systems. These studies have revealed the interplay between capillarity, inertia and viscosity for different microfluidic junction geometries and their effects on drop formation (Van der Graaf et al. Reference Van der Graaf, Nisisako, Schroën, Van Der Sman and Boom2006; Li et al. Reference Li, Li, Yang, Kinoshita, Oishi and Oshima2012; Lan et al. Reference Lan, Li, Wang and Luo2014; Ngo et al. Reference Ngo, Dang, Byon and Joo2015; Zhao et al. Reference Zhao, Riaud, Luo, Jin and Cheng2015; Soh, Yeoh & Timchenko Reference Soh, Yeoh and Timchenko2016; Kahouadji et al. Reference Kahouadji, Nowak, Kovalchuk, Chergui, Juric, Shin, Simmons, Craster and Matar2018; Filimonov, Wu & Sundén Reference Filimonov, Wu and Sundén2021). Recent studies in the presence of surfactants have provided a detailed description of the heterogeneous distribution of surfactant concentration at the interface and the effect on drop formation time and drop size. Riaud et al. (Reference Riaud, Zhang, Wang, Wang and Luo2018) performed numerical simulations inside a T-junction microchannel for a Span80-octane/water mixture and compared the results against ![]() $\mu$PIV experiments. The authors found that the interfacial distribution of surfactants on growing droplets is not uniform but surfactants tend to concentrate at the droplet tip. They also reported that surfactant adsorption is faster than drop formation at low velocities and low

$\mu$PIV experiments. The authors found that the interfacial distribution of surfactants on growing droplets is not uniform but surfactants tend to concentrate at the droplet tip. They also reported that surfactant adsorption is faster than drop formation at low velocities and low ![]() $Ca$. As

$Ca$. As ![]() $Ca$ is increased, either by lowering the interfacial tension or by increasing the inlet velocity, the characteristic drop formation time is reduced and thus adsorption becomes slower than formation time. The authors showed that droplet volume increases with increasing dispersed phase flow rate and decreasing

$Ca$ is increased, either by lowering the interfacial tension or by increasing the inlet velocity, the characteristic drop formation time is reduced and thus adsorption becomes slower than formation time. The authors showed that droplet volume increases with increasing dispersed phase flow rate and decreasing ![]() $Ca$; both parameters are therefore necessary to predict the drop size. Jin, Gupta & Stebe (Reference Jin, Gupta and Stebe2006) studied the effect of soluble surfactants on drop necking and used a nonlinear model to relate interfacial tension to surfactant concentration at the interface, by accounting for maximum surfactant packing at the interface. The analysis revealed that a family of necks formed, as a result of a primary and a secondary thinning rate of the neck, depending on the local accumulation of surfactants, and demonstrated that drop detachment behaviour can be used to quantify surfactant dynamics. Antonopoulou et al. (Reference Antonopoulou, Harlen, Rump, Segers and Walkley2021) performed experimental and numerical studies on the flow behaviour during inkjet printing and explained the effect different surfactants have on pinch-off during jetting.

$Ca$; both parameters are therefore necessary to predict the drop size. Jin, Gupta & Stebe (Reference Jin, Gupta and Stebe2006) studied the effect of soluble surfactants on drop necking and used a nonlinear model to relate interfacial tension to surfactant concentration at the interface, by accounting for maximum surfactant packing at the interface. The analysis revealed that a family of necks formed, as a result of a primary and a secondary thinning rate of the neck, depending on the local accumulation of surfactants, and demonstrated that drop detachment behaviour can be used to quantify surfactant dynamics. Antonopoulou et al. (Reference Antonopoulou, Harlen, Rump, Segers and Walkley2021) performed experimental and numerical studies on the flow behaviour during inkjet printing and explained the effect different surfactants have on pinch-off during jetting.

This paper combines unique experimental and numerical approaches to investigate surfactant transport in the bulk, distribution at the interface and Marangoni phenomena during the fast drop formation process in a microfluidic channel. A non-ionic (CMC![]() $_{TX100} = 3.5$ mM) surfactant is used in the dispersed aqueous phase at concentrations below and above the CMC. A novel high-speed

$_{TX100} = 3.5$ mM) surfactant is used in the dispersed aqueous phase at concentrations below and above the CMC. A novel high-speed ![]() $\mu$PIV system is able to follow all stages of the fast drop formation process, which is a key improvement compared with previous works (Riaud et al. Reference Riaud, Zhang, Wang, Wang and Luo2018; Roumpea et al. Reference Roumpea, Kovalchuk, Chinaud, Nowak, Simmons and Angeli2019). The CFD simulations include the exchange of surfactant between the bulk of the drop and the interface, as opposed to previous works that considered only transport at the interface (Riaud et al. Reference Riaud, Zhang, Wang, Wang and Luo2018; Antonopoulou et al. Reference Antonopoulou, Harlen, Rump, Segers and Walkley2021). The effect of surfactant on the vortical structures and velocity fields are discussed for the different stages of drop formation. The CFD simulations provide information on surfactant concentrations at the interface that cannot be obtained experimentally. In addition, they reveal the vortical structures very close to the interface where measurements are not accurate because of the low concentration of the PIV tracer particles in this region (i.e. at the neck region just before pinch-off). They also enable investigations of the drop in three dimensions, which are very challenging to obtain experimentally. The experiments on the other hand provide data on the effect of the surfactant at high concentrations above the CMC, which is beyond the capabilities of the current model. The Marangoni stresses at the interface are calculated and presented as a function of time, space, and dispersed phase flow rate for the first time during the whole drop formation process.

$\mu$PIV system is able to follow all stages of the fast drop formation process, which is a key improvement compared with previous works (Riaud et al. Reference Riaud, Zhang, Wang, Wang and Luo2018; Roumpea et al. Reference Roumpea, Kovalchuk, Chinaud, Nowak, Simmons and Angeli2019). The CFD simulations include the exchange of surfactant between the bulk of the drop and the interface, as opposed to previous works that considered only transport at the interface (Riaud et al. Reference Riaud, Zhang, Wang, Wang and Luo2018; Antonopoulou et al. Reference Antonopoulou, Harlen, Rump, Segers and Walkley2021). The effect of surfactant on the vortical structures and velocity fields are discussed for the different stages of drop formation. The CFD simulations provide information on surfactant concentrations at the interface that cannot be obtained experimentally. In addition, they reveal the vortical structures very close to the interface where measurements are not accurate because of the low concentration of the PIV tracer particles in this region (i.e. at the neck region just before pinch-off). They also enable investigations of the drop in three dimensions, which are very challenging to obtain experimentally. The experiments on the other hand provide data on the effect of the surfactant at high concentrations above the CMC, which is beyond the capabilities of the current model. The Marangoni stresses at the interface are calculated and presented as a function of time, space, and dispersed phase flow rate for the first time during the whole drop formation process.

2. Experimental methods

2.1. Droplet generation

The experiments were performed in a glass flow-focusing microchannel from Dolomite Microfluidics (Part No. 3000436) already used in previous works (Kovalchuk et al. Reference Kovalchuk, Roumpea, Nowak, Chinaud, Angeli and Simmons2018; Roumpea et al. Reference Roumpea, Kovalchuk, Chinaud, Nowak, Simmons and Angeli2019). At the cross-junction the inlet dimensions are ![]() $195\,{\rm \mu}{\rm m}\times 190\,{\rm \mu}{\rm m}$ (width

$195\,{\rm \mu}{\rm m}\times 190\,{\rm \mu}{\rm m}$ (width ![]() $\times$ depth) and the dimensions of the main channel are

$\times$ depth) and the dimensions of the main channel are ![]() $390\,{\rm \mu}{\rm m} \times 190\,{\rm \mu}{\rm m}$ (width

$390\,{\rm \mu}{\rm m} \times 190\,{\rm \mu}{\rm m}$ (width ![]() $\times$ depth). The continuous phase was introduced via the side channels and then the aqueous phase via the central channel of the junction (see figure 1a). For all configurations, silicone oil (Clearco, density:

$\times$ depth). The continuous phase was introduced via the side channels and then the aqueous phase via the central channel of the junction (see figure 1a). For all configurations, silicone oil (Clearco, density: ![]() $\rho _c = 920$ kg m

$\rho _c = 920$ kg m![]() $^{-3}$, viscosity:

$^{-3}$, viscosity: ![]() $\mu _c = 4.6$ mPa s at 20

$\mu _c = 4.6$ mPa s at 20 ![]() $^\circ$C) was used as the continuous phase and a mixture of 52 % w/w glycerol and 48 % w/w water (Sigma Aldrich,

$^\circ$C) was used as the continuous phase and a mixture of 52 % w/w glycerol and 48 % w/w water (Sigma Aldrich, ![]() $\geq$99.5 %, density:

$\geq$99.5 %, density: ![]() $\rho _d = 1132$ kg m

$\rho _d = 1132$ kg m![]() $^{-3}$, viscosity

$^{-3}$, viscosity ![]() $\mu _d = 6.8$ mPa s at 20

$\mu _d = 6.8$ mPa s at 20 ![]() $^{\circ }$C) with and without surfactant was selected as the dispersed phase. Based on the work of Kalli et al. (Reference Kalli, Chagot and Angeli2022), the flow rates were selected to form drops in the dripping regime. Using syringe pumps (KDS Scientific,

$^{\circ }$C) with and without surfactant was selected as the dispersed phase. Based on the work of Kalli et al. (Reference Kalli, Chagot and Angeli2022), the flow rates were selected to form drops in the dripping regime. Using syringe pumps (KDS Scientific, ![]() ${\pm }5\times 10^{-9}$ ml min

${\pm }5\times 10^{-9}$ ml min![]() $^{-1}$), the continuous phase was introduced with a total flow rate

$^{-1}$), the continuous phase was introduced with a total flow rate ![]() $Q_c=0.12$ ml min

$Q_c=0.12$ ml min![]() $^{-1}$, while the dispersed phase had a flow rate of

$^{-1}$, while the dispersed phase had a flow rate of ![]() $Q_d=0.01,0.02$ ml min

$Q_d=0.01,0.02$ ml min![]() $^{-1}$. To observe the impact of interfacial tension on the drop formation, several concentrations of the non-ionic surfactant Triton X-100 (TX100), (Acros organics,

$^{-1}$. To observe the impact of interfacial tension on the drop formation, several concentrations of the non-ionic surfactant Triton X-100 (TX100), (Acros organics, ![]() $M_w = 646.85$ g mol

$M_w = 646.85$ g mol![]() $^{-1}$,

$^{-1}$, ![]() $\ge$95 %) were dissolved in the dispersed phase at concentrations of

$\ge$95 %) were dissolved in the dispersed phase at concentrations of ![]() $(0.1, 0.2, 0.6, 1.0, 1.4, 2.1, 2.9, 4.3, 5.7, 8.6)\times {\rm CMC}$. Figure 1(b) shows the equilibrium interfacial tension values (

$(0.1, 0.2, 0.6, 1.0, 1.4, 2.1, 2.9, 4.3, 5.7, 8.6)\times {\rm CMC}$. Figure 1(b) shows the equilibrium interfacial tension values (![]() $\sigma$), normalised by the final equilibrium interfacial tension value at

$\sigma$), normalised by the final equilibrium interfacial tension value at ![]() ${\rm CMC} = 3.5$ mM (

${\rm CMC} = 3.5$ mM (![]() $\sigma _{\varGamma =\varGamma _{\infty }} = 2.9$ mN m

$\sigma _{\varGamma =\varGamma _{\infty }} = 2.9$ mN m![]() $^{-1}$) as measured using a Du Noüy ring attached to a Force K100 Tensiometer (Krüss GmbH).

$^{-1}$) as measured using a Du Noüy ring attached to a Force K100 Tensiometer (Krüss GmbH).

Figure 1. (a) Numerical configuration, and an illustrative snapshot of a top view of the interface (top), and the corresponding high-speed image from experiments (bottom); (b) interfacial tension isotherm for TX100 surfactant showing the variation of equilibrium interfacial tension, ![]() $\sigma$. Black points represent dimensionless

$\sigma$. Black points represent dimensionless ![]() $\tilde {\sigma }$ (normalised by the surfactant-free value of interfacial tension,

$\tilde {\sigma }$ (normalised by the surfactant-free value of interfacial tension, ![]() $\sigma _s$) with the semi-log variation of the dimensionless surfactant bulk concentration

$\sigma _s$) with the semi-log variation of the dimensionless surfactant bulk concentration ![]() $\tilde {C}$ (normalised by the CMC). Red points represent the dimensionless interfacial surfactant concentration,

$\tilde {C}$ (normalised by the CMC). Red points represent the dimensionless interfacial surfactant concentration, ![]() $\tilde {\varGamma }$ (normalised by

$\tilde {\varGamma }$ (normalised by ![]() $\varGamma$ saturation value,

$\varGamma$ saturation value, ![]() $\varGamma _{\infty }$) obtained using (3.7) and

$\varGamma _{\infty }$) obtained using (3.7) and ![]() $\varGamma = \varGamma _{\infty }K_L C/(1+K_L C)$. The blue dashed line represents the fitting of

$\varGamma = \varGamma _{\infty }K_L C/(1+K_L C)$. The blue dashed line represents the fitting of ![]() $\tilde {\sigma }=1+0.1\ln (1-\tilde {\varGamma })$; (c) geometrical details of the microfluidic channel decomposed into

$\tilde {\sigma }=1+0.1\ln (1-\tilde {\varGamma })$; (c) geometrical details of the microfluidic channel decomposed into ![]() $240=30 \times 8 \times 1$ subdomains. Each subdomain contains an equal and structured mesh resolution of

$240=30 \times 8 \times 1$ subdomains. Each subdomain contains an equal and structured mesh resolution of ![]() $32^3$, for a total of

$32^3$, for a total of ![]() $960\times 256 \times 32$ cells.

$960\times 256 \times 32$ cells.

2.2. Optical techniques

The experimental set-up is shown in figure 2. Two different illumination modes were used for the ![]() $\mu$PIV or the high-speed imaging (HSI). To allow full optical access for all measurements and avoid optical distortions, in particular close to the channel wall, both phases were selected to match the refractive index of the glass microchannel (

$\mu$PIV or the high-speed imaging (HSI). To allow full optical access for all measurements and avoid optical distortions, in particular close to the channel wall, both phases were selected to match the refractive index of the glass microchannel (![]() $n_i = 1.39$). For both modes, the images were taken with a 12-bit high-speed camera (Phantom v1212,

$n_i = 1.39$). For both modes, the images were taken with a 12-bit high-speed camera (Phantom v1212, ![]() $1 280 \times 800$ pixels resolution). In the HSI experiments, the acquisition frequency was 10 000 Hz and the camera was equipped with a Nivatar

$1 280 \times 800$ pixels resolution). In the HSI experiments, the acquisition frequency was 10 000 Hz and the camera was equipped with a Nivatar ![]() $\times$20 zoom lens and an LED backlight for illumination. Results were averaged for at least 15 drops (drop size polydispersity

$\times$20 zoom lens and an LED backlight for illumination. Results were averaged for at least 15 drops (drop size polydispersity ![]() $\leq$1.2 %). The experimental error is 3

$\leq$1.2 %). The experimental error is 3 ![]() ${\rm \mu}$m per pixel for the spatial resolution and 0.1 ms for the time resolution.

${\rm \mu}$m per pixel for the spatial resolution and 0.1 ms for the time resolution.

Figure 2. Experimental set-up of the HSI and ![]() $\mu$PIV techniques.

$\mu$PIV techniques.

The high-speed ![]() $\mu$PIV experiments were performed by switching modes from the LED light (2) to the laser source (1) as shown in figure 2. The laser illumination was generated with a high-speed 60 W pulsed Nd-Yag (Litron), which allows the observation in time of the droplet generation. The dispersed phase was seeded with 1

$\mu$PIV experiments were performed by switching modes from the LED light (2) to the laser source (1) as shown in figure 2. The laser illumination was generated with a high-speed 60 W pulsed Nd-Yag (Litron), which allows the observation in time of the droplet generation. The dispersed phase was seeded with 1 ![]() ${\rm \mu}$m carboxylate-modified microspheres FluoSpheres, with an absorbance of 542 nm and an emission of 612 nm. For the PIV image pairs, the camera was equipped with a

${\rm \mu}$m carboxylate-modified microspheres FluoSpheres, with an absorbance of 542 nm and an emission of 612 nm. For the PIV image pairs, the camera was equipped with a ![]() $\times$20 microscope lens (Mitutoyo Ltd) and focal depth of 1.6

$\times$20 microscope lens (Mitutoyo Ltd) and focal depth of 1.6 ![]() ${\rm \mu}$m. The lens was mounted with a high-pass filter (

${\rm \mu}$m. The lens was mounted with a high-pass filter (![]() ${>}565$ nm) to eliminate reflections from the channel walls. Moreover, to be able to follow the interface during the PIV measurements, a small amount of rhodamine B (with absorbance of 510 nm and emission of 610 nm) was added in the dispersed phase (0.05 ppm). The high-speed

${>}565$ nm) to eliminate reflections from the channel walls. Moreover, to be able to follow the interface during the PIV measurements, a small amount of rhodamine B (with absorbance of 510 nm and emission of 610 nm) was added in the dispersed phase (0.05 ppm). The high-speed ![]() $\mu$PIV allows measurements in the channel centre during drop formation, which follow the whole process from the expansion

$\mu$PIV allows measurements in the channel centre during drop formation, which follow the whole process from the expansion ![]() $t=t_{exp}$ to the pinch-off stage

$t=t_{exp}$ to the pinch-off stage ![]() $t=t_{pin}$. For each measurement, 2000 image pairs were acquired at a frequency of 3000 Hz which represent

$t=t_{pin}$. For each measurement, 2000 image pairs were acquired at a frequency of 3000 Hz which represent ![]() $\sim$20 drop formation cycles. The measurements were performed in the entire channel width (

$\sim$20 drop formation cycles. The measurements were performed in the entire channel width (![]() $y/l_c\in [-1, 1]$, with

$y/l_c\in [-1, 1]$, with ![]() $y$ the transverse direction) and around the droplet emergence area (

$y$ the transverse direction) and around the droplet emergence area (![]() $x/l_c\in [-2,2]$, with

$x/l_c\in [-2,2]$, with ![]() $x$ the streamwise direction). The local coordinate system is defined in figure 1(a) where

$x$ the streamwise direction). The local coordinate system is defined in figure 1(a) where ![]() $(x,y)=(0,0)$ is the centre of the cross-junction. All velocity fields were computed with the free PIV software CPIV-IMFT developed at IMFT. It is based on an FFT cross-correlation method with peak-locking reduction schemes and parallelisation. In the processing,

$(x,y)=(0,0)$ is the centre of the cross-junction. All velocity fields were computed with the free PIV software CPIV-IMFT developed at IMFT. It is based on an FFT cross-correlation method with peak-locking reduction schemes and parallelisation. In the processing, ![]() $16\times 16$ pixels interrogation boxes and 50 % overlap were used, yielding a grid resolution of 1.4

$16\times 16$ pixels interrogation boxes and 50 % overlap were used, yielding a grid resolution of 1.4 ![]() ${\rm \mu}$m.

${\rm \mu}$m.

3. Numerical formulation, scaling and validation

3.1. Numerical formulation and problem statement

As mentioned in § 2, the microfluidic channel used in this study consists of a combination of both cross-junction and flow-focusing devices. Its computational representation and dimensions are illustrated in figure 1(c). The four branches of this device are identical with an oval cross-section shape of length ![]() $l_c = 390\,{\rm \mu}$m and width

$l_c = 390\,{\rm \mu}$m and width ![]() $w_c = 190\,{\rm \mu}$m. This cross-section is comprised a rectangular piece of dimensions

$w_c = 190\,{\rm \mu}$m. This cross-section is comprised a rectangular piece of dimensions ![]() $w_{c} \times (l_{c} - w_{c})$ connected to two semicircles of diameter

$w_{c} \times (l_{c} - w_{c})$ connected to two semicircles of diameter ![]() $w_{c}$. Figure 1(c) also shows the three-dimensional computational domain and its decomposition into

$w_{c}$. Figure 1(c) also shows the three-dimensional computational domain and its decomposition into ![]() $240=30\times 8\times 1$ sub-domains used for the message passing interface computing protocol. The numerical construction of this device follows a similar approach as that used in Kahouadji et al. (Reference Kahouadji, Nowak, Kovalchuk, Chergui, Juric, Shin, Simmons, Craster and Matar2018). This approach bypasses the typical obstacles in construction and meshing that arise when handling complex geometries by employing a static distance function for several primitive objects (e.g. cylinders, planes, and tori), and simple algebraic operations between them, such as ‘union’ and ‘intersection’.

$240=30\times 8\times 1$ sub-domains used for the message passing interface computing protocol. The numerical construction of this device follows a similar approach as that used in Kahouadji et al. (Reference Kahouadji, Nowak, Kovalchuk, Chergui, Juric, Shin, Simmons, Craster and Matar2018). This approach bypasses the typical obstacles in construction and meshing that arise when handling complex geometries by employing a static distance function for several primitive objects (e.g. cylinders, planes, and tori), and simple algebraic operations between them, such as ‘union’ and ‘intersection’.

The flow is considered incompressible and both the continuous and dispersed phases are assumed to be Newtonian. The following scaling is adopted to non-dimensionalise the equations governing the flow dynamics coupled to the surfactant transport in the bulk of the dispersed phase and at the interface:

\begin{equation} \left.\begin{gathered}

\tilde{\boldsymbol{x}}=\frac{\boldsymbol{x}}{l_c},\quad

\tilde{\boldsymbol{u}}=\frac{\boldsymbol{u}} {U_{sc}},\quad

\tilde{t}=\frac{t}{l_c/U_{sc}},\quad

\tilde{p}=\frac{p}{\mu_{c}U_{sc}/l_{c}},\quad

\tilde{\sigma} = \frac{\sigma}{\sigma_s},\\

\tilde{\varGamma}=\frac{\varGamma}{\varGamma_\infty},\quad

\tilde{C}=\frac{C}{CMC},\quad

\widetilde{C_s}=\frac{C_s}{CMC}. \end{gathered}\right\}

\end{equation}

\begin{equation} \left.\begin{gathered}

\tilde{\boldsymbol{x}}=\frac{\boldsymbol{x}}{l_c},\quad

\tilde{\boldsymbol{u}}=\frac{\boldsymbol{u}} {U_{sc}},\quad

\tilde{t}=\frac{t}{l_c/U_{sc}},\quad

\tilde{p}=\frac{p}{\mu_{c}U_{sc}/l_{c}},\quad

\tilde{\sigma} = \frac{\sigma}{\sigma_s},\\

\tilde{\varGamma}=\frac{\varGamma}{\varGamma_\infty},\quad

\tilde{C}=\frac{C}{CMC},\quad

\widetilde{C_s}=\frac{C_s}{CMC}. \end{gathered}\right\}

\end{equation}

Here, the tildes designate dimensionless quantities, and ![]() $\boldsymbol {x}$,

$\boldsymbol {x}$, ![]() $t$,

$t$, ![]() $\boldsymbol {u}$ and

$\boldsymbol {u}$ and ![]() $p$ are the spatial coordinate, time, velocity and pressure, respectively; the interface surfactant concentration is represented by

$p$ are the spatial coordinate, time, velocity and pressure, respectively; the interface surfactant concentration is represented by ![]() $\varGamma$,

$\varGamma$, ![]() $C$ and

$C$ and ![]() $C_{s}$ are the concentrations at the bulk and the bulk sub-phase, located immediately adjacent to the interface, respectively (Shin et al. Reference Shin, Chergui, Juric, Kahouadji, Matar and Craster2018; Batchvarov et al. Reference Batchvarov, Kahouadji, Magnini, Constante-Amores, Shin, Chergui, Juric, Craster and Matar2020; Constante-Amores et al. Reference Constante-Amores, Kahouadji, Batchvarov, Shin, Chergui, Juric and Matar2020, Reference Constante-Amores, Batchvarov, Kahouadji, Shin, Chergui, Juric and Matar2021a,Reference Constante-Amores, Kahouadji, Batchvarov, Shin, Chergui, Juric and Matarb), and

$C_{s}$ are the concentrations at the bulk and the bulk sub-phase, located immediately adjacent to the interface, respectively (Shin et al. Reference Shin, Chergui, Juric, Kahouadji, Matar and Craster2018; Batchvarov et al. Reference Batchvarov, Kahouadji, Magnini, Constante-Amores, Shin, Chergui, Juric, Craster and Matar2020; Constante-Amores et al. Reference Constante-Amores, Kahouadji, Batchvarov, Shin, Chergui, Juric and Matar2020, Reference Constante-Amores, Batchvarov, Kahouadji, Shin, Chergui, Juric and Matar2021a,Reference Constante-Amores, Kahouadji, Batchvarov, Shin, Chergui, Juric and Matarb), and ![]() $\sigma$ is the local interfacial tension varying as function of

$\sigma$ is the local interfacial tension varying as function of ![]() $\varGamma$. The length scale

$\varGamma$. The length scale ![]() $l_c$, the average surface velocity of the continuous phase in the main portion of the channel,

$l_c$, the average surface velocity of the continuous phase in the main portion of the channel, ![]() $U_{sc} = Q_{c}/A$ (

$U_{sc} = Q_{c}/A$ (![]() $A = l_c w_c + ({\rm \pi} /4 -1)w_c^2$), the interfacial tension in a surfactant-free system,

$A = l_c w_c + ({\rm \pi} /4 -1)w_c^2$), the interfacial tension in a surfactant-free system, ![]() $\sigma _{s}$, the saturation interfacial concentration,

$\sigma _{s}$, the saturation interfacial concentration, ![]() $\varGamma _{\infty }$, and the CMC, are used as the characteristic length, velocity, interfacial tension and interfacial and bulk surfactant concentration scales, respectively;

$\varGamma _{\infty }$, and the CMC, are used as the characteristic length, velocity, interfacial tension and interfacial and bulk surfactant concentration scales, respectively; ![]() $\rho _c$ and

$\rho _c$ and ![]() $\mu _c$ are the continuous phase density and dynamical viscosity, respectively. The dimensionless governing equations for the flow and surfactant transport are formulated in (3.2)–(3.7):

$\mu _c$ are the continuous phase density and dynamical viscosity, respectively. The dimensionless governing equations for the flow and surfactant transport are formulated in (3.2)–(3.7):

\begin{gather} \boldsymbol{\nabla}\boldsymbol{\cdot} \tilde{\boldsymbol{u}}=0,\quad \tilde{\rho}Re\left(\frac{\partial \tilde{\boldsymbol{u}}}{\partial \tilde{t}}+ \tilde{\boldsymbol{u}} \boldsymbol{\cdot}\boldsymbol{\nabla} \tilde{\boldsymbol{u}}\right) =- \boldsymbol{\nabla} \tilde{p} + \boldsymbol{\nabla}\boldsymbol{\cdot} \left [ \tilde{\mu} (\boldsymbol{\nabla} \tilde{\boldsymbol{u}} +\boldsymbol{\nabla} \tilde{\boldsymbol{u}}^{\rm T}) \right ] \nonumber\\ +\,\frac{1}{Ca} \int_{\tilde{A}} \left(\tilde{\sigma} \tilde{\kappa} \boldsymbol{n}+ \boldsymbol{\nabla}_s \tilde{\sigma} \right)\delta \left(\tilde{\boldsymbol{x}} - \tilde{\boldsymbol{x}}_{_f} \right) {\rm d}\tilde{A}, \end{gather}

\begin{gather} \boldsymbol{\nabla}\boldsymbol{\cdot} \tilde{\boldsymbol{u}}=0,\quad \tilde{\rho}Re\left(\frac{\partial \tilde{\boldsymbol{u}}}{\partial \tilde{t}}+ \tilde{\boldsymbol{u}} \boldsymbol{\cdot}\boldsymbol{\nabla} \tilde{\boldsymbol{u}}\right) =- \boldsymbol{\nabla} \tilde{p} + \boldsymbol{\nabla}\boldsymbol{\cdot} \left [ \tilde{\mu} (\boldsymbol{\nabla} \tilde{\boldsymbol{u}} +\boldsymbol{\nabla} \tilde{\boldsymbol{u}}^{\rm T}) \right ] \nonumber\\ +\,\frac{1}{Ca} \int_{\tilde{A}} \left(\tilde{\sigma} \tilde{\kappa} \boldsymbol{n}+ \boldsymbol{\nabla}_s \tilde{\sigma} \right)\delta \left(\tilde{\boldsymbol{x}} - \tilde{\boldsymbol{x}}_{_f} \right) {\rm d}\tilde{A}, \end{gather} \begin{gather} \left.\begin{gathered} \tilde{\rho}\left( \boldsymbol{x},t\right)=\frac{\rho_d}{\rho_c} + \left(1-\frac{\rho_d}{\rho_c}\right) \mathcal{H}\left( \boldsymbol{x},t\right),\\ \tilde{\mu}\left( \boldsymbol{x},t\right)=\frac{\mu _d}{\mu _c}+ \left(1-\frac{\mu _c}{\mu _d}\right) \mathcal{H}\left( \boldsymbol{x},t\right), \end{gathered}\right\} \end{gather}

\begin{gather} \left.\begin{gathered} \tilde{\rho}\left( \boldsymbol{x},t\right)=\frac{\rho_d}{\rho_c} + \left(1-\frac{\rho_d}{\rho_c}\right) \mathcal{H}\left( \boldsymbol{x},t\right),\\ \tilde{\mu}\left( \boldsymbol{x},t\right)=\frac{\mu _d}{\mu _c}+ \left(1-\frac{\mu _c}{\mu _d}\right) \mathcal{H}\left( \boldsymbol{x},t\right), \end{gathered}\right\} \end{gather}

with ![]() $\epsilon _{\sigma }$ set to 0.05, a numerical threshold to avoid non-physical negative values for

$\epsilon _{\sigma }$ set to 0.05, a numerical threshold to avoid non-physical negative values for ![]() $\tilde {\sigma }$. The dimensionless numbers shown in the above equations are defined by

$\tilde {\sigma }$. The dimensionless numbers shown in the above equations are defined by

\begin{equation} \left.\begin{gathered} Re=\frac{\rho_cU_{sc} l_c}{\mu _c};\quad Ca=\frac{\mu _cU_{sc}}{\sigma_s};\quad Pe_c=\frac{U_{sc} l_c}{D_c};\quad Pe_s=\frac{U_{sc} l_c}{D_s};\quad Bi=\frac{k_d l_c}{U_{sc}}; \\ Da=\frac{\varGamma_\infty}{l_c CMC};\quad k=\frac{k_a CMC}{k_d}, \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} Re=\frac{\rho_cU_{sc} l_c}{\mu _c};\quad Ca=\frac{\mu _cU_{sc}}{\sigma_s};\quad Pe_c=\frac{U_{sc} l_c}{D_c};\quad Pe_s=\frac{U_{sc} l_c}{D_s};\quad Bi=\frac{k_d l_c}{U_{sc}}; \\ Da=\frac{\varGamma_\infty}{l_c CMC};\quad k=\frac{k_a CMC}{k_d}, \end{gathered}\right\} \end{equation}

where ![]() $Ca$ and

$Ca$ and ![]() $Re$ are the liquid capillary and Reynolds numbers, respectively; in which

$Re$ are the liquid capillary and Reynolds numbers, respectively; in which ![]() $\mu _c$ is the continuous phase viscosity;

$\mu _c$ is the continuous phase viscosity; ![]() $Pe_c$ and

$Pe_c$ and ![]() $Pe_s$ are the bulk and interfacial Péclet numbers that represent the interplay between convective and diffusive forces for the surfactant species at the bulk and interface, respectively, in which

$Pe_s$ are the bulk and interfacial Péclet numbers that represent the interplay between convective and diffusive forces for the surfactant species at the bulk and interface, respectively, in which ![]() $D_c$ and

$D_c$ and ![]() $D_s$ are the (constant) surfactant diffusion coefficients in the bulk continuous phase and the plane of the interface, respectively. The Biot number,

$D_s$ are the (constant) surfactant diffusion coefficients in the bulk continuous phase and the plane of the interface, respectively. The Biot number, ![]() $Bi$, represents the competition between the time scales of desorption and convection, characterised by

$Bi$, represents the competition between the time scales of desorption and convection, characterised by ![]() $k_d^{-1}$ and

$k_d^{-1}$ and ![]() $l_c/U_{sc}$, respectively. Finally,

$l_c/U_{sc}$, respectively. Finally, ![]() $k$ represents the competition between adsorption and desorption time scales, characterised by

$k$ represents the competition between adsorption and desorption time scales, characterised by ![]() $(k_{a}CMC)^{-1}$ and

$(k_{a}CMC)^{-1}$ and ![]() $k_{d}^{-1}$, respectively. Lastly, the Damköhler number,

$k_{d}^{-1}$, respectively. Lastly, the Damköhler number, ![]() $Da$, provides a dimensionless measure of interfacial saturation with surfactant.

$Da$, provides a dimensionless measure of interfacial saturation with surfactant.

The continuity and momentum equations (3.2) are written in a three-dimensional Cartesian domain using a single-fluid formulation. ![]() $\mathcal {H}( \tilde {\boldsymbol {x}},\tilde {t})$ represents a smoothed Heaviside function that takes the value of zero in the continuous phase and unity in the dispersed phase. The normal and tangential components of the interfacial tension force are expressed by the last two terms on the right-hand side of (3.2), respectively. The latter term representing the interfacial tension gradients across the interface, which give rise to Marangoni stresses;

$\mathcal {H}( \tilde {\boldsymbol {x}},\tilde {t})$ represents a smoothed Heaviside function that takes the value of zero in the continuous phase and unity in the dispersed phase. The normal and tangential components of the interfacial tension force are expressed by the last two terms on the right-hand side of (3.2), respectively. The latter term representing the interfacial tension gradients across the interface, which give rise to Marangoni stresses; ![]() $\tilde {\kappa }$ corresponds to the interface curvature and

$\tilde {\kappa }$ corresponds to the interface curvature and ![]() $\delta (\tilde {\boldsymbol {x}}-\tilde {\boldsymbol {x}}_f)$ is the three-dimensional Dirac delta function equal to unity at the interface (

$\delta (\tilde {\boldsymbol {x}}-\tilde {\boldsymbol {x}}_f)$ is the three-dimensional Dirac delta function equal to unity at the interface (![]() $\tilde {\boldsymbol {x}} = \tilde {\boldsymbol {x}}_f$) and zero elsewhere. In (3.4),

$\tilde {\boldsymbol {x}} = \tilde {\boldsymbol {x}}_f$) and zero elsewhere. In (3.4), ![]() $\boldsymbol {\nabla }_s = (\boldsymbol {I} - \boldsymbol {n}\boldsymbol {n})\boldsymbol {\cdot }\boldsymbol {\nabla }$ is the surface gradient operator,

$\boldsymbol {\nabla }_s = (\boldsymbol {I} - \boldsymbol {n}\boldsymbol {n})\boldsymbol {\cdot }\boldsymbol {\nabla }$ is the surface gradient operator, ![]() $\boldsymbol {n}$ is the outward-pointing unit normal to the interface, and

$\boldsymbol {n}$ is the outward-pointing unit normal to the interface, and ![]() $\boldsymbol {I}$ is the identity tensor;

$\boldsymbol {I}$ is the identity tensor; ![]() $\tilde {\boldsymbol {u}}_t=(\tilde {\boldsymbol {u}}_s \boldsymbol {\cdot }\tilde {\boldsymbol {t}})\tilde {\boldsymbol {t}}$ corresponds to the tangential velocity, where

$\tilde {\boldsymbol {u}}_t=(\tilde {\boldsymbol {u}}_s \boldsymbol {\cdot }\tilde {\boldsymbol {t}})\tilde {\boldsymbol {t}}$ corresponds to the tangential velocity, where ![]() $\tilde {\boldsymbol {u}}_s$ is the surface velocity, and

$\tilde {\boldsymbol {u}}_s$ is the surface velocity, and ![]() ${\boldsymbol {t}}$ is the unit vector tangent to the interface. The last terms on the right-hand side of (3.4) and (3.7) represent the source term for surfactant exchange between the interface and the section of the bulk immediately adjacent to the interface.

${\boldsymbol {t}}$ is the unit vector tangent to the interface. The last terms on the right-hand side of (3.4) and (3.7) represent the source term for surfactant exchange between the interface and the section of the bulk immediately adjacent to the interface.

As seen from figure 1(b) and (3.7), the dependence of ![]() $\sigma$ on

$\sigma$ on ![]() $\varGamma$ is described by a nonlinear Langmuir equation of state in which

$\varGamma$ is described by a nonlinear Langmuir equation of state in which ![]() $\beta _{s} = \Re T\varGamma _{\infty }/\sigma _{s}$ modulates this dependency, as suggested by Muradoglu & Tryggvason (Reference Muradoglu and Tryggvason2014);

$\beta _{s} = \Re T\varGamma _{\infty }/\sigma _{s}$ modulates this dependency, as suggested by Muradoglu & Tryggvason (Reference Muradoglu and Tryggvason2014); ![]() $\Re$ and

$\Re$ and ![]() $T$ are the ideal gas constant and the temperature, respectively. The components of the interfacial tension force that induce Marangoni stresses can be written in terms of

$T$ are the ideal gas constant and the temperature, respectively. The components of the interfacial tension force that induce Marangoni stresses can be written in terms of ![]() $\varGamma$ by

$\varGamma$ by

where ![]() $\tilde {\tau }$ is the dimensionless Marangoni stress and

$\tilde {\tau }$ is the dimensionless Marangoni stress and ![]() $Ma\equiv \beta _s/Ca$ represents a Marangoni parameter.

$Ma\equiv \beta _s/Ca$ represents a Marangoni parameter.

From the properties of TX100 and the operating conditions of the system, the relevant dimensionless numbers that characterise the system are given by ![]() $Re = 2.35$,

$Re = 2.35$, ![]() $Ca = 4.33\times 10^{-3}$,

$Ca = 4.33\times 10^{-3}$, ![]() $Pe_{c} = Pe_{d} = 2.35\times 10^{5}$,

$Pe_{c} = Pe_{d} = 2.35\times 10^{5}$, ![]() $Bi = 8.41\times 10^{-5}$,

$Bi = 8.41\times 10^{-5}$, ![]() $Da = 1.04\times 10^{-3}$,

$Da = 1.04\times 10^{-3}$, ![]() $k = 5.55\times 10^{3}$,

$k = 5.55\times 10^{3}$, ![]() $\beta _{s} = 0.10$ and

$\beta _{s} = 0.10$ and ![]() $Ma = 23.08$. We define a capillary time scale as

$Ma = 23.08$. We define a capillary time scale as ![]() $\tau _{cap} = \sqrt {\rho _{c}l^{3}_{c}/\sigma _{s}} = 1.31\times 10^{-3}$ s, a velocity time scale as

$\tau _{cap} = \sqrt {\rho _{c}l^{3}_{c}/\sigma _{s}} = 1.31\times 10^{-3}$ s, a velocity time scale as ![]() $\tau _{vel} = \sqrt {\sigma _{s}/(\rho _{c}l_{c})} = 2.99\times 10^{-1}$ s and a Marangoni time scale as

$\tau _{vel} = \sqrt {\sigma _{s}/(\rho _{c}l_{c})} = 2.99\times 10^{-1}$ s and a Marangoni time scale as ![]() $\tau _{mar} = \mu_{c}l_{c}/{\rm \Delta} \sigma = 6.16\times 10^{-5}$ s. Here, it has been assumed that

$\tau _{mar} = \mu_{c}l_{c}/{\rm \Delta} \sigma = 6.16\times 10^{-5}$ s. Here, it has been assumed that ![]() $D_{c} = D_{s} = \mathcal {D}$, and

$D_{c} = D_{s} = \mathcal {D}$, and ![]() $\varGamma _{\infty }$ and

$\varGamma _{\infty }$ and ![]() $K_L = k/CMC$ were found by fitting the experimental data in figure 1(b) to the Langmuir–Szyszkowski equation (Teipel & Aksel Reference Teipel and Aksel2001), as in previous work (Kalli et al. Reference Kalli, Chagot and Angeli2022);

$K_L = k/CMC$ were found by fitting the experimental data in figure 1(b) to the Langmuir–Szyszkowski equation (Teipel & Aksel Reference Teipel and Aksel2001), as in previous work (Kalli et al. Reference Kalli, Chagot and Angeli2022); ![]() $\varGamma$ was calculated using the Langmuir equation of state with the measured experimental values of

$\varGamma$ was calculated using the Langmuir equation of state with the measured experimental values of ![]() $\sigma$ for each

$\sigma$ for each ![]() $C$ (see (3.7) and

$C$ (see (3.7) and ![]() $\varGamma = \varGamma _{\infty }K_L C/(1+K_L C)$) and plotted in a dimensionless form on the secondary axis of figure 1(b). Using the literature value of TX100 desorption in water (

$\varGamma = \varGamma _{\infty }K_L C/(1+K_L C)$) and plotted in a dimensionless form on the secondary axis of figure 1(b). Using the literature value of TX100 desorption in water (![]() $k_{d}$) (Gassin et al. Reference Gassin, Martin-Gassin, Meyer, Dufrêche and Diat2012),

$k_{d}$) (Gassin et al. Reference Gassin, Martin-Gassin, Meyer, Dufrêche and Diat2012), ![]() $k_{a}$ was calculated using

$k_{a}$ was calculated using ![]() $k_{a} = K_L k_{d}$ and shown in table 1. Finally, the diffusion coefficient,

$k_{a} = K_L k_{d}$ and shown in table 1. Finally, the diffusion coefficient, ![]() $\mathcal {D}$, was estimated using the Wilke–Chang correlation (Wilke & Chang Reference Wilke and Chang1955).

$\mathcal {D}$, was estimated using the Wilke–Chang correlation (Wilke & Chang Reference Wilke and Chang1955).

Table 1. Physical properties of TX100 surfactant*.

*![]() $k_{d}$ was obtained from Gassin et al. (Reference Gassin, Martin-Gassin, Meyer, Dufrêche and Diat2012) and the rest of the parameters were calculated experimentally as explained in § 3.1

$k_{d}$ was obtained from Gassin et al. (Reference Gassin, Martin-Gassin, Meyer, Dufrêche and Diat2012) and the rest of the parameters were calculated experimentally as explained in § 3.1

Fully three-dimensional direct numerical simulations were performed within the context of the level contour reconstruction method for the interface advection, as previously detailed in Shin & Juric (Reference Shin and Juric2002) and Shin et al. (Reference Shin, Abdel-Khalik, Daru and Juric2005, Reference Shin, Chergui, Juric, Kahouadji, Matar and Craster2018) and Shin, Chergui & Juric (Reference Shin, Chergui and Juric2017). This method handles the interface and the forces arising from surface tension through a hybrid front-tracking/level-set technique in conjunction with surfactant transport at the interface and bulk. At the inlet branches, an analytical solution following a Poiseuille profile is set for the velocity, together with a Neumann condition for the pressure (![]() $\partial p/\partial \boldsymbol {n} = 0$). The full derivation of this velocity profile ((3.10) in dimensionless form) in the cross-section shown in figure 1(c) (right) can be found in § A. At the outlet, a Neumann condition is specified for both velocity and pressure. The walls are treated as no-slip boundaries. For the surfactant-laden cases, Neumann conditions are set for surfactant concentration on all boundaries, with the exception of the disperse phase inlet. For this inlet,

$\partial p/\partial \boldsymbol {n} = 0$). The full derivation of this velocity profile ((3.10) in dimensionless form) in the cross-section shown in figure 1(c) (right) can be found in § A. At the outlet, a Neumann condition is specified for both velocity and pressure. The walls are treated as no-slip boundaries. For the surfactant-laden cases, Neumann conditions are set for surfactant concentration on all boundaries, with the exception of the disperse phase inlet. For this inlet, ![]() $C$ is specified as a constant value according to the experimental set-up (

$C$ is specified as a constant value according to the experimental set-up (![]() $\tilde {C} = 0.006$,

$\tilde {C} = 0.006$, ![]() $\tilde {C} = 0.06$ and

$\tilde {C} = 0.06$ and ![]() $\tilde {C} = 0.21$) and

$\tilde {C} = 0.21$) and ![]() $\varGamma$ as calculated in figure 1(b)

$\varGamma$ as calculated in figure 1(b)

\begin{equation}

\tilde{\boldsymbol{u}}(\tilde{x},\tilde{y})=\begin{cases}

\tilde{\mathcal{A}}\left(\dfrac{(\tilde{y}-\widetilde{y_{0}})^{2}}{\widetilde{R^{2}}}-1\right)

& \text{if } |\tilde{x}-\widetilde{x_{0}}|\le \tilde{L}

\\

\tilde{\mathcal{A}}\left(\dfrac{(\tilde{x}-\widetilde{x_{0}}-\tilde{L})^{2}}{\tilde{R}^{2}}

+

\dfrac{(\tilde{y}-\widetilde{y_{0}})^{2}}{\widetilde{R^{2}}}

-1\right) & \text{otherwise}, \end{cases}

\end{equation}

\begin{equation}

\tilde{\boldsymbol{u}}(\tilde{x},\tilde{y})=\begin{cases}

\tilde{\mathcal{A}}\left(\dfrac{(\tilde{y}-\widetilde{y_{0}})^{2}}{\widetilde{R^{2}}}-1\right)

& \text{if } |\tilde{x}-\widetilde{x_{0}}|\le \tilde{L}

\\

\tilde{\mathcal{A}}\left(\dfrac{(\tilde{x}-\widetilde{x_{0}}-\tilde{L})^{2}}{\tilde{R}^{2}}

+

\dfrac{(\tilde{y}-\widetilde{y_{0}})^{2}}{\widetilde{R^{2}}}

-1\right) & \text{otherwise}, \end{cases}

\end{equation}

where ![]() $\mathcal {A} = {-Q}/{(\frac {8}{3}RL + ({{\rm \pi} }/{2})R^{2})}$,

$\mathcal {A} = {-Q}/{(\frac {8}{3}RL + ({{\rm \pi} }/{2})R^{2})}$, ![]() $Q$ represents the flow rate of the phase on each inlet (continuous for the two lateral branches and disperse for the central branch),

$Q$ represents the flow rate of the phase on each inlet (continuous for the two lateral branches and disperse for the central branch), ![]() $x_{0}$ and

$x_{0}$ and ![]() $y_{0}$ are the coordinates of the centre points of the inlet cross sections, and

$y_{0}$ are the coordinates of the centre points of the inlet cross sections, and ![]() $R = w_{c}/2$ and

$R = w_{c}/2$ and ![]() $L = (l_{c} - w_{c})/2$, as highlighted in figure 1(c). Each variable has been non-dimensionalised according to the scaling parameters described previously, with

$L = (l_{c} - w_{c})/2$, as highlighted in figure 1(c). Each variable has been non-dimensionalised according to the scaling parameters described previously, with ![]() $\tilde {\mathcal {A}} = {-\tilde {Q} U_{sc}}/{(\frac {8}{3}\tilde {R}\tilde {L} + ({{\rm \pi} }/{2})\tilde {R}^{2})}$.

$\tilde {\mathcal {A}} = {-\tilde {Q} U_{sc}}/{(\frac {8}{3}\tilde {R}\tilde {L} + ({{\rm \pi} }/{2})\tilde {R}^{2})}$.

3.2. Validation

The numerical simulation in an identical geometry was validated experimentally with a surfactant-free system in previous work (Kahouadji et al. Reference Kahouadji, Nowak, Kovalchuk, Chergui, Juric, Shin, Simmons, Craster and Matar2018). Further validation with experimental results for surfactant-laden cases is made in this section. As seen in previous work (Kalli et al. Reference Kalli, Chagot and Angeli2022), a semi-empirical model can be developed to relate the dimensionless drop diameter to the capillary number (and thus the global value of interfacial tension); drop size is found to be proportional to the ![]() $Ca$ in a microfluidic system in the presence of surfactants. As a result, the addition of surfactant is expected to result in smaller drops with shorter formation times, due to the lower interfacial tension.

$Ca$ in a microfluidic system in the presence of surfactants. As a result, the addition of surfactant is expected to result in smaller drops with shorter formation times, due to the lower interfacial tension.

Figure 3(a) shows the effect of surfactant addition on the drop diameter for ![]() $Q_c = 0.12$ and 0.01 ml min

$Q_c = 0.12$ and 0.01 ml min![]() $^{-1}$

$^{-1}$ ![]() $\leq Q_d \leq 0.02$ ml min

$\leq Q_d \leq 0.02$ ml min![]() $^{-1}$, using HSI,

$^{-1}$, using HSI, ![]() $\mu$PIV and CFD. As

$\mu$PIV and CFD. As ![]() $\tilde {C}$ increases from 0 to 5.7, the dimensionless drop diameter

$\tilde {C}$ increases from 0 to 5.7, the dimensionless drop diameter ![]() $d/l_c$ decreases for both flow rates, due to the lower interfacial tension. Larger drops are observed at higher

$d/l_c$ decreases for both flow rates, due to the lower interfacial tension. Larger drops are observed at higher ![]() $Q_d$ as expected. The effect of surfactant addition on the drop formation time for

$Q_d$ as expected. The effect of surfactant addition on the drop formation time for ![]() $Q_c = 0.12$ and 0.01 ml min

$Q_c = 0.12$ and 0.01 ml min![]() $^{-1}$

$^{-1}$ ![]() $\leq Q_{d} \leq 0.02$ ml min

$\leq Q_{d} \leq 0.02$ ml min![]() $^{-1}$ is shown in figure 3(b). As

$^{-1}$ is shown in figure 3(b). As ![]() $\tilde {C}$ increases from 0 to 5.7, the dimensionless formation time

$\tilde {C}$ increases from 0 to 5.7, the dimensionless formation time ![]() $\tilde {t}$ decreases for both flow rates, due to lower interfacial tension. Shorter formation times are observed at larger

$\tilde {t}$ decreases for both flow rates, due to lower interfacial tension. Shorter formation times are observed at larger ![]() $Q_d$, as opposed to drop diameter. The above results are compared with the numerical simulations and good agreement is found, with an average error of 0.8 % for

$Q_d$, as opposed to drop diameter. The above results are compared with the numerical simulations and good agreement is found, with an average error of 0.8 % for ![]() $d/l_c$ and 2.4 % for

$d/l_c$ and 2.4 % for ![]() $\tilde {t}$. The HSI experiments also agreed well with the

$\tilde {t}$. The HSI experiments also agreed well with the ![]() $\mu$PIV results, as seen from figure 3 with an error below 1 %.

$\mu$PIV results, as seen from figure 3 with an error below 1 %.

Figure 3. Effect of TX100 concentration on dimensionless drop (a) diameter (![]() $d/l_c$) and (b) formation time (

$d/l_c$) and (b) formation time (![]() $\tilde {t}$) using HSI,

$\tilde {t}$) using HSI, ![]() $\mu$PIV, CFD and the Bayesian regularised artificial neural network (BRANN) model from Chagot et al. (Reference Chagot, Quilodrán-Casas, Kalli, Kovalchuk, Simmons, Matar, Arcucci and Angeli2022).

$\mu$PIV, CFD and the Bayesian regularised artificial neural network (BRANN) model from Chagot et al. (Reference Chagot, Quilodrán-Casas, Kalli, Kovalchuk, Simmons, Matar, Arcucci and Angeli2022).

Moreover, a prediction of the drop size was obtained by using a data-driven model (Chagot et al. Reference Chagot, Quilodrán-Casas, Kalli, Kovalchuk, Simmons, Matar, Arcucci and Angeli2022). As discussed by Kalli et al. (Reference Kalli, Chagot and Angeli2022), the dynamic interfacial tension should be used to obtain accurate drop size predictions, but it is difficult to be obtained experimentally. For this reason, CFD should preferably be used to estimate the droplet volume in the presence of surfactants. Alternatively, data-driven models can also be used if there is a large database available.

4. Results and discussion

The vortical structures and the velocity fields obtained from the CFD simulations and the high-speed ![]() $\mu$PIV experiments in surfactant-free and surfactant-laden systems, as well as the concentration profiles in the bulk and at the interface are discussed here, for all stages of the drop formation process. The results for the surfactant-free case will be discussed first to show the spatio-temporal evolution of the interface, as well as the vortical structures during each stage. In addition, the surfactant concentrations in the bulk and at the interface for the various stages of drop formation will be discussed based on the CFD simulations.

$\mu$PIV experiments in surfactant-free and surfactant-laden systems, as well as the concentration profiles in the bulk and at the interface are discussed here, for all stages of the drop formation process. The results for the surfactant-free case will be discussed first to show the spatio-temporal evolution of the interface, as well as the vortical structures during each stage. In addition, the surfactant concentrations in the bulk and at the interface for the various stages of drop formation will be discussed based on the CFD simulations.

4.1. Surfactant-free case

The spatio-temporal evolution of the interface during the complete drop formation process was first simulated for the surfactant-free case. Figure 4 shows the changes in the shape of the interface during expansion (a), necking (b) and pinch-off (c) for ![]() $Q_d = 0.02$ and

$Q_d = 0.02$ and ![]() $Q_c = 0.12$ ml min

$Q_c = 0.12$ ml min![]() $^{-1}$. A different output time step is used for each stage equal to 1, 0.5, and 0.1 ms, respectively, with the longest one used for the expansion stage and the shortest for pinch-off. Specifically, the evolution of the interface is slow during expansion, becomes moderately rapid during necking and very rapid just before pinch-off. In previous work, expansion times were also found to be longer compared with necking ones, for both surfactant-free and surfactant-laden cases in the dripping regime (Kalli & Angeli Reference Kalli and Angeli2022). A similar trend was seen by Kahouadji et al. (Reference Kahouadji, Nowak, Kovalchuk, Chergui, Juric, Shin, Simmons, Craster and Matar2018) for pancake-shaped drops. The vortical structures inside the drop are shown in figure 4(d) for the expansion and necking stages and in figure 4(e) for pinch-off. The velocity fields from the experiments with and without surfactant are shown in figure 5, which agree very well with the simulation results. Initially for the surfactant-free case (at

$^{-1}$. A different output time step is used for each stage equal to 1, 0.5, and 0.1 ms, respectively, with the longest one used for the expansion stage and the shortest for pinch-off. Specifically, the evolution of the interface is slow during expansion, becomes moderately rapid during necking and very rapid just before pinch-off. In previous work, expansion times were also found to be longer compared with necking ones, for both surfactant-free and surfactant-laden cases in the dripping regime (Kalli & Angeli Reference Kalli and Angeli2022). A similar trend was seen by Kahouadji et al. (Reference Kahouadji, Nowak, Kovalchuk, Chergui, Juric, Shin, Simmons, Craster and Matar2018) for pancake-shaped drops. The vortical structures inside the drop are shown in figure 4(d) for the expansion and necking stages and in figure 4(e) for pinch-off. The velocity fields from the experiments with and without surfactant are shown in figure 5, which agree very well with the simulation results. Initially for the surfactant-free case (at ![]() $\tilde {C} = 0$ and

$\tilde {C} = 0$ and ![]() $\tilde {t} = 0.10$, figure 4d), two vortical structures are seen close to the front of the drop which grow larger and move closer to the interface later on (at

$\tilde {t} = 0.10$, figure 4d), two vortical structures are seen close to the front of the drop which grow larger and move closer to the interface later on (at ![]() $\tilde {t} = 0.50$). This is in agreement with the experimental results, where large internal circulation patterns are observed in expansion at

$\tilde {t} = 0.50$). This is in agreement with the experimental results, where large internal circulation patterns are observed in expansion at ![]() $\tilde {t} = 0.10$ and

$\tilde {t} = 0.10$ and ![]() $\tilde {t}=0.50$ (figure 5(a,b) respectively). The circulation pattern is more pronounced in the second stage of expansion (

$\tilde {t}=0.50$ (figure 5(a,b) respectively). The circulation pattern is more pronounced in the second stage of expansion (![]() $\tilde {t} = 0.50$, figure 5b), where two circulation zones are clearly seen, one on each side of the growing drop and high velocities in the middle, reaching a maximum of

$\tilde {t} = 0.50$, figure 5b), where two circulation zones are clearly seen, one on each side of the growing drop and high velocities in the middle, reaching a maximum of ![]() $|U_{max}|/U_{sc} = 0.45$. From the shape of the interface (black dotted line) it is clear that originally the drop grows in the radial direction, as the continuous phase obstructs the flow of the dispersed phase. The high velocities on the sides of the dispersed phase during expansion suggest that the liquid is mainly transported through the sides of the drop. This is in agreement with observations reported previously by several authors (Pirbodaghi et al. Reference Pirbodaghi, Vigolo, Akbari and DeMello2015; Roumpea et al. Reference Roumpea, Kovalchuk, Chinaud, Nowak, Simmons and Angeli2019). Previous works using ghost particle velocimetry in rectangular flow-focusing microchannels reported a stagnation point at the base of the growing drop, during the second stage of expansion, but no significant circulation in the surfactant-free case (Kiratzis et al. Reference Kiratzis, Kovalchuk, Simmons and Vigolo2022). Even though a stagnation point can be seen in this work during the second stage of expansion (figure 5e), the presence of the strong circulation can be attributed to the higher flow rates used in this study and the differences in microchannel geometries. In rectangular channels, there is corner flow in the gutters of the channel, which is absent in the current work where the channels have an oval cross-section. The gutter flow can also reverse the direction of the flow fields after the drop has formed (Mießner et al. Reference Mießner, Helmers, Lindken and Westerweel2020; Kovalchuk & Simmons Reference Kovalchuk and Simmons2021).

$|U_{max}|/U_{sc} = 0.45$. From the shape of the interface (black dotted line) it is clear that originally the drop grows in the radial direction, as the continuous phase obstructs the flow of the dispersed phase. The high velocities on the sides of the dispersed phase during expansion suggest that the liquid is mainly transported through the sides of the drop. This is in agreement with observations reported previously by several authors (Pirbodaghi et al. Reference Pirbodaghi, Vigolo, Akbari and DeMello2015; Roumpea et al. Reference Roumpea, Kovalchuk, Chinaud, Nowak, Simmons and Angeli2019). Previous works using ghost particle velocimetry in rectangular flow-focusing microchannels reported a stagnation point at the base of the growing drop, during the second stage of expansion, but no significant circulation in the surfactant-free case (Kiratzis et al. Reference Kiratzis, Kovalchuk, Simmons and Vigolo2022). Even though a stagnation point can be seen in this work during the second stage of expansion (figure 5e), the presence of the strong circulation can be attributed to the higher flow rates used in this study and the differences in microchannel geometries. In rectangular channels, there is corner flow in the gutters of the channel, which is absent in the current work where the channels have an oval cross-section. The gutter flow can also reverse the direction of the flow fields after the drop has formed (Mießner et al. Reference Mießner, Helmers, Lindken and Westerweel2020; Kovalchuk & Simmons Reference Kovalchuk and Simmons2021).

Figure 4. Numerical results for the surfactant-free case generated with ![]() $Q_d = 0.02$ and

$Q_d = 0.02$ and ![]() $Q_c = 0.12$ ml min. (a–c) Depict the spatio-temporal evolution of the interface with time differences between the curves of

$Q_c = 0.12$ ml min. (a–c) Depict the spatio-temporal evolution of the interface with time differences between the curves of ![]() $1$,

$1$, ![]() $0.5$ and

$0.5$ and ![]() $0.1$ ms, respectively; (d) highlights the vortical structures for three different times that can also be compared with experimental PIV of figure 5(a–c) (shown in red lines); (e) shows the development of a neck followed by pinch-off which is accompanied by satellite formation; (f) shows top views of the periodic drop formation in the channel with a period of 13.5 ms.

$0.1$ ms, respectively; (d) highlights the vortical structures for three different times that can also be compared with experimental PIV of figure 5(a–c) (shown in red lines); (e) shows the development of a neck followed by pinch-off which is accompanied by satellite formation; (f) shows top views of the periodic drop formation in the channel with a period of 13.5 ms.

Figure 5. Effect of TX100 concentration on velocity fields from PIV measurements during expansion and necking stages at ![]() $Q_d = 0.02$ ml min

$Q_d = 0.02$ ml min![]() $^{-1}$ for (a–c)

$^{-1}$ for (a–c) ![]() $\tilde {C} = 0$, (d–f)

$\tilde {C} = 0$, (d–f) ![]() $\tilde {C} = 0.06$ and (g–i)

$\tilde {C} = 0.06$ and (g–i) ![]() $\tilde {C} = 2.89$.

$\tilde {C} = 2.89$.

As the drop grows, it obstructs the inlet of the oil phase, which now pushes the interface perpendicular to the drop and changes its curvature. This marks the beginning of the necking stage, with the neck defined as the bridge between the growing drop and the dispersed phase remaining attached to the inlet. The curvature of the interface becomes negative and the pressure build-up from the continuous phase causes the flow to be higher in the neck compared with the rest of the dispersed phase (with ![]() $|U_{max}|/U_{sc} = 0.25$), while the velocities near the interface decrease. In addition, the vortical structures decrease in size (

$|U_{max}|/U_{sc} = 0.25$), while the velocities near the interface decrease. In addition, the vortical structures decrease in size (![]() $\tilde {t} = 0.67$ in figures 4(d) and 5(c)). This indicates that the transport of the dispersed phase from the sides is significantly weaker than in the expansion stage. As the process approaches pinch-off (see figure 4(e), left panel), large vortical structures form in the region of the dispersed phase that remains attached to the inlet. Immediately after the pinch-off, the vortical structures grow large in the middle of the cross-junction (figure 4(e), right panel). This vortex dipole just before and at pinch-off was also observed during the formation of surfactant-free plugs (Kahouadji et al. Reference Kahouadji, Nowak, Kovalchuk, Chergui, Juric, Shin, Simmons, Craster and Matar2018). Another agreement between the two works is the stagnation point present just at the location of pinch-off. A small satellite drop is also seen at the point where the neck broke. The distance between four subsequent drops is equal, as shown in figure 4(f), indicating that the drop formation process is periodic with exactly the same formation time of 13.5 ms in each cycle.

$\tilde {t} = 0.67$ in figures 4(d) and 5(c)). This indicates that the transport of the dispersed phase from the sides is significantly weaker than in the expansion stage. As the process approaches pinch-off (see figure 4(e), left panel), large vortical structures form in the region of the dispersed phase that remains attached to the inlet. Immediately after the pinch-off, the vortical structures grow large in the middle of the cross-junction (figure 4(e), right panel). This vortex dipole just before and at pinch-off was also observed during the formation of surfactant-free plugs (Kahouadji et al. Reference Kahouadji, Nowak, Kovalchuk, Chergui, Juric, Shin, Simmons, Craster and Matar2018). Another agreement between the two works is the stagnation point present just at the location of pinch-off. A small satellite drop is also seen at the point where the neck broke. The distance between four subsequent drops is equal, as shown in figure 4(f), indicating that the drop formation process is periodic with exactly the same formation time of 13.5 ms in each cycle.

4.2. Surfactant-laden cases

4.2.1. Expansion and necking stages

Upon addition of the TX100 surfactant at ![]() $\tilde {C} = 0.06$, the velocity fields change significantly from their surfactant-free counterparts throughout all stages of the drop formation process. At the start (see figure 5(d) at

$\tilde {C} = 0.06$, the velocity fields change significantly from their surfactant-free counterparts throughout all stages of the drop formation process. At the start (see figure 5(d) at ![]() $\tilde {t} = 0.08$), the average velocities appear higher and more uniform at the back of the forming drop and a less intense circulation pattern can be seen in the centre. The two circulation zones still appear in the second phase of the expansion stage (see figure 5(e) at

$\tilde {t} = 0.08$), the average velocities appear higher and more uniform at the back of the forming drop and a less intense circulation pattern can be seen in the centre. The two circulation zones still appear in the second phase of the expansion stage (see figure 5(e) at ![]() $\tilde {t} = 0.33$), however, their velocities are lower than in the surfactant-free case. During the necking stage at TX100 concentrations below CMC (figure 5f), higher velocities are observed near the neck, with maximum values of

$\tilde {t} = 0.33$), however, their velocities are lower than in the surfactant-free case. During the necking stage at TX100 concentrations below CMC (figure 5f), higher velocities are observed near the neck, with maximum values of ![]() $|U_{max}|/U_{sc} = 0.45$. The reduced interfacial tension due to the presence of surfactant accelerates the neck thinning and results in high velocities (figure 5(f) at

$|U_{max}|/U_{sc} = 0.45$. The reduced interfacial tension due to the presence of surfactant accelerates the neck thinning and results in high velocities (figure 5(f) at ![]() $\tilde {t} = 0.41$), as also observed by Kiratzis et al. (Reference Kiratzis, Kovalchuk, Simmons and Vigolo2022). The circulation pattern completely disappears during necking at low TX100 concentrations, which agreed with the CFD simulations. For concentrations above the CMC, during the first expansion phase (see figure 5(g) at

$\tilde {t} = 0.41$), as also observed by Kiratzis et al. (Reference Kiratzis, Kovalchuk, Simmons and Vigolo2022). The circulation pattern completely disappears during necking at low TX100 concentrations, which agreed with the CFD simulations. For concentrations above the CMC, during the first expansion phase (see figure 5(g) at ![]() $\tilde {t} = 0.05$), velocities are high inside the whole of the growing drop, reaching a maximum of

$\tilde {t} = 0.05$), velocities are high inside the whole of the growing drop, reaching a maximum of ![]() $|U_{max}|/U_{SC} = 0.4$. Velocities then increase significantly as shown in figure 5(h–i) as the drop expands into the main channel, and at the necking stage at

$|U_{max}|/U_{SC} = 0.4$. Velocities then increase significantly as shown in figure 5(h–i) as the drop expands into the main channel, and at the necking stage at ![]() $\tilde {t} = 0.18$ and 0.26, reaching a

$\tilde {t} = 0.18$ and 0.26, reaching a ![]() $|U_{max}|/U_{sc} = 0.5$.

$|U_{max}|/U_{sc} = 0.5$.

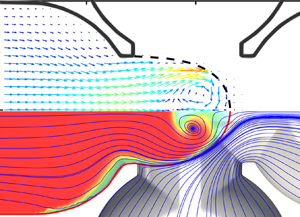

4.2.2. Pinch-off

Pinch-off is further discussed in this section, using both the numerical and experimental results. The effect of TX100 surfactant on drop shape and velocity fields at pinch-off from HSI and ![]() $\mu$PIV experiments, as well as CFD simulations at

$\mu$PIV experiments, as well as CFD simulations at ![]() $Q_d = 0.02$ ml min

$Q_d = 0.02$ ml min![]() $^{-1}$ as shown in figure 6. As can be seen in figure 6(a,d,g), smaller droplets are formed upon TX100 addition and satellite drops are seen after pinch-off. It should be noted that the shadow from the edge of the channel observed when using HSI does not exist in the

$^{-1}$ as shown in figure 6. As can be seen in figure 6(a,d,g), smaller droplets are formed upon TX100 addition and satellite drops are seen after pinch-off. It should be noted that the shadow from the edge of the channel observed when using HSI does not exist in the ![]() $\mu$PIV images, which can mislead the comparison of the droplet sizes in figure 6(c,f). In the case of no surfactant present, high velocities at the rear of the formed drop and circulation patterns in the dispersed phase remaining attached to the inlet are seen in figure 6(b,c) (see also figure 4). The higher velocities at the rear of the drop, as opposed to its front, are also observed in the surfactant-free simulations of Zhao et al. (Reference Zhao, Riaud, Luo, Jin and Cheng2015). Similar observations were reported from CFD simulations of mass transfer in a flow-focusing microchannel by Lan et al. (Reference Lan, Li, Wang and Luo2014).