A concentrating solar power (CSP) plant consists of a ∼150 m-high power tower surrounded by solar-tracking mirrors called heliostats. The heliostats reflect the sunlight in the direction of a receiver located at the top of the tower. This receiver is made of 10–20-m-long tubes of nickel or aluminum alloys, into which water or molten salts are flowed. When the sun shines, the light reflected by all the heliostats heats the receiver to above 650°C, producing steam or a flow of the molten salt, generating power.

One approach to enhance the power generation of a CSP plant is to increase light absorption at the receiver tubes. Typically, 4–5% of the energy from the heliostats is lost by radiation due to heating of the tubes. Increasing the absorption, that is, decreasing the reflectance, is particularly challenging because traditional antireflective coatings made of organic composites cannot withstand high temperatures. To address this issue, researchers from the University of California, San Diego, led by Renkun Chen, have developed nano-needle arrays made of ceramics that increase the solar absorptance. The results from this development were published in APL Materials (doi:10.1063/1.5084086).

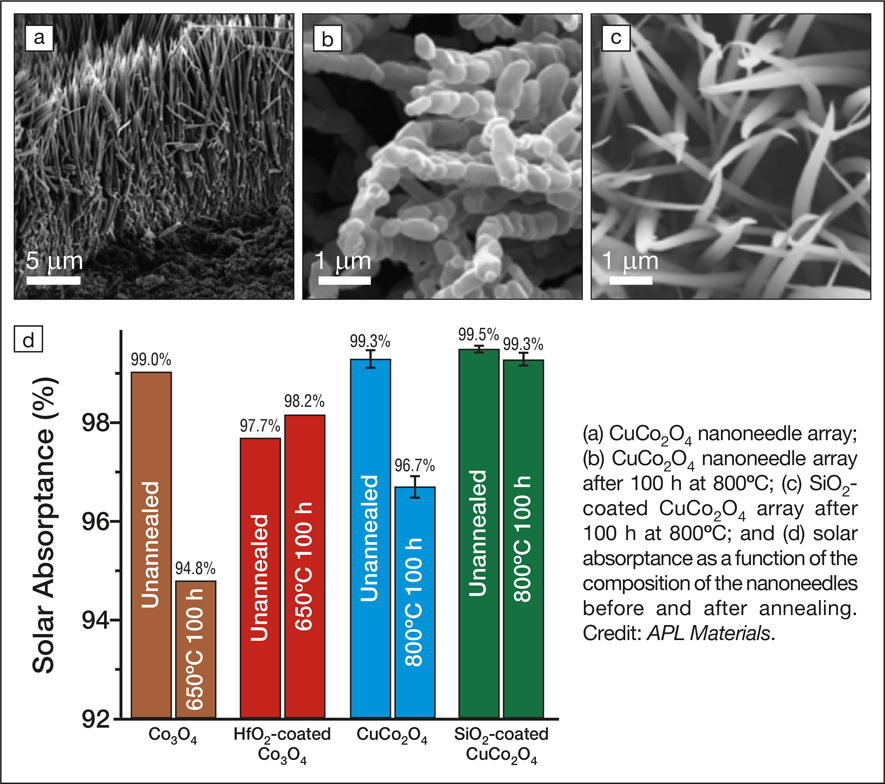

The researchers used a hydrothermal process to grow CuCo2O4 or Co3O4 on a substrate made of the same material as the receiver tubes, a nickel-chromium-tungsten-molybdenum alloy (Haynes 230) with excellent high-temperature strength and oxidation resistance. During this process, they added urea as a cationic surfactant to drive the preferential formation of oriented nanoneedles instead of spherical deposits. An array made of needle-shaped particles is desired because it can create antireflective properties. For example, this type of structure can be found in the wings of cicadas.

Using simulations, the researchers investigated the influence of the length, spacing, and diameter of the needles in the array on the absorption of sunlight under normal incidence and found that 4–5-µm-long and ∼800-nm-thick needles separated by 170 nm produced the highest absorption. The sharpness of the tips of the nanoneedles was also important to achieving good antireflective properties. This is an issue when the temperature rises above 650°C due to grain growth and diffusion. To maintain the sharpness of the tips, despite the high-temperature treatment, the researchers deposited 3–5 nm of a glassy SiO2 or HfO2 on the ceramic needles. As predicted, the sharpness of the needle was maintained and the solar absorptance improved. Of the two ceramics and coating compositions investigated, the SiO2-coated CuCo2O4 nanoneedle arrays displayed the highest solar absorptance of 99.5%.

During the operation of a CSP plant, the receiver is subjected to temperature cycles for a long time. The researchers found that even after 100 h at 800°C, the SiO2-coated CuCo2O4 nanoneedle arrays still absorbed 99.3% of the sunlight. To apply this strategy as a coating for the long metallic tubes of the receiver, Chen and his team plan to develop a more scalable process and avoid the atomic layer deposition process of the protective coating that is both costly and not easily scalable. Also, they would like to reduce the absorption in the mid-IR region to further enlarge the reflectance, by optimizing the nanoneedle spacing and height. “It is still a big challenge in the field to develop a coating that is highly absorbing in the solar spectrum, highly reflective in the mid-IR spectrum, and also stable in air at high temperature,” says Chen.

Zehui Du, group leader at the Temasek Laboratories at Nanyang Technological University of Singapore, who did not participate in the study, further comments that their structures “are very similar to the core–shell ZnO/TiO2 or MnO2/ZnO nanorods that have been developed to enhance energy density or device performance. Applying an oxide ceramic coating onto a metal or another oxide nanostructure can be a facile approach to enhance the thermal stability at elevated temperature and to tailor the optical properties as well as electrical and mechanical. This is particularly a promising material design for electrochemical energy storage, catalysis, and thermomechanical applications that require a nanomaterial to function at high temperature.”