1. Introduction

Dense suspensions of Brownian and non-Brownian solid particles in viscous liquid present intriguing flow properties, and understanding their rheology is a subject of both fundamental and technological relevance (Stickel & Powell Reference Stickel and Powell2005; Ness, Seto & Mari Reference Ness, Seto and Mari2022). Of particular interest are suspensions comprising particles with radius ![]() $a\approx 1$

$a\approx 1$ ![]() $\mathrm {\mu }$m, or more broadly in the range 0.1–10

$\mathrm {\mu }$m, or more broadly in the range 0.1–10 ![]() $\mathrm {\mu }$m. These are present in numerous applications, in all areas of food science (Jambrak et al. Reference Jambrak, Herceg, Šubarić, Babić, Brnčić, Brnčić, Bosiljkov, Čvek, Tripalo and Gelo2010) and consumer products, as well as across the manufacturing and construction sectors (Roussel et al. Reference Roussel, Lemaître, Flatt and Coussot2010) and indeed in many geophysical contexts (Kostynick et al. Reference Kostynick, Matinpour, Pradeep, Haber, Sauret, Meiburg, Dunne, Arratia and Jerolmack2022). Often their physics are challenging because their Brownian diffusion time may be comparable to the processing or macroscopic time scales involved in their use, so that they sit at the boundary of colloidal and granular systems (Guy, Hermes & Poon Reference Guy, Hermes and Poon2015).

$\mathrm {\mu }$m. These are present in numerous applications, in all areas of food science (Jambrak et al. Reference Jambrak, Herceg, Šubarić, Babić, Brnčić, Brnčić, Bosiljkov, Čvek, Tripalo and Gelo2010) and consumer products, as well as across the manufacturing and construction sectors (Roussel et al. Reference Roussel, Lemaître, Flatt and Coussot2010) and indeed in many geophysical contexts (Kostynick et al. Reference Kostynick, Matinpour, Pradeep, Haber, Sauret, Meiburg, Dunne, Arratia and Jerolmack2022). Often their physics are challenging because their Brownian diffusion time may be comparable to the processing or macroscopic time scales involved in their use, so that they sit at the boundary of colloidal and granular systems (Guy, Hermes & Poon Reference Guy, Hermes and Poon2015).

Particle-based simulation offers a promising route to better understand the physics of these materials, providing highly resolved information complementary to what can be obtained by experiment. With simultaneous access to particle trajectories and bulk rheology, one might devise new micromechanical constitutive equations (Gillissen et al. Reference Gillissen, Ness, Peterson, Wilson and Cates2020) or develop microstructural insight that could guide the future analysis of experimental data. Numerical models might also be useful for exploring the parameter space and systematically linking aspects of particle-level physics (friction (Seto et al. Reference Seto, Mari, Morris and Denn2013), adhesion (Richards et al. Reference Richards, Guy, Blanco, Hermes, Poy and Poon2020) and roughness (Lobry et al. Reference Lobry, Lemaire, Blanc, Gallier and Peters2019)) to the bulk flow behaviour. As a result, one might aim to optimise industrial processes such as mixing and extrusion, or indeed to optimise the design of the materials themselves through additives, using insight gained through particle-based simulation.

Stokesian dynamics (SD) (Brady & Bossis Reference Brady and Bossis1988; Banchio & Brady Reference Banchio and Brady2003) is a computational method used to simulate the rheological behaviour of colloidal and granular particles suspended in a viscous fluid, addressing the special case of inertia-free flow where the Stokes number is zero (Ermak & McCammon Reference Ermak and McCammon1978). The latter quantity is similar to a Reynolds number, and is defined as the ratio between the shearing time scale ![]() $1/\dot {\gamma }$ and

$1/\dot {\gamma }$ and ![]() $\rho a^2/\eta$, with

$\rho a^2/\eta$, with ![]() $\dot{\gamma}$ the shear rate,

$\dot{\gamma}$ the shear rate, ![]() $\rho$ the particle density (assumed equal to that of the fluid in the remainder of this article),

$\rho$ the particle density (assumed equal to that of the fluid in the remainder of this article), ![]() $a$ the particle size and

$a$ the particle size and ![]() $\eta$ the liquid viscosity. Other forms of Reynolds number may be defined, for instance based on the fluid density (if it differs from that of the particles) or on another length scale. In the limit of zero Stokes number, analytical solutions of the Stokes equation of motion can be used to derive particle-scale hydrodynamic interactions. The SD method involves balancing all of the forces and torques on each particle by evaluating their velocities via a grand mobility matrix containing information on the relative positions of every particle in the system, ensuring conservation of translational and angular momentum. Despite accurately capturing the long- and short-range hydrodynamic interactions between particles, SD has not been adopted widely as a predictive tool in applied and industrial settings in the same way as other particle-based simulation methods have, due to the complexity of its implementation and its computational expense (notwithstanding recent developments that significantly speed it up (Sierou & Brady Reference Sierou and Brady2001; Fiore & Swan Reference Fiore and Swan2019)).

$\eta$ the liquid viscosity. Other forms of Reynolds number may be defined, for instance based on the fluid density (if it differs from that of the particles) or on another length scale. In the limit of zero Stokes number, analytical solutions of the Stokes equation of motion can be used to derive particle-scale hydrodynamic interactions. The SD method involves balancing all of the forces and torques on each particle by evaluating their velocities via a grand mobility matrix containing information on the relative positions of every particle in the system, ensuring conservation of translational and angular momentum. Despite accurately capturing the long- and short-range hydrodynamic interactions between particles, SD has not been adopted widely as a predictive tool in applied and industrial settings in the same way as other particle-based simulation methods have, due to the complexity of its implementation and its computational expense (notwithstanding recent developments that significantly speed it up (Sierou & Brady Reference Sierou and Brady2001; Fiore & Swan Reference Fiore and Swan2019)).

The discrete element method (DEM) (Cundall & Strack Reference Cundall and Strack1979), on the other hand, is a particle-based computational method (a variant of molecular dynamics) that is used widely to simulate the behaviour of granular materials including powders, particles and grains, taking into account their pairwise interactions. In contrast to SD, DEM does not explicitly balance the forces on each particle. Instead, inertia is present, and one simply sums the forces and torques and the resultant leads to linear and rotational accelerations that can be realised through a conventional timestepping algorithm such as velocity-Verlet. This approach has proven to be useful for studying overdamped suspensions under shear flow (Trulsson, Andreotti & Claudin Reference Trulsson, Andreotti and Claudin2012; Ness & Sun Reference Ness and Sun2015), where one introduces short-ranged lubrication forces and sets the Stokes number to be ![]() $O(10^{-2})$ or smaller (assuming that hydrodynamic force and torque interactions derived in the limit of zero Stokes number still apply). Moreover, it is pragmatic in the sense that the physics associated with flowing dense suspensions can be implemented in existing, widely used codes with large user bases, so that they have a clear path to adoption in engineering and other applied contexts. To date, there is not, to our knowledge, an open-source DEM simulation that includes the relevant physics of dense suspensions at the colloidal-to-granular interface, accounting for short-ranged hydrodynamics, Brownian forces and (frictional) particle–particle contacts.

$O(10^{-2})$ or smaller (assuming that hydrodynamic force and torque interactions derived in the limit of zero Stokes number still apply). Moreover, it is pragmatic in the sense that the physics associated with flowing dense suspensions can be implemented in existing, widely used codes with large user bases, so that they have a clear path to adoption in engineering and other applied contexts. To date, there is not, to our knowledge, an open-source DEM simulation that includes the relevant physics of dense suspensions at the colloidal-to-granular interface, accounting for short-ranged hydrodynamics, Brownian forces and (frictional) particle–particle contacts.

Here, we present a minimal particle-based simulation model for predicting the rheology of dense Brownian and non-Brownian suspensions. Our model comprises hydrodynamic lubrication, particle–particle contacts and Brownian forces. After first describing the model in detail, we present some aspects of the effective interactions and diffusion that arise, before giving a detailed account of the rheological predictions of the model. The model reproduces well the main features of the experimentally observed rheology of dense suspensions, namely a low shear rate plateau that gives way to shear thinning and later shear thickening as the shear rate is increased, with the relative viscosity of the suspension increasing sharply with solid volume fraction and particle–particle friction coefficient.

2. Methodology

We consider a model system of nearly monodisperse solid spheres, dispersed at high solids volume fraction ![]() $\phi$ in a density-matched Newtonian liquid. The microscopic physics included in our model represents a minimal set of ingredients necessary to make useful predictions of the rheology of suspensions comprising particles with radius in the range

$\phi$ in a density-matched Newtonian liquid. The microscopic physics included in our model represents a minimal set of ingredients necessary to make useful predictions of the rheology of suspensions comprising particles with radius in the range ![]() $10^{-7}$ to

$10^{-7}$ to ![]() $10^{-4}$ m. The trajectories of individual particles with translational and rotational motion are governed by Langevin equations that comprise three force (

$10^{-4}$ m. The trajectories of individual particles with translational and rotational motion are governed by Langevin equations that comprise three force (![]() $\boldsymbol {F}$) and torque (

$\boldsymbol {F}$) and torque (![]() $\boldsymbol {T}$) contributions: direct particle contacts (

$\boldsymbol {T}$) contributions: direct particle contacts (![]() $\boldsymbol {F}^{C}$,

$\boldsymbol {F}^{C}$, ![]() $\boldsymbol {T}^{C}$), hydrodynamics (

$\boldsymbol {T}^{C}$), hydrodynamics (![]() $\boldsymbol {F}^{H}$,

$\boldsymbol {F}^{H}$, ![]() $\boldsymbol {T}^{H}$) and Brownian noise (

$\boldsymbol {T}^{H}$) and Brownian noise (![]() $\boldsymbol {F}^{B}$,

$\boldsymbol {F}^{B}$, ![]() $\boldsymbol {T}^{B}$). The equations of motion for the translation and rotation of the particles are written, respectively, as

$\boldsymbol {T}^{B}$). The equations of motion for the translation and rotation of the particles are written, respectively, as

$$\begin{gather} m_i\frac{{\rm d}^2\boldsymbol{x}_i}{{\rm d}t^2} = \sum_j\boldsymbol{F}_{i,\,j}^{C} + \boldsymbol{F}_{i}^{H,D} + \sum_j\boldsymbol{F}_{i,\,j}^{H,L} + \boldsymbol{F}_{i}^{B,D} + \sum_j\boldsymbol{F}_{i,\,j}^{B,L}, \end{gather}$$

$$\begin{gather} m_i\frac{{\rm d}^2\boldsymbol{x}_i}{{\rm d}t^2} = \sum_j\boldsymbol{F}_{i,\,j}^{C} + \boldsymbol{F}_{i}^{H,D} + \sum_j\boldsymbol{F}_{i,\,j}^{H,L} + \boldsymbol{F}_{i}^{B,D} + \sum_j\boldsymbol{F}_{i,\,j}^{B,L}, \end{gather}$$ $$\begin{gather}\frac{2}{5}m_ia_i^2\frac{{\rm d}\boldsymbol{\varOmega}_i}{{\rm d}t} = \sum_j\boldsymbol{T}_{i,\,j}^{C} + \boldsymbol{T}_{i,\,j}^{H,D} + \sum_j\boldsymbol{T}_{i,\,j}^{H,L} + \boldsymbol{T}_{i,\,j}^{B,D} + \sum_j\boldsymbol{T}_{i,\,j}^{B,L} , \end{gather}$$

$$\begin{gather}\frac{2}{5}m_ia_i^2\frac{{\rm d}\boldsymbol{\varOmega}_i}{{\rm d}t} = \sum_j\boldsymbol{T}_{i,\,j}^{C} + \boldsymbol{T}_{i,\,j}^{H,D} + \sum_j\boldsymbol{T}_{i,\,j}^{H,L} + \boldsymbol{T}_{i,\,j}^{B,D} + \sum_j\boldsymbol{T}_{i,\,j}^{B,L} , \end{gather}$$

where ![]() $\boldsymbol {x}_i$ represents the position of particle

$\boldsymbol {x}_i$ represents the position of particle ![]() $i$,

$i$, ![]() $\boldsymbol {\varOmega }_i$ represents its rotational velocity and

$\boldsymbol {\varOmega }_i$ represents its rotational velocity and ![]() $a_i$ and

$a_i$ and ![]() $m_i$ are its radius and mass, respectively. The subscript

$m_i$ are its radius and mass, respectively. The subscript ![]() $i$ represents single-body forces and torques acting on particle

$i$ represents single-body forces and torques acting on particle ![]() $i$, while the subscript

$i$, while the subscript ![]() $i,\,j$ represents pairwise forces and torques acting between particles labelled

$i,\,j$ represents pairwise forces and torques acting between particles labelled ![]() $i$ and

$i$ and ![]() $j$. The superscripts C, H, B, D and L refer to the force and torque components arising due to contacts (C), hydrodynamics (H) and Brownian (B) effects, with the latter two acting both through drag (D) and lubrication (L). Each of these force and torque terms is described in detail below. These equations of motion can be understood as Langevin equations in which the

$j$. The superscripts C, H, B, D and L refer to the force and torque components arising due to contacts (C), hydrodynamics (H) and Brownian (B) effects, with the latter two acting both through drag (D) and lubrication (L). Each of these force and torque terms is described in detail below. These equations of motion can be understood as Langevin equations in which the ![]() $\langle {\cdot }\rangle ^C$ terms represent particle–particle interactions; the

$\langle {\cdot }\rangle ^C$ terms represent particle–particle interactions; the ![]() $\langle {\cdot }\rangle ^H$ terms represent configuration-dependent viscous friction (i.e. dissipative forces linear in the particle velocities); and the

$\langle {\cdot }\rangle ^H$ terms represent configuration-dependent viscous friction (i.e. dissipative forces linear in the particle velocities); and the ![]() $\langle {\cdot }\rangle ^B$ terms represent configuration-dependent (multiplicative) noise. Although particle inertia is present in the model, we omit fluid inertia (Hinch Reference Hinch1975), arguing that, for the regimes of interest, the principal contributions to the overall bulk rheology will come from particle–particle contact and hydrodynamic lubrication interactions. Particles are subjected to a liquid flow field given by

$\langle {\cdot }\rangle ^B$ terms represent configuration-dependent (multiplicative) noise. Although particle inertia is present in the model, we omit fluid inertia (Hinch Reference Hinch1975), arguing that, for the regimes of interest, the principal contributions to the overall bulk rheology will come from particle–particle contact and hydrodynamic lubrication interactions. Particles are subjected to a liquid flow field given by ![]() $\boldsymbol {U}^\infty$ (acting through the body force

$\boldsymbol {U}^\infty$ (acting through the body force ![]() $\boldsymbol {F}^{H,D}_i$ as described below), leading to a rate of strain tensor

$\boldsymbol {F}^{H,D}_i$ as described below), leading to a rate of strain tensor ![]() $\mathbb {E}=\frac {1}{2}(\boldsymbol {\nabla }\boldsymbol {U}^\infty + (\boldsymbol {\nabla }\boldsymbol {U}^\infty )^{T})$. Pairwise forces and torques are summed over the neighbours

$\mathbb {E}=\frac {1}{2}(\boldsymbol {\nabla }\boldsymbol {U}^\infty + (\boldsymbol {\nabla }\boldsymbol {U}^\infty )^{T})$. Pairwise forces and torques are summed over the neighbours ![]() $j$ of each particle

$j$ of each particle ![]() $i$, and the positions, velocities and acceleration are updated in a stepwise manner following the velocity-Verlet algorithm (Swope et al. Reference Swope, Andersen, Berens and Wilson1982; Frenkel & Smit Reference Frenkel and Smit2023). Below, we describe each of the force and torque contributions in detail; shown in figure 1 are illustrative schematics of each of the forces.

$i$, and the positions, velocities and acceleration are updated in a stepwise manner following the velocity-Verlet algorithm (Swope et al. Reference Swope, Andersen, Berens and Wilson1982; Frenkel & Smit Reference Frenkel and Smit2023). Below, we describe each of the force and torque contributions in detail; shown in figure 1 are illustrative schematics of each of the forces.

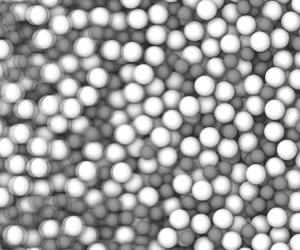

Figure 1. Snapshot of simulation box, and schematics of the leading pairwise force terms present in the model. In all cases, the leading component of the pairwise force acts along the (positive or negative) direction of the unit vector ![]() $\boldsymbol {n}_{i,\,j}$ pointing from the centre of particle

$\boldsymbol {n}_{i,\,j}$ pointing from the centre of particle ![]() $i$ to the centre of particle

$i$ to the centre of particle ![]() $j$. (a) Snapshot of the simulation box showing particles of radii

$j$. (a) Snapshot of the simulation box showing particles of radii ![]() $a$ (blue) and

$a$ (blue) and ![]() $1.4a$ (red), and the cubic domain length

$1.4a$ (red), and the cubic domain length ![]() $L$. Particles are mixed in approximately equal volume. We used a minimum particle number

$L$. Particles are mixed in approximately equal volume. We used a minimum particle number ![]() $N=1000$ (

$N=1000$ (![]() $L\approx 25a$) to ensure statistically significant results. (b) Contact force, with force acting along

$L\approx 25a$) to ensure statistically significant results. (b) Contact force, with force acting along ![]() $\boldsymbol {n}_{i,\,j}$; shown from left to right are (i) sketch of contacting particles

$\boldsymbol {n}_{i,\,j}$; shown from left to right are (i) sketch of contacting particles ![]() $i$ and

$i$ and ![]() $j$, with the overlap

$j$, with the overlap ![]() $\delta _{i,\,j}$ shown in green; (ii) the unit vector

$\delta _{i,\,j}$ shown in green; (ii) the unit vector ![]() $\boldsymbol {n}_{i,\,j}$ pointing from the centre of particle

$\boldsymbol {n}_{i,\,j}$ pointing from the centre of particle ![]() $i$ to

$i$ to ![]() $j$; (iii) repulsive contact

$j$; (iii) repulsive contact ![]() $F^C$ forces acting along the positive and negative directions of

$F^C$ forces acting along the positive and negative directions of ![]() $\boldsymbol {n}_{i,\,j}$. (c) Pairwise hydrodynamic lubrication force, with force set by the component of the relative particle velocity acting along

$\boldsymbol {n}_{i,\,j}$. (c) Pairwise hydrodynamic lubrication force, with force set by the component of the relative particle velocity acting along ![]() $\boldsymbol {n}_{i,\,j}$; shown from left to right are (i) sketch showing the velocity vectors

$\boldsymbol {n}_{i,\,j}$; shown from left to right are (i) sketch showing the velocity vectors ![]() $\boldsymbol {U}$ of neighbouring particles

$\boldsymbol {U}$ of neighbouring particles ![]() $i$ and

$i$ and ![]() $j$; (ii) the relative velocity

$j$; (ii) the relative velocity ![]() $U_j-U_i$ breaks down into tangential (blue) and normal (red) components, with the latter pointing along

$U_j-U_i$ breaks down into tangential (blue) and normal (red) components, with the latter pointing along ![]() $\boldsymbol {n}_{i,\,j}$; (iii) lubrication forces act along the positive and negative directions of

$\boldsymbol {n}_{i,\,j}$; (iii) lubrication forces act along the positive and negative directions of ![]() $\boldsymbol {n}_{i,\,j}$, proportional to the normal part of the relative velocity. (d) Pairwise Brownian lubrication force with a random pairwise vector

$\boldsymbol {n}_{i,\,j}$, proportional to the normal part of the relative velocity. (d) Pairwise Brownian lubrication force with a random pairwise vector ![]() $\boldsymbol {\theta }_{i,\,j}$ projected onto

$\boldsymbol {\theta }_{i,\,j}$ projected onto ![]() $\boldsymbol {n}_{i,\,j}$. Shown from left to right are (i) neighbouring particles with centre-to-centre unit vector

$\boldsymbol {n}_{i,\,j}$. Shown from left to right are (i) neighbouring particles with centre-to-centre unit vector ![]() $\boldsymbol {n}_{i,\,j}$; (ii) random vectors

$\boldsymbol {n}_{i,\,j}$; (ii) random vectors ![]() $\boldsymbol {\theta }_{i,\,j}$ drawn from a Gaussian distribution (green) are projected onto

$\boldsymbol {\theta }_{i,\,j}$ drawn from a Gaussian distribution (green) are projected onto ![]() $\boldsymbol {n}_{i,\,j}$ by the tangential (blue) and normal (red) operators; (iii) Brownian forces act along the positive and negative directions of

$\boldsymbol {n}_{i,\,j}$ by the tangential (blue) and normal (red) operators; (iii) Brownian forces act along the positive and negative directions of ![]() $\boldsymbol {n}_{i,\,j}$, proportional to the normal part of the random vector.

$\boldsymbol {n}_{i,\,j}$, proportional to the normal part of the random vector.

2.1. Contact forces and torques

The particle–particle contact force ![]() $\boldsymbol {F}^C$ follows a conventional granular-type interaction (Cundall & Strack Reference Cundall and Strack1979), and is activated for any two particles

$\boldsymbol {F}^C$ follows a conventional granular-type interaction (Cundall & Strack Reference Cundall and Strack1979), and is activated for any two particles ![]() $i$ and

$i$ and ![]() $j$ for which the centre-to-centre distance

$j$ for which the centre-to-centre distance ![]() $|\boldsymbol {r}_{i,\,j}|$ is smaller than the sum of the radii

$|\boldsymbol {r}_{i,\,j}|$ is smaller than the sum of the radii ![]() $a_i + a_j$. Contact forces include a repulsive part acting normal to the pairwise centre-to-centre vector

$a_i + a_j$. Contact forces include a repulsive part acting normal to the pairwise centre-to-centre vector ![]() $\boldsymbol {r}_{i,\,j}$ (we define a unit vector

$\boldsymbol {r}_{i,\,j}$ (we define a unit vector ![]() $\boldsymbol {n}_{i,\,j} = \boldsymbol {r}_{i,\,j}/|\boldsymbol {r}_{i,\,j}|$), and a tangential part. For simplicity, we model contacts as linear springs, so that particle pairs experience repulsive contact forces proportional to their scalar overlap, defined once in contact as

$\boldsymbol {n}_{i,\,j} = \boldsymbol {r}_{i,\,j}/|\boldsymbol {r}_{i,\,j}|$), and a tangential part. For simplicity, we model contacts as linear springs, so that particle pairs experience repulsive contact forces proportional to their scalar overlap, defined once in contact as ![]() $\delta _{i,\,j} = (a_i+a_j)-|\boldsymbol {r}_{i,\,j}|$. The implementation of our model within LAMMPS (Plimpton Reference Plimpton1995) nonetheless allows straightforward deployment of more complex

$\delta _{i,\,j} = (a_i+a_j)-|\boldsymbol {r}_{i,\,j}|$. The implementation of our model within LAMMPS (Plimpton Reference Plimpton1995) nonetheless allows straightforward deployment of more complex ![]() $\delta _{i,\,j}$ dependence (we note that, in LAMMPS, the skin argument of the neighbour command has units of (length)). Tangential forces are linear in

$\delta _{i,\,j}$ dependence (we note that, in LAMMPS, the skin argument of the neighbour command has units of (length)). Tangential forces are linear in ![]() $\boldsymbol {\xi }_{i,\,j}$, a vector describing the accumulated displacement of the particle pair perpendicular to

$\boldsymbol {\xi }_{i,\,j}$, a vector describing the accumulated displacement of the particle pair perpendicular to ![]() $\boldsymbol {n}_{i,\,j}$ since the initiation of the contact. Contact force and torque magnitudes are controlled by normal and tangential stiffness constants

$\boldsymbol {n}_{i,\,j}$ since the initiation of the contact. Contact force and torque magnitudes are controlled by normal and tangential stiffness constants ![]() $k_n$ and

$k_n$ and ![]() $k_t$ that set the hardness of the particles. The force and torque are given, respectively, by

$k_t$ that set the hardness of the particles. The force and torque are given, respectively, by

We additionally introduce a static friction coefficient ![]() $\mu$ that constrains the tangential force to

$\mu$ that constrains the tangential force to ![]() $|k_t\boldsymbol {\xi }_{i,\,j}|\leq \mu k_n\delta _{i,\,j}$. For larger values of

$|k_t\boldsymbol {\xi }_{i,\,j}|\leq \mu k_n\delta _{i,\,j}$. For larger values of ![]() $k_t\boldsymbol {\xi }_{i,\,j}$, the tangential part of the force and the torque are truncated, and particle contacts transition from a rolling to a sliding regime. We present data for

$k_t\boldsymbol {\xi }_{i,\,j}$, the tangential part of the force and the torque are truncated, and particle contacts transition from a rolling to a sliding regime. We present data for ![]() $\mu =0$ throughout, except in figure 6, where we explore the role of contact friction. Damping is not included in

$\mu =0$ throughout, except in figure 6, where we explore the role of contact friction. Damping is not included in ![]() $\boldsymbol {F}_{i,\,j}^{C}$ or

$\boldsymbol {F}_{i,\,j}^{C}$ or ![]() $\boldsymbol {T}_{i,\,j}^{C}$ as the lubrication forces and torques described below already render particle–particle contacts well within the overdamped regime. Each pairwise contact between particles

$\boldsymbol {T}_{i,\,j}^{C}$ as the lubrication forces and torques described below already render particle–particle contacts well within the overdamped regime. Each pairwise contact between particles ![]() $i$ and

$i$ and ![]() $j$ contributes to the overall contact stress of the system with a tensorial stresslet given by the outer product

$j$ contributes to the overall contact stress of the system with a tensorial stresslet given by the outer product ![]() $-\boldsymbol {F}^{C}_{i,\,j} \otimes \boldsymbol {r}_{i,\,j}$. The contact stress

$-\boldsymbol {F}^{C}_{i,\,j} \otimes \boldsymbol {r}_{i,\,j}$. The contact stress ![]() $\unicode{x2140}^C$ is obtained by summing this quantity over all contacting particle pairs and dividing by the system volume and dimension.

$\unicode{x2140}^C$ is obtained by summing this quantity over all contacting particle pairs and dividing by the system volume and dimension.

Contact forces of this kind have successfully been deployed in numerical models for rate-independent granular suspension rheology (Boyer, Guazzelli & Pouliquen Reference Boyer, Guazzelli and Pouliquen2011; Trulsson et al. Reference Trulsson, Andreotti and Claudin2012; Cheal & Ness Reference Cheal and Ness2018; Ge & Brandt Reference Ge and Brandt2020) and for models of shear thickening suspensions (Seto et al. Reference Seto, Mari, Morris and Denn2013) (in the latter case, rate dependence arises from a ‘critical load’ that the contact force must exceed before static friction is activated).

2.2. Hydrodynamic forces and torques

In general, hydrodynamic interactions in suspensions appear as single-particle drag forces ![]() $\boldsymbol {F}^{H,D}$, pairwise near-contact lubrication forces

$\boldsymbol {F}^{H,D}$, pairwise near-contact lubrication forces ![]() $\boldsymbol {F}^{H,L}$ and many-body long-range forces. In high volume fraction dense suspensions, however, it is argued by many authors that the hydrodynamic interactions are dominated by near-contact lubrication interactions (Ball & Melrose Reference Ball and Melrose1997) (which diverge on close approach) and that long-range interactions are effectively screened by intervening particles (Seto et al. Reference Seto, Mari, Morris and Denn2013; More & Ardekani Reference More and Ardekani2020). We follow this reasoning and therefore omit long-range hydrodynamics from our model, although we note there exist several implementations of coupling schemes between LAMMPS and fluid solvers that extend the capability down to dilute and semi-dilute regimes (see e.g. Sun & Xiao Reference Sun and Xiao2016). Below, we describe in detail the drag and lubrication forces deployed in the model. Single-particle drag forces and torques are given by

$\boldsymbol {F}^{H,L}$ and many-body long-range forces. In high volume fraction dense suspensions, however, it is argued by many authors that the hydrodynamic interactions are dominated by near-contact lubrication interactions (Ball & Melrose Reference Ball and Melrose1997) (which diverge on close approach) and that long-range interactions are effectively screened by intervening particles (Seto et al. Reference Seto, Mari, Morris and Denn2013; More & Ardekani Reference More and Ardekani2020). We follow this reasoning and therefore omit long-range hydrodynamics from our model, although we note there exist several implementations of coupling schemes between LAMMPS and fluid solvers that extend the capability down to dilute and semi-dilute regimes (see e.g. Sun & Xiao Reference Sun and Xiao2016). Below, we describe in detail the drag and lubrication forces deployed in the model. Single-particle drag forces and torques are given by

where we use the isolated-particle Stokes terms and, for simplicity, do not introduce volume-fraction-dependent hindrance functions. Here, ![]() $\eta$ is the liquid viscosity,

$\eta$ is the liquid viscosity, ![]() $\boldsymbol {U}^\infty (\boldsymbol {x}_i)$ is the value of the liquid streaming velocity at the position of the centre of mass of particle

$\boldsymbol {U}^\infty (\boldsymbol {x}_i)$ is the value of the liquid streaming velocity at the position of the centre of mass of particle ![]() $i$, and

$i$, and ![]() $\boldsymbol {\varOmega }^\infty = \frac {1}{2}(\boldsymbol {\nabla }\times \boldsymbol {U}^\infty )$ (spatially uniform assuming

$\boldsymbol {\varOmega }^\infty = \frac {1}{2}(\boldsymbol {\nabla }\times \boldsymbol {U}^\infty )$ (spatially uniform assuming ![]() $\boldsymbol {U}^\infty$ varies linearly in space). The drag forces lead to a per particle stress given by

$\boldsymbol {U}^\infty$ varies linearly in space). The drag forces lead to a per particle stress given by ![]() $\unicode{x2140}^{H,D}_i = \frac {20}{3}{\rm \pi} \eta a_i^3\mathbb {E}$.

$\unicode{x2140}^{H,D}_i = \frac {20}{3}{\rm \pi} \eta a_i^3\mathbb {E}$.

For pairwise lubrication forces and torques acting between interacting particles ![]() $i$ and

$i$ and ![]() $j$ we start from the conventional representation given by Kim & Karrila (Reference Kim and Karrila2013) as

$j$ we start from the conventional representation given by Kim & Karrila (Reference Kim and Karrila2013) as

\begin{equation} \begin{pmatrix}

\boldsymbol{F}_{i,\,j}^{H,L} \\ \boldsymbol{F}_{j,i}^{H,L} \\

\boldsymbol{T}_{i,\,j}^{H,L} \\ \boldsymbol{T}_{j,i}^{H,L}\\

\unicode{x2140}_{i,\,j}^{H,L}\\ \unicode{x2140}_{j,i}^{H,L}

\end{pmatrix} =\eta{\mathbb{R}} \begin{pmatrix}

\boldsymbol{U}^\infty(\boldsymbol{x}_i)-\boldsymbol{U}_i \\

\boldsymbol{U}^\infty(\boldsymbol{x}_j)-\boldsymbol{U}_j \\

\boldsymbol{\varOmega}^\infty-\boldsymbol{\varOmega}_i \\

\boldsymbol{\varOmega}^\infty-\boldsymbol{\varOmega}_j \\

\mathbb{E}\\ \mathbb{E} \end{pmatrix},

\end{equation}

\begin{equation} \begin{pmatrix}

\boldsymbol{F}_{i,\,j}^{H,L} \\ \boldsymbol{F}_{j,i}^{H,L} \\

\boldsymbol{T}_{i,\,j}^{H,L} \\ \boldsymbol{T}_{j,i}^{H,L}\\

\unicode{x2140}_{i,\,j}^{H,L}\\ \unicode{x2140}_{j,i}^{H,L}

\end{pmatrix} =\eta{\mathbb{R}} \begin{pmatrix}

\boldsymbol{U}^\infty(\boldsymbol{x}_i)-\boldsymbol{U}_i \\

\boldsymbol{U}^\infty(\boldsymbol{x}_j)-\boldsymbol{U}_j \\

\boldsymbol{\varOmega}^\infty-\boldsymbol{\varOmega}_i \\

\boldsymbol{\varOmega}^\infty-\boldsymbol{\varOmega}_j \\

\mathbb{E}\\ \mathbb{E} \end{pmatrix},

\end{equation}

where ![]() ${\mathbb {R}}$ is the resistance matrix containing tensorial operations that linearly couple pairwise particle forces (torques) to velocities (rotational velocities), taking into account relative particle positions. After some algebra and omitting terms that vanish with the size of the interparticle gap (see Radhakrishnan Reference Radhakrishnan2018 for details) one can obtain the forces in a simplified pairwise form as

${\mathbb {R}}$ is the resistance matrix containing tensorial operations that linearly couple pairwise particle forces (torques) to velocities (rotational velocities), taking into account relative particle positions. After some algebra and omitting terms that vanish with the size of the interparticle gap (see Radhakrishnan Reference Radhakrishnan2018 for details) one can obtain the forces in a simplified pairwise form as

\begin{align} \boldsymbol{F}_{i,\,j}^{H,L}=-\boldsymbol{F}_{j,i}^{H,L}&= ( X^A_{11}\mathbb{N}_{i,\,j}+Y^A_{11}\mathbb{T}_{i,\,j})(\boldsymbol{U}_j-\boldsymbol{U}_i)\nonumber\\ &\quad +Y^B_{11}(\boldsymbol{\varOmega}_i\times\boldsymbol{n}_{i,\,j})\nonumber\\ &\quad +Y^B_{21}(\boldsymbol{\varOmega}_j\times\boldsymbol{n}_{i,\,j}), \end{align}

\begin{align} \boldsymbol{F}_{i,\,j}^{H,L}=-\boldsymbol{F}_{j,i}^{H,L}&= ( X^A_{11}\mathbb{N}_{i,\,j}+Y^A_{11}\mathbb{T}_{i,\,j})(\boldsymbol{U}_j-\boldsymbol{U}_i)\nonumber\\ &\quad +Y^B_{11}(\boldsymbol{\varOmega}_i\times\boldsymbol{n}_{i,\,j})\nonumber\\ &\quad +Y^B_{21}(\boldsymbol{\varOmega}_j\times\boldsymbol{n}_{i,\,j}), \end{align}

where ![]() $\boldsymbol {F}_{i,\,j}^{H,L}$ is the force acting on particle

$\boldsymbol {F}_{i,\,j}^{H,L}$ is the force acting on particle ![]() $i$ by particle

$i$ by particle ![]() $j$;

$j$; ![]() $\mathbb {N}=\boldsymbol {n}_{i,\,j}\otimes \boldsymbol {n}_{i,\,j}$ is a tensorial normal operator;

$\mathbb {N}=\boldsymbol {n}_{i,\,j}\otimes \boldsymbol {n}_{i,\,j}$ is a tensorial normal operator; ![]() $\mathbb {T}=\mathbb {I} - \boldsymbol {n}_{i,\,j}\otimes \boldsymbol {n}_{i,\,j}$ is a tensorial projection operator;

$\mathbb {T}=\mathbb {I} - \boldsymbol {n}_{i,\,j}\otimes \boldsymbol {n}_{i,\,j}$ is a tensorial projection operator; ![]() $\boldsymbol {n}_{i,\,j}$ is the unit vector pointing from particle

$\boldsymbol {n}_{i,\,j}$ is the unit vector pointing from particle ![]() $i$ to particle

$i$ to particle ![]() $j$;

$j$; ![]() $\boldsymbol {U}_i$ is the velocity of particle

$\boldsymbol {U}_i$ is the velocity of particle ![]() $i$;

$i$; ![]() $\boldsymbol {\varOmega }_i$ is the rotational velocity of particle

$\boldsymbol {\varOmega }_i$ is the rotational velocity of particle ![]() $i$; and

$i$; and ![]() $\mathbb {I}$ is the identity tensor in three dimensions. The scalar prefactors

$\mathbb {I}$ is the identity tensor in three dimensions. The scalar prefactors ![]() $X$ and

$X$ and ![]() $Y$ encode the geometry of the interacting pair, namely the size of the interparticle gap and the size ratio of the interacting particles. Their superscripts

$Y$ encode the geometry of the interacting pair, namely the size of the interparticle gap and the size ratio of the interacting particles. Their superscripts ![]() $A$,

$A$, ![]() $B$ and subscripts

$B$ and subscripts ![]() $11$,

$11$, ![]() $22$ are more appropriate to the labelling convention used by Kim & Karrila (Reference Kim and Karrila2013) but nonetheless we retain them here for ease of referencing to that work. The particle size ratio is written as

$22$ are more appropriate to the labelling convention used by Kim & Karrila (Reference Kim and Karrila2013) but nonetheless we retain them here for ease of referencing to that work. The particle size ratio is written as ![]() $\beta =a_j/a_i$ and the dimensionless interparticle gap is

$\beta =a_j/a_i$ and the dimensionless interparticle gap is ![]() $\xi = 2(|\boldsymbol {r}_{i,\,j}|-(a_i+a_j))/(a_i+a_j)$. The scalar prefactors are given by

$\xi = 2(|\boldsymbol {r}_{i,\,j}|-(a_i+a_j))/(a_i+a_j)$. The scalar prefactors are given by

Meanwhile, the torques on particles ![]() $i$ and

$i$ and ![]() $j$ as a result of their interaction with particles

$j$ as a result of their interaction with particles ![]() $j$ and

$j$ and ![]() $i$, respectively, are written as

$i$, respectively, are written as

with scalar prefactors given by

Similar expressions may be obtained for the elements of the hydrodynamic lubrication stress tensor, although these can be shown to be equivalent (up to an order-![]() $\xi$ term in the normal stresses) to the form used for the contact forces. The contribution to the hydrodynamic stress coming from each pairwise interaction is thus given by

$\xi$ term in the normal stresses) to the form used for the contact forces. The contribution to the hydrodynamic stress coming from each pairwise interaction is thus given by ![]() $\unicode{x2140}^{H,L}_{i,\,j} = -\boldsymbol {F}^{H,L}_{i,\,j} \otimes \boldsymbol {r}_{i,\,j}$. To mitigate against divergence in the scalar prefactors at particle contacts (that is, where

$\unicode{x2140}^{H,L}_{i,\,j} = -\boldsymbol {F}^{H,L}_{i,\,j} \otimes \boldsymbol {r}_{i,\,j}$. To mitigate against divergence in the scalar prefactors at particle contacts (that is, where ![]() $\xi \to 0$) we use

$\xi \to 0$) we use ![]() $\xi _{min}=10^{-3}$ in the calculation whenever

$\xi _{min}=10^{-3}$ in the calculation whenever ![]() $\xi < \xi _{min}$. We do not calculate pairwise lubrication forces when particles are separated by gaps

$\xi < \xi _{min}$. We do not calculate pairwise lubrication forces when particles are separated by gaps ![]() $\xi >\xi _{max}$, with

$\xi >\xi _{max}$, with ![]() $\xi _{max}=0.05$. This choice does not influence the overall effective potential between interacting pairs (see figure 2a,b), but it does have a quantitative effect on the reported viscosities as described by Mari et al. (Reference Mari, Seto, Morris and Denn2014) (see also figure 5e).

$\xi _{max}=0.05$. This choice does not influence the overall effective potential between interacting pairs (see figure 2a,b), but it does have a quantitative effect on the reported viscosities as described by Mari et al. (Reference Mari, Seto, Morris and Denn2014) (see also figure 5e).

Figure 2. Evaluating the potential of mean force and the diffusion properties that arise from the particle-level forces described above, in the absence of shear flow. (a) The radial distribution function ![]() $g(r)$ (with

$g(r)$ (with ![]() $r = |\boldsymbol {r}_{i,\,j}|$) computed from a two-particle simulation (inset: snapshot of simulation). (b) Potential of mean force

$r = |\boldsymbol {r}_{i,\,j}|$) computed from a two-particle simulation (inset: snapshot of simulation). (b) Potential of mean force ![]() $U(r)$, showing measured result (points) and the input particle stiffness (solid line). (c,d) Mean squared displacement as a function of elapsed time for (c) three values of the time scale ratio

$U(r)$, showing measured result (points) and the input particle stiffness (solid line). (c,d) Mean squared displacement as a function of elapsed time for (c) three values of the time scale ratio ![]() $\tau _I/\tau _B$ at

$\tau _I/\tau _B$ at ![]() $\phi =0.001$. (d) Three values of

$\phi =0.001$. (d) Three values of ![]() $\phi$ at

$\phi$ at ![]() $\tau _I/\tau _B=1.7$. (e) Diffusion coefficient as a function of elapsed time for a range of

$\tau _I/\tau _B=1.7$. (e) Diffusion coefficient as a function of elapsed time for a range of ![]() $\phi$ at

$\phi$ at ![]() $\tau _I/\tau _B=1.7$. The solid line in (c-e) represents the predictions of (3.1). (f) Long-time diffusion coefficient at a broad range of

$\tau _I/\tau _B=1.7$. The solid line in (c-e) represents the predictions of (3.1). (f) Long-time diffusion coefficient at a broad range of ![]() $\phi$ and

$\phi$ and ![]() $\tau _I/\tau _B$.

$\tau _I/\tau _B$.

2.3. Brownian forces and torques

To satisfy fluctuation–dissipation theorem, we must produce Brownian forces that follow

where ![]() $\mathcal {F}_B$ is a list of the Brownian forces and torques,

$\mathcal {F}_B$ is a list of the Brownian forces and torques, ![]() $\mathcal {R}$ is the overall resistance operator for the system (taking into account both one-body and pairwise hydrodynamic dissipation that we describe separately below). Here,

$\mathcal {R}$ is the overall resistance operator for the system (taking into account both one-body and pairwise hydrodynamic dissipation that we describe separately below). Here, ![]() $k_b$ is the Boltzmann constant and

$k_b$ is the Boltzmann constant and ![]() $T$ is the temperature, so that

$T$ is the temperature, so that ![]() $k_bT$ is the thermal energy, and

$k_bT$ is the thermal energy, and ![]() $\Delta t$ is the computational timestep (discussed in more detail below).

$\Delta t$ is the computational timestep (discussed in more detail below).

For one-body Brownian forces we need 6 random numbers (i.e. two vectors in three-dimensional space ![]() $\boldsymbol {\psi }_i$ and

$\boldsymbol {\psi }_i$ and ![]() $\boldsymbol {\varphi }_i$) to satisfy the translational and rotational degrees of freedom of each particle

$\boldsymbol {\varphi }_i$) to satisfy the translational and rotational degrees of freedom of each particle ![]() $i$. The elements of the random vectors

$i$. The elements of the random vectors ![]() $\boldsymbol {\psi }_i$,

$\boldsymbol {\psi }_i$, ![]() $\boldsymbol {\varphi }_i$ are drawn from a Gaussian distribution and satisfy

$\boldsymbol {\varphi }_i$ are drawn from a Gaussian distribution and satisfy ![]() $\langle \varphi _\alpha \varphi _\beta \rangle = \langle \psi _\alpha \psi _\beta \rangle = \delta _{\alpha \beta }$ and they are uncorrelated with each other so that

$\langle \varphi _\alpha \varphi _\beta \rangle = \langle \psi _\alpha \psi _\beta \rangle = \delta _{\alpha \beta }$ and they are uncorrelated with each other so that ![]() $\langle \varphi _\alpha \psi _\beta \rangle =0$. The following forces and torques satisfy fluctuation–dissipation theorem (we label them as Brownian drag ‘B,D’ to align with the hydrodynamic drag forces and torques defined above). The one-body Brownian force and torque on particle

$\langle \varphi _\alpha \psi _\beta \rangle =0$. The following forces and torques satisfy fluctuation–dissipation theorem (we label them as Brownian drag ‘B,D’ to align with the hydrodynamic drag forces and torques defined above). The one-body Brownian force and torque on particle ![]() $i$ are given by

$i$ are given by

Averaging ![]() $\langle \boldsymbol {F}_i^{B,D}\otimes \boldsymbol {F}_i^{B,D}\rangle$ and

$\langle \boldsymbol {F}_i^{B,D}\otimes \boldsymbol {F}_i^{B,D}\rangle$ and ![]() $\langle \boldsymbol {T}_i^{B,D}\otimes \boldsymbol {T}_i^{B,D}\rangle$ over many realisations of the vectors

$\langle \boldsymbol {T}_i^{B,D}\otimes \boldsymbol {T}_i^{B,D}\rangle$ over many realisations of the vectors ![]() $\boldsymbol {\psi }_i$ and

$\boldsymbol {\psi }_i$ and ![]() $\boldsymbol {\varphi }_i$ leads, respectively, to

$\boldsymbol {\varphi }_i$ leads, respectively, to ![]() $({2k_bT}/{\Delta t})6{\rm \pi} \eta a_i \mathbb {I}$ and

$({2k_bT}/{\Delta t})6{\rm \pi} \eta a_i \mathbb {I}$ and ![]() $({2k_bT}/{\Delta t})8{\rm \pi} \eta a_i^3 \mathbb {I}$ as required (with

$({2k_bT}/{\Delta t})8{\rm \pi} \eta a_i^3 \mathbb {I}$ as required (with ![]() $\mathbb {I}$ the identity matrix in three dimensions).

$\mathbb {I}$ the identity matrix in three dimensions).

Pairwise Brownian forces and torques similarly require two random vectors ![]() $\boldsymbol {\theta }_{i,\,j}$ and

$\boldsymbol {\theta }_{i,\,j}$ and ![]() $\boldsymbol {\chi }_{i,\,j}$ (independent of

$\boldsymbol {\chi }_{i,\,j}$ (independent of ![]() $\boldsymbol {\psi }_i$ and

$\boldsymbol {\psi }_i$ and ![]() $\boldsymbol {\varphi }_i$ but with the same properties) to satisfy the relative translational and rotational motion of two interacting particles (see also Kumar & Higdon Reference Kumar and Higdon2010). The pairwise forces and torques must be constructed in such a way that, for particles

$\boldsymbol {\varphi }_i$ but with the same properties) to satisfy the relative translational and rotational motion of two interacting particles (see also Kumar & Higdon Reference Kumar and Higdon2010). The pairwise forces and torques must be constructed in such a way that, for particles ![]() $i$ and

$i$ and ![]() $j$, averaging

$j$, averaging ![]() $\langle \boldsymbol {F}_{i,\,j}^{B,L} \otimes \boldsymbol {F}_{i,\,j}^{B,L} \rangle$ and

$\langle \boldsymbol {F}_{i,\,j}^{B,L} \otimes \boldsymbol {F}_{i,\,j}^{B,L} \rangle$ and ![]() $\langle \boldsymbol {T}_{i,\,j}^{B,L} \otimes \boldsymbol {T}_{i,\,j}^{B,L} \rangle$ over many realisations of

$\langle \boldsymbol {T}_{i,\,j}^{B,L} \otimes \boldsymbol {T}_{i,\,j}^{B,L} \rangle$ over many realisations of ![]() $\boldsymbol {\theta }_{i,\,j}$ and

$\boldsymbol {\theta }_{i,\,j}$ and ![]() $\boldsymbol {\chi }_{i,\,j}$ recovers the form of the pairwise hydrodynamic lubrication forces and torques described above. Doing so (see Appendix A for details), which involves exploiting the fact that the normal and projection operators present in the definition of the lubrication forces and torques are idempotent (i.e.

$\boldsymbol {\chi }_{i,\,j}$ recovers the form of the pairwise hydrodynamic lubrication forces and torques described above. Doing so (see Appendix A for details), which involves exploiting the fact that the normal and projection operators present in the definition of the lubrication forces and torques are idempotent (i.e. ![]() $\langle (\mathbb {N}_{i,\,j}\boldsymbol {\theta }_{i,\,j})\otimes (\mathbb {N}_{i,\,j}\boldsymbol {\theta }_{i,\,j})\rangle = \mathbb {N}_{i,\,j}$) and orthogonal (i.e.

$\langle (\mathbb {N}_{i,\,j}\boldsymbol {\theta }_{i,\,j})\otimes (\mathbb {N}_{i,\,j}\boldsymbol {\theta }_{i,\,j})\rangle = \mathbb {N}_{i,\,j}$) and orthogonal (i.e. ![]() $\langle (\mathbb {N}_{i,\,j}\boldsymbol {\theta }_{i,\,j})\otimes (\mathbb {T}_{i,\,j}\boldsymbol {\theta }_{i,\,j})\rangle = 0$), one obtains the following expressions for the pairwise Brownian force and torque (calculated when

$\langle (\mathbb {N}_{i,\,j}\boldsymbol {\theta }_{i,\,j})\otimes (\mathbb {T}_{i,\,j}\boldsymbol {\theta }_{i,\,j})\rangle = 0$), one obtains the following expressions for the pairwise Brownian force and torque (calculated when ![]() $\xi <\xi _{max}$):

$\xi <\xi _{max}$):

$$\begin{gather}\boldsymbol{T}_{i,\,j}^{B,L} = \sqrt{\frac{2k_bT}{\Delta t}}\left(\frac{Y_B^{11}}{\sqrt{Y_A^{11}}}\boldsymbol{\theta}_{i,\,j}\times \boldsymbol{n}_{i,\,j} + \sqrt{Y_C^{11}-\frac{(Y_B^{11})^2}{Y_A^{11}}}\mathbb{T}\boldsymbol{\chi}_{i,\,j} \right)\!, \end{gather}$$

$$\begin{gather}\boldsymbol{T}_{i,\,j}^{B,L} = \sqrt{\frac{2k_bT}{\Delta t}}\left(\frac{Y_B^{11}}{\sqrt{Y_A^{11}}}\boldsymbol{\theta}_{i,\,j}\times \boldsymbol{n}_{i,\,j} + \sqrt{Y_C^{11}-\frac{(Y_B^{11})^2}{Y_A^{11}}}\mathbb{T}\boldsymbol{\chi}_{i,\,j} \right)\!, \end{gather}$$ $$\begin{gather}\boldsymbol{T}_{j,i}^{B,L} = \sqrt{\frac{2k_bT}{\Delta t}}\left(\frac{Y_B^{21}}{\sqrt{Y_A^{11}}}\boldsymbol{\theta}_{i,\,j}\times \boldsymbol{n}_{i,\,j} - \sqrt{Y_C^{22}-\frac{(Y_B^{21})^2}{Y_A^{11}}}\mathbb{T}\boldsymbol{\chi}_{i,\,j} \right)\!. \end{gather}$$

$$\begin{gather}\boldsymbol{T}_{j,i}^{B,L} = \sqrt{\frac{2k_bT}{\Delta t}}\left(\frac{Y_B^{21}}{\sqrt{Y_A^{11}}}\boldsymbol{\theta}_{i,\,j}\times \boldsymbol{n}_{i,\,j} - \sqrt{Y_C^{22}-\frac{(Y_B^{21})^2}{Y_A^{11}}}\mathbb{T}\boldsymbol{\chi}_{i,\,j} \right)\!. \end{gather}$$Our model thus involves computing (2.1) and (2.2) to evaluate the trajectory of each particle, subject to imposed forces given by (2.3), (2.5), (2.8), (2.21) and (2.23), and torques given by (2.4), (2.6), (2.13), (2.14), (2.22), (2.24) and (2.25). Our model is similar to that of Mari et al. (Reference Mari, Seto, Morris and Denn2015), seeking to examine aspects of the same physics (albeit with inertia present in our model) but using an alternative integration scheme.

2.4. Brownian stress calculation

One can similarly obtain from fluctuation–dissipation theorem an expression for the Brownian stress resulting from the pairwise interaction between particles ![]() $i$ and

$i$ and ![]() $j$ that averages over many realisations so that

$j$ that averages over many realisations so that ![]() $\langle \unicode{x2140}^{B,L}_{i,\,j}\otimes \unicode{x2140}^{B,L}_{i,\,j} \rangle$ recovers the form of the hydrodynamic lubrication stress, but as described above, this can similarly be shown to be equivalent to

$\langle \unicode{x2140}^{B,L}_{i,\,j}\otimes \unicode{x2140}^{B,L}_{i,\,j} \rangle$ recovers the form of the hydrodynamic lubrication stress, but as described above, this can similarly be shown to be equivalent to ![]() $\unicode{x2140}^{B,L}_{i,\,j} = -\boldsymbol {F}^{B,L}_{i,\,j} \otimes \boldsymbol {r}_{i,\,j}$. Since the pairwise Brownian force term contains the normal operator

$\unicode{x2140}^{B,L}_{i,\,j} = -\boldsymbol {F}^{B,L}_{i,\,j} \otimes \boldsymbol {r}_{i,\,j}$. Since the pairwise Brownian force term contains the normal operator ![]() $\mathbb {N}_{i,\,j}$ acting on the random vector

$\mathbb {N}_{i,\,j}$ acting on the random vector ![]() $\boldsymbol {\theta }_{i,\,j}$, one obtains a prefactor in the stress containing the dot product

$\boldsymbol {\theta }_{i,\,j}$, one obtains a prefactor in the stress containing the dot product ![]() $\boldsymbol {n}_{i,\,j}\boldsymbol{\cdot }\boldsymbol {\theta }_{i,\,j}$. This quantity will always approach zero when averaged over many realisations of

$\boldsymbol {n}_{i,\,j}\boldsymbol{\cdot }\boldsymbol {\theta }_{i,\,j}$. This quantity will always approach zero when averaged over many realisations of ![]() $\boldsymbol {\theta }_{i,\,j}$, so that the Brownian stress computed in this way averages to zero. Nonetheless, particle pairs do experience non-zero Brownian forces acting at all timesteps that will influence their trajectories so that the resulting contact and lubrication stresses will be altered by the presence of the Brownian forces. Below, we describe a method that allows us to estimate the contribution of Brownian motion to the overall stress.

$\boldsymbol {\theta }_{i,\,j}$, so that the Brownian stress computed in this way averages to zero. Nonetheless, particle pairs do experience non-zero Brownian forces acting at all timesteps that will influence their trajectories so that the resulting contact and lubrication stresses will be altered by the presence of the Brownian forces. Below, we describe a method that allows us to estimate the contribution of Brownian motion to the overall stress.

It is important to note here that our method, in which particle inertia is accounted for, is fundamentally different to other computational approaches, notably SD (Ermak & McCammon Reference Ermak and McCammon1978; Brady & Bossis Reference Brady and Bossis1988; Bossis & Brady Reference Bossis and Brady1989), in which the trajectories are evolved with a timestep longer than the inertial one. In the latter methods (see in particular Banchio & Brady (Reference Banchio and Brady2003)) the Brownian stress for the overall system is obtained as ![]() $\unicode{x2140}^B = k_bT\boldsymbol {\nabla }\boldsymbol{\cdot }(\mathcal {R}_{SU}\boldsymbol{\cdot } \mathcal {R}_{FU}^{-1})$, in practice using a midpoint scheme in which the positions and velocities of every particle are sampled at some increment of the overall timestep. Here,

$\unicode{x2140}^B = k_bT\boldsymbol {\nabla }\boldsymbol{\cdot }(\mathcal {R}_{SU}\boldsymbol{\cdot } \mathcal {R}_{FU}^{-1})$, in practice using a midpoint scheme in which the positions and velocities of every particle are sampled at some increment of the overall timestep. Here, ![]() $\mathcal {R}_{SU}$ and

$\mathcal {R}_{SU}$ and ![]() $\mathcal {R}_{FU}$ represent parts of the overall resistance matrix that couple, respectively, stresses to velocities and forces to velocities. Our method described above is based on the Langevin equation so that particle inertia is small but present, and force balance is not strictly achieved at each timestep. In order to obtain an estimate of the Brownian contribution to the stress, we deploy a structural method that exploits the anisotropy of the radial distribution function, using the approach described by Brady (Reference Brady1993). The Brownian stress attributable to the pair

$\mathcal {R}_{FU}$ represent parts of the overall resistance matrix that couple, respectively, stresses to velocities and forces to velocities. Our method described above is based on the Langevin equation so that particle inertia is small but present, and force balance is not strictly achieved at each timestep. In order to obtain an estimate of the Brownian contribution to the stress, we deploy a structural method that exploits the anisotropy of the radial distribution function, using the approach described by Brady (Reference Brady1993). The Brownian stress attributable to the pair ![]() $i,\,j$ can be written as

$i,\,j$ can be written as

\begin{equation} \unicode{x2140}^B_{i,\,j} =-n k_bT a \int_{S_2} (\boldsymbol{n}_{i,\,j}\otimes \boldsymbol{n}_{i,\,j}) p_{1/1}(\boldsymbol{x}_j| \boldsymbol{x}_i) \,{\rm d}\boldsymbol{S}_2 , \end{equation}

\begin{equation} \unicode{x2140}^B_{i,\,j} =-n k_bT a \int_{S_2} (\boldsymbol{n}_{i,\,j}\otimes \boldsymbol{n}_{i,\,j}) p_{1/1}(\boldsymbol{x}_j| \boldsymbol{x}_i) \,{\rm d}\boldsymbol{S}_2 , \end{equation}

where ![]() $p_{1/1}(\boldsymbol {x}_j\,| \,\boldsymbol {x}_i)$ is the probability density for finding a particle at

$p_{1/1}(\boldsymbol {x}_j\,| \,\boldsymbol {x}_i)$ is the probability density for finding a particle at ![]() $\boldsymbol {x}_j$ given that there is a particle at

$\boldsymbol {x}_j$ given that there is a particle at ![]() $\boldsymbol {x}_i$, and

$\boldsymbol {x}_i$, and ![]() $n=N/V$ is the number density of particles in the suspension (where

$n=N/V$ is the number density of particles in the suspension (where ![]() $V$ and

$V$ and ![]() $N$ are the system volume and particle number, respectively). The integral is over the surface of contact

$N$ are the system volume and particle number, respectively). The integral is over the surface of contact ![]() $S_2$ of two touching particles.

$S_2$ of two touching particles.

To compute this function we sum for each particle the dyadic product of its unit vector with each of its neighbours within a thin shell ![]() $\varDelta = 0.05a_i$, so that, for a given configuration, the Brownian contribution to the stress is (Lin et al. Reference Lin, Bierbaum, Schall, Sethna and Cohen2016)

$\varDelta = 0.05a_i$, so that, for a given configuration, the Brownian contribution to the stress is (Lin et al. Reference Lin, Bierbaum, Schall, Sethna and Cohen2016)

\begin{equation} \unicode{x2140}^{B} =-\frac{k_bT}{V}\sum_i \frac{a_i}{\varDelta} \sum_{j \in \varDelta}(\boldsymbol{n}_{i,\,j} \otimes \boldsymbol{n}_{i,\,j}). \end{equation}

\begin{equation} \unicode{x2140}^{B} =-\frac{k_bT}{V}\sum_i \frac{a_i}{\varDelta} \sum_{j \in \varDelta}(\boldsymbol{n}_{i,\,j} \otimes \boldsymbol{n}_{i,\,j}). \end{equation}The stress obtained by this approach is not added to the hydrodynamic and contact stresses computed in our model, but rather it measures what fraction of the total stress (the sum of hydrodynamic and contacts stresses) is attributable to Brownian motion. It is thus available to provide insight into the role of Brownian motion in setting the overall material response.

2.5. Additional simulation details

We simulate ![]() $N=1000$ spherical particles of radius

$N=1000$ spherical particles of radius ![]() $a$ and

$a$ and ![]() $1.4a$ (mixed approximately equally by volume) in a cubic periodic simulation box of length

$1.4a$ (mixed approximately equally by volume) in a cubic periodic simulation box of length ![]() $L$. For each set of flow conditions we carried out between 10 and 800 realisations (dependent on the Péclet number, see figure 3a) in order to obtain satisfactory ensemble averages.

$L$. For each set of flow conditions we carried out between 10 and 800 realisations (dependent on the Péclet number, see figure 3a) in order to obtain satisfactory ensemble averages.

Figure 3. Computing the suspension viscosity ![]() $\eta _r$ under sheared and non-sheared conditions, and the scaling of computational run time with system size. Shown in (a) is the convergence of the measured

$\eta _r$ under sheared and non-sheared conditions, and the scaling of computational run time with system size. Shown in (a) is the convergence of the measured ![]() $\eta _r$ as a function of the number of snapshots averaged over, for

$\eta _r$ as a function of the number of snapshots averaged over, for ![]() $Pe=0.01$ (red),

$Pe=0.01$ (red), ![]() $1$ (green) and

$1$ (green) and ![]() $10^4$ (blue). The noisy stress signal when Brownian motion dominates necessitates large numbers of realisations (we take

$10^4$ (blue). The noisy stress signal when Brownian motion dominates necessitates large numbers of realisations (we take ![]() $10^6$ samples per realisation). In (b) is

$10^6$ samples per realisation). In (b) is ![]() $\eta _{B,GK}$ measured via the Green–Kubo relation taking the autocorrelation of the Brownian shear stress as input, plotted as a function of the correlation time. (c) Simulation run time vs number of particles for

$\eta _{B,GK}$ measured via the Green–Kubo relation taking the autocorrelation of the Brownian shear stress as input, plotted as a function of the correlation time. (c) Simulation run time vs number of particles for ![]() $\phi =0.5$,

$\phi =0.5$, ![]() $Pe=1$, when running a serial compilation of LAMMPS on a single processor. We show data for a short simulation comprising

$Pe=1$, when running a serial compilation of LAMMPS on a single processor. We show data for a short simulation comprising ![]() $10^7$ timesteps.

$10^7$ timesteps.

The principal particle properties (these set the length, mass and time scales) are the characteristic particle radius ![]() $a$ (length), the particle density

$a$ (length), the particle density ![]() $\rho$ (mass length

$\rho$ (mass length![]() $^{-3}$) (taken throughout to be equal to the fluid density so that the particles are neutrally buoyant) and the particle normal stiffness

$^{-3}$) (taken throughout to be equal to the fluid density so that the particles are neutrally buoyant) and the particle normal stiffness ![]() $k_n$ (mass time

$k_n$ (mass time![]() $^{-2}$) (this has a tangential counterpart

$^{-2}$) (this has a tangential counterpart ![]() $k_t$). The remaining material properties to be defined are the fluid viscosity

$k_t$). The remaining material properties to be defined are the fluid viscosity ![]() $\eta$ (mass (length

$\eta$ (mass (length![]() $\,\times\,$time)

$\,\times\,$time)![]() $^{-1}$) and the particle–particle friction coefficient

$^{-1}$) and the particle–particle friction coefficient ![]() $\mu$ (dimensionless), relevant for micron sized (and larger) particles. The thermal energy scale in the system is set by the product of the Boltzmann constant

$\mu$ (dimensionless), relevant for micron sized (and larger) particles. The thermal energy scale in the system is set by the product of the Boltzmann constant ![]() $k_b$ (held constant in the simulation) and the temperature

$k_b$ (held constant in the simulation) and the temperature ![]() $T$. In what follows we write this as

$T$. In what follows we write this as ![]() $k_bT$. As described below, we vary

$k_bT$. As described below, we vary ![]() $k_n$ from unity on physical grounds, and we provide a full list of parameter values in table 1.

$k_n$ from unity on physical grounds, and we provide a full list of parameter values in table 1.

Table 1. The parameters used to generate each data point in figure 5(a). Shown in the second row are the dimensions of each quantity in terms of mass (M), length (L) and time (T), with (–) representing a dimensionless quantity.

The simulation box is deformed according to a specified ![]() $\boldsymbol {\nabla }\boldsymbol {U}^\infty$. For instance, when the only non-zero element of

$\boldsymbol {\nabla }\boldsymbol {U}^\infty$. For instance, when the only non-zero element of ![]() $\boldsymbol {\nabla }\boldsymbol {U}^\infty$ is an off diagonal (say

$\boldsymbol {\nabla }\boldsymbol {U}^\infty$ is an off diagonal (say ![]() $\dot {\gamma }$), shearing is applied by tilting the triclinic box (at fixed volume) according to

$\dot {\gamma }$), shearing is applied by tilting the triclinic box (at fixed volume) according to ![]() $L_{xy}(t) = L_{xy}(t_0) + L\dot {\gamma }t$, where

$L_{xy}(t) = L_{xy}(t_0) + L\dot {\gamma }t$, where ![]() $L_{xy}$ is the displacement along

$L_{xy}$ is the displacement along ![]() $x$ of the uppermost surface of the box. When the strain (

$x$ of the uppermost surface of the box. When the strain (![]() $\gamma =\dot {\gamma }t$, with

$\gamma =\dot {\gamma }t$, with ![]() $t$ the time for which the simulation has run) reaches 0.5 in this example, the system is remapped to a strain of

$t$ the time for which the simulation has run) reaches 0.5 in this example, the system is remapped to a strain of ![]() $-$0.5. This has no effect on the particle–particle forces or on the stress, and is simply a numerical tool to permit unbounded shear deformation while preventing the domain from becoming elongated in one axis (Ness Reference Ness2023). The system is initialised in a randomised, non-overlapping configuration, and before all rheology measurements we shear the system to steady state such that its initial arrangement has been forgotten. Reported in the following is the relative viscosity of the suspension

$-$0.5. This has no effect on the particle–particle forces or on the stress, and is simply a numerical tool to permit unbounded shear deformation while preventing the domain from becoming elongated in one axis (Ness Reference Ness2023). The system is initialised in a randomised, non-overlapping configuration, and before all rheology measurements we shear the system to steady state such that its initial arrangement has been forgotten. Reported in the following is the relative viscosity of the suspension ![]() $\eta _r=\varSigma _{xy}/\eta \dot {\gamma }$, with

$\eta _r=\varSigma _{xy}/\eta \dot {\gamma }$, with ![]() $\varSigma _{xy}$ the shear component of the stress tensor,

$\varSigma _{xy}$ the shear component of the stress tensor, ![]() $\dot {\gamma }$ the shear rate and

$\dot {\gamma }$ the shear rate and ![]() $\eta$ the fluid viscosity.

$\eta$ the fluid viscosity.

2.6. The time scales that appear in the simulation

The full list of dimensional parameters taken as inputs to the model is then ![]() $a$,

$a$, ![]() $L$,

$L$, ![]() $t$,

$t$, ![]() $\rho$,

$\rho$, ![]() $k_n$,

$k_n$, ![]() $k_bT$,

$k_bT$, ![]() $\eta$ and

$\eta$ and ![]() $\dot {\gamma }$. Taking

$\dot {\gamma }$. Taking ![]() $a/L\ll 1$ and

$a/L\ll 1$ and ![]() $\dot {\gamma }t\gg 1$, dimensional analysis dictates that we require three non-dimensional groups to fully characterise this system. In other words, a measured non-dimensional quantity e.g. the reduced viscosity

$\dot {\gamma }t\gg 1$, dimensional analysis dictates that we require three non-dimensional groups to fully characterise this system. In other words, a measured non-dimensional quantity e.g. the reduced viscosity ![]() $\eta _r = \varSigma _{xy}/\eta \dot {\gamma }$, can be a function of at most three non-dimensional control parameters. This is in addition to non-dimensional inputs viz. the volume fraction

$\eta _r = \varSigma _{xy}/\eta \dot {\gamma }$, can be a function of at most three non-dimensional control parameters. This is in addition to non-dimensional inputs viz. the volume fraction ![]() $\phi$ and the friction coefficient

$\phi$ and the friction coefficient ![]() $\mu$. Central to our work will be the study of viscosities as a function of Péclet number, since this latter quantity will control the colloidal to granular cross-over. It is desirous to choose the remaining two non-dimensional control parameters such that particles are effectively hard and non-inertial. To obtain an appropriate set of non-dimensional control parameters, we consider the following list of time scales present in the model (in which we only include dimensional elements for simplicity):

$\mu$. Central to our work will be the study of viscosities as a function of Péclet number, since this latter quantity will control the colloidal to granular cross-over. It is desirous to choose the remaining two non-dimensional control parameters such that particles are effectively hard and non-inertial. To obtain an appropriate set of non-dimensional control parameters, we consider the following list of time scales present in the model (in which we only include dimensional elements for simplicity):

$$\begin{gather} \tau_{C}=\sqrt{\frac{\rho a^3}{k_n}}, \end{gather}$$

$$\begin{gather} \tau_{C}=\sqrt{\frac{\rho a^3}{k_n}}, \end{gather}$$ The contact time ![]() $\tau _C$ is a characteristic time spent by two particles in contact (assuming contacts are describable as linear springs), in the absence of other forces playing a role. It is obtained by solving the following equation of motion for the overlap

$\tau _C$ is a characteristic time spent by two particles in contact (assuming contacts are describable as linear springs), in the absence of other forces playing a role. It is obtained by solving the following equation of motion for the overlap ![]() $\delta$ between contacting particles:

$\delta$ between contacting particles: ![]() $\rho a^3({\rm d}^2\delta /{\rm d}t^2)=k_n\delta$. In practice, we adjust

$\rho a^3({\rm d}^2\delta /{\rm d}t^2)=k_n\delta$. In practice, we adjust ![]() $k_n$ to approximate the hard-sphere limit, so that

$k_n$ to approximate the hard-sphere limit, so that ![]() $\tau _C$ does not compare with any other time scale in the system under any conditions. Here, the lubrication and Brownian contributions to the final viscosity become independent of

$\tau _C$ does not compare with any other time scale in the system under any conditions. Here, the lubrication and Brownian contributions to the final viscosity become independent of ![]() $k_n$ (see figure 5b below). We note that other authors (Mari et al. Reference Mari, Seto, Morris and Denn2014) have used a less stringent criterion for

$k_n$ (see figure 5b below). We note that other authors (Mari et al. Reference Mari, Seto, Morris and Denn2014) have used a less stringent criterion for ![]() $k_n$, so that there may be weak dependence of the rheology on this quantity under some flow conditions. The inertial relaxation time

$k_n$, so that there may be weak dependence of the rheology on this quantity under some flow conditions. The inertial relaxation time ![]() $\tau _I$ is the characteristic time taken for the velocity of a particle to reach that of the background fluid in the absence of other forces. It is obtained by solving the following equation of motion for the velocity

$\tau _I$ is the characteristic time taken for the velocity of a particle to reach that of the background fluid in the absence of other forces. It is obtained by solving the following equation of motion for the velocity ![]() $v$ of a particle:

$v$ of a particle: ![]() $\rho a^3 ({\rm d}v/{\rm d}t) = \eta a v$. The Brownian time

$\rho a^3 ({\rm d}v/{\rm d}t) = \eta a v$. The Brownian time ![]() $\tau _B$ is the characteristic time take for a particle to diffuse by a distance equal to its own radius under thermal motion in the absence of other forces. The convective time scale

$\tau _B$ is the characteristic time take for a particle to diffuse by a distance equal to its own radius under thermal motion in the absence of other forces. The convective time scale ![]() $\tau _S$ is simply the inverse of the shear rate. To resolve each of these time scales accurately within the simulation we chose the numerical timestep to be substantially smaller than the smallest of the time scales listed above. The Péclet number (

$\tau _S$ is simply the inverse of the shear rate. To resolve each of these time scales accurately within the simulation we chose the numerical timestep to be substantially smaller than the smallest of the time scales listed above. The Péclet number (![]() $Pe$) described above is given by

$Pe$) described above is given by ![]() $6{\rm \pi} \tau _B/\tau _S = 6{\rm \pi} \eta a^3\dot {\gamma }/k_bT$, and we vary this quantity across a broad range from 0.01 to 100 000, aiming to explore the colloidal to granular transition.

$6{\rm \pi} \tau _B/\tau _S = 6{\rm \pi} \eta a^3\dot {\gamma }/k_bT$, and we vary this quantity across a broad range from 0.01 to 100 000, aiming to explore the colloidal to granular transition.

The contact time ![]() $\tau _C$ should be chosen to be sufficiently small that overlaps between particles are orders of magnitude smaller than the particle radii, such that particles be considered hard spheres. To do this, we ensure throughout that

$\tau _C$ should be chosen to be sufficiently small that overlaps between particles are orders of magnitude smaller than the particle radii, such that particles be considered hard spheres. To do this, we ensure throughout that ![]() $\tau _c$ is at least an order of magnitude smaller than the next smallest time scale. The role of particle inertia can be expressed via (i) a Stokes number

$\tau _c$ is at least an order of magnitude smaller than the next smallest time scale. The role of particle inertia can be expressed via (i) a Stokes number ![]() $\tau _I/\tau _S=\rho a^2\dot {\gamma }/\eta$, and (ii) an inertia–diffusion ratio

$\tau _I/\tau _S=\rho a^2\dot {\gamma }/\eta$, and (ii) an inertia–diffusion ratio ![]() $\tau _I/\tau _B = \rho k_bT/\eta ^2 a$. Below, we explore how small each of these quantities needs to be set in order to ensure inertia plays no significant role in the measured results.

$\tau _I/\tau _B = \rho k_bT/\eta ^2 a$. Below, we explore how small each of these quantities needs to be set in order to ensure inertia plays no significant role in the measured results.

3. Results: interactions and diffusion

3.1. Two-particle simulations measuring the effective potential

To evaluate the net pairwise potential resulting from the particle-level forces described above, we carried out simulations of two particles with radius ![]() $a$ in a cubic periodic box of length

$a$ in a cubic periodic box of length ![]() $4.1a$ (see snapshot in figure 2a Inset) subject to all of the forces described above, and with

$4.1a$ (see snapshot in figure 2a Inset) subject to all of the forces described above, and with ![]() $\boldsymbol {U}^\infty =0$. We calculate the radial distribution function

$\boldsymbol {U}^\infty =0$. We calculate the radial distribution function ![]() $g(r)$ with

$g(r)$ with ![]() $r=|\boldsymbol {r}_{i,\,j}|$ and averaged this across timesteps in the steady state and across all realisations (figure 2a), then obtained the potential of mean force as

$r=|\boldsymbol {r}_{i,\,j}|$ and averaged this across timesteps in the steady state and across all realisations (figure 2a), then obtained the potential of mean force as ![]() $U(r)/k_bT = -\ln (g(r))$, figure 2(b). The result confirms that there is no net potential acting between particles when they are not in contact (i.e. when

$U(r)/k_bT = -\ln (g(r))$, figure 2(b). The result confirms that there is no net potential acting between particles when they are not in contact (i.e. when ![]() $r>2a$), so the lubrication and Brownian forces do not introduce an overall repulsion or attraction. When particles are in contact (

$r>2a$), so the lubrication and Brownian forces do not introduce an overall repulsion or attraction. When particles are in contact (![]() $r/(a_i+a_j)<1$) there is a steep repulsive potential that, as expected, is related to the stiffness of our contacts defined above as

$r/(a_i+a_j)<1$) there is a steep repulsive potential that, as expected, is related to the stiffness of our contacts defined above as ![]() $U(r)/k_bT = 0.5 k_n \delta _{i,\,j}^2$. The model thus approximates a suspension of colloidal hard spheres, in which the particle–particle interaction is zero and infinite for non-contacts and contacts, respectively.

$U(r)/k_bT = 0.5 k_n \delta _{i,\,j}^2$. The model thus approximates a suspension of colloidal hard spheres, in which the particle–particle interaction is zero and infinite for non-contacts and contacts, respectively.

3.2. Mean squared displacement

We next verify that our simulated particles follow statistically the anticipated trajectories by computing their mean squared displacement (MSD) under various conditions. An isolated particle with motion governed by the single-body drag and Brownian forces described above is expected to follow a trajectory with a short-time ballistic part and a long-time diffusive part that leads to an overall MSD given by Lemons & Gythiel (Reference Lemons and Gythiel1997) and Hammond & Corwin (Reference Hammond and Corwin2017) as

with ![]() $m=(4/3){\rm \pi} \rho a^3$ and

$m=(4/3){\rm \pi} \rho a^3$ and ![]() $\gamma =6{\rm \pi} \eta a$. This expression gives

$\gamma =6{\rm \pi} \eta a$. This expression gives ![]() $\langle x^2\rangle \sim t^2$ and

$\langle x^2\rangle \sim t^2$ and ![]() $\langle x^2\rangle \sim t$ at small and large times, respectively. It can equivalently be written in terms of our characteristic time scales defined above as

$\langle x^2\rangle \sim t$ at small and large times, respectively. It can equivalently be written in terms of our characteristic time scales defined above as

Shown in figure 2(c) are MSDs for a dilute sample of monodisperse particles with ![]() $\phi =0.001$ in which pairwise particle–particle interactions are absent. In terms of our model time scales, we set

$\phi =0.001$ in which pairwise particle–particle interactions are absent. In terms of our model time scales, we set ![]() $\tau _S=\infty$ (i.e. no shear);

$\tau _S=\infty$ (i.e. no shear); ![]() $\tau _C=10^{-3}$;

$\tau _C=10^{-3}$; ![]() $\tau _I=10^{-1}$; and we vary

$\tau _I=10^{-1}$; and we vary ![]() $\tau _B$ to explore the behaviour at different temperatures. We measure the elapsed time in units of

$\tau _B$ to explore the behaviour at different temperatures. We measure the elapsed time in units of ![]() $\tau _I$, so that the cross-over from ballistic to diffusive behaviour begins in each case at

$\tau _I$, so that the cross-over from ballistic to diffusive behaviour begins in each case at ![]() $t/\tau _I\sim 1$. As expected, based on the expression above, increasing temperature (which decreases

$t/\tau _I\sim 1$. As expected, based on the expression above, increasing temperature (which decreases ![]() $\tau _B$) while keeping all other variables constant simply shifts the MSD result vertically with

$\tau _B$) while keeping all other variables constant simply shifts the MSD result vertically with ![]() $\langle x^2\rangle \sim k_bT$.

$\langle x^2\rangle \sim k_bT$.

We next calculate the MSD for a series of larger ![]() $\phi$, with results shown in figure 2(d,e). In all cases the particles follow a ballistic trajectory at short times that is roughly independent of

$\phi$, with results shown in figure 2(d,e). In all cases the particles follow a ballistic trajectory at short times that is roughly independent of ![]() $\phi$. The longer time behaviour shows a decreasing diffusion coefficient (

$\phi$. The longer time behaviour shows a decreasing diffusion coefficient (![]() $\mathcal {D}={\rm d}/{\rm d}t(\langle x^2 \rangle$)) with increasing

$\mathcal {D}={\rm d}/{\rm d}t(\langle x^2 \rangle$)) with increasing ![]() $\phi$, a consequence of pairwise hydrodynamic and contact interactions resisting particle motion. For all volume fractions below jamming,

$\phi$, a consequence of pairwise hydrodynamic and contact interactions resisting particle motion. For all volume fractions below jamming, ![]() $\mathcal {D}$ approaches a constant at long time scales, confirming the presence of a diffusive regime.

$\mathcal {D}$ approaches a constant at long time scales, confirming the presence of a diffusive regime.

In order for inertia to play a negligible role in our model, it is important for the diffusive time scale to be longer than the inertial relaxation one. In other words, the time taken for a particle velocity to relax to that of the background fluid should be much shorter than the time taken for the particle to diffuse by its own radius. To understand quantitatively how to achieve this, we measured ![]() $\mathcal {D}$ for varying

$\mathcal {D}$ for varying ![]() $\tau _I/\tau _B$ across a broad range of

$\tau _I/\tau _B$ across a broad range of ![]() $\phi$. The normalised long time diffusion coefficient (

$\phi$. The normalised long time diffusion coefficient (![]() $\mathcal {D}(\phi )/\mathcal {D}_0$) is shown in figure 2(f), with

$\mathcal {D}(\phi )/\mathcal {D}_0$) is shown in figure 2(f), with ![]() $\mathcal {D}_0=k_bT/{\rm \pi} \eta a (=a^2/\tau _B)$. Our result shows that, when

$\mathcal {D}_0=k_bT/{\rm \pi} \eta a (=a^2/\tau _B)$. Our result shows that, when ![]() $\tau _I/\tau _B$ is smaller than

$\tau _I/\tau _B$ is smaller than ![]() $0.17$,

$0.17$, ![]() $D(\phi )/D_0$ becomes independent of temperature and follows a linearly decreasing trend. This suggests a criterion for the maximum value of

$D(\phi )/D_0$ becomes independent of temperature and follows a linearly decreasing trend. This suggests a criterion for the maximum value of ![]() $\tau _I/\tau _B$, which we check under shearing conditions in the following.

$\tau _I/\tau _B$, which we check under shearing conditions in the following.

4. Results: rheology