1. Introduction

The process of impingement of a gas jet onto a liquid layer is important in numerous industrial applications. For example, it is used in steel production in the basic oxygen furnace process (e.g. Turkdogan Reference Turkdogan1996; Hwang & Irons Reference Hwang and Irons2012), in coating applications in the gas-jet wiping process (e.g. Thornton & Graff Reference Thornton and Graff1976; Lacanette et al. Reference Lacanette, Gosset, Vincent, Buchlin and Arquis2006) and in immersion lithography to remove water from a photoresist coated wafer (e.g. Berendsen et al. Reference Berendsen, Zeegers, Kruis, Riepen and Darhuber2012; Berendsen, Zeegers & Darhuber Reference Berendsen, Zeegers and Darhuber2013). A closely related process is that of impingement of a gas plasma jet (instead of simply a gas jet) onto a layer of a liquid which appears, for example, in the arc welding process (e.g. Berghmans Reference Berghmans1972), in medical applications such as wound healing and skin treatment (e.g. Tian & Kushner Reference Tian and Kushner2014; Verlackt, Van Boxem & Bogaerts Reference Verlackt, Van Boxem and Bogaerts2018) and in environmental applications such as water treatment and disinfection (e.g. Foster Reference Foster2017).

The impact of gas jets onto layers of liquids has been previously studied mainly for the case when the layer of the liquid is relatively thick. A gas jet impinging onto a liquid layer exerts normal and tangential stresses on its surface, which result in its deformation creating a cavity and flow inside the liquid. Most of the previous research was focused on analysing the shape of the cavity and its stability. An early experimental study was performed by Banks & Chandrasekhara (Reference Banks and Chandrasekhara1963), who identified three regimes, namely, a steady cavity, an oscillating cavity and splashing. They focused on the analysis of steady cavities and suggested scaling approaches to establish a relation between the impact of the jet and the depth of the cavity. Turkdogan (Reference Turkdogan1966) carried out the Banks & Chandrasekhara (Reference Banks and Chandrasekhara1963) experiments with liquids of different densities but focused on the effects of the gas nozzle diameter and the nozzle distance from the liquid surface. Cheslak, Nicholls & Sichel (Reference Cheslak, Nicholls and Sichel1969) performed an analysis similar to Banks & Chandrasekhara (Reference Banks and Chandrasekhara1963) and concluded that the occurrence of splashing or a smooth cavity depends on the jet velocity, while the viscosity of the liquid and surface tension are less important. Molloy (Reference Molloy1970) studied not only the effect of the gas jet on the cavity, but also the effect of the liquid properties. Previous analytical work investigating the shapes of steady cavities has been mainly based on a conformal mapping approach, in which the flow in the liquid is neglected and the system is assumed to be two dimensional, although both of the assumptions are clearly not valid in practice. The first analytical work using a conformal mapping method was done by Olmstead & Raynor (Reference Olmstead and Raynor1964), who studied the cavity shape at relatively small gas velocities in the case of a small cavity. Vanden-Broeck (Reference Vanden-Broeck1981) used a similar approach but solved the problem using a different numerical procedure, which allowed analysis of the system for larger gas velocities. A more recent analytical work based on a conformal mapping approach was done by He & Belmonte (Reference He and Belmonte2010), who analysed the cavity shape without requiring it to be small. Mordasov, Savenkov & Chechetov (Reference Mordasov, Savenkov and Chechetov2016) employed the balance equations for forces at the gas–liquid interface and not the balance equation for pressure as was used in most previous studies and obtained good agreement with experiments. Despite previous analytical approaches, detailed understanding of the cavity instability mechanisms is still missing. More recent work on gas jets impinging onto liquids has been mainly focused on experimental and direct numerical simulations (DNS) investigations (see e.g. Nguyen & Evans Reference Nguyen and Evans2006; Solórzano-López, Zenit & Ramírez-Argáez Reference Solórzano-López, Zenit and Ramírez-Argáez2011; Muñoz-Esparza et al. Reference Muñoz-Esparza, Buchlin, Myrillas and Berger2012; Liu et al. Reference Liu, Chen, Hu, Xie and Fu2015; Adib, Ehteram & Tabrizi Reference Adib, Ehteram and Tabrizi2018).

There has been less investigation for the case when the layer of the liquid is relatively thin. In such a case, if the gas-jet flow is sufficiently strong, the film ruptures and dewetting is initiated. Gas-jet induced dewetting of thin liquid films was first considered by Berendsen et al. (Reference Berendsen, Zeegers, Kruis, Riepen and Darhuber2012, Reference Berendsen, Zeegers and Darhuber2013) both experimentally and using modelling, via a reduced-order thin-film equation. In Berendsen et al. (Reference Berendsen, Zeegers, Kruis, Riepen and Darhuber2012) the authors focused on analysing the liquid film rupture times and the influence of surfactants and found good agreement between the experimental and modelling results, while an additional investigation of the effect of the movement of the gas jet was conducted in Berendsen et al. (Reference Berendsen, Zeegers and Darhuber2013).

In the present study we expand on a comprehensive theoretical and experimental investigation of the deformation and dewetting of (thin and moderately thin) liquid films in a cylindrical beaker under the influence of an impinging gas jet that is generated by maintaining a constant gas flow rate from a stationary cylindrical tube. Our goal is two-fold. On the one hand, we aim to provide an improved theoretical characterisation of the interfacial deformation process that lies at the centre of the physical systems, both in terms of the balance of forces and interaction with the surrounding flow fields in the liquid and gas phases. On the other hand, we wish to examine challenging features related to dewetting dynamics that merit further understanding and mathematical description (here to be performed using a dynamical systems approach) as a prototypical case for more complex real-world scenarios. To obtain initial insight into relevant flow regimes and time scales of the system, we use a systematically derived thin-film equation that in the axisymmetric case coincides with the model of Berendsen et al. (Reference Berendsen, Zeegers, Kruis, Riepen and Darhuber2012). The equation is obtained under the long-wave assumption, that has been extensively used in the literature (see, e.g. Thiele Reference Thiele2007; Craster & Matar Reference Craster and Matar2009), and by decoupling the problem for the gas from that for the liquid, under the so-called quasi-static assumption. This involves modelling the gas–liquid interface as a solid wall for the gas problem, which is valid when the typical velocity in the gas is much larger than that in the liquid; see, e.g. Tuck (Reference Tuck1975) and also more recent work by Tseluiko & Kalliadasis (Reference Tseluiko and Kalliadasis2011) and Vellingiri, Tseluiko & Kalliadasis (Reference Vellingiri, Tseluiko and Kalliadasis2015). Under such an assumption, the gas effects enter through the normal and tangential stresses exerted by the gas on the gas–liquid interface. In some previous studies, approximate expressions for these stresses were used that were typically constructed on the basis of general unbounded domains. Often, the gas influence was modelled via only the imposed gas normal stress, typically of a Gaussian form, ignoring the gas tangential stress (see, e.g. Kriegsmann, Miksis & Vanden-Broeck Reference Kriegsmann, Miksis and Vanden-Broeck1998; Lunz & Howell Reference Lunz and Howell2018), or via the imposed gas tangential stress, ignoring the gas normal stress (see, e.g. Sullivan, Wilson & Duffy Reference Sullivan, Wilson and Duffy2008; Davis, Gratton & Davis Reference Davis, Gratton and Davis2010). In our study we incorporate the gas effects into the thin-film equation using detailed DNS for the gas phase. This allows us to obtain accurate functional expressions for the gas normal and tangential stresses, and thus close the liquid problem and develop an accurate ‘one-sided’ model. We also use an iterative procedure for the computation of the gas normal and tangential stresses exerted onto the gas–liquid interface which has two notable advantages: (i) it produces significantly more accurate results by taking into account a realistically computed gas flow rather than an approximated prescribed formula; and (ii) it allows the study of non-trivial geometrical settings (here finite-size effects) since the functional form of the stresses can now incorporate detailed nonlinear features which are otherwise difficult to predict.

The thin-film equation is built on the basis of experimental insight and developed in tandem with the more computationally expensive DNS for the full coupled system of the governing equations for our set-up. We make use of two different packages, the computational fluid dynamics (CFD) package in COMSOL (see, e.g. Pryor Reference Pryor2011) with a moving mesh interface and the volume-of-fluid Gerris package (see, e.g. Popinet Reference Popinet2009). These two numerical methodologies offer distinct advantages and features improving our understanding of the system. Direct numerical simulations are used to estimate the range of validity of the reduced-order model and allow us, on the one hand, to access regimes that would be inaccessible with the reduced-order model and, on the other hand, to analyse flow characteristics that would be very difficult to image in the experiments reliably (e.g. the velocity field). In addition to studying dewetting, we also analyse the post-dewetting dynamics, when the flow of the gas is switched off. An insight into the expected behaviours for various parameter values is provided by a bifurcation diagram of steady-state solutions for the system in the absence of the gas flow.

The manuscript is organised as follows. In § 2 we describe our experimental set-up. In § 3 we present the governing equations for the system and derive a reduced-order model. Next, § 4 explains our computational framework. In § 5 we present and discuss the results. Finally, in § 6 we give our conclusions.

2. Experimental set-up

A schematic representation of the experimental set-up is shown in figure 1. We consider a layer of a liquid in a transparent cylindrical beaker and we study the deformation of the surface of the liquid under the influence of an impinging gas jet. The beaker is ![]() $6\ \mathrm {cm}$ in height and

$6\ \mathrm {cm}$ in height and ![]() $3\ \mathrm {cm}$ in diameter and it is placed in a transparent square tank to minimise the distortion of the image. The liquid used in the experiments is water at room temperature. The beaker is made of an acrylic polymer with the static contact angle of

$3\ \mathrm {cm}$ in diameter and it is placed in a transparent square tank to minimise the distortion of the image. The liquid used in the experiments is water at room temperature. The beaker is made of an acrylic polymer with the static contact angle of ![]() $30^\circ$ for water; see the appendix for the details on the relevant experimental measurements. The gas jet is generated by maintaining a gas flow at a constant rate from a stationary cylindrical tube (nozzle) with its axis coinciding with the axis of the beaker. The inner diameter of the nozzle is

$30^\circ$ for water; see the appendix for the details on the relevant experimental measurements. The gas jet is generated by maintaining a gas flow at a constant rate from a stationary cylindrical tube (nozzle) with its axis coinciding with the axis of the beaker. The inner diameter of the nozzle is ![]() $1.6\ \mathrm {mm}$. The nozzle is connected to a compressed gas tank, and the flow rate is controlled by a mass flow controller (MKS, PR4000B). The gas used in most of the experiments is air at room temperature. The nozzle is fixed with a clamp which can be moved to adjust the distance from the nozzle to the surface of the liquid. We typically consider a distance of

$1.6\ \mathrm {mm}$. The nozzle is connected to a compressed gas tank, and the flow rate is controlled by a mass flow controller (MKS, PR4000B). The gas used in most of the experiments is air at room temperature. The nozzle is fixed with a clamp which can be moved to adjust the distance from the nozzle to the surface of the liquid. We typically consider a distance of ![]() $5\ \mathrm {mm}$. The position can be read from a movable calibrated scale.

$5\ \mathrm {mm}$. The position can be read from a movable calibrated scale.

Figure 1. Schematic representation of the experimental set-up.

A high-speed camera (Photron Fastcam, M2.1) with the resolution ![]() $512\times 512$ pixels and 2000 fps coupled with a long-distance lens (Infinity, KC) is placed on one side of the square tank in order to record images of the deformed liquid layer. The camera is connected to a computer to enable gathering of the data for analysis. A light source (Kern dual fiber unit LED) is placed on the opposite side of the square tank to provide illumination for the images. The camera is fixed on an adjustable

$512\times 512$ pixels and 2000 fps coupled with a long-distance lens (Infinity, KC) is placed on one side of the square tank in order to record images of the deformed liquid layer. The camera is connected to a computer to enable gathering of the data for analysis. A light source (Kern dual fiber unit LED) is placed on the opposite side of the square tank to provide illumination for the images. The camera is fixed on an adjustable ![]() $x$-

$x$-![]() $y$-

$y$-![]() $z$ stage allowing us to modify the camera's position properly and capture images in the beaker at different places. In particular, the initial position of the camera is adjusted by placing a graticule at the centre of an empty beaker and moving the camera along the stage until the image of the graticule comes into focus. This also allows measuring the size of the interrogation window. An example of an image of the graticule is included in the supplementary material available at https://doi.org/10.1017/jfm.2020.751. The recorded images were analysed with the software package ImageJ (e.g. Abràmoff, Magalhães & Ram Reference Abràmoff, Magalhães and Ram2004). Examples of processed recorded images (with increased contrast) are shown in figure 2 for a relatively thin water film (of undisturbed thickness

$z$ stage allowing us to modify the camera's position properly and capture images in the beaker at different places. In particular, the initial position of the camera is adjusted by placing a graticule at the centre of an empty beaker and moving the camera along the stage until the image of the graticule comes into focus. This also allows measuring the size of the interrogation window. An example of an image of the graticule is included in the supplementary material available at https://doi.org/10.1017/jfm.2020.751. The recorded images were analysed with the software package ImageJ (e.g. Abràmoff, Magalhães & Ram Reference Abràmoff, Magalhães and Ram2004). Examples of processed recorded images (with increased contrast) are shown in figure 2 for a relatively thin water film (of undisturbed thickness ![]() $0.2\ \mathrm {mm}$) in figure 2(a) and a relatively thick water film (of undisturbed thickness

$0.2\ \mathrm {mm}$) in figure 2(a) and a relatively thick water film (of undisturbed thickness ![]() $1\ \mathrm {mm}$) in figure 2(b). The corresponding raw images are included in the supplementary material. In figures 2(a) and 2(b) the water films were deformed by air jets of flow rates

$1\ \mathrm {mm}$) in figure 2(b). The corresponding raw images are included in the supplementary material. In figures 2(a) and 2(b) the water films were deformed by air jets of flow rates ![]() $0.15$ and

$0.15$ and ![]() $0.5\ \mathrm {slpm}$ (standard litres per minute), respectively. Given that the typical size of the interrogation window is

$0.5\ \mathrm {slpm}$ (standard litres per minute), respectively. Given that the typical size of the interrogation window is ![]() $2.6\ \mathrm {mm}\times 2.6\ \mathrm {mm}$ and the camera resolution is

$2.6\ \mathrm {mm}\times 2.6\ \mathrm {mm}$ and the camera resolution is ![]() $512\times 512$ pixels, we can conclude that the error of the measurements is

$512\times 512$ pixels, we can conclude that the error of the measurements is ![]() $O(10)\ \mathrm {\mu }\textrm {m}$. A deformation of the gas–liquid interface can be clearly seen in both cases. The gas–liquid interface is constructed by curve fitting in the software package Matlab.

$O(10)\ \mathrm {\mu }\textrm {m}$. A deformation of the gas–liquid interface can be clearly seen in both cases. The gas–liquid interface is constructed by curve fitting in the software package Matlab.

Figure 2. Experimental results for (a) an air jet of flow rate ![]() $0.15\ \mathrm {slpm}$ impinging onto a film of water of thickness

$0.15\ \mathrm {slpm}$ impinging onto a film of water of thickness ![]() $0.2\ \mathrm {mm}$ and (b) an air jet of flow rate

$0.2\ \mathrm {mm}$ and (b) an air jet of flow rate ![]() $0.5\ \mathrm {slpm}$ impinging onto a film of water of thickness

$0.5\ \mathrm {slpm}$ impinging onto a film of water of thickness ![]() $1\ \mathrm {mm}$. The images show regions of width

$1\ \mathrm {mm}$. The images show regions of width ![]() $2.6\ \mathrm {mm}$.

$2.6\ \mathrm {mm}$.

3. Mathematical model

3.1. Problem statement and full governing equations

A schematic representation of the model system is shown in figure 3. We denote the radius of the beaker by ![]() $R_b$ and its height by

$R_b$ and its height by ![]() $H$. The thickness of the undisturbed liquid layer is denoted by

$H$. The thickness of the undisturbed liquid layer is denoted by ![]() $h_0$. The inner and outer radii of the nozzle are denoted by

$h_0$. The inner and outer radii of the nozzle are denoted by ![]() $R_i$ and

$R_i$ and ![]() $R_o$, respectively, and the distance between the nozzle and the undisturbed gas–liquid interface is denoted by

$R_o$, respectively, and the distance between the nozzle and the undisturbed gas–liquid interface is denoted by ![]() $h_1$. We introduce cylindrical polar coordinates

$h_1$. We introduce cylindrical polar coordinates ![]() $(R,\varphi ,z)$ with the

$(R,\varphi ,z)$ with the ![]() $z$-axis pointing upwards along the axis of the beaker in the direction opposite to gravity

$z$-axis pointing upwards along the axis of the beaker in the direction opposite to gravity ![]() $\boldsymbol {g}$, and with the bottom of the beaker coinciding with the

$\boldsymbol {g}$, and with the bottom of the beaker coinciding with the ![]() $z=0$ plane. The deformed gas–liquid interface is denoted by

$z=0$ plane. The deformed gas–liquid interface is denoted by ![]() $\varSigma$ and is given by the equation

$\varSigma$ and is given by the equation ![]() ${f(R,\varphi ,z,t)=0}$. In the simplest case, the interface is given by the graph of a function,

${f(R,\varphi ,z,t)=0}$. In the simplest case, the interface is given by the graph of a function, ![]() $z=h(R,\varphi ,t)$ and, hence,

$z=h(R,\varphi ,t)$ and, hence, ![]() $f=h-z$. We assume that the liquid and the gas are of the same constant temperature.

$f=h-z$. We assume that the liquid and the gas are of the same constant temperature.

Figure 3. Schematic representation of a gas jet impinging onto the surface of a liquid in a cylindrical beaker.

As the gas jet strikes the liquid surface at the centre, the surface of the liquid deforms and a cavity appears. Motion in the liquid, in the form of eddies is also generated. The eddies affect the mass transfer and mixing in the liquid. In order to describe such a system, the Navier–Stokes and continuity equations are used and the corresponding boundary conditions must be satisfied.

As the typical velocity in the liquid will be assumed to be small compared to the speed of sound in the liquid, it is appropriate to model the liquid problem by the incompressible Navier–Stokes equations

where ![]() $\rho _l$ is the liquid density, which is assumed to be constant,

$\rho _l$ is the liquid density, which is assumed to be constant, ![]() $\boldsymbol {u}$ is the velocity field in the liquid,

$\boldsymbol {u}$ is the velocity field in the liquid, ![]() $\textrm {D}/\textrm {D}t={\partial }/{\partial t}+\boldsymbol {u}\boldsymbol {\cdot }\boldsymbol {\nabla }$ is the usual material derivative and

$\textrm {D}/\textrm {D}t={\partial }/{\partial t}+\boldsymbol {u}\boldsymbol {\cdot }\boldsymbol {\nabla }$ is the usual material derivative and ![]() $\boldsymbol {\sigma }_l$ is the viscous stress tensor for the liquid given by

$\boldsymbol {\sigma }_l$ is the viscous stress tensor for the liquid given by

where ![]() $p_l$ is the pressure in the liquid,

$p_l$ is the pressure in the liquid, ![]() $\mu _l$ is the viscosity of the liquid, which is assumed to be constant,

$\mu _l$ is the viscosity of the liquid, which is assumed to be constant, ![]() $\boldsymbol {\delta }$ is the identity tensor and

$\boldsymbol {\delta }$ is the identity tensor and ![]() $\boldsymbol{\mathsf{S}}_l=[(\boldsymbol {\nabla }\boldsymbol {u})^\textrm {T} +\boldsymbol {\nabla }\boldsymbol {u}]/{2}$ is the strain-rate tensor.

$\boldsymbol{\mathsf{S}}_l=[(\boldsymbol {\nabla }\boldsymbol {u})^\textrm {T} +\boldsymbol {\nabla }\boldsymbol {u}]/{2}$ is the strain-rate tensor.

In the present study we consider gas velocities up to ![]() $50\ \mathrm {m} \ \mathrm {s}^{-1}$. For such gas velocities, compressibility effects may also be neglected in the gas phase. For such gas velocities it is still appropriate to assume that the gas flow is laminar. The incompressible Navier–Stokes equations in the gas then take the form

$50\ \mathrm {m} \ \mathrm {s}^{-1}$. For such gas velocities, compressibility effects may also be neglected in the gas phase. For such gas velocities it is still appropriate to assume that the gas flow is laminar. The incompressible Navier–Stokes equations in the gas then take the form

where ![]() $\rho _g$ is the gas density,

$\rho _g$ is the gas density, ![]() $\boldsymbol {v}$ is the gas velocity and

$\boldsymbol {v}$ is the gas velocity and ![]() $\boldsymbol {\sigma }_g$ is the viscous stress tensor for the gas given by

$\boldsymbol {\sigma }_g$ is the viscous stress tensor for the gas given by

where ![]() $p_g$ is the gas pressure,

$p_g$ is the gas pressure, ![]() $\mu _g$ is the viscosity of the gas, which is assumed to be constant, and

$\mu _g$ is the viscosity of the gas, which is assumed to be constant, and ![]() $\boldsymbol{\boldsymbol{\mathsf{S}}}_g=[(\boldsymbol {\nabla }\boldsymbol {v})^\textrm {T} +\boldsymbol {\nabla }\boldsymbol {v}]/{2}$ is the strain-rate tensor in the gas.

$\boldsymbol{\boldsymbol{\mathsf{S}}}_g=[(\boldsymbol {\nabla }\boldsymbol {v})^\textrm {T} +\boldsymbol {\nabla }\boldsymbol {v}]/{2}$ is the strain-rate tensor in the gas.

We impose no-slip and no-penetration conditions both for the liquid and for the gas at the solid boundaries (![]() $\boldsymbol {u}=\textbf {0}$ and

$\boldsymbol {u}=\textbf {0}$ and ![]() $\boldsymbol {v}=\textbf {0}$) except at the beaker side wall, where no-penetration still applies, but instead of no-slip, we impose the Navier slip condition to allow for the motion of the contact line (see, e.g. Sibley, Savva & Kalliadasis Reference Sibley, Savva and Kalliadasis2012). So for the liquid when

$\boldsymbol {v}=\textbf {0}$) except at the beaker side wall, where no-penetration still applies, but instead of no-slip, we impose the Navier slip condition to allow for the motion of the contact line (see, e.g. Sibley, Savva & Kalliadasis Reference Sibley, Savva and Kalliadasis2012). So for the liquid when ![]() $R=R_b$, we have

$R=R_b$, we have

where ![]() $\hat {\boldsymbol {n}}_w$ is a unit normal vector to the side wall pointing into the beaker (i.e.

$\hat {\boldsymbol {n}}_w$ is a unit normal vector to the side wall pointing into the beaker (i.e. ![]() $\hat {\boldsymbol {n}}_w=-\hat {\boldsymbol {R}}$, where

$\hat {\boldsymbol {n}}_w=-\hat {\boldsymbol {R}}$, where ![]() $\hat {\boldsymbol {R}}$ is a unit vector pointing in the

$\hat {\boldsymbol {R}}$ is a unit vector pointing in the ![]() $R$ direction),

$R$ direction), ![]() $\hat {\boldsymbol {t}}_w$ is a unit tangent vector to the wall,

$\hat {\boldsymbol {t}}_w$ is a unit tangent vector to the wall, ![]() $\beta _{NS}^l$ is the slip coefficient for the liquid. For the gas when

$\beta _{NS}^l$ is the slip coefficient for the liquid. For the gas when ![]() $R=R_b$, we have

$R=R_b$, we have

where ![]() $\beta _{NS}^g$ is the slip coefficient for the gas.

$\beta _{NS}^g$ is the slip coefficient for the gas.

Note that in (3.5) and (3.6), there are, in general, two independent tangent directions to the wall, i.e. each of the equations results in two scalar equations, by taking ![]() $\hat {\boldsymbol {t}}_w=\hat {\boldsymbol {k}}$ and

$\hat {\boldsymbol {t}}_w=\hat {\boldsymbol {k}}$ and ![]() $\hat {\boldsymbol {t}}_w=\hat {\boldsymbol {\varphi }}$, where

$\hat {\boldsymbol {t}}_w=\hat {\boldsymbol {\varphi }}$, where ![]() $\hat {\boldsymbol {k}}$ and

$\hat {\boldsymbol {k}}$ and ![]() $\hat {\boldsymbol {\varphi }}$ are unit vectors pointing in the

$\hat {\boldsymbol {\varphi }}$ are unit vectors pointing in the ![]() $z$ and

$z$ and ![]() $\varphi$ directions. However, we will later assume axisymmetry, i.e. no dependence on

$\varphi$ directions. However, we will later assume axisymmetry, i.e. no dependence on ![]() $\varphi$, and then it will be sufficient to only consider

$\varphi$, and then it will be sufficient to only consider ![]() $\hat {\boldsymbol {t}}_w=\hat {\boldsymbol {k}}$.

$\hat {\boldsymbol {t}}_w=\hat {\boldsymbol {k}}$.

In addition, we impose a fixed contact angle condition at the contact line, so that when the interface is given by ![]() $z=h(R,\varphi ,t)$, we have

$z=h(R,\varphi ,t)$, we have

when ![]() $R=R_b$ and

$R=R_b$ and ![]() $z=h(R_b,\varphi ,t)$, where

$z=h(R_b,\varphi ,t)$, where ![]() $\theta _c$ is the angle the liquid makes with the wall at the contact line.

$\theta _c$ is the angle the liquid makes with the wall at the contact line.

In a subset of our numerical simulations presented below, at the bottom of the beaker we also impose the Navier slip condition instead of the no-slip condition. This allows us to study dewetting induced by the gas jet using DNS where topological transitions of the gas–liquid interface are allowed. We do this with the volume-of-fluid package Gerris (e.g. Popinet Reference Popinet2009), as will be explained below. The contact angle at the bottom of the beaker will be denoted by ![]() $\theta _{eq}$. We also performed DNS in the CFD finite-element package COMSOL (e.g. Pryor Reference Pryor2011), and our implementation allows for mesh movements so that the mesh deformations follow the gas–liquid interface motion. Such an implementation allows us to analyse the deformations of the interface very accurately but forbids topological transitions.

$\theta _{eq}$. We also performed DNS in the CFD finite-element package COMSOL (e.g. Pryor Reference Pryor2011), and our implementation allows for mesh movements so that the mesh deformations follow the gas–liquid interface motion. Such an implementation allows us to analyse the deformations of the interface very accurately but forbids topological transitions.

At the gas inlet, when ![]() $z=h_0+h_1$ and

$z=h_0+h_1$ and ![]() $0\leq R\leq R_i$, we impose the fully developed laminar Poiseuille velocity profile

$0\leq R\leq R_i$, we impose the fully developed laminar Poiseuille velocity profile

where ![]() $v_{max}=2q_g/{\rm \pi} R_i^2$, with

$v_{max}=2q_g/{\rm \pi} R_i^2$, with ![]() $q_g$ denoting the imposed gas flow rate.

$q_g$ denoting the imposed gas flow rate.

At the gas outlet, when ![]() $z=H$ and

$z=H$ and ![]() $R_o<R<R_b$, we impose normal flow, and prescribe normal stress, i.e. we require

$R_o<R<R_b$, we impose normal flow, and prescribe normal stress, i.e. we require ![]() $\hat {\boldsymbol {k}}\boldsymbol {\cdot }\boldsymbol {\sigma }_g\boldsymbol {\cdot }\hat {\boldsymbol {k}}=-p_a$, where

$\hat {\boldsymbol {k}}\boldsymbol {\cdot }\boldsymbol {\sigma }_g\boldsymbol {\cdot }\hat {\boldsymbol {k}}=-p_a$, where ![]() $p_a$ is the atmospheric pressure.

$p_a$ is the atmospheric pressure.

Finally, we discuss conditions that must be satisfied at the gas–liquid interface ![]() $\varSigma$. First, we have the kinematic condition

$\varSigma$. First, we have the kinematic condition

where we remind that ![]() $f$ is a function such that

$f$ is a function such that ![]() $\varSigma$ is given by the equation

$\varSigma$ is given by the equation ![]() ${f(R,\varphi ,z,t)=0}$. Continuity of velocity must also be satisfied at the interface,

${f(R,\varphi ,z,t)=0}$. Continuity of velocity must also be satisfied at the interface, ![]() $\boldsymbol {u}=\boldsymbol {v}$, and we must have dynamic balance of stress at

$\boldsymbol {u}=\boldsymbol {v}$, and we must have dynamic balance of stress at ![]() $\varSigma$:

$\varSigma$:

Here, ![]() $\hat {\boldsymbol {n}}$ is the unit normal vector to the interface pointing into the liquid. The term on the right-hand side is due to the Laplace pressure, where

$\hat {\boldsymbol {n}}$ is the unit normal vector to the interface pointing into the liquid. The term on the right-hand side is due to the Laplace pressure, where ![]() $\gamma$ is the gas–liquid surface tension coefficient (which is assumed to be constant) and

$\gamma$ is the gas–liquid surface tension coefficient (which is assumed to be constant) and ![]() $\kappa =\boldsymbol {\nabla }\boldsymbol {\cdot }\hat {\boldsymbol {n}}$ is twice the mean curvature of the interface

$\kappa =\boldsymbol {\nabla }\boldsymbol {\cdot }\hat {\boldsymbol {n}}$ is twice the mean curvature of the interface ![]() $\varSigma$.

$\varSigma$.

Note that to study dewetting induced by the gas jet in a numerical formulation where topological transitions are not allowed, we also include a Derjaguin (or disjoining) pressure in the stress balance condition. This approach is applicable when ![]() $\varSigma$ is a graph of a function,

$\varSigma$ is a graph of a function, ![]() $z=h(R,\varphi ,t)$. The stress balance condition then becomes

$z=h(R,\varphi ,t)$. The stress balance condition then becomes

The disjoining pressure represents an effective interaction between the gas–liquid interface and the liquid–substrate interface. It can be written as ![]() $\varPi (h)=-\mathrm {d} V(h)/\textrm {d}h$, where

$\varPi (h)=-\mathrm {d} V(h)/\textrm {d}h$, where ![]() $V(h)$ is the so-called binding potential (e.g. de Gennes, Brochard-Wyart & Quéré Reference de Gennes, Brochard-Wyart and Quéré2013). The disjoining pressure is assumed to be of the form (e.g. Pismen Reference Pismen2002; Galvagno et al. Reference Galvagno, Tseluiko, Lopez and Thiele2014)

$V(h)$ is the so-called binding potential (e.g. de Gennes, Brochard-Wyart & Quéré Reference de Gennes, Brochard-Wyart and Quéré2013). The disjoining pressure is assumed to be of the form (e.g. Pismen Reference Pismen2002; Galvagno et al. Reference Galvagno, Tseluiko, Lopez and Thiele2014)

where the first term results from the long-range attractive forces (with ![]() $A$ representing the Hamaker constant) and the second term results from the short-range repulsive forces. The second term prevents the liquid film from breaking down, and instead of this occurring we obtain a very thin precursor film. In practice, where the film thickness is equal to the thickness of the precursor film, we may assume that a dry spot has appeared. At equilibrium, the thickness of the precursor film corresponds to the minimum of the binding potential

$A$ representing the Hamaker constant) and the second term results from the short-range repulsive forces. The second term prevents the liquid film from breaking down, and instead of this occurring we obtain a very thin precursor film. In practice, where the film thickness is equal to the thickness of the precursor film, we may assume that a dry spot has appeared. At equilibrium, the thickness of the precursor film corresponds to the minimum of the binding potential ![]() $V(h)$ and is equal to

$V(h)$ and is equal to

with the contact angle at the apparent contact line is given by (e.g. Rauscher & Dietrich Reference Rauscher and Dietrich2008; Hughes, Thiele & Archer Reference Hughes, Thiele and Archer2015)

Note that given the precursor thickness, ![]() $h_{eq}$, and the equilibrium contact angle,

$h_{eq}$, and the equilibrium contact angle, ![]() $\theta _{eq}$, the constants

$\theta _{eq}$, the constants ![]() $A$ and

$A$ and ![]() $B$ can be recovered using relations (3.13) and (3.14) given above.

$B$ can be recovered using relations (3.13) and (3.14) given above.

3.2. Thin-film model

Solving the full system of governing equations is a computationally expensive task. We therefore aim to simplify the problem by deriving an accurate reduced-order model. Such a model not only provides insight into the fundamental features of the system in an efficient way, but also serves as a mechanism to guide the more computationally prohibitive DNS tools towards suitable regimes with a much more informed view of an otherwise vast parameter space. The first step is to decouple the problem for the gas from that for the liquid, which is possible when the typical velocity in the liquid is much smaller than that in the gas. Then, for the gas problem it is appropriate to neglect the motion of the liquid and to use the quasi-static assumption, i.e. it is appropriate to model the interface as a rigid wall and solve the gas problem independently; see, e.g. Tuck (Reference Tuck1975) who states that such an assumption is appropriate when the typical liquid velocity is less than approximately ![]() $4\,\%$ of the typical gas velocity, which is always the case in our study (see also Tseluiko & Kalliadasis (Reference Tseluiko and Kalliadasis2011), Vellingiri et al. (Reference Vellingiri, Tseluiko and Kalliadasis2015) for more recent studies, where the quasi-static assumption was used in the modelling of a liquid film sheared by a turbulent gas).

$4\,\%$ of the typical gas velocity, which is always the case in our study (see also Tseluiko & Kalliadasis (Reference Tseluiko and Kalliadasis2011), Vellingiri et al. (Reference Vellingiri, Tseluiko and Kalliadasis2015) for more recent studies, where the quasi-static assumption was used in the modelling of a liquid film sheared by a turbulent gas).

The solution of the gas problem can then be used to obtain the stress exerted by the gas onto the gas–liquid interface, which can then be fed into the normal and tangential stress balance conditions at the interface. We denote such a stress by ![]() $\boldsymbol {s}_g$ so that

$\boldsymbol {s}_g$ so that

For the analysis in this section, we first consider the general non-axisymmetric case and, for convenience, we use Cartesian coordinates ![]() $(x,y,z)$ (so that the

$(x,y,z)$ (so that the ![]() $z$ direction remains as before).

$z$ direction remains as before).

We non-dimensionalise the equations using ![]() $h_0$ as the length scale,

$h_0$ as the length scale, ![]() $U_0$ as the velocity scale (to be specified later),

$U_0$ as the velocity scale (to be specified later), ![]() $h_0/U_0$ as the time scale and

$h_0/U_0$ as the time scale and ![]() $\mu _l U_0/h_0$ as the scale for pressure and the gas stress, so from now on all the variables will be assumed to be dimensionless. We thus introduce dimensionless variables via the following mappings:

$\mu _l U_0/h_0$ as the scale for pressure and the gas stress, so from now on all the variables will be assumed to be dimensionless. We thus introduce dimensionless variables via the following mappings:

Here we denote by ![]() $u$,

$u$, ![]() $v$ and

$v$ and ![]() $w$ the

$w$ the ![]() $x$,

$x$, ![]() $y$ and

$y$ and ![]() $z$ components of the velocity, respectively.

$z$ components of the velocity, respectively.

The incompressible Navier–Stokes and continuity equations in the liquid become

where ![]() $Re$ and

$Re$ and ![]() $G$ are the Reynolds and the gravity numbers, respectively, given by

$G$ are the Reynolds and the gravity numbers, respectively, given by

The no-slip and no-penetration conditions at the bottom of the beaker become

The kinematic condition at the interface, ![]() $z=h(x,y,t)$, takes the form

$z=h(x,y,t)$, takes the form

The normal stress balance condition takes the form

\begin{align} &-p_l+\frac{2}{1+h_x^2+h_y^2}\left[h_x^2u_x+h_y^2v_y+w_z+h_xh_y(u_y+v_x)-h_x(u_z+w_x)-h_y(v_z+w_y)\right]\nonumber\\ &\quad =\frac{1}{Ca} \frac{(1+h_x^2)h_{yy}-2h_xh_yh_{xy}+(1+h_y^2)h_{xx}}{(1+h_x^2+h_y^2)}-N_s+\bar{\varPi}(h) \end{align}

\begin{align} &-p_l+\frac{2}{1+h_x^2+h_y^2}\left[h_x^2u_x+h_y^2v_y+w_z+h_xh_y(u_y+v_x)-h_x(u_z+w_x)-h_y(v_z+w_y)\right]\nonumber\\ &\quad =\frac{1}{Ca} \frac{(1+h_x^2)h_{yy}-2h_xh_yh_{xy}+(1+h_y^2)h_{xx}}{(1+h_x^2+h_y^2)}-N_s+\bar{\varPi}(h) \end{align}

at ![]() $z=h(x,y,t)$, where

$z=h(x,y,t)$, where ![]() $Ca$ is the capillary number given by

$Ca$ is the capillary number given by

![]() $N_s$ is the dimensionless normal stress exerted by the gas on the gas–liquid interface

$N_s$ is the dimensionless normal stress exerted by the gas on the gas–liquid interface

which under the quasi-static assumption can be assumed to be a functional of the interface shape, ![]() $N_s=N_s[h]$, and finally,

$N_s=N_s[h]$, and finally, ![]() $\bar {\varPi }(h)$ is the dimensionless disjoining pressure, given by

$\bar {\varPi }(h)$ is the dimensionless disjoining pressure, given by

where ![]() $\bar {A}=A/\mu _lU_0h_0^2$ and

$\bar {A}=A/\mu _lU_0h_0^2$ and ![]() $\bar {B}=B/\mu _lU_0h_0^5$.

$\bar {B}=B/\mu _lU_0h_0^5$.

Taking ![]() $\hat {\boldsymbol {t}}=\hat {\boldsymbol {t}}_1={(1, 0, h_x)}/{\sqrt {1+h_x^2}}$ and

$\hat {\boldsymbol {t}}=\hat {\boldsymbol {t}}_1={(1, 0, h_x)}/{\sqrt {1+h_x^2}}$ and ![]() $\hat {\boldsymbol {t}}=\hat {\boldsymbol {t}}_2={(0, 1, h_y)}/{\sqrt {1+h_y^2}}$ in the tangential stress balance condition, we obtain

$\hat {\boldsymbol {t}}=\hat {\boldsymbol {t}}_2={(0, 1, h_y)}/{\sqrt {1+h_y^2}}$ in the tangential stress balance condition, we obtain

\begin{gather}\frac{2h_y\left(v_y-w_z\right)+\left(h_y^2-1\right)\left(v_z+w_y\right)+h_x\left(u_y+v_x\right) +h_xh_y\left(u_z+w_x\right)}{[\left(1+h_x^2+h_y^2\right)\left(1+h_x^2\right)]^{1/2}}=-T_{s2} \end{gather}

\begin{gather}\frac{2h_y\left(v_y-w_z\right)+\left(h_y^2-1\right)\left(v_z+w_y\right)+h_x\left(u_y+v_x\right) +h_xh_y\left(u_z+w_x\right)}{[\left(1+h_x^2+h_y^2\right)\left(1+h_x^2\right)]^{1/2}}=-T_{s2} \end{gather}

at ![]() $z=h(x,y,t)$, where

$z=h(x,y,t)$, where ![]() $T_{si}$,

$T_{si}$, ![]() $i=1,2$, are the

$i=1,2$, are the ![]() $\hat {\boldsymbol {t}}_1$ and

$\hat {\boldsymbol {t}}_1$ and ![]() $\hat {\boldsymbol {t}}_2$ components of the tangential stress exerted by the gas on the gas–liquid interface,

$\hat {\boldsymbol {t}}_2$ components of the tangential stress exerted by the gas on the gas–liquid interface, ![]() $T_{si}=\boldsymbol {s}_g\boldsymbol {\cdot }\widehat {\boldsymbol {t}_i}$, which under the quasi-static assumption can be assumed to be functionals of the interface shape,

$T_{si}=\boldsymbol {s}_g\boldsymbol {\cdot }\widehat {\boldsymbol {t}_i}$, which under the quasi-static assumption can be assumed to be functionals of the interface shape, ![]() $T_{si}=T_{si}[h]$. The tangential stress exerted by the gas on the gas–liquid interface is then expressed as

$T_{si}=T_{si}[h]$. The tangential stress exerted by the gas on the gas–liquid interface is then expressed as

Next, we utilise the so-called thin-film or long-wave approximation, namely, we assume that the undisturbed film thickness, ![]() $h_0$, is much smaller than the characteristic horizontal length scale

$h_0$, is much smaller than the characteristic horizontal length scale ![]() $\ell$ over which variations in the film thickness occur, and we introduce the so-called thin-film parameter

$\ell$ over which variations in the film thickness occur, and we introduce the so-called thin-film parameter ![]() $\epsilon =h_0/\ell \ll 1$. We now use the following additional rescalings of variables that are standard for the thin-film approximation:

$\epsilon =h_0/\ell \ll 1$. We now use the following additional rescalings of variables that are standard for the thin-film approximation:

To derive the thin-film equation, we consider the asymptotic limit ![]() $\epsilon \rightarrow 0$. Then, to keep capillary effects at leading order, we assume that

$\epsilon \rightarrow 0$. Then, to keep capillary effects at leading order, we assume that ![]() $Ca$ is asymptotically bounded above and below by

$Ca$ is asymptotically bounded above and below by ![]() $\epsilon ^3$. To neglect inertia at leading order, we assume that

$\epsilon ^3$. To neglect inertia at leading order, we assume that ![]() $Re\ll 1/\epsilon$. We also assume that

$Re\ll 1/\epsilon$. We also assume that ![]() $G=O(1/\epsilon )$, so that gravitational effects may enter at leading order. For the disjoining pressure, it is appropriate to assume that

$G=O(1/\epsilon )$, so that gravitational effects may enter at leading order. For the disjoining pressure, it is appropriate to assume that ![]() $\bar {\varPi }=O(1/\epsilon )$. In addition, for the dimensionless gas stress, we need to assume that

$\bar {\varPi }=O(1/\epsilon )$. In addition, for the dimensionless gas stress, we need to assume that ![]() $N_s=O(1/\epsilon )$ and

$N_s=O(1/\epsilon )$ and ![]() $T_{si}=O(1)$,

$T_{si}=O(1)$, ![]() $i=1,2$. We then introduce the rescaled parameters

$i=1,2$. We then introduce the rescaled parameters

so that ![]() $\tilde {C}a$ is asymptotically bounded above and below by non-zero constants and

$\tilde {C}a$ is asymptotically bounded above and below by non-zero constants and ![]() $\tilde {G}=O(1)$, and the rescaled gas normal stress

$\tilde {G}=O(1)$, and the rescaled gas normal stress

so that ![]() $\tilde {N}_s=O(1)$, and the rescaled disjoining pressure

$\tilde {N}_s=O(1)$, and the rescaled disjoining pressure

so that ![]() $\tilde {\varPi }=O(1)$.

$\tilde {\varPi }=O(1)$.

The problem at leading order becomes

with the no-slip and no-penetration conditions

at ![]() $z=0$ and the tangential and normal stress balances

$z=0$ and the tangential and normal stress balances

at ![]() $z=h(\xi ,\eta ,\tau )$. We also have the kinematic condition, which can be rewritten as

$z=h(\xi ,\eta ,\tau )$. We also have the kinematic condition, which can be rewritten as

where ![]() $\boldsymbol {\nabla }=(\partial /\partial \xi , \partial /\partial \eta )$ and

$\boldsymbol {\nabla }=(\partial /\partial \xi , \partial /\partial \eta )$ and

\begin{equation} \boldsymbol{q}=\left(\int_0^hu\,\mathrm{d}z,\int_0^hv\,\mathrm{d}z\right) \end{equation}

\begin{equation} \boldsymbol{q}=\left(\int_0^hu\,\mathrm{d}z,\int_0^hv\,\mathrm{d}z\right) \end{equation}

is the flux vector parallel to the plane ![]() $z=0$.

$z=0$.

Then we find that the pressure at leading order is given by

and the velocity components at leading order are given by

Substituting the leading-order expressions for ![]() $u$ and

$u$ and ![]() $v$ into the expression for the flux vector (3.40), we find that at leading order

$v$ into the expression for the flux vector (3.40), we find that at leading order

Substituting this expression into the kinematic condition (3.39) gives the following evolution equation for the film thickness, the so-called thin-film equation:

Scaling back to the dimensionless variables ![]() $x$,

$x$, ![]() $y$ and

$y$ and ![]() $t$, we obtain

$t$, we obtain

where the dimensionless leading-order pressure is given by

and ![]() $\boldsymbol {\nabla }=(\partial /\partial x, \partial /\partial y)$.

$\boldsymbol {\nabla }=(\partial /\partial x, \partial /\partial y)$.

For convenience, it is possible to eliminate one of the dimensionless parameters by, for example, multiplying the thin-film equation by ![]() $Ca$ and appropriately rescaling time. This is equivalent to choosing

$Ca$ and appropriately rescaling time. This is equivalent to choosing ![]() $U_0=\gamma /\mu _l$, for which the time scale becomes

$U_0=\gamma /\mu _l$, for which the time scale becomes ![]() $\mu _l h_0/\gamma$ and the scale for pressure and the gas stress becomes

$\mu _l h_0/\gamma$ and the scale for pressure and the gas stress becomes ![]() $\gamma /h_0$. Then the pressure in the thin-film equation takes the form

$\gamma /h_0$. Then the pressure in the thin-film equation takes the form

where ![]() $Bo$ is the Bond number given by

$Bo$ is the Bond number given by

and the dimensionless coefficients in the disjoining pressure are ![]() $\bar {A}=A/\gamma h_0^2$ and

$\bar {A}=A/\gamma h_0^2$ and ![]() $\bar {B}=B/\gamma h_0^5$.

$\bar {B}=B/\gamma h_0^5$.

For the validity of the thin-film equation in terms of dimensionless parameters that are independent of ![]() $U_0$, we must have

$U_0$, we must have ![]() $Bo=O(\epsilon ^2)$ and

$Bo=O(\epsilon ^2)$ and ![]() $La\ll 1/\epsilon ^4$, where

$La\ll 1/\epsilon ^4$, where ![]() $La$ is the Laplace number given by

$La$ is the Laplace number given by

The latter condition is needed for inertia to be negligible. We must additionally have ![]() $N_s=O(\epsilon ^2)$ and

$N_s=O(\epsilon ^2)$ and ![]() $T_{si}=O(\epsilon ^3)$,

$T_{si}=O(\epsilon ^3)$, ![]() $i=1,2$. The validity of the thin-film equation for the experimental parameter values that we have used is discussed § 5.

$i=1,2$. The validity of the thin-film equation for the experimental parameter values that we have used is discussed § 5.

Finally, going back to cylindrical polar coordinates ![]() $(R,\varphi ,z)$ and assuming axisymmetry, we obtain the equation

$(R,\varphi ,z)$ and assuming axisymmetry, we obtain the equation

where ![]() $T_s$ denotes the gas tangential stress in the

$T_s$ denotes the gas tangential stress in the ![]() $R$-direction and pressure is given by

$R$-direction and pressure is given by

Note that here ![]() $R$ is assumed to be non-dimensionalised using

$R$ is assumed to be non-dimensionalised using ![]() $h_0$ as the length scale. To solve the thin-film equation (3.51) numerically, we also need to impose appropriate boundary conditions. Conditions at

$h_0$ as the length scale. To solve the thin-film equation (3.51) numerically, we also need to impose appropriate boundary conditions. Conditions at ![]() $R=0$ follow from the symmetry assumption

$R=0$ follow from the symmetry assumption

At the side wall, we will assume for simplicity that the contact angle is ![]() $90^\circ$, so that

$90^\circ$, so that

where ![]() $\bar {R}_b=R_b/h_0$, and we will impose zero flux in the

$\bar {R}_b=R_b/h_0$, and we will impose zero flux in the ![]() $R$ direction, so that

$R$ direction, so that

For analysing flow patterns in the liquid film, it is also useful to give the ![]() $R$ and

$R$ and ![]() $z$ velocity components in cylindrical polar coordinates:

$z$ velocity components in cylindrical polar coordinates:

Note that the main model equation (3.51) provides a highly efficient route towards studying mechanistic aspects of the flow and generating an understanding of the underlying physics, thus forming a valuable part of our methodology toolkit.

To close the thin-film model, we need to specify stress contributions ![]() $N_s$ and

$N_s$ and ![]() $T_s$. There are different possible approaches for incorporating these. As mentioned in the introduction, often approximate expressions for these stresses were used that were typically constructed on the basis of general unbounded domains. For example, Kriegsmann et al. (Reference Kriegsmann, Miksis and Vanden-Broeck1998) and Lunz & Howell (Reference Lunz and Howell2018) assumed a Gaussian form for the normal stress and completely ignored the shear stress. We choose to integrate the gas effects into the thin-film equation more carefully by means of exploiting detailed knowledge of the flow field in the gas extracted from DNS. In the first instance and for comparison purposes, we suggest computationally informed functional expressions for

$T_s$. There are different possible approaches for incorporating these. As mentioned in the introduction, often approximate expressions for these stresses were used that were typically constructed on the basis of general unbounded domains. For example, Kriegsmann et al. (Reference Kriegsmann, Miksis and Vanden-Broeck1998) and Lunz & Howell (Reference Lunz and Howell2018) assumed a Gaussian form for the normal stress and completely ignored the shear stress. We choose to integrate the gas effects into the thin-film equation more carefully by means of exploiting detailed knowledge of the flow field in the gas extracted from DNS. In the first instance and for comparison purposes, we suggest computationally informed functional expressions for ![]() $N_s$ and

$N_s$ and ![]() $T_s$, thus developing an accurate ‘one-sided’ model. However, more generally, we also introduce and utilise an iterative numerical procedure for computing

$T_s$, thus developing an accurate ‘one-sided’ model. However, more generally, we also introduce and utilise an iterative numerical procedure for computing ![]() $N_s$ and

$N_s$ and ![]() $T_s$, which provides an accurate update mechanism that is computationally inexpensive and powerful in the context of predictive modelling, especially in the context of finite-size effects generated by the presence of the lateral walls of the beaker.

$T_s$, which provides an accurate update mechanism that is computationally inexpensive and powerful in the context of predictive modelling, especially in the context of finite-size effects generated by the presence of the lateral walls of the beaker.

4. Computational framework

Complementing the experimental and analytical investigations we also considered two distinct numerical platforms to simulate the unsimplified and fully coupled Navier–Stokes and continuity equations in both liquid and gas phases within the target physical system. The two packages (described in more detail in the paragraphs to follow) offer distinct advantages and features that aid our understanding of the flow characteristics. They act not only to bridge the gap between the previous approaches, but also to access regimes that would be inaccessible with a reduced-order model approach on the one hand, as well as easily allow the inspection of quantities in the flow that would be very difficult to visualise experimentally.

First, we implemented the set-up in the commercial software platform COMSOL Multiphysics 5.3a. We used the CFD module which is a standard tool to simulating systems that involve complex fluid flow models. A two-dimensional axisymmetric geometry was built using the parameters from the experiments. COMSOL uses an unstructured mesh finite-element approach, which is highly suitable for tracking details near specific target regions of the domain. However, for the present problem, we found it challenging and computationally highly expensive to accurately describe the evolution of the gas–liquid interface and topological transitions, occurring, for example, in the dewetting process, using the built-in level-set and phase-field methods. Specific difficulties were encountered in conserving volume. Addressing this would require a prohibitively large number of degrees of freedom even with a powerful machine. We thus utilised a more computationally efficient moving-mesh approach in which the gas–liquid interface is modelled as a sharp surface separating the two phases and the mesh deformations follow the deformations of the interface. However, such an implementation is not directly suitable for describing topological transitions such as in the dewetting process (as this functionality is not available in COMSOL altogether for the moving-mesh formulation). Thus, as discussed in § 3.1, we included the disjoining pressure into the normal stress balance condition to study dewetting which prevents the liquid film from breaking down so that a dry spot is modelled with a very thin precursor film. We should note that this approach still has limitations in modelling dewetting. For example, it is not suitable for describing dewetting on hydrophobic surfaces for which the contact angle is greater than ![]() $90^\circ$.

$90^\circ$.

To overcome the limitations of our COMSOL implementation with respect to topological transitions, we also implemented the set-up in the open-source package Gerris (e.g. Popinet Reference Popinet2009). Well known in the interfacial flow community for more than a decade, its strengths lie in the adaptive mesh refinement and parallelisation capabilities that make it an ideal testbed for multi-scale flow problems. The transparent structure of the code allows for careful validation of any in-house implemented extensions, as have been employed here. For example, one particular region of interest in the flow is the near-wall region where dewetting can be considered without the need to introduce a precursor film. The interface-capturing techniques, coupled with well-established contact line models (e.g. Afkhami et al. Reference Afkhami, Buongiorno, Guion, Popinet, Saade, Scardovelli and Zaleski2018) and control over any imposed Navier-slip-type conditions, provide an added perspective to the overall investigation. The chosen refinement strategy concentrates on adequately addressing the sensitive regions near the gas nozzle and the walls in contact with the liquid, while adaptive refinement is used to steer degrees of freedom towards any changes in interfacial position, as well as changes in components of the velocity field and vorticity in order to accurately capture non-trivial flow regions in both the liquid and the gas.

The runs in the sections to follow have been executed in parallel on local computing facilities, typically amounting to ![]() $O(10^3)$ CPU hours in Gerris, depending on flow parameters. While the chosen adaptive strategy restricts the number of grid nodes to

$O(10^3)$ CPU hours in Gerris, depending on flow parameters. While the chosen adaptive strategy restricts the number of grid nodes to ![]() $O(10^5)$, a gain of two orders of magnitude over a uniform grid with the same minimum cell size, the delicate interplay between the gas–liquid coupling requires special measures from a linear algebra and stability viewpoint, leading to relatively small time steps in order to ensure mesh-independent results. The Courant–Friedrichs–Lewy limited procedure, alongside criteria based on surface tension effects (the time step needs to be smaller than the period of the shortest capillary wave) and viscosity lead to a time step

$O(10^5)$, a gain of two orders of magnitude over a uniform grid with the same minimum cell size, the delicate interplay between the gas–liquid coupling requires special measures from a linear algebra and stability viewpoint, leading to relatively small time steps in order to ensure mesh-independent results. The Courant–Friedrichs–Lewy limited procedure, alongside criteria based on surface tension effects (the time step needs to be smaller than the period of the shortest capillary wave) and viscosity lead to a time step ![]() ${\rm \Delta} t = O(10^{-4})\ \mathrm {s}$ during the entire evolution of the flow. By contrast, we found that the computations in COMSOL were significantly faster for a similar number of degrees of freedom (we typically used

${\rm \Delta} t = O(10^{-4})\ \mathrm {s}$ during the entire evolution of the flow. By contrast, we found that the computations in COMSOL were significantly faster for a similar number of degrees of freedom (we typically used ![]() $O(10^5)$ triangular elements), with a typical computation for the fully coupled problem taking approximately

$O(10^5)$ triangular elements), with a typical computation for the fully coupled problem taking approximately ![]() $O(10^2)$ CPU hours. This is due to a relaxation of the time step tolerance in COMSOL that allows it to increase to

$O(10^2)$ CPU hours. This is due to a relaxation of the time step tolerance in COMSOL that allows it to increase to ![]() ${\rm \Delta} t = O(10^{-1})\ \mathrm {s}$, thus requiring significantly fewer iterations of the underlying large scale solver. While resulting in a welcome speedup, it is unclear whether this less conservative strategy adopted by the commercial software could in principle cope with unexpected changes in the flow conditions. Ultimately, even taking the runtime advantages into account, we have already noted above some of the restrictions on the study of dewetting phenomena, which is one of the central topics of the present investigation. Thus, the functionalities of each of the two packages become complementary and contribute towards a versatile computational framework for our set-up.

${\rm \Delta} t = O(10^{-1})\ \mathrm {s}$, thus requiring significantly fewer iterations of the underlying large scale solver. While resulting in a welcome speedup, it is unclear whether this less conservative strategy adopted by the commercial software could in principle cope with unexpected changes in the flow conditions. Ultimately, even taking the runtime advantages into account, we have already noted above some of the restrictions on the study of dewetting phenomena, which is one of the central topics of the present investigation. Thus, the functionalities of each of the two packages become complementary and contribute towards a versatile computational framework for our set-up.

We have validated both implementations extensively by systematically decreasing the cell size or increasing the number of mesh elements until the convergence in the numerical results was achieved. Quantitative measurements (norm-based estimates of both converged and dynamic features of the flow) have underpinned the verifications of such grid-size studies and have guided us in designing appropriate temporal and spatial adaptivity strategies. Comparisons to analytical and experimental data have been used as reference when possible, while the most expensive (and accurate) calculations in regimes outside the reach of the other techniques have been used otherwise. We have thus established a robust and mesh-independent solution strategy for the numerical results presented in the following section.

5. Results

Throughout this section we consider the following geometrical parameters in both the mathematical model and in the numerical simulations: the diameter of the beaker is ![]() $3\ \mathrm {cm}$ and its height is

$3\ \mathrm {cm}$ and its height is ![]() $6\ \mathrm {cm}$; the inner diameter of the gas nozzle is

$6\ \mathrm {cm}$; the inner diameter of the gas nozzle is ![]() $1.6\ \mathrm {mm}$ and its distance from the undisturbed liquid surface is

$1.6\ \mathrm {mm}$ and its distance from the undisturbed liquid surface is ![]() $5\ \mathrm {mm}$, as in the experiments. Also, the liquid is water and the gas is air at room temperature. The density and viscosity of water at room temperature are

$5\ \mathrm {mm}$, as in the experiments. Also, the liquid is water and the gas is air at room temperature. The density and viscosity of water at room temperature are ![]() $\rho _l=1000\ \mathrm {kg} \ \mathrm {m}^{-3}$ and

$\rho _l=1000\ \mathrm {kg} \ \mathrm {m}^{-3}$ and ![]() $\mu _l=8.9\times 10^{-4}\ \mathrm {Pa} \ \mathrm {s}$, respectively. For the density and viscosity of air, we use

$\mu _l=8.9\times 10^{-4}\ \mathrm {Pa} \ \mathrm {s}$, respectively. For the density and viscosity of air, we use ![]() $\rho _g=1.22\ \mathrm {kg} \ \mathrm {m}^{-3}$ and

$\rho _g=1.22\ \mathrm {kg} \ \mathrm {m}^{-3}$ and ![]() $\mu _g=1.81\times 10^{-5}\ \mathrm {Pa} \ \mathrm {s}$. The surface tension coefficient for the air–water interface is set to

$\mu _g=1.81\times 10^{-5}\ \mathrm {Pa} \ \mathrm {s}$. The surface tension coefficient for the air–water interface is set to ![]() $\gamma =72\times 10^{-3}\ \mathrm {N} \ \mathrm {m}^{-1}$. Regarding the results obtained with the thin-film equation (3.51), for the asymptotic validity of the equation

$\gamma =72\times 10^{-3}\ \mathrm {N} \ \mathrm {m}^{-1}$. Regarding the results obtained with the thin-film equation (3.51), for the asymptotic validity of the equation ![]() $Bo\ll 1$ is required and also

$Bo\ll 1$ is required and also ![]() $La\ll 1/Bo^2$. It can be verified that for a water film

$La\ll 1/Bo^2$. It can be verified that for a water film ![]() $La$ becomes smaller than

$La$ becomes smaller than ![]() $1/Bo^2$ if

$1/Bo^2$ if ![]() $h_0<0.226\ \mathrm {mm}$ (and then

$h_0<0.226\ \mathrm {mm}$ (and then ![]() $Bo<0.007$). Thus, strictly speaking for the validity of the thin-film model the thickness of the film must be less than

$Bo<0.007$). Thus, strictly speaking for the validity of the thin-film model the thickness of the film must be less than ![]() ${\approx }0.23\ \mathrm {mm}$. As regards gas flow rates suitable for the validity of the thin-film equation, we note that for a film of thickness

${\approx }0.23\ \mathrm {mm}$. As regards gas flow rates suitable for the validity of the thin-film equation, we note that for a film of thickness ![]() $0.226\ \mathrm {mm}$ and an air jet flowing at the rate

$0.226\ \mathrm {mm}$ and an air jet flowing at the rate ![]() $0.2\ \mathrm {slpm}$, the maximum values of the normal and tangential stresses non-dimensionalised with

$0.2\ \mathrm {slpm}$, the maximum values of the normal and tangential stresses non-dimensionalised with ![]() $\gamma /h_0$ turn out to be

$\gamma /h_0$ turn out to be ![]() $0.007$ and

$0.007$ and ![]() $0.0008$, respectively, which is appropriate for the validity of the model. For an air jet flowing at the rate

$0.0008$, respectively, which is appropriate for the validity of the model. For an air jet flowing at the rate ![]() $0.4\ \mathrm {slpm}$, the maximum values of the dimensionless normal and tangential stresses turn out to be

$0.4\ \mathrm {slpm}$, the maximum values of the dimensionless normal and tangential stresses turn out to be ![]() $0.028$ and

$0.028$ and ![]() $0.0025$, respectively, which is also close to the region of the validity of the model. However, it will be shown below that the thin-film equation turns out to produce good agreement with DNS and experiments also for film thicknesses significantly larger than

$0.0025$, respectively, which is also close to the region of the validity of the model. However, it will be shown below that the thin-film equation turns out to produce good agreement with DNS and experiments also for film thicknesses significantly larger than ![]() $0.226\ \mathrm {mm}$ (of

$0.226\ \mathrm {mm}$ (of ![]() $O(1)\ \mathrm {mm}$) and for gas flow rates significantly higher than

$O(1)\ \mathrm {mm}$) and for gas flow rates significantly higher than ![]() $0.4\ \mathrm {slpm}$ (of

$0.4\ \mathrm {slpm}$ (of ![]() $O(1)\ \mathrm {slpm}$). For even thicker water films and higher gas flow rates, inertial effects become important and the derived thin-film equation is not valid. Such parameter regimes can be accessed with the developed DNS framework.

$O(1)\ \mathrm {slpm}$). For even thicker water films and higher gas flow rates, inertial effects become important and the derived thin-film equation is not valid. Such parameter regimes can be accessed with the developed DNS framework.

5.1. Decoupled gas problem

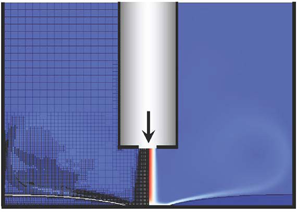

First, we discuss the decoupled gas problem and explain how the gas normal and tangential stresses exerted on the interface are computed using an iterative procedure. Under the quasi-static assumption, we model the liquid surface as a solid wall obtaining a problem for the gas only, and initially we assume that the interface is flat. The gas flow rapidly develops into a steady state. The resulting gas flow pattern at steady state obtained using COMSOL is shown in figure 4(a) for the gas flow rate ![]() $q_g = 1\ \mathrm {slpm}$, which corresponds to the maximum gas speed of approximately

$q_g = 1\ \mathrm {slpm}$, which corresponds to the maximum gas speed of approximately ![]() $16\ \mathrm {m} \ \mathrm {s}^{-1}$. In this section we assume that the undisturbed interface is located at

$16\ \mathrm {m} \ \mathrm {s}^{-1}$. In this section we assume that the undisturbed interface is located at ![]() $z=0$. We note that Gerris simulations agree with the COMSOL results. The colour scheme indicates the gas speed in metres per second and the thin white lines show streamlines. We can observe that the gas jet impinges onto the lower wall, and then the gas flows in the direction parallel to the wall radially outwards with its speed decreasing as the radial distance increases. We can also observe that a relatively large recirculation zone (eddy) is generated in the gas, and there is also a small, relatively slow eddy in the bottom-right corner. This solution of the gas problem for the interface modelled as a flat solid wall is used to compute the normal and tangential stresses exerted by the gas jet on the interface at different radial locations. Next, we use these stresses in the thin-film equation (3.51) to solve the problem for the liquid film and, therefore, obtain the deformation of the interface resulting from these stresses. The thin-film equation is solved numerically in Matlab using finite-difference approximations for the spatial derivatives and Matlab's ode15s solver for stepping in time. For this gas flow rate, the solution evolves into a steady state within a few seconds. An example of a deformed interface computed in this way is shown in figure 4(b). A liquid film of thickness

$z=0$. We note that Gerris simulations agree with the COMSOL results. The colour scheme indicates the gas speed in metres per second and the thin white lines show streamlines. We can observe that the gas jet impinges onto the lower wall, and then the gas flows in the direction parallel to the wall radially outwards with its speed decreasing as the radial distance increases. We can also observe that a relatively large recirculation zone (eddy) is generated in the gas, and there is also a small, relatively slow eddy in the bottom-right corner. This solution of the gas problem for the interface modelled as a flat solid wall is used to compute the normal and tangential stresses exerted by the gas jet on the interface at different radial locations. Next, we use these stresses in the thin-film equation (3.51) to solve the problem for the liquid film and, therefore, obtain the deformation of the interface resulting from these stresses. The thin-film equation is solved numerically in Matlab using finite-difference approximations for the spatial derivatives and Matlab's ode15s solver for stepping in time. For this gas flow rate, the solution evolves into a steady state within a few seconds. An example of a deformed interface computed in this way is shown in figure 4(b). A liquid film of thickness ![]() $5\ \mathrm {mm}$ was used for illustrative purposes (although we note that the thin-film equation is not expected to be valid for such a thickness). Next, we use this deformed interface as the lower boundary for the gas domain and again assume that it is a solid wall and recompute the solution of the decoupled gas problem. It can be seen in figure 4(b) that the computed solution is qualitatively similar to the one in figure 4(a). We extract the gas stresses from this solution and use these updated stresses to solve the thin-film equation again to obtain an updated steady-stated interface shape. This procedure is repeated until a converged steady-state interface shape is achieved. Typically, we find that for the relatively thin films considered in the present study, 2–3 iterations are sufficient to obtain a converged profile to within graphical accuracy. It is expected that for thicker liquid films and stronger interfacial deformations more iterations might be needed. Other fluid systems with properties further away from the present modelling assumptions are also anticipated to give rise to a more challenging convergence procedure.

$5\ \mathrm {mm}$ was used for illustrative purposes (although we note that the thin-film equation is not expected to be valid for such a thickness). Next, we use this deformed interface as the lower boundary for the gas domain and again assume that it is a solid wall and recompute the solution of the decoupled gas problem. It can be seen in figure 4(b) that the computed solution is qualitatively similar to the one in figure 4(a). We extract the gas stresses from this solution and use these updated stresses to solve the thin-film equation again to obtain an updated steady-stated interface shape. This procedure is repeated until a converged steady-state interface shape is achieved. Typically, we find that for the relatively thin films considered in the present study, 2–3 iterations are sufficient to obtain a converged profile to within graphical accuracy. It is expected that for thicker liquid films and stronger interfacial deformations more iterations might be needed. Other fluid systems with properties further away from the present modelling assumptions are also anticipated to give rise to a more challenging convergence procedure.

Figure 4. Numerical solutions at steady state of the decoupled gas problem for the gas flow rate ![]() $q_g=1\ \mathrm {slpm}$ obtained using COMSOL. The colour scheme illustrates the gas speed in metres per second as indicated in the colour bars and the white thin lines show streamlines. (a) Gas jet impinging onto the interface modelled as a flat wall. (b) Gas jet impinging onto the interface modelled as a deformed wall, with the shape of the deformation obtained by solving the problem for the liquid film using the thin-film equation (3.51) with the gas stresses obtained from the solution shown in (a), when the interface is modelled as a flat wall.

$q_g=1\ \mathrm {slpm}$ obtained using COMSOL. The colour scheme illustrates the gas speed in metres per second as indicated in the colour bars and the white thin lines show streamlines. (a) Gas jet impinging onto the interface modelled as a flat wall. (b) Gas jet impinging onto the interface modelled as a deformed wall, with the shape of the deformation obtained by solving the problem for the liquid film using the thin-film equation (3.51) with the gas stresses obtained from the solution shown in (a), when the interface is modelled as a flat wall.

Next, we will analyse in detail how the normal and tangential stresses exerted by the gas onto the interface behave when the gas flow rate varies for the case when the interface is modelled as a flat solid wall. The results are presented in figure 5. Figures 5(a) and 5(e) show the normal and tangential stresses for the gas flow rate ![]() $q_g$ changing from

$q_g$ changing from ![]() $0.2$ (red dashed lines) to

$0.2$ (red dashed lines) to ![]() $2\ \mathrm {slpm}$ (thick blue solid lines) with the increment of

$2\ \mathrm {slpm}$ (thick blue solid lines) with the increment of ![]() $0.2\ \mathrm {slpm}$. As expected, the stresses grow as the gas flow rate increases. The normal stresses have their maximum values in the centre (at

$0.2\ \mathrm {slpm}$. As expected, the stresses grow as the gas flow rate increases. The normal stresses have their maximum values in the centre (at ![]() $R=0$) and then rapidly decay as the radial distance increases. However, as is apparent from the zoom in figure 5(b), the decay is not monotonic, and there is a region where the normal stress becomes negative and then increases. The tangential stresses vanish at the centre and have their maximum values at a distance slightly away from the centre, at approximately

$R=0$) and then rapidly decay as the radial distance increases. However, as is apparent from the zoom in figure 5(b), the decay is not monotonic, and there is a region where the normal stress becomes negative and then increases. The tangential stresses vanish at the centre and have their maximum values at a distance slightly away from the centre, at approximately ![]() $R=0.1\ \mathrm {cm}$. Then they slowly decay as

$R=0.1\ \mathrm {cm}$. Then they slowly decay as ![]() $R$ increases up to approximately

$R$ increases up to approximately ![]() $R = 1.2\ \mathrm {cm}$. After this distance, the tangential stresses become small and negative, as can be seen in the zoom in figure 5(f). This may be associated with the presence of a slow recirculation zone in the corner, as seen in figure 4. Figures 5(c) and 5(g) show the maxima of the normal and tangential stresses (blue solid lines), respectively, versus the gas flow rate,

$R = 1.2\ \mathrm {cm}$. After this distance, the tangential stresses become small and negative, as can be seen in the zoom in figure 5(f). This may be associated with the presence of a slow recirculation zone in the corner, as seen in figure 4. Figures 5(c) and 5(g) show the maxima of the normal and tangential stresses (blue solid lines), respectively, versus the gas flow rate, ![]() $q_g$, on the log-log scale and suggest a power law behaviour, i.e.

$q_g$, on the log-log scale and suggest a power law behaviour, i.e. ![]() $max\,N_s$ scales approximately as

$max\,N_s$ scales approximately as ![]() $q_g^2$ and

$q_g^2$ and ![]() $max\,T_s$ scales approximately as

$max\,T_s$ scales approximately as ![]() $q_g^{\alpha }$, where

$q_g^{\alpha }$, where ![]() $\alpha \approx 1.2$. Indeed, the red dashed lines in figures 5(c) and 5(g) have slopes

$\alpha \approx 1.2$. Indeed, the red dashed lines in figures 5(c) and 5(g) have slopes ![]() $2$ and

$2$ and ![]() $1.2$, respectively. It can be observed that the scaling for the normal stresses works well for all the values of the flow rate, whereas for the tangential stresses the scaling works better for larger values of the flow rate. We plotted the rescaled normal and tangential stresses

$1.2$, respectively. It can be observed that the scaling for the normal stresses works well for all the values of the flow rate, whereas for the tangential stresses the scaling works better for larger values of the flow rate. We plotted the rescaled normal and tangential stresses ![]() $N_s/q_g^2$ and

$N_s/q_g^2$ and ![]() $T_s/q_g^{1.2}$ in figures 5(d) and 5(h), respectively. For the normal stresses, we can observe that the curves seem to collapse onto the same universal curve (except for the smallest gas flow rate for which there is a slight deviation, see the red curve). For the tangential stresses, in order to build towards a universal scaling, the horizontal axis also needs to be rescaled as

$T_s/q_g^{1.2}$ in figures 5(d) and 5(h), respectively. For the normal stresses, we can observe that the curves seem to collapse onto the same universal curve (except for the smallest gas flow rate for which there is a slight deviation, see the red curve). For the tangential stresses, in order to build towards a universal scaling, the horizontal axis also needs to be rescaled as ![]() $R/q_g^{\beta }$, where

$R/q_g^{\beta }$, where ![]() $\beta \approx 0.3$. The scaling works well only for relatively large gas flow rates. The scaling for the normal stress follows from the fact that the stagnation point pressure (i.e. the pressure or normal stress where the gas jet impinges on the wall at

$\beta \approx 0.3$. The scaling works well only for relatively large gas flow rates. The scaling for the normal stress follows from the fact that the stagnation point pressure (i.e. the pressure or normal stress where the gas jet impinges on the wall at ![]() $R=0$) is associated with the dynamic pressure at the centre line of the gas jet, which follows from Bernoulli's theorem (assuming incompressible flow); see, e.g. Cheslak et al. (Reference Cheslak, Nicholls and Sichel1969) and Clancy (Reference Clancy2006). The scaling then follows from the fact that the dynamic pressure is proportional to the square of the jet velocity, which in turn is proportional to the flow rate

$R=0$) is associated with the dynamic pressure at the centre line of the gas jet, which follows from Bernoulli's theorem (assuming incompressible flow); see, e.g. Cheslak et al. (Reference Cheslak, Nicholls and Sichel1969) and Clancy (Reference Clancy2006). The scaling then follows from the fact that the dynamic pressure is proportional to the square of the jet velocity, which in turn is proportional to the flow rate ![]() $q_g$. The reason for the apparent scaling for the tangential stresses is not immediately obvious from the governing equations and is left as a topic for future investigation.

$q_g$. The reason for the apparent scaling for the tangential stresses is not immediately obvious from the governing equations and is left as a topic for future investigation.

Figure 5. Stresses exerted by the gas onto the gas–liquid interface modelled as a flat solid wall. (a–d) Correspond to normal stresses and (e–h) correspond to tangential stresses. (a,e) The stresses for the gas flow rate ![]() $q_g$ changing from

$q_g$ changing from ![]() $0.2$ to

$0.2$ to ![]() $2\ \mathrm {slpm}$ (red dashed and thick blue solid lines, respectively) with the increment of

$2\ \mathrm {slpm}$ (red dashed and thick blue solid lines, respectively) with the increment of ![]() $0.2\ \mathrm {slpm}$. (b,e) Zooms of the stresses in the regions away from the centre. (c,g) The maxima of the stresses (blue solid lines) versus