1. Introduction

In our previous works, we have analysed the viscous flow through an inhomogeneous granular material. As a first step, Sano (Reference Sano1983) analysed the effect of a macroscopic cylindrical hollow space (hereafter referred to as a ‘cavity’) exposed to an otherwise uniform flow ![]() $U^\infty$ at infinity. The magnitude of the effect depends on the ratio

$U^\infty$ at infinity. The magnitude of the effect depends on the ratio ![]() $\zeta _0 \equiv R_0/\sqrt {k}$, where

$\zeta _0 \equiv R_0/\sqrt {k}$, where ![]() $R_0$ is the cavity size and

$R_0$ is the cavity size and ![]() $k$ is the permeability of the material. As

$k$ is the permeability of the material. As ![]() $\zeta _0$ increases, the velocity at the centre of the circular cylindrical cavity

$\zeta _0$ increases, the velocity at the centre of the circular cylindrical cavity ![]() $v_S^C$ becomes as large as

$v_S^C$ becomes as large as ![]() $3 U^\infty$, whereas the volume flux into that cavity region

$3 U^\infty$, whereas the volume flux into that cavity region ![]() $Q_S$ amounts to two times the volume flux

$Q_S$ amounts to two times the volume flux ![]() $Q_0$ that would pass through the same region without the cavity. The analysis was extended to a three-dimensional cavity. Raja Sekhar & Sano (Reference Raja Sekhar and Sano2000) analysed the effect of a macroscopic spherical cavity exposed to an otherwise uniform flow

$Q_0$ that would pass through the same region without the cavity. The analysis was extended to a three-dimensional cavity. Raja Sekhar & Sano (Reference Raja Sekhar and Sano2000) analysed the effect of a macroscopic spherical cavity exposed to an otherwise uniform flow ![]() $U^\infty$ at infinity. The latter revealed that the velocity at the centre of the cavity

$U^\infty$ at infinity. The latter revealed that the velocity at the centre of the cavity ![]() $v_S^C$ amounts to

$v_S^C$ amounts to ![]() $6 U^\infty$, and that the volume flux into the cavity region

$6 U^\infty$, and that the volume flux into the cavity region ![]() $Q_S$ amounts to

$Q_S$ amounts to ![]() $3 Q_0$ as

$3 Q_0$ as ![]() $\zeta _0$ increases. These results were experimentally verified by laser Doppler velocimetry (LDV) measurement for a cylindrical cavity (Momii Reference Momii1989). Meanwhile, experimental verification of a three-dimensional (3-D) cavity is limited because of the difficulty in experimental set-up and measurement of the 3-D cavity. However, as far as the hemispherical cavity bounded by a transparent plate across the diameter is concerned, the velocity field was measured by an LDV, and good agreement with theory was obtained except for the region very close to the plane boundary (Sano et al. Reference Sano, Sano, Takagi and Yamada2013). Above a certain critical velocity

$\zeta _0$ increases. These results were experimentally verified by laser Doppler velocimetry (LDV) measurement for a cylindrical cavity (Momii Reference Momii1989). Meanwhile, experimental verification of a three-dimensional (3-D) cavity is limited because of the difficulty in experimental set-up and measurement of the 3-D cavity. However, as far as the hemispherical cavity bounded by a transparent plate across the diameter is concerned, the velocity field was measured by an LDV, and good agreement with theory was obtained except for the region very close to the plane boundary (Sano et al. Reference Sano, Sano, Takagi and Yamada2013). Above a certain critical velocity ![]() $U_c^\infty$, the cavity is found to be destroyed from the upstream-side boundary (see Kaneko & Sano Reference Kaneko and Sano2005; Sano & Kaneko Reference Sano and Kaneko2005; Koizumi, Shirahashi & Sano Reference Koizumi, Shirahashi and Sano2009; Sano et al. Reference Sano, Sano, Takagi and Yamada2013).

$U_c^\infty$, the cavity is found to be destroyed from the upstream-side boundary (see Kaneko & Sano Reference Kaneko and Sano2005; Sano & Kaneko Reference Sano and Kaneko2005; Koizumi, Shirahashi & Sano Reference Koizumi, Shirahashi and Sano2009; Sano et al. Reference Sano, Sano, Takagi and Yamada2013).

The interaction of two or more cavities in two-dimensional case are examined both experimentally (Kaneko & Sano Reference Kaneko and Sano2003, Reference Kaneko and Sano2005) and numerically (Sano & Nagata Reference Sano and Nagata2006a; Sano Reference Sano2008, Reference Sano2011). For instance, the interaction of two cavities of equal sizes depends on the centre-to-centre distance ![]() $l$ between them as well as the orientation angle

$l$ between them as well as the orientation angle ![]() $\alpha$ between the centreline connecting the two cavities and the incident flow direction. These studies revealed that (i) the volume flux into the downstream cavity increases in a configuration with smaller

$\alpha$ between the centreline connecting the two cavities and the incident flow direction. These studies revealed that (i) the volume flux into the downstream cavity increases in a configuration with smaller ![]() $\alpha$ and smaller

$\alpha$ and smaller ![]() $l$, e.g. as much as

$l$, e.g. as much as ![]() $10\,\%$ increase was observed for

$10\,\%$ increase was observed for ![]() $| \alpha | \lesssim 15^{\circ}$ and

$| \alpha | \lesssim 15^{\circ}$ and ![]() $l \lesssim 3$. On the other hand, they found that (ii) it decreases for larger

$l \lesssim 3$. On the other hand, they found that (ii) it decreases for larger ![]() $\alpha$ and smaller

$\alpha$ and smaller ![]() $l$, e.g. as much as

$l$, e.g. as much as ![]() $10\,\%$ decrease was observed for

$10\,\%$ decrease was observed for ![]() $|\alpha - 90^{\circ} |\lesssim 15^{\circ}$ and

$|\alpha - 90^{\circ} |\lesssim 15^{\circ}$ and ![]() $l \lesssim 3$. The variations increase as much as

$l \lesssim 3$. The variations increase as much as ![]() $20\,\%$ as the distance

$20\,\%$ as the distance ![]() $l$ becomes small, but decrease to a few per cent as

$l$ becomes small, but decrease to a few per cent as ![]() $l$ becomes as large as 5. They also pointed out the possibility of the collapse of the cavities and fluidisation, which are caused by the local increase of the stress on the cavity boundaries due to the increase of the velocity (Kaneko & Sano Reference Kaneko and Sano2005; Sano & Kaneko Reference Sano and Kaneko2005; Sano & Nagata Reference Sano and Nagata2006a,Reference Sano and Nagatab; Sano Reference Sano2011, Reference Sano2020).

$l$ becomes as large as 5. They also pointed out the possibility of the collapse of the cavities and fluidisation, which are caused by the local increase of the stress on the cavity boundaries due to the increase of the velocity (Kaneko & Sano Reference Kaneko and Sano2005; Sano & Kaneko Reference Sano and Kaneko2005; Sano & Nagata Reference Sano and Nagata2006a,Reference Sano and Nagatab; Sano Reference Sano2011, Reference Sano2020).

Recently, an asymptotic analysis of the two interacting cavities has been made in the 2-D case (Sano Reference Sano2020), and 3-D case (Sano, Karmakar & Sekhar Reference Sano, Karmakar and Sekhar2022). In the former, two circular cylindrical cavities are arranged in an arbitrary configuration, and the velocity, volume flux, stress distribution on the cavity boundaries, etc. are analysed by taking account of the effect of the other cavity asymptotically. The latter theory is applied to explain the experimental results on the collapse of two 2-D cavities, and the dependence of the position of the onset of collapse on the orientation angle ![]() $\alpha$ is elucidated. The analysis is extended to the 3-D case, where two spherical cavities of the same radius

$\alpha$ is elucidated. The analysis is extended to the 3-D case, where two spherical cavities of the same radius ![]() $R_0$ are arranged along the stream. Making use of the axisymmetry and the fore–aft symmetry, the effect of the other cavity is asymptotically taken into account up to the order of

$R_0$ are arranged along the stream. Making use of the axisymmetry and the fore–aft symmetry, the effect of the other cavity is asymptotically taken into account up to the order of ![]() $(R_0/l)^4$. The dependence of the velocity, volume flux, stress distribution on the cavity boundaries, etc. on the parameter

$(R_0/l)^4$. The dependence of the velocity, volume flux, stress distribution on the cavity boundaries, etc. on the parameter ![]() $\zeta _0$ and the separation distance of the cavities

$\zeta _0$ and the separation distance of the cavities ![]() $l$ are examined. For practical application, however, we need further analysis on two or more 3-D cavities of unequal sizes in a general configuration.

$l$ are examined. For practical application, however, we need further analysis on two or more 3-D cavities of unequal sizes in a general configuration.

In order to access a solution that is applicable to a general configuration and is valid for any arbitrary position ![]() $r$, one may develop a numerical solution that is based on computational approaches like the finite element, finite volume or boundary integral equations. Indeed, there is a preliminary numerical simulation of two spherical cavities of radius

$r$, one may develop a numerical solution that is based on computational approaches like the finite element, finite volume or boundary integral equations. Indeed, there is a preliminary numerical simulation of two spherical cavities of radius ![]() $a$ exposed to a uniform flow based on a two-fluid model (Sano Reference Sano2008). Although the latter provides the flow field in special cases such as

$a$ exposed to a uniform flow based on a two-fluid model (Sano Reference Sano2008). Although the latter provides the flow field in special cases such as ![]() $\alpha =0,\ {\rm \pi}/3$ and

$\alpha =0,\ {\rm \pi}/3$ and ![]() $\alpha ={\rm \pi} /2$ etc., under fixed

$\alpha ={\rm \pi} /2$ etc., under fixed ![]() $l/a=3$, as well as the volume flux

$l/a=3$, as well as the volume flux ![]() $l/a$ vs

$l/a$ vs ![]() $\alpha$ diagram into respective cavities (

$\alpha$ diagram into respective cavities (![]() $l$ is the centre-to-centre distance of the two cavities;

$l$ is the centre-to-centre distance of the two cavities; ![]() $\alpha$ is the orientational angle), there is not much literature available in this direction. In this paper, the asymptotic analysis is extended to the interaction of two spherical cavities of radius

$\alpha$ is the orientational angle), there is not much literature available in this direction. In this paper, the asymptotic analysis is extended to the interaction of two spherical cavities of radius ![]() $a$ and

$a$ and ![]() $b$ with arbitrary configuration

$b$ with arbitrary configuration ![]() $(l, \alpha )$. Although the present analysis is limited up to the order of

$(l, \alpha )$. Although the present analysis is limited up to the order of ![]() $(a/l)^3$ or

$(a/l)^3$ or ![]() $(b/l)^3$, it allows cavities of arbitrary sizes and orientation. Particular attention is paid to the interaction of two cavities of equal size, and the dependences of the volume flux on the orientation

$(b/l)^3$, it allows cavities of arbitrary sizes and orientation. Particular attention is paid to the interaction of two cavities of equal size, and the dependences of the volume flux on the orientation ![]() $\alpha$ are examined. This is with a view to elucidating the mechanism of the collapse of cavities, as observed in 2-D experiments and the numerical simulation mentioned above, which may predict landslides, the collapse of the river banks and cliffs at times of heavy rainfall as well as create the new water channels in an otherwise impermeable granular tissues as in angiogenesis.

$\alpha$ are examined. This is with a view to elucidating the mechanism of the collapse of cavities, as observed in 2-D experiments and the numerical simulation mentioned above, which may predict landslides, the collapse of the river banks and cliffs at times of heavy rainfall as well as create the new water channels in an otherwise impermeable granular tissues as in angiogenesis.

Note that the characteristics of the collapse, deformation and movement of our macroscopic cavity in a granular material are different from the behaviour of the void region in a fluidised bed observed in a solid–gas or fluid–gas transportation or processing system. In a solid–gas system such as a vertically set reactor of packed bed, void spaces in a granular material grow with the upward flow of gas. Here, the solid phase (the granular material) is dense and regarded as a continuous phase, among which small void domains (gas phase, sometimes referred to as ‘bubbles’) are distributed. Under a vertical stream, initially small void spaces side-by-side merge and/or catch up with each other as they rise up the packed bed of particles, which grow in size, and continue upward motion with acceleration by hydrostatic pressure. The macroscopic interface that distinguishes the solid and gas phases may depend on many factors, such as flow rate of the gas phase, concentration and distribution (or homogeneity) of each phase, ratio of material densities, etc. so that the boundary of these ‘bubbles’ may not necessarily be clear, but their direction of motion is the same as the main gas flow directed upward. With the increase of flow, the whole system turns into a pneumatic transport regime, through bubbling fluidisation and turbulent fluidisation (see Davidson & Harrison Reference Davidson and Harrison1963; Davidson, Harrison & Guedes de Carvalho Reference Davidson, Harrison and Guedes de Carvalho1977; Grace Reference Grace1986; Holdich Reference Holdich2002; Yang Reference Yang2003; Kunii & Levenspiel Reference Kunii and Levenspiel2013).

On the other hand, in the fluid–gas system, where fluid is the continuous phase, bubbles rise through the fluid phase, and their front boundaries form clear convex interfaces. Depending on the Reynolds number, Eötös number and Morton number, the rear side of the bubble may be dimpled, skirted or irregularly deformed, sometimes associated with a wobbling motion in addition to the convective motion by the upward main stream (Clift, Grace & Weber Reference Clift, Grace and Weber1978). Even in the absence of the main stream, bubbles move upwards under gravitational acceleration. In this case, if the bubble is viewed from the coordinate system fixed to the bubble, the latter is observed to be stationary, and is exposed to a uniform flow at infinity, which reveals the motion toward the upstream direction. The latter situation looks similar to our void space in a granular material exposed to a uniform flow at infinity. However, the difference lies in the presence of flux into the cavity, which obscures the front boundary. Our granular material with macroscopic cavity, which may be called a heterogeneous granular material, is in a quasi-equilibrium state, so that the mechanical structure is maintained by solid contact forces between highly concentrated grains. Viewed as a two-phase system, it may be regarded as a ‘fixed-bed’ regime as classified in the literature (Grace Reference Grace1986), but the flow direction is free from gravity in our system. So far, the fixed-bed regime has seemed to attract little attention in an industrial application or particle technology for the purpose of transportation of two-phase flows under gravity. Although a description of the slowly moving ‘bubble’ has been found, in which gas flow bends toward the bubble (Davidson & Harrison Reference Davidson and Harrison1963; Holdich Reference Holdich2002; Yang Reference Yang2003; Kunii & Levenspiel Reference Kunii and Levenspiel2013), the direction of motion of the ‘bubble’ is the same as that of the gas flow. In the latter, determination of minimum fluidisation velocity focuses on the force balance between the gravitational force and fluid drag, in which the bed is well expanded with the increase of fluid flow in the upward direction. However, in a far earlier stage before such an expansion occurs in which the main bodies of the particles are still in solid contact, the configuration change of grains at the boundary of a void space (larger than the interstices of particles) can trigger the global scale structural change. Thus, the prediction of an accurate velocity of the gas flow mentioned above will be important in fluidisation technology, to which such inhomogeneity of the gas phase (void space) is decisive. The transition from the fixed-bed regime to another regime is much more important in basically solid structures, where the local change of structure can trigger catastrophic phenomena, such as landslides, collapse of river banks and cliffs. As will be shown in this paper, the direction of propagation of the collapse in our case is opposite to the flow, which is a striking contrast to the void space propagation in a vertically set reactor of a solid–gas transportation system. Although our analytical approach is limited to a very early stage of the collapse, in which the cavity remains almost spherical, it provides the most vulnerable configuration of cavities and the direction of spread of the void space. Our findings will provide a clue to the mechanism of the collapse of the material by the enhanced fluid mechanical force, and will bridge the gap between fluidisation and solidification in granular materials (see Campbell Reference Campbell1990; MiDi Reference MiDi2004; Aranson & Tsimring Reference Aranson and Tsimring2006; Forterre & Pouliquen Reference Forterre and Pouliquen2008; Gray Reference Gray2018; Morris Reference Morris2020).

In the following, we show the method of calculation (§ 2), results on the flow and stresses due to the interaction of 3-D cavities (§ 3) and discuss (§ 4) their characteristics and physical implications for the collapse of granular material, based on the present calculation and the previous one. Conclusions (§ 5) and appendices follow.

2. Method of calculation

2.1. Governing equations

The basic equations we adopt are the equations of continuity for an incompressible viscous flow

the generalised Darcy equation in a granular material

and the Stokes equation inside a clear fluid region

where ![]() ${\boldsymbol v}^*$ and

${\boldsymbol v}^*$ and ![]() $p^*$ are the velocity and the pressure, respectively, with physical dimensions,

$p^*$ are the velocity and the pressure, respectively, with physical dimensions, ![]() $\mu$ is the viscosity of the fluid and

$\mu$ is the viscosity of the fluid and ![]() $k$ is the permeability of the granular material. The existing literature indicates that, although the ratio

$k$ is the permeability of the granular material. The existing literature indicates that, although the ratio ![]() $\mu _e / \mu$ (

$\mu _e / \mu$ (![]() $\mu _e$ is the effective viscosity of fluid in the granular material) is of some interest, there is no precise mechanism to define it accurately. Accordingly, different models have been used to estimate the dependency of the effective viscosity

$\mu _e$ is the effective viscosity of fluid in the granular material) is of some interest, there is no precise mechanism to define it accurately. Accordingly, different models have been used to estimate the dependency of the effective viscosity ![]() $\mu _e$ on the viscosity

$\mu _e$ on the viscosity ![]() $\mu$ inside a porous medium (see Givler & Altobelli Reference Givler and Altobelli1994; Martys, Bentz & Garboczi Reference Martys, Bentz and Garboczi1994; Ochoa-Tapia & Whitaker Reference Ochoa-Tapia and Whitaker1995; Nield & Bejan Reference Nield and Bejan2013). In order to avoid any ambiguity, several authors considered the ratio

$\mu$ inside a porous medium (see Givler & Altobelli Reference Givler and Altobelli1994; Martys, Bentz & Garboczi Reference Martys, Bentz and Garboczi1994; Ochoa-Tapia & Whitaker Reference Ochoa-Tapia and Whitaker1995; Nield & Bejan Reference Nield and Bejan2013). In order to avoid any ambiguity, several authors considered the ratio ![]() $\mu _e / \mu =1$ (see Koch, Hill & Sangani Reference Koch, Hill and Sangani1998; Masoud, Stone & Shelley Reference Masoud, Stone and Shelley2013), which is also the present case. For the general case

$\mu _e / \mu =1$ (see Koch, Hill & Sangani Reference Koch, Hill and Sangani1998; Masoud, Stone & Shelley Reference Masoud, Stone and Shelley2013), which is also the present case. For the general case ![]() $\mu _e/ \mu \ne 1$, see Appendix A. We impose the continuity of velocity and stress at the boundary of the cavity, which were satisfactorily satisfied by our previous analysis and experiments.

$\mu _e/ \mu \ne 1$, see Appendix A. We impose the continuity of velocity and stress at the boundary of the cavity, which were satisfactorily satisfied by our previous analysis and experiments.

2.2. Flow through a single spherical cavity

2.2.1. General expressions

We have already obtained the flow through a macroscopic spherical cavity in an otherwise homogeneous granular material (Sano et al. Reference Sano, Karmakar and Sekhar2022). The variables are made non-dimensional by the characteristic length ![]() $\sqrt {k}$ (microscopic scale) and the typical size of the cavity

$\sqrt {k}$ (microscopic scale) and the typical size of the cavity ![]() $R_0$ (macroscopic scale), velocity

$R_0$ (macroscopic scale), velocity ![]() $U^\infty$ and viscosity

$U^\infty$ and viscosity ![]() $\mu$ as

$\mu$ as

so that we have the basic equations in non-dimensional form

where ![]() $\zeta _0 = R_0/ \sqrt {k}$. If we consider a cavity of radius

$\zeta _0 = R_0/ \sqrt {k}$. If we consider a cavity of radius ![]() $a^*$ (or in normalised form

$a^*$ (or in normalised form ![]() $a =a^*/R_0$) exposed to an otherwise uniform flow

$a =a^*/R_0$) exposed to an otherwise uniform flow ![]() $U_j^\infty$ in the

$U_j^\infty$ in the ![]() $x_j$ direction, the flow field in non-dimensional form is given as follows.

$x_j$ direction, the flow field in non-dimensional form is given as follows.

(i) Outside cavity (![]() $r \ge a$)

$r \ge a$)

where

(ii) Inside cavity (![]() $r \le a$)

$r \le a$)

where

\begin{equation} \left.\begin{gathered} A(a)={-} \frac{3\zeta_0^2 (1+\zeta_0 a)}{\varDelta_0 (a)},\quad B(a)=\frac{\varDelta_2(a)}{\varDelta_0 (a)},\\ \varDelta_2(a)=3[2(\zeta_0 a)^3+7(\zeta_0 a)^2+15 \zeta_0 a +15]. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} A(a)={-} \frac{3\zeta_0^2 (1+\zeta_0 a)}{\varDelta_0 (a)},\quad B(a)=\frac{\varDelta_2(a)}{\varDelta_0 (a)},\\ \varDelta_2(a)=3[2(\zeta_0 a)^3+7(\zeta_0 a)^2+15 \zeta_0 a +15]. \end{gathered}\right\} \end{equation}2.2.2. Flow through a single spherical cavity under  $U^\infty$ in the

$U^\infty$ in the  $x$ direction

$x$ direction

For a particular case ![]() $U_j^\infty = \delta _{jx}$, the above expressions are described as

$U_j^\infty = \delta _{jx}$, the above expressions are described as

In terms of the spherical coordinate system, with the ![]() $x$ axis along the flow direction at infinity, they are for

$x$ axis along the flow direction at infinity, they are for ![]() $r \ge a$

$r \ge a$

and for ![]() $r \le a$

$r \le a$

2.3. Interaction of two spherical cavities

We consider two spherical cavities ![]() ${{\rm C}a}$ and

${{\rm C}a}$ and ![]() ${{\rm C}b}$ in a general configuration. This situation is described by first choosing the

${{\rm C}b}$ in a general configuration. This situation is described by first choosing the ![]() $x$ axis along the uniform flow, which passes the centre of the cavity

$x$ axis along the uniform flow, which passes the centre of the cavity ![]() ${{\rm C}a}$ (denoted by

${{\rm C}a}$ (denoted by ![]() $O$). Next, we choose the

$O$). Next, we choose the ![]() $y$ axis such that it passes the centre of cavity

$y$ axis such that it passes the centre of cavity ![]() ${{\rm C}a}$ and that the

${{\rm C}a}$ and that the ![]() $xy$ plane includes the centre of the other cavity

$xy$ plane includes the centre of the other cavity ![]() ${{\rm C}b}$ (denoted by

${{\rm C}b}$ (denoted by ![]() $O'$). The third axis

$O'$). The third axis ![]() $z$ is chosen perpendicular to the

$z$ is chosen perpendicular to the ![]() $xy$ plane, so that the

$xy$ plane, so that the ![]() $x, y, z$ axes form the right-handed Cartesian coordinate system (see figure 1). We denote the radius of the cavities

$x, y, z$ axes form the right-handed Cartesian coordinate system (see figure 1). We denote the radius of the cavities ![]() ${{\rm C}a}$ and

${{\rm C}a}$ and ![]() ${{\rm C}b}$ by

${{\rm C}b}$ by ![]() $a$ and

$a$ and ![]() $b$, respectively, and the centre-to-centre distance of the cavities by

$b$, respectively, and the centre-to-centre distance of the cavities by ![]() $l$. We assume non-overlapping cavities (

$l$. We assume non-overlapping cavities (![]() $l > a+b$), and denote the angle of orientation of the line connecting the centres of the two cavities from the

$l > a+b$), and denote the angle of orientation of the line connecting the centres of the two cavities from the ![]() $x$ direction by

$x$ direction by ![]() $\alpha$. We also take a spherical polar coordinate system

$\alpha$. We also take a spherical polar coordinate system ![]() $(r, \theta, \phi )$ with its origin at O, where

$(r, \theta, \phi )$ with its origin at O, where ![]() $\theta$ is the zenith angle measured from the

$\theta$ is the zenith angle measured from the ![]() $x$ axis. We denote the position vector of

$x$ axis. We denote the position vector of ![]() ${\boldsymbol{OP}}$ by

${\boldsymbol{OP}}$ by ![]() $\boldsymbol r$,

$\boldsymbol r$, ![]() ${\boldsymbol{O'P}}$ by

${\boldsymbol{O'P}}$ by ![]() ${\boldsymbol r}'$ and

${\boldsymbol r}'$ and ![]() ${\boldsymbol{OO'}}$ by

${\boldsymbol{OO'}}$ by ![]() $\boldsymbol l$. Then the distance

$\boldsymbol l$. Then the distance ![]() $r' (\equiv |{\boldsymbol r}'|)$ is given by

$r' (\equiv |{\boldsymbol r}'|)$ is given by ![]() $r' = \sqrt {l^2+r^2-2rl\cos (\theta -\alpha )+z^2}$, where

$r' = \sqrt {l^2+r^2-2rl\cos (\theta -\alpha )+z^2}$, where ![]() $r = |{\boldsymbol r}|$.

$r = |{\boldsymbol r}|$.

Figure 1. Interaction of two cavities.

2.3.1. Flow outside the cavity

(i) Flow outside the two independent cavities

The flow field around a cavity ![]() ${{\rm C}a}$ exposed to a uniform velocity

${{\rm C}a}$ exposed to a uniform velocity ![]() $U^\infty \ (=1)$ in the

$U^\infty \ (=1)$ in the ![]() $x$ direction at infinity, (2.4a,b) is expressed by

$x$ direction at infinity, (2.4a,b) is expressed by

and the flow around a cavity ![]() ${{\rm C}b}$ is similarly given. In the presence of two independent cavities, we assume that the total flow field outside of the cavities is described by the superposition

${{\rm C}b}$ is similarly given. In the presence of two independent cavities, we assume that the total flow field outside of the cavities is described by the superposition

(ii) Flow outside the two interacting cavities

To increase the accuracy taking account of the effect of the other cavity, we estimate the induced flow ![]() $\delta {\boldsymbol U}(O)$ near the cavity

$\delta {\boldsymbol U}(O)$ near the cavity ![]() ${{\rm C}a}$ due to the cavity

${{\rm C}a}$ due to the cavity ![]() ${{\rm C}b}$ assuming that the two cavities are sufficiently far apart (

${{\rm C}b}$ assuming that the two cavities are sufficiently far apart (![]() $l \gg a+b$)

$l \gg a+b$)

\begin{align} (\delta {U}_x^\infty (O), \delta { U}_y^\infty (O), \delta {U}_z^\infty (O)) &\equiv \left( T_{xx}({\boldsymbol r}',b), T_{yx}({\boldsymbol r}',b), T_{zx}({\boldsymbol r}',b) \right)|_{O}\nonumber\\ &=\frac{D_b}{l^3} ( K_x, K_y, 0)+O\left(\frac{r}{l}\right)^4, \end{align}

\begin{align} (\delta {U}_x^\infty (O), \delta { U}_y^\infty (O), \delta {U}_z^\infty (O)) &\equiv \left( T_{xx}({\boldsymbol r}',b), T_{yx}({\boldsymbol r}',b), T_{zx}({\boldsymbol r}',b) \right)|_{O}\nonumber\\ &=\frac{D_b}{l^3} ( K_x, K_y, 0)+O\left(\frac{r}{l}\right)^4, \end{align}where

and ![]() $D_b = D(b)$ for brevity. The latter is the additional uniform flow on the cavity

$D_b = D(b)$ for brevity. The latter is the additional uniform flow on the cavity ![]() ${{\rm C}a}$ due to cavity

${{\rm C}a}$ due to cavity ![]() ${{\rm C}b}$. Similarly, the additional uniform flow on the cavity

${{\rm C}b}$. Similarly, the additional uniform flow on the cavity ![]() ${{\rm C}b}$ due to cavity

${{\rm C}b}$ due to cavity ![]() ${{\rm C}a}$ is

${{\rm C}a}$ is

Taking into account of the exponential decay of the Darcylet, and the ![]() $r^{-3}$ decay of the dipole flow, we assume the local flow around respective cavities up to order

$r^{-3}$ decay of the dipole flow, we assume the local flow around respective cavities up to order ![]() $O(l^{-3})$ will be generated by the uniform flow

$O(l^{-3})$ will be generated by the uniform flow ![]() $\delta _{xj} + \delta {U}_j^\infty$. In this approach, the velocity around the cavity

$\delta _{xj} + \delta {U}_j^\infty$. In this approach, the velocity around the cavity ![]() ${{\rm C}a}$ is given by

${{\rm C}a}$ is given by

Local velocity field around cavity ![]() ${{\rm C}b}$ is similarly given by shifting the origin of the coordinate system to

${{\rm C}b}$ is similarly given by shifting the origin of the coordinate system to ![]() $O'$, describing the position vector

$O'$, describing the position vector ![]() ${\boldsymbol r}'$ from the latter and exchanging the roles of

${\boldsymbol r}'$ from the latter and exchanging the roles of ![]() $a$ and

$a$ and ![]() $b$.

$b$.

To describe the global flow field we examine the superposition of (2.26a–c) and the similar flow field in which the roles of ![]() ${{\rm C}a}$ and

${{\rm C}a}$ and ![]() ${{\rm C}b}$ are exchanged. However, the asymptotic behaviour

${{\rm C}b}$ are exchanged. However, the asymptotic behaviour ![]() $(r \gg 1)$ of the above yields

$(r \gg 1)$ of the above yields

which should be ![]() ${v}_x=1,\ {v}_y={v}_z=0$. Thus, our global flow field should be described by subtracting the flow field

${v}_x=1,\ {v}_y={v}_z=0$. Thus, our global flow field should be described by subtracting the flow field

from the simply superposed flow field (for this renormalisation, see also Appendix B), so that we have

\begin{align} {v}_x &= [1+T_{xx}({\boldsymbol r},a)] \left(1+\frac{D_b}{l^3} K_x\right) +T_{xy}({\boldsymbol r},a)\left(\frac{D_b}{l^3}K_y\right) \nonumber\\ &\quad +[1+T_{xx}({\boldsymbol r'},b)] \left(1+\frac{D_a}{l^3} K_x\right) +T_{xy}({\boldsymbol r'},b)\left(\frac{D_a}{l^3}K_y\right) -1-\frac{K_x}{l^3} (D_a+D_b), \end{align}

\begin{align} {v}_x &= [1+T_{xx}({\boldsymbol r},a)] \left(1+\frac{D_b}{l^3} K_x\right) +T_{xy}({\boldsymbol r},a)\left(\frac{D_b}{l^3}K_y\right) \nonumber\\ &\quad +[1+T_{xx}({\boldsymbol r'},b)] \left(1+\frac{D_a}{l^3} K_x\right) +T_{xy}({\boldsymbol r'},b)\left(\frac{D_a}{l^3}K_y\right) -1-\frac{K_x}{l^3} (D_a+D_b), \end{align} \begin{align} {v}_y &= T_{yx}({\boldsymbol r},a) \left(1+\frac{D_b}{l^3} K_x\right)+ [1+T_{yy}({\boldsymbol r},a)]\left( \frac{D_b}{l^3}K_y\right) \nonumber\\ &\quad +T_{yx}({\boldsymbol r'},b) \left(1+\frac{D_a}{l^3} K_x\right) + [1+T_{yy}({\boldsymbol r'},b)]\left( \frac{D_a}{l^3}K_y\right) -\frac{K_y}{l^3} (D_a+D_b), \end{align}

\begin{align} {v}_y &= T_{yx}({\boldsymbol r},a) \left(1+\frac{D_b}{l^3} K_x\right)+ [1+T_{yy}({\boldsymbol r},a)]\left( \frac{D_b}{l^3}K_y\right) \nonumber\\ &\quad +T_{yx}({\boldsymbol r'},b) \left(1+\frac{D_a}{l^3} K_x\right) + [1+T_{yy}({\boldsymbol r'},b)]\left( \frac{D_a}{l^3}K_y\right) -\frac{K_y}{l^3} (D_a+D_b), \end{align} \begin{align} {v}_z &= T_{zx}({\boldsymbol r},a)\left(1+\frac{D_b}{l^3} K_x\right) +T_{zy}({\boldsymbol r},a) \left( \frac{D_b}{l^3} K_y\right) +T_{zx}({\boldsymbol r'},b)\left(1+\frac{D_a}{l^3} K_x\right) \nonumber\\ &\quad +T_{zy}({\boldsymbol r'},b) \left( \frac{D_a}{l^3} K_y\right). \end{align}

\begin{align} {v}_z &= T_{zx}({\boldsymbol r},a)\left(1+\frac{D_b}{l^3} K_x\right) +T_{zy}({\boldsymbol r},a) \left( \frac{D_b}{l^3} K_y\right) +T_{zx}({\boldsymbol r'},b)\left(1+\frac{D_a}{l^3} K_x\right) \nonumber\\ &\quad +T_{zy}({\boldsymbol r'},b) \left( \frac{D_a}{l^3} K_y\right). \end{align}2.3.2. Flow inside the cavity

(i) Local flow field outside of cavities in terms of spherical coordinate system

To obtain the flow field inside the cavity ![]() ${{\rm C}a}$, we rewrite (2.26a)–(2.26c) to a local spherical polar coordinate system

${{\rm C}a}$, we rewrite (2.26a)–(2.26c) to a local spherical polar coordinate system ![]() $(r, \theta, \phi )$, whose origin is at the centre of cavity

$(r, \theta, \phi )$, whose origin is at the centre of cavity ![]() ${{\rm C}a}$. The polar axis is chosen along the

${{\rm C}a}$. The polar axis is chosen along the ![]() $x$ axis from which the zenith angle

$x$ axis from which the zenith angle ![]() $\theta$ is measured, while the azimuthal angle

$\theta$ is measured, while the azimuthal angle ![]() $\phi$ is measured from the

$\phi$ is measured from the ![]() $y$ axis. By these choices, we have

$y$ axis. By these choices, we have

Relations between the velocity components in the present spherical coordinate system and the Cartesian coordinates are

\begin{equation}

\left({\begin{array}{@{}c@{}} {{v_r}}\\ {{v_\theta }}\\

{{v_\phi }} \end{array}} \right) = \left(

{\begin{array}{@{}ccc@{}} {\cos \theta } & {\sin \theta \cos

\phi } & {\sin \theta \sin \phi }\\ { - \sin \theta } &

{\cos \theta \cos \phi } & {\cos \theta \sin \phi }\\ 0 & {

- \sin \phi } & {\cos \phi } \end{array}} \right)\left(

{\begin{array}{@{}c@{}} {{v_x}}\\ {{v_y}}\\ {{v_z}}

\end{array}} \right).

\end{equation}

\begin{equation}

\left({\begin{array}{@{}c@{}} {{v_r}}\\ {{v_\theta }}\\

{{v_\phi }} \end{array}} \right) = \left(

{\begin{array}{@{}ccc@{}} {\cos \theta } & {\sin \theta \cos

\phi } & {\sin \theta \sin \phi }\\ { - \sin \theta } &

{\cos \theta \cos \phi } & {\cos \theta \sin \phi }\\ 0 & {

- \sin \phi } & {\cos \phi } \end{array}} \right)\left(

{\begin{array}{@{}c@{}} {{v_x}}\\ {{v_y}}\\ {{v_z}}

\end{array}} \right).

\end{equation}

In this coordinate system, the flow outside of the cavity ![]() ${\rm C}{a}\ (r\ge a)$ is given by

${\rm C}{a}\ (r\ge a)$ is given by

where

\begin{equation} \left.\begin{gathered} L(r,a) = C(a)[f(r)-g(r)]\exp({-\zeta_0 r})+\frac{2D(a)}{r^3},\\ M(r,a) = C(a) f(r) \exp({-\zeta_0 r})-\frac{D(a)}{r^3}, \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} L(r,a) = C(a)[f(r)-g(r)]\exp({-\zeta_0 r})+\frac{2D(a)}{r^3},\\ M(r,a) = C(a) f(r) \exp({-\zeta_0 r})-\frac{D(a)}{r^3}, \end{gathered}\right\} \end{equation}

and ![]() $f(r),\ g(r)$ are the same as those defined in (2.6a,b). The pressure and stress components up to

$f(r),\ g(r)$ are the same as those defined in (2.6a,b). The pressure and stress components up to ![]() $O((r/l)^3)$ are as follows:

$O((r/l)^3)$ are as follows:

\begin{align} \tau_{rr} &= \left[\zeta_0^2 r +\frac{4}{r} C(a) g(r)\exp({-\zeta_0 r})-D(a) \left(\frac{\zeta_0^2}{r^2}+\frac{12}{r^4}\right)\right] \nonumber\\ &\quad \times\left[\left(1+\frac{D_b}{l^3}K_x\right)\cos\theta+ \frac{D_b}{l^3} K_y\sin\theta\cos\phi \right], \end{align}

\begin{align} \tau_{rr} &= \left[\zeta_0^2 r +\frac{4}{r} C(a) g(r)\exp({-\zeta_0 r})-D(a) \left(\frac{\zeta_0^2}{r^2}+\frac{12}{r^4}\right)\right] \nonumber\\ &\quad \times\left[\left(1+\frac{D_b}{l^3}K_x\right)\cos\theta+ \frac{D_b}{l^3} K_y\sin\theta\cos\phi \right], \end{align} \begin{align} \tau_{\theta r} &= \left[C(a)\left(\frac{\zeta_0^3}{r}+\frac{3\zeta_0^2}{r^2}+\frac{6\zeta_0}{r^3}+ \frac{6}{r^4}\right)\exp({-\zeta_0 r}) -\frac{6D(a)}{r^4}\right] \nonumber\\ &\quad \times\left[\left(1+\frac{D_b}{l^3}K_x\right)\sin\theta-\frac{D_b}{l^3} K_y \cos\theta\cos\phi \right], \end{align}

\begin{align} \tau_{\theta r} &= \left[C(a)\left(\frac{\zeta_0^3}{r}+\frac{3\zeta_0^2}{r^2}+\frac{6\zeta_0}{r^3}+ \frac{6}{r^4}\right)\exp({-\zeta_0 r}) -\frac{6D(a)}{r^4}\right] \nonumber\\ &\quad \times\left[\left(1+\frac{D_b}{l^3}K_x\right)\sin\theta-\frac{D_b}{l^3} K_y \cos\theta\cos\phi \right], \end{align}

The flow pertaining to cavity ![]() ${{\rm C}b}$ is similarly given with replacement of

${{\rm C}b}$ is similarly given with replacement of ![]() $a, b, x, \ldots, r$ by

$a, b, x, \ldots, r$ by ![]() $b, a, x', \ldots, r'$, using the local spherical polar coordinate system with origin

$b, a, x', \ldots, r'$, using the local spherical polar coordinate system with origin ![]() $O'$.

$O'$.

(ii) Flow inside the respective cavities

Results shown in the previous subsections suggest that the flow inside cavity ![]() ${{\rm C}a}$ is given by the type of solution (2.9), where the asymptotic flow

${{\rm C}a}$ is given by the type of solution (2.9), where the asymptotic flow ![]() $[1+( D_b/l^3) K_x+O(D_b / l^{4}) ] U^\infty$ in the

$[1+( D_b/l^3) K_x+O(D_b / l^{4}) ] U^\infty$ in the ![]() $x$ direction and the one

$x$ direction and the one ![]() $(D_b/l^3)[K_y+O(D_b / l^{4}) ] U^\infty$ in the

$(D_b/l^3)[K_y+O(D_b / l^{4}) ] U^\infty$ in the ![]() $y$ direction are superposed, so that the flow inside the cavity

$y$ direction are superposed, so that the flow inside the cavity ![]() ${{\rm C}a}$ is expected to be of the form

${{\rm C}a}$ is expected to be of the form

The flow inside the cavity ![]() ${{\rm C}b}$ is similarly described by exchanging

${{\rm C}b}$ is similarly described by exchanging ![]() $a, b, x, y, r$ with

$a, b, x, y, r$ with ![]() $b, a, x', y', r'$.

$b, a, x', y', r'$.

In terms of the local spherical polar coordinate system pertaining to cavity ![]() ${{\rm C}a}$, velocity components inside the cavity (2.36a–c) are given by

${{\rm C}a}$, velocity components inside the cavity (2.36a–c) are given by

The coefficients ![]() $A(a), B(a), C(a), D(a)$ are determined by the continuity of the velocity components and stress components at the boundary

$A(a), B(a), C(a), D(a)$ are determined by the continuity of the velocity components and stress components at the boundary ![]() $r=a$, which are the same as (2.10a,b) and (2.7a,b). The flow inside the cavity

$r=a$, which are the same as (2.10a,b) and (2.7a,b). The flow inside the cavity ![]() ${{\rm C}b}$ is similarly determined by exchanging the roles of cavities

${{\rm C}b}$ is similarly determined by exchanging the roles of cavities ![]() ${{\rm C}a}$ and

${{\rm C}a}$ and ![]() ${{\rm C}b}$.

${{\rm C}b}$.

3. Results

In a typical granular material we encounter, such as sand of grain size ![]() $0.1 \sim 0.25$ mm, the observed value of the permeability is

$0.1 \sim 0.25$ mm, the observed value of the permeability is ![]() $k \sim 2 \times 10^{-7}\,\textrm {cm}^2$, which implies that the value of

$k \sim 2 \times 10^{-7}\,\textrm {cm}^2$, which implies that the value of ![]() $\zeta _0$ is

$\zeta _0$ is ![]() $2 \times 10^3$ for a cavity of 1 cm. We have shown in our previous papers (Sano Reference Sano1983; Raja Sekhar & Sano Reference Raja Sekhar and Sano2000; Sano et al. Reference Sano, Karmakar and Sekhar2022) that the

$2 \times 10^3$ for a cavity of 1 cm. We have shown in our previous papers (Sano Reference Sano1983; Raja Sekhar & Sano Reference Raja Sekhar and Sano2000; Sano et al. Reference Sano, Karmakar and Sekhar2022) that the ![]() $\zeta _0$-effect saturates at around

$\zeta _0$-effect saturates at around ![]() $\zeta _0 \approx 100$. Therefore, we choose the magnitude of

$\zeta _0 \approx 100$. Therefore, we choose the magnitude of ![]() $\zeta _0 = 100$ as a consistent value in the following, unless otherwise stated. As far as the special case

$\zeta _0 = 100$ as a consistent value in the following, unless otherwise stated. As far as the special case ![]() $\alpha = 0$ of the present calculation is concerned, our previous result (Sano et al. (Reference Sano, Karmakar and Sekhar2022), denoted here JFM2022), which is valid up to

$\alpha = 0$ of the present calculation is concerned, our previous result (Sano et al. (Reference Sano, Karmakar and Sekhar2022), denoted here JFM2022), which is valid up to ![]() $O(1/l^4)$, agrees with the present analysis up to

$O(1/l^4)$, agrees with the present analysis up to ![]() $O(1/l^3)$ by the change of renormalisation. More precisely, the normalisation of

$O(1/l^3)$ by the change of renormalisation. More precisely, the normalisation of ![]() $\varPsi ^e$ ((4.2) of our JFM2022 paper) is made to all expressions by multiplying by a factor of

$\varPsi ^e$ ((4.2) of our JFM2022 paper) is made to all expressions by multiplying by a factor of ![]() $1/(1+2E/l^3)$, which is equal to

$1/(1+2E/l^3)$, which is equal to ![]() $\varDelta / \varDelta _0$ ((4.15a–e) and (4.16a–c)). Then, the normalised

$\varDelta / \varDelta _0$ ((4.15a–e) and (4.16a–c)). Then, the normalised ![]() $\varPsi$ differs from the

$\varPsi$ differs from the ![]() $\alpha =0$ of the present case by

$\alpha =0$ of the present case by ![]() $(3E_1r^3/l^4)\sin ^2\theta \cos \theta$. Here, the order of the latter is

$(3E_1r^3/l^4)\sin ^2\theta \cos \theta$. Here, the order of the latter is ![]() $O(1/l^4)$, but the flux into the cavity, estimated at

$O(1/l^4)$, but the flux into the cavity, estimated at ![]() $r=a, \theta ={\rm \pi} /2$, happens to be zero, because of the vanishing coefficient. This implies that the interaction appears to be at utmost

$r=a, \theta ={\rm \pi} /2$, happens to be zero, because of the vanishing coefficient. This implies that the interaction appears to be at utmost ![]() $O(1/l^5)$, which is

$O(1/l^5)$, which is ![]() $0.03, 0.01, 0.004, \ldots$ for

$0.03, 0.01, 0.004, \ldots$ for ![]() $l=2, 2.5, 3, \ldots$, respectively. In the present configuration, the above argument may not strictly be applied, but is expected to be valid in the

$l=2, 2.5, 3, \ldots$, respectively. In the present configuration, the above argument may not strictly be applied, but is expected to be valid in the ![]() $\alpha \approx 0$ region that covers the most influential part. We also show a comparison of our flow field with that obtained by numerical simulation as given in Appendix C, to support qualitative agreement. Based on this evidence, results obtained for

$\alpha \approx 0$ region that covers the most influential part. We also show a comparison of our flow field with that obtained by numerical simulation as given in Appendix C, to support qualitative agreement. Based on this evidence, results obtained for ![]() $l/a \gtrsim 2.5$ are shown in the following.

$l/a \gtrsim 2.5$ are shown in the following.

3.1. Velocity field

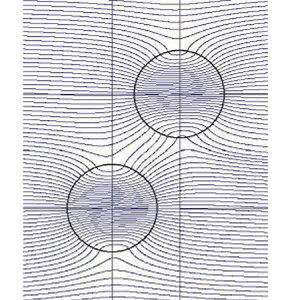

We show some examples of the streamlines on the ![]() $z=0$ plane.

$z=0$ plane.

Figure 2(a–c) shows the dependence on the separation distance ![]() $l$ of the two cavities of the same size

$l$ of the two cavities of the same size ![]() $(a=1, b=1)$ positioned in tandem (

$(a=1, b=1)$ positioned in tandem (![]() $\alpha =0^{\circ }$); (a)

$\alpha =0^{\circ }$); (a) ![]() $l=2.5$, (b)

$l=2.5$, (b) ![]() $l=3$, and (c)

$l=3$, and (c) ![]() $l=5$. We see that the flow field is symmetric with respect to the mid-plane between the cavities.

$l=5$. We see that the flow field is symmetric with respect to the mid-plane between the cavities.

Figure 2. Dependence of the flow field on the separation distance ![]() $l$ (

$l$ (![]() $a=1, b=1, \alpha =0^{\circ }$,

$a=1, b=1, \alpha =0^{\circ }$, ![]() $\zeta _0=100$): (a)

$\zeta _0=100$): (a) ![]() $l=2.5$; (b)

$l=2.5$; (b) ![]() $l=3$; (c)

$l=3$; (c) ![]() $l=5$.

$l=5$.

Figure 3(a–c) shows the dependence on the orientation ![]() $\alpha$ of the two cavities of the same size

$\alpha$ of the two cavities of the same size ![]() $(a=1, b=1)$ with

$(a=1, b=1)$ with ![]() $l=3$; (a)

$l=3$; (a) ![]() $\alpha =30^{\circ }$, (b)

$\alpha =30^{\circ }$, (b) ![]() $\alpha =60^{\circ }$ and (c)

$\alpha =60^{\circ }$ and (c) ![]() $\alpha =90^{\circ }$.

$\alpha =90^{\circ }$.

Figure 3. Dependence of the flow field on ![]() $\alpha$ in the

$\alpha$ in the ![]() $z=0$ plane (

$z=0$ plane (![]() $a=1, b=1, l=3$,

$a=1, b=1, l=3$, ![]() $\zeta _0=100$): (a)

$\zeta _0=100$): (a) ![]() $\alpha =30^{\circ }$; (b)

$\alpha =30^{\circ }$; (b) ![]() $\alpha =60^{\circ }$; (c)

$\alpha =60^{\circ }$; (c) ![]() $\alpha =90^{\circ }$.

$\alpha =90^{\circ }$.

Figure 4(a–d) shows the flow field for ![]() $\alpha = 0^{\circ }, 30^{\circ }, 60^{\circ }, 90^{\circ }$, with

$\alpha = 0^{\circ }, 30^{\circ }, 60^{\circ }, 90^{\circ }$, with ![]() $a=1, b=2$ and

$a=1, b=2$ and ![]() $l=6$. We see a change in flow pattern depending on the configuration of the two cavities.

$l=6$. We see a change in flow pattern depending on the configuration of the two cavities.

Figure 4. Dependence of the flow field on ![]() $\alpha$ in the

$\alpha$ in the ![]() $z=0$ plane (

$z=0$ plane (![]() $a=1, b=2, l=6$,

$a=1, b=2, l=6$, ![]() $\zeta _0=100$): (a)

$\zeta _0=100$): (a) ![]() $\alpha =0^{\circ }$; (b)

$\alpha =0^{\circ }$; (b) ![]() $\alpha =30^{\circ }$; (c)

$\alpha =30^{\circ }$; (c) ![]() $\alpha =60^{\circ }$; (d)

$\alpha =60^{\circ }$; (d) ![]() $\alpha =90^{\circ }$.

$\alpha =90^{\circ }$.

Figure 5(a,b) describes examples of the perspective view of the streamlines. To avoid the complexity due to the overlapping streamlines, only those that flow into respective cavities are drawn. Here, the black broken lines show the positions of the cavities, whose centres are on the ![]() $z=0$ plane. Note that only the dividing streamlines which flow into cavities

$z=0$ plane. Note that only the dividing streamlines which flow into cavities ![]() ${{\rm C}a}$ and

${{\rm C}a}$ and ![]() ${{\rm C}b}$ are drawn in blue and red, respectively, and that those of the upstream-side ones are drawn.

${{\rm C}b}$ are drawn in blue and red, respectively, and that those of the upstream-side ones are drawn.

Figure 5. Perspective view of the streamlines for (a) ![]() $\alpha = 45^{\circ}$ and (b)

$\alpha = 45^{\circ}$ and (b) ![]() $\alpha = 10^{\circ}$, (

$\alpha = 10^{\circ}$, (![]() $a=b=1, l=4.0$).

$a=b=1, l=4.0$).

3.2. Velocity profiles

Figure 6 shows the contour plot of the velocity ![]() $v = \sqrt {v^2_x+ v^2_y}$ on the

$v = \sqrt {v^2_x+ v^2_y}$ on the ![]() $z = 0$ plane. The dotted pink and black circles show the position of the cavities. We see that the velocity increases as we move towards the centre of the respective cavities. The flow behaviour is

$z = 0$ plane. The dotted pink and black circles show the position of the cavities. We see that the velocity increases as we move towards the centre of the respective cavities. The flow behaviour is ![]() $180^{\circ}$ rotational symmetric about the mid-point between the centre of the two cavities. The flow field around each of the cavities reflects the dipole characteristics. Namely, the far field around a single cavity is

$180^{\circ}$ rotational symmetric about the mid-point between the centre of the two cavities. The flow field around each of the cavities reflects the dipole characteristics. Namely, the far field around a single cavity is

so that ![]() $v \approx 1$ for

$v \approx 1$ for ![]() $\theta =\alpha _c \equiv \pm \cos ^{-1}(1/\sqrt {3}) = \pm 54.7356\cdots ^{\circ} (\textrm {mod}\ 180^{\circ} )$ for

$\theta =\alpha _c \equiv \pm \cos ^{-1}(1/\sqrt {3}) = \pm 54.7356\cdots ^{\circ} (\textrm {mod}\ 180^{\circ} )$ for ![]() $r \gg a$. The main contribution to the flow at a distance comes from the second term in

$r \gg a$. The main contribution to the flow at a distance comes from the second term in ![]() $T_{ij}$, that characterises the potential doublet. Indeed, respective terms of

$T_{ij}$, that characterises the potential doublet. Indeed, respective terms of ![]() $T_{ij}$ are

$T_{ij}$ are

\begin{align} \left.\begin{gathered} C(a) h_{ij} \sim C(a)\exp({-\zeta_0 r}) \sim \frac{15}{\zeta_0 r} \left(1-\frac{6}{\zeta_0 a} +O\left(\frac{1}{\zeta_0 a}\right)^2\right) \exp({-\zeta_0 (r-a)}),\\ D(a)H_{ij} \sim \frac{a^3}{r^3}\left(1-\frac{30}{(\zeta_0 a)^2}+O\left(\frac{1}{\zeta_0 a}\right)^3\right), \end{gathered}\right\} \end{align}

\begin{align} \left.\begin{gathered} C(a) h_{ij} \sim C(a)\exp({-\zeta_0 r}) \sim \frac{15}{\zeta_0 r} \left(1-\frac{6}{\zeta_0 a} +O\left(\frac{1}{\zeta_0 a}\right)^2\right) \exp({-\zeta_0 (r-a)}),\\ D(a)H_{ij} \sim \frac{a^3}{r^3}\left(1-\frac{30}{(\zeta_0 a)^2}+O\left(\frac{1}{\zeta_0 a}\right)^3\right), \end{gathered}\right\} \end{align}

the former being very small compared with the latter for ![]() $\zeta _0 \gg 1, r \gg a$. Here, contour-value unity is due to the uniform far field condition. Fore-and-aft symmetry of the flow field is observed for the case

$\zeta _0 \gg 1, r \gg a$. Here, contour-value unity is due to the uniform far field condition. Fore-and-aft symmetry of the flow field is observed for the case ![]() $\alpha = 0^{\circ}$ with respect to the mid-plane (see figure 6a). One may observe that, for the cases

$\alpha = 0^{\circ}$ with respect to the mid-plane (see figure 6a). One may observe that, for the cases ![]() $\alpha = 0^{\circ}$ and

$\alpha = 0^{\circ}$ and ![]() $30^{\circ}$, the water chain connecting the cavities is strong (see figure 6a,b), and for the case

$30^{\circ}$, the water chain connecting the cavities is strong (see figure 6a,b), and for the case ![]() $\alpha \gtrsim 55^{\circ }$ the water chain is weak (figure 6c,d). In other words, the interaction of the cavities is more prominent when the two cavities are oriented nearly along the flow and less prominent with increase of

$\alpha \gtrsim 55^{\circ }$ the water chain is weak (figure 6c,d). In other words, the interaction of the cavities is more prominent when the two cavities are oriented nearly along the flow and less prominent with increase of ![]() $\alpha$ (up to

$\alpha$ (up to ![]() $\alpha \lesssim 55^{\circ }$). As

$\alpha \lesssim 55^{\circ }$). As ![]() $\alpha$ further increases, the water chain almost disappears and contour lines in the respective cavities tend to become independent. For the case

$\alpha$ further increases, the water chain almost disappears and contour lines in the respective cavities tend to become independent. For the case ![]() $\alpha =90^{\circ }$ we can recognise a negative interaction between the cavities, and the water chain disappears completely (see figure 6d).

$\alpha =90^{\circ }$ we can recognise a negative interaction between the cavities, and the water chain disappears completely (see figure 6d).

Figure 6. Contour plot of the magnitude of velocity ![]() $v$ on the

$v$ on the ![]() $z=0$ plane (

$z=0$ plane (![]() $a=b=1, l=2.5, \zeta _0=100$): (a)

$a=b=1, l=2.5, \zeta _0=100$): (a) ![]() $\alpha =0^{\circ }$; (b)

$\alpha =0^{\circ }$; (b) ![]() $\alpha =30^{\circ }$; (c)

$\alpha =30^{\circ }$; (c) ![]() $\alpha =55^{\circ }$; (d)

$\alpha =55^{\circ }$; (d) ![]() $\alpha =90^{\circ }$.

$\alpha =90^{\circ }$.

Dependence of ![]() $v_{x}$ on

$v_{x}$ on ![]() $l$ for two equal sized cavities positioned in tandem is shown in figure 7(a). We see that the velocity profile in this case is symmetric with respect to the plane

$l$ for two equal sized cavities positioned in tandem is shown in figure 7(a). We see that the velocity profile in this case is symmetric with respect to the plane ![]() $x=l/2$. As

$x=l/2$. As ![]() $l$ increases the velocity at the respective centres decreases. For sufficiently large

$l$ increases the velocity at the respective centres decreases. For sufficiently large ![]() $l$, two cavities are almost independent. As

$l$, two cavities are almost independent. As ![]() $l$ decreases, the velocity at the centre of the respective cavities increases. These dependencies will be further clarified in the next subsection.

$l$ decreases, the velocity at the centre of the respective cavities increases. These dependencies will be further clarified in the next subsection.

Figure 7. Velocity profile along the ![]() $x$ axis for two cavities of equal radii (

$x$ axis for two cavities of equal radii (![]() $a=b=1, \zeta _0=100$). (a) Dependence of

$a=b=1, \zeta _0=100$). (a) Dependence of ![]() $v_x$ on

$v_x$ on ![]() $l$ (

$l$ (![]() $\alpha =0^{\circ }$). (b) Dependence of

$\alpha =0^{\circ }$). (b) Dependence of ![]() $v_x$ on

$v_x$ on ![]() $\alpha$ (

$\alpha$ (![]() $l=4$).

$l=4$).

Figure 7(b) depicts the axial velocity for two equal size cavities but with different orientation angles ![]() $\alpha$. Difference of the velocity is remarkable for the cases

$\alpha$. Difference of the velocity is remarkable for the cases ![]() $\alpha =0^{\circ }$ and

$\alpha =0^{\circ }$ and ![]() $\alpha =30^{\circ }$ whereas it is less when

$\alpha =30^{\circ }$ whereas it is less when ![]() $\alpha =60^{\circ }$ and

$\alpha =60^{\circ }$ and ![]() $\alpha =90^{\circ }$. The reason is easily seen from figures 6(c) and 6(d), where contour lines around cavity

$\alpha =90^{\circ }$. The reason is easily seen from figures 6(c) and 6(d), where contour lines around cavity ![]() ${\rm C}{b}$ have almost no overlap across the mid-plane between the centre of the two cavities. One noticeable thing is that the axial velocity in the neighbouring portion of the first cavity for

${\rm C}{b}$ have almost no overlap across the mid-plane between the centre of the two cavities. One noticeable thing is that the axial velocity in the neighbouring portion of the first cavity for ![]() $\alpha \approx 55^{\circ }$ case is the same as that of a single cavity (see figure 7b).

$\alpha \approx 55^{\circ }$ case is the same as that of a single cavity (see figure 7b).

Figure 8 shows the velocity profile ![]() $v_{x}$ on the plane passing the centres of both cavities. Here, the velocity profile is plotted with respect to

$v_{x}$ on the plane passing the centres of both cavities. Here, the velocity profile is plotted with respect to ![]() $x=0$ (blue line) and

$x=0$ (blue line) and ![]() $x=l \cos \alpha$ (red line). As

$x=l \cos \alpha$ (red line). As ![]() $\alpha$ increases, the maximum velocity at the respective centres decreases. We see that, for

$\alpha$ increases, the maximum velocity at the respective centres decreases. We see that, for ![]() $\alpha =0^{\circ }$, the magnitude of the axial velocity is larger (see figure 8a) than that for

$\alpha =0^{\circ }$, the magnitude of the axial velocity is larger (see figure 8a) than that for ![]() $\alpha =30^{\circ }$ and

$\alpha =30^{\circ }$ and ![]() $\alpha =60^{\circ }$ (see figure 8b,c). This fact implies that cavities positioned nearly along the flow interact strongly.

$\alpha =60^{\circ }$ (see figure 8b,c). This fact implies that cavities positioned nearly along the flow interact strongly.

Figure 8. Velocity profile on the ![]() $z=0$ plane along

$z=0$ plane along ![]() $x=0$ (blue) and

$x=0$ (blue) and ![]() $x=l \cos \alpha$ (red) (

$x=l \cos \alpha$ (red) (![]() $a=b=1,l=2.5,\zeta _0=100$): (a)

$a=b=1,l=2.5,\zeta _0=100$): (a) ![]() $\alpha =0^{\circ }$; (b)

$\alpha =0^{\circ }$; (b) ![]() $\alpha =30^{\circ }$; (c)

$\alpha =30^{\circ }$; (c) ![]() $\alpha =60^{\circ }$.

$\alpha =60^{\circ }$.

Figure 9 shows the axial velocity profile along the ![]() $x$-axis for two cavities of different sizes in a tandem position (

$x$-axis for two cavities of different sizes in a tandem position (![]() $\alpha =0^{\circ}$). Figure 9(a) shows the

$\alpha =0^{\circ}$). Figure 9(a) shows the ![]() $v_x$ profile for different sizes of cavity

$v_x$ profile for different sizes of cavity ![]() ${{\rm C}b}$ keeping the size of

${{\rm C}b}$ keeping the size of ![]() ${{\rm C}a}$ and the distance

${{\rm C}a}$ and the distance ![]() $l$ constant. We observe that the peak velocity of

$l$ constant. We observe that the peak velocity of ![]() ${{\rm C}a}$ increases as

${{\rm C}a}$ increases as ![]() $b$ increases, whereas the peak velocity of

$b$ increases, whereas the peak velocity of ![]() ${{\rm C}b}$ is almost unchanged. The same characteristics are recognised if the positions of

${{\rm C}b}$ is almost unchanged. The same characteristics are recognised if the positions of ![]() ${{\rm C}a}$ and

${{\rm C}a}$ and ![]() ${{\rm C}b}$ are exchanged. Thus, it follows that, if two cavities of different sizes are placed at a fixed distance along the stream, the peak velocity of the larger cavity is almost unchanged whereas that of the smaller cavity is remarkably influenced. Figure 9(b) shows the dependence of

${{\rm C}b}$ are exchanged. Thus, it follows that, if two cavities of different sizes are placed at a fixed distance along the stream, the peak velocity of the larger cavity is almost unchanged whereas that of the smaller cavity is remarkably influenced. Figure 9(b) shows the dependence of ![]() $v_x$ on

$v_x$ on ![]() $\zeta _0$, in which two cavities of different sizes are positioned in tandem. We see that the magnitude of the velocity increases with

$\zeta _0$, in which two cavities of different sizes are positioned in tandem. We see that the magnitude of the velocity increases with ![]() $\zeta _0$. The velocity is almost uniform for low values of

$\zeta _0$. The velocity is almost uniform for low values of ![]() $\zeta _0$ due to the high permeability of the porous medium. We see that, when

$\zeta _0$ due to the high permeability of the porous medium. We see that, when ![]() $r \gg 1$,

$r \gg 1$, ![]() $v_x \approx 1$ owing to the undisturbed flow.

$v_x \approx 1$ owing to the undisturbed flow.

Figure 9. Velocity profile along the ![]() $x$ axis for two cavities of unequal radii (

$x$ axis for two cavities of unequal radii (![]() $a=1, \alpha =0^{\circ}, l=6$). (a) Dependence on

$a=1, \alpha =0^{\circ}, l=6$). (a) Dependence on ![]() $b$, and (b) dependence on

$b$, and (b) dependence on ![]() $\zeta _0$.

$\zeta _0$.

3.3. Velocity at the centre of the cavity

From (2.36a)–(2.36c), the velocity at the centre of the cavity ![]() ${{\rm C}a}$ is

${{\rm C}a}$ is

where ![]() $\epsilon _{bl}=D_b/l^3$, so that the magnitude

$\epsilon _{bl}=D_b/l^3$, so that the magnitude ![]() $v^{C}_{a}$ and orientation

$v^{C}_{a}$ and orientation ![]() $\theta ^{C}_{a}$ are

$\theta ^{C}_{a}$ are

\begin{align} v^{C}_{a} &= B(a) \sqrt{(1+\epsilon_{bl}K_x)^2+(\epsilon_{bl}K_y)^2} \nonumber\\ &= B(a) \sqrt{[1+\epsilon_{bl}(3\cos^2\alpha-1)]^2+9(\epsilon_{bl}\cos\alpha \sin\alpha)^2}, \end{align}

\begin{align} v^{C}_{a} &= B(a) \sqrt{(1+\epsilon_{bl}K_x)^2+(\epsilon_{bl}K_y)^2} \nonumber\\ &= B(a) \sqrt{[1+\epsilon_{bl}(3\cos^2\alpha-1)]^2+9(\epsilon_{bl}\cos\alpha \sin\alpha)^2}, \end{align}

The velocity and orientation of the flow at the centre of cavity ![]() ${{\rm C}b}$ are similarly given by exchanging the roles of

${{\rm C}b}$ are similarly given by exchanging the roles of ![]() ${{\rm C}a}$ and

${{\rm C}a}$ and ![]() ${{\rm C}b}$.

${{\rm C}b}$.

3.3.1. Velocity at the centre of cavities positioned in tandem

The maximum velocity ![]() ${v^{C}_{a}}_{max}$ at the centre of cavity

${v^{C}_{a}}_{max}$ at the centre of cavity ![]() ${{\rm C}a}$ is achieved at

${{\rm C}a}$ is achieved at ![]() $\alpha =0^{\circ}$, and is given by

$\alpha =0^{\circ}$, and is given by

whereas that of the maximum velocity at the centre of cavity ![]() ${{\rm C}b}$ is

${{\rm C}b}$ is

For ![]() $\zeta _0 \gg 1$, (3.5a) and (3.5b) are approximated as

$\zeta _0 \gg 1$, (3.5a) and (3.5b) are approximated as

and

Under given values of fixed ![]() $a, l$ and larger

$a, l$ and larger ![]() $\zeta _0$, variation of

$\zeta _0$, variation of ![]() $b$ influences

$b$ influences ![]() ${v^{C}_{a}}_{max}$ remarkably, whereas it influences

${v^{C}_{a}}_{max}$ remarkably, whereas it influences ![]() ${v^{C}_{b}}_{max}$ only slightly. For example, by putting

${v^{C}_{b}}_{max}$ only slightly. For example, by putting ![]() $a=1,\ l=6, \zeta _0=100$, as shown in figure 9(a), we have

$a=1,\ l=6, \zeta _0=100$, as shown in figure 9(a), we have ![]() ${v^{C}_{a}}_{max}\approx 5.89, 6.02, 6.27$ and

${v^{C}_{a}}_{max}\approx 5.89, 6.02, 6.27$ and ![]() $6.68$, whereas

$6.68$, whereas ![]() ${v^{C}_{b}}_{max} \approx 5.89, 5.95, 5.98$ and

${v^{C}_{b}}_{max} \approx 5.89, 5.95, 5.98$ and ![]() $5.99$, respectively, for

$5.99$, respectively, for ![]() $b=1, 1.5, 2$ and

$b=1, 1.5, 2$ and ![]() $2.5$.

$2.5$.

Similarly, for ![]() $a=1,\ b=2,\ l=6$ as shown in figure 9(b), we have

$a=1,\ b=2,\ l=6$ as shown in figure 9(b), we have ![]() ${v^{C}_{a}}_{max}\approx 6.07$ and

${v^{C}_{a}}_{max}\approx 6.07$ and ![]() ${v^{C}_{b}}_{max} \approx 5.89$ for

${v^{C}_{b}}_{max} \approx 5.89$ for ![]() $\zeta _0=50$, whereas

$\zeta _0=50$, whereas ![]() ${v^{C}_{a}}_{max} \approx 4.39$ and

${v^{C}_{a}}_{max} \approx 4.39$ and ![]() ${v^{C}_{b}}_{max} \approx 5.09$ for

${v^{C}_{b}}_{max} \approx 5.09$ for ![]() $\zeta _0=10$, respectively, which confirm the results shown in figure 9(a,b).

$\zeta _0=10$, respectively, which confirm the results shown in figure 9(a,b).

3.3.2. Configuration dependence on the velocity at the centre of the cavities

We consider the magnitude of the velocity and flow direction at the centres of two cavities of equal size. In this case, the flow field has ![]() $180^{\circ}$ rotational symmetry about the mid-point joining their centres. Figure 10(a) shows the dependence of the magnitude of the velocity

$180^{\circ}$ rotational symmetry about the mid-point joining their centres. Figure 10(a) shows the dependence of the magnitude of the velocity ![]() $v^{C}_{a}$ at the centre of cavity

$v^{C}_{a}$ at the centre of cavity ![]() ${{\rm C}a}$ on the configuration

${{\rm C}a}$ on the configuration ![]() $\alpha$ and

$\alpha$ and ![]() $l$ of cavity

$l$ of cavity ![]() ${{\rm C}b}$ for the

${{\rm C}b}$ for the ![]() $\zeta _0=100$ case. Note that the latter maximum velocity amounts to 6.28, 5.94 and 5.86 at

$\zeta _0=100$ case. Note that the latter maximum velocity amounts to 6.28, 5.94 and 5.86 at ![]() $\alpha =0$ for

$\alpha =0$ for ![]() $l=3, 5, 10$, respectively, which agrees with our previous calculation (see Sano et al. (Reference Sano, Karmakar and Sekhar2022), figure 14). We also note that the velocity

$l=3, 5, 10$, respectively, which agrees with our previous calculation (see Sano et al. (Reference Sano, Karmakar and Sekhar2022), figure 14). We also note that the velocity ![]() $v^{C}_{a}$ is larger than that for a single cavity

$v^{C}_{a}$ is larger than that for a single cavity ![]() $v^C_S ({\approx }5.8377\ \textrm {for}\ \zeta _0=100)$ when the angle of orientation

$v^C_S ({\approx }5.8377\ \textrm {for}\ \zeta _0=100)$ when the angle of orientation ![]() $\alpha$ is less than approximately

$\alpha$ is less than approximately ![]() $\alpha _c \approx 55^{\circ}$. The magnitude

$\alpha _c \approx 55^{\circ}$. The magnitude ![]() $v^{C}_{a}$ decreases monotonically as

$v^{C}_{a}$ decreases monotonically as ![]() $\alpha$ increases, and becomes smaller than

$\alpha$ increases, and becomes smaller than ![]() $v^C_S$ when

$v^C_S$ when ![]() $\alpha$ exceeds

$\alpha$ exceeds ![]() $\alpha _c$. The range of variation, however, decreases with the increase of the distance between the two cavities. Figure 10(b) shows the flow direction

$\alpha _c$. The range of variation, however, decreases with the increase of the distance between the two cavities. Figure 10(b) shows the flow direction ![]() $\theta ^{C}_{a}$ at the centre of cavity

$\theta ^{C}_{a}$ at the centre of cavity ![]() ${{\rm C}a}$. The dotted line shows the configuration in which

${{\rm C}a}$. The dotted line shows the configuration in which ![]() $\theta ^{C}_{a}$ becomes maximum (the same positions are also shown in figure 10a). The latter is given by

$\theta ^{C}_{a}$ becomes maximum (the same positions are also shown in figure 10a). The latter is given by ![]() $\theta ^{C}_{a} \approx (3/2) \epsilon _{bl} \sin 2\alpha +\cdots$ for a given configuration

$\theta ^{C}_{a} \approx (3/2) \epsilon _{bl} \sin 2\alpha +\cdots$ for a given configuration ![]() $l,\ b$ with

$l,\ b$ with ![]() $\epsilon _{bl} \ll 1$, so that it tends to

$\epsilon _{bl} \ll 1$, so that it tends to ![]() $\alpha =45 ^{\circ}$ as

$\alpha =45 ^{\circ}$ as ![]() $\epsilon _{bl}$ goes to zero. However, the two cavities become almost independent for sufficiently large

$\epsilon _{bl}$ goes to zero. However, the two cavities become almost independent for sufficiently large ![]() $l$, so that the velocity at respective centres looks parallel to the incident flow in the

$l$, so that the velocity at respective centres looks parallel to the incident flow in the ![]() $x$ direction.

$x$ direction.

Figure 10. Dependence of the velocity ![]() $v^{C}_{a}$ on the separation distance

$v^{C}_{a}$ on the separation distance ![]() $l$ of two cavities of equal size (

$l$ of two cavities of equal size (![]() $\zeta _0=100$): (a) magnitude and (b) flow direction.

$\zeta _0=100$): (a) magnitude and (b) flow direction.

When the sizes of the two cavities are not equal, the above-mentioned tendency is much enhanced in the smaller cavity, whereas the influence is less remarkable in the larger cavity. Figures 11(a) and 11(b) are examples of ![]() $v^{C}_{a}, v^{C}_{b}$ and

$v^{C}_{a}, v^{C}_{b}$ and ![]() $\theta ^{C}_{a},\ \theta ^{C}_{b}$, respectively. Here,

$\theta ^{C}_{a},\ \theta ^{C}_{b}$, respectively. Here, ![]() $l=5, a=1$ and

$l=5, a=1$ and ![]() $\zeta _0=100$ are fixed, and

$\zeta _0=100$ are fixed, and ![]() $b$ is varied. To see the tendency, data for

$b$ is varied. To see the tendency, data for ![]() $b$ up to 2.5 are also added. The data points for

$b$ up to 2.5 are also added. The data points for ![]() ${{\rm C}a}$ and

${{\rm C}a}$ and ![]() ${{\rm C}b}$ are shown by solid curves and dotted curves, respectively, although the variation of the latter are indistinguishably small compared with those of the former. The influence of the larger cavity

${{\rm C}b}$ are shown by solid curves and dotted curves, respectively, although the variation of the latter are indistinguishably small compared with those of the former. The influence of the larger cavity ![]() ${{\rm C}b}$ on the smaller cavity

${{\rm C}b}$ on the smaller cavity ![]() ${{\rm C}a}$ is remarkable. For

${{\rm C}a}$ is remarkable. For ![]() $a=1, b=2, l=5$, for example, the velocity at the centre of cavity

$a=1, b=2, l=5$, for example, the velocity at the centre of cavity ![]() $v^{C}_{a}$ amounts to 6.58 whereas that for cavity

$v^{C}_{a}$ amounts to 6.58 whereas that for cavity ![]() $v^{C}_{b}$ is 6.02 (for

$v^{C}_{b}$ is 6.02 (for ![]() $a=1, b=2.5, l=5$, they are

$a=1, b=2.5, l=5$, they are ![]() $v^{C}_{a}=7.30$ and

$v^{C}_{a}=7.30$ and ![]() $v^{C}_{b}=6.03$). The maximum deflections of the flow direction at respective centres are

$v^{C}_{b}=6.03$). The maximum deflections of the flow direction at respective centres are ![]() $\theta _a^C=5.33^{\circ}$ and

$\theta _a^C=5.33^{\circ}$ and ![]() $\theta _b^C=0.68^{\circ}$ for the case

$\theta _b^C=0.68^{\circ}$ for the case ![]() $a=1, b=2, l=5$, whereas they are

$a=1, b=2, l=5$, whereas they are ![]() $\theta _a^C=10.1^{\circ}$ and

$\theta _a^C=10.1^{\circ}$ and ![]() $\theta _b^C=0.68^{\circ}$ for the

$\theta _b^C=0.68^{\circ}$ for the ![]() $a=1, b=2.5, l=5$ case. These examples show that the smaller cavity is highly involved in the local flow created by the larger cavity, but that the larger cavity suffers less influence from the smaller one (e.g. see particularly figures 4(b,c) and 9(a,b)).

$a=1, b=2.5, l=5$ case. These examples show that the smaller cavity is highly involved in the local flow created by the larger cavity, but that the larger cavity suffers less influence from the smaller one (e.g. see particularly figures 4(b,c) and 9(a,b)).

Figure 11. Comparison of the (a) magnitude of the velocity ![]() $v^{C}_{a},\ v^{C}_{b}$ and (b) flow direction

$v^{C}_{a},\ v^{C}_{b}$ and (b) flow direction ![]() $\theta ^{C}_{a},\ \theta ^{C}_{b}$ at the centres of cavities of different sizes, where

$\theta ^{C}_{a},\ \theta ^{C}_{b}$ at the centres of cavities of different sizes, where ![]() $a = 1$ and

$a = 1$ and ![]() $l=5$ are fixed while

$l=5$ are fixed while ![]() $b$ is varied (

$b$ is varied (![]() $\zeta _0=100$);

$\zeta _0=100$); ![]() ${{\rm C}a}$ (solid curves) and

${{\rm C}a}$ (solid curves) and ![]() ${{\rm C}b}$ (dotted curves).

${{\rm C}b}$ (dotted curves).

These results agree with those shown in the previous subsection, which will be discussed later in the collapse of two cavities of different sizes.

3.4. Volume flux into the cavities

We shall consider two spherical cavities positioned at an arbitrary configuration, and examine the effect of the interaction on the volume flux into the respective cavities. To do this, we assume that the sizes of the cavities are the same (![]() $a=b=1$) as a simplest case, and focus our attention on the dependence on the configuration. Figures 12(a) and 12(b) show the volume fluxes into

$a=b=1$) as a simplest case, and focus our attention on the dependence on the configuration. Figures 12(a) and 12(b) show the volume fluxes into ![]() ${{\rm C}a}$ and

${{\rm C}a}$ and ![]() ${{\rm C}b}$, respectively. In each figure, the abscissa is the centre-to-centre distance

${{\rm C}b}$, respectively. In each figure, the abscissa is the centre-to-centre distance ![]() $l$ between the two cavities, and the ordinate is the orientation

$l$ between the two cavities, and the ordinate is the orientation ![]() $\alpha$ of

$\alpha$ of ![]() ${{\rm C}b}$ with respect to the direction of the velocity at infinity. The value of the volume flux is normalised by the flux

${{\rm C}b}$ with respect to the direction of the velocity at infinity. The value of the volume flux is normalised by the flux ![]() $Q_S$ into a single cavity of radius

$Q_S$ into a single cavity of radius ![]() $a$, where

$a$, where ![]() $Q_S \rightarrow 3({\rm \pi} a^2)$ as

$Q_S \rightarrow 3({\rm \pi} a^2)$ as ![]() $\zeta _0 \rightarrow \infty$. The contour map describing the

$\zeta _0 \rightarrow \infty$. The contour map describing the ![]() $\alpha - l$ dependence is qualitatively the same as that obtained for two 2-D cavities (Kaneko & Sano Reference Kaneko and Sano2003; Sano & Nagata Reference Sano and Nagata2006a; Sano Reference Sano2020).

$\alpha - l$ dependence is qualitatively the same as that obtained for two 2-D cavities (Kaneko & Sano Reference Kaneko and Sano2003; Sano & Nagata Reference Sano and Nagata2006a; Sano Reference Sano2020).

Figure 12. Volume flux into cavities of the same size ![]() ${{\rm C}a}$ and

${{\rm C}a}$ and ![]() ${{\rm C}b}$ (

${{\rm C}b}$ (![]() $\zeta _0=100$); dependence of configuration. The inset is the close-up view around this region. (a) Upstream cavity

$\zeta _0=100$); dependence of configuration. The inset is the close-up view around this region. (a) Upstream cavity ![]() ${{\rm C}a}$; (b) downstream cavity

${{\rm C}a}$; (b) downstream cavity ![]() ${{\rm C}b}$.

${{\rm C}b}$.

We first note that, in the ![]() $\alpha =0^{\circ}$ case, the volume flux into each cavity is larger than that which flows into a single cavity, as a result of the global effect that the combined two cavities play the role of a single larger cavity. The interaction duly decreases with the distance

$\alpha =0^{\circ}$ case, the volume flux into each cavity is larger than that which flows into a single cavity, as a result of the global effect that the combined two cavities play the role of a single larger cavity. The interaction duly decreases with the distance ![]() $l$, and tends to the same value as that for the single cavity. The two-cavity interaction described above agrees with our previous work dealing with axisymmetric case (Sano et al. Reference Sano, Karmakar and Sekhar2022). These tendencies are also recognised for smaller

$l$, and tends to the same value as that for the single cavity. The two-cavity interaction described above agrees with our previous work dealing with axisymmetric case (Sano et al. Reference Sano, Karmakar and Sekhar2022). These tendencies are also recognised for smaller ![]() $\alpha$.

$\alpha$.

How about the off-axial configuration? Figures 12(a) and 12(b) show that the variation of the volume flux into respective cavities is generally recognised in ![]() $l \lesssim 5$. The volume flux is enhanced in the region

$l \lesssim 5$. The volume flux is enhanced in the region ![]() $\alpha \lesssim \alpha _1(l)$, whereas it is reduced in the region

$\alpha \lesssim \alpha _1(l)$, whereas it is reduced in the region ![]() $\alpha \gtrsim \alpha _2(l)$. The numerical value of these criteria depends, of course, on the configuration. Roughly speaking, a

$\alpha \gtrsim \alpha _2(l)$. The numerical value of these criteria depends, of course, on the configuration. Roughly speaking, a ![]() $5\,\%$ increase of the volume flux is expected within the region bounded by the

$5\,\%$ increase of the volume flux is expected within the region bounded by the ![]() $(l, \alpha _1) \approx (3.5, 0^{\circ} ) - (3.3, 15^{\circ} ) - (3.0, 30^{\circ} ) - (2.5, 45^{\circ} )$ curve, and an increase of

$(l, \alpha _1) \approx (3.5, 0^{\circ} ) - (3.3, 15^{\circ} ) - (3.0, 30^{\circ} ) - (2.5, 45^{\circ} )$ curve, and an increase of ![]() $10\,\%$ is expected within the

$10\,\%$ is expected within the ![]() $(l, \alpha _2) \approx (2.7, 0^{\circ} ) - (2.6, 15^{\circ} ) - (2.5, 25^{\circ} )$ curve. In contrast, a

$(l, \alpha _2) \approx (2.7, 0^{\circ} ) - (2.6, 15^{\circ} ) - (2.5, 25^{\circ} )$ curve. In contrast, a ![]() $5\,\%$ decrease is observed within the region bounded by the

$5\,\%$ decrease is observed within the region bounded by the ![]() $(l, \alpha _3) \approx (2.7, 90^{\circ} ) - (2.5, 80^{\circ} )$ curve. The latter is ascribed to our observation that the two cavities exert their suction effect almost independently, so that the fluid volume in the middle region on the upstream side that overlaps their influences is divided and flows into respective cavities (see i.e. figure 3c).

$(l, \alpha _3) \approx (2.7, 90^{\circ} ) - (2.5, 80^{\circ} )$ curve. The latter is ascribed to our observation that the two cavities exert their suction effect almost independently, so that the fluid volume in the middle region on the upstream side that overlaps their influences is divided and flows into respective cavities (see i.e. figure 3c).

It should be remarked that the dependence of the volume flux on ![]() $l$ and

$l$ and ![]() $\alpha$ differs between the upstream cavity and the downstream one. Although the magnitude of the difference is not very large, a region is recognised in which the volume flux varies non-monotonically in the downstream cavity, whereas it is not the case in the upstream cavity. This apparent asymmetric

$\alpha$ differs between the upstream cavity and the downstream one. Although the magnitude of the difference is not very large, a region is recognised in which the volume flux varies non-monotonically in the downstream cavity, whereas it is not the case in the upstream cavity. This apparent asymmetric ![]() $l-\alpha$ dependence between

$l-\alpha$ dependence between ![]() ${{\rm C}a}$ and

${{\rm C}a}$ and ![]() ${{\rm C}b}$ is recognised around the configuration

${{\rm C}b}$ is recognised around the configuration ![]() $l\approx 4$ and

$l\approx 4$ and ![]() $\alpha \approx 15 \sim 45^{\circ}$, which we shall examine in more detail. Figure 13(b–d) shows the stream tubes projected on the

$\alpha \approx 15 \sim 45^{\circ}$, which we shall examine in more detail. Figure 13(b–d) shows the stream tubes projected on the ![]() $xy$ plane, where the flows into cavity

$xy$ plane, where the flows into cavity ![]() ${{\rm C}a}$ and

${{\rm C}a}$ and ![]() ${{\rm C}b}$, respectively, are drawn in blue and red curves. In figure 13(a), red closed circles show the region where the volume flux into cavity

${{\rm C}b}$, respectively, are drawn in blue and red curves. In figure 13(a), red closed circles show the region where the volume flux into cavity ![]() ${{\rm C}b}$ is larger than that into cavity

${{\rm C}b}$ is larger than that into cavity ![]() ${{\rm C}a}$. Figure 13(b–d) corresponds to the typical configurations marked

${{\rm C}a}$. Figure 13(b–d) corresponds to the typical configurations marked ![]() $\textrm {A}\sim \textrm {C}$ as shown in figure 13(a). A closer look at figure 12(b) reveals that the volume flux contour shows a non-monotonic behaviour around

$\textrm {A}\sim \textrm {C}$ as shown in figure 13(a). A closer look at figure 12(b) reveals that the volume flux contour shows a non-monotonic behaviour around ![]() $l\approx 4$ and

$l\approx 4$ and ![]() $\alpha \approx 20^{\circ }$. As shown in figure 13(b), where

$\alpha \approx 20^{\circ }$. As shown in figure 13(b), where ![]() $l= 4$ and