1 Introduction

The interaction of fluids with structures has long attracted the attention of scientists due to its importance in the design of products in many traditional engineering fields such as aeronautics, wind engineering and off-shore oil extraction. The divergence and flutter analysis of wings is for instance an important step in the design of an aircraft, since these phenomena may induce premature fatigue and even lead to fracture of the structure. The vortex-induced vibration of elongated marine risers is another example of an industrial system where structural oscillations are detrimental. Because of the high flow speeds and the large scales of the structures encountered in most of these applications, inviscid models have often been used to describe the high Reynolds number flows (Dowell Reference Dowell2004).

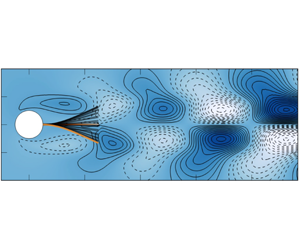

However, neglecting the viscous effects in the aerodynamic model is not always possible, for instance when addressing the aeroelastic design of micro- and unmanned air vehicles that fly at lower speed. New phenomena may occur, such as the spontaneous pitching oscillations of airfoils, observed and characterized experimentally by Poirel, Harris & Benaissa (Reference Poirel, Harris and Benaissa2008) for the transitional flow regime ( $Re=10^{4}{-}10^{5}$). The use of a viscous flow model is then essential to capture the laminar flow separation at the origin of the airfoil oscillations. In the renewable energy industry, new concepts are developed to exploit the flow-induced vibrations of small-scale structures (Young, Lai & Platzer Reference Young, Lai and Platzer2014) and transform their kinetic energy into energy using piezoelectric and electromagnetic technologies (Khaligh, Zeng & Zheng Reference Khaligh, Zeng and Zheng2009). For instance, Leontini & Thompson (Reference Leontini and Thompson2012) showed that a small active rotational oscillation of an elastically mounted cylinder can result in very large transverse oscillations, and is therefore an efficient method to transfer energy from the fluid to the structure. Peng & Zhu (Reference Peng and Zhu2009) proposed a purely passive device relying on self-induced and self-sustained oscillations. Rather than actively controlling the pitching motion, the foil motion is completely excited by flow-induced instability, using the same mechanism responsible for flutter of airfoils. Recent advances in energy harvesting from flow-induced vibrations or aeroelastic phenomena can be found in the review by Abdelkefi (Reference Abdelkefi2016). The main aim when designing an energy harvesting system is to predict the geometrical and physical properties of the system allowing sustained oscillating limit cycles to emerge (Olivieri et al. Reference Olivieri, Boccalero, Mazzino and Boragno2017). The simple argument to identify such oscillating states is based on a simple resonance condition between the natural frequencies of the flow and structure. But the validity of this resonance condition strongly depends on the solid-to-fluid density ratio. For density ratios close to unity, typical of fluid–structure experiments in water experimental facilities, large-amplitude oscillations can be obtained even far from the resonance condition (see for instance Mittal (Reference Mittal2016) for the vortex-induced vibration of a circular cylinder). Numerical simulations of the evolution equations governing the coupled fluid–solid nonlinear dynamics can be performed to explore the existence of self-sustained oscillating states and to characterize the vibration amplitude that results from the nonlinear saturation. However, the complex dynamics obtained with those temporal simulations is somehow difficult to analyse and the inherent nonlinearity of this approach prevents us from identifying simple linear mechanisms that may be predominant, and explaining the emergence of self-sustained oscillations. One of the objectives of the present study is to use linear stability analyses of the coupled fluid–structure problem so as to predict regions of the parameter space where self-sustained fluid–solid oscillations occur and to characterize their frequency. Such linear analyses have successfully been used to predict and explain the vortex-induced vibrations of rigid bodies (Mittal Reference Mittal2016) or the wake-induced oscillatory paths of rigid bodies freely rising or falling in fluids (Tchoufag, Fabre & Magnaudet Reference Tchoufag, Fabre and Magnaudet2014a; Tchoufag, Magnaudet & Fabre Reference Tchoufag, Magnaudet and Fabre2014b). In the same spirit, we aim here at simulating the self-sustained deformation of elastic splitter plates attached to the rear of a circular cylinder immersed in an incompressible flow and explaining the emergence of those limit cycle solutions based on a linear stability analysis. In the following subsections, we review previous studies, first on the flow past a circular cylinder with rigid and flexible splitter plates, and then on the linear fluid–solid stability analyses of rigid and flexible structures interacting with wake flows.

$Re=10^{4}{-}10^{5}$). The use of a viscous flow model is then essential to capture the laminar flow separation at the origin of the airfoil oscillations. In the renewable energy industry, new concepts are developed to exploit the flow-induced vibrations of small-scale structures (Young, Lai & Platzer Reference Young, Lai and Platzer2014) and transform their kinetic energy into energy using piezoelectric and electromagnetic technologies (Khaligh, Zeng & Zheng Reference Khaligh, Zeng and Zheng2009). For instance, Leontini & Thompson (Reference Leontini and Thompson2012) showed that a small active rotational oscillation of an elastically mounted cylinder can result in very large transverse oscillations, and is therefore an efficient method to transfer energy from the fluid to the structure. Peng & Zhu (Reference Peng and Zhu2009) proposed a purely passive device relying on self-induced and self-sustained oscillations. Rather than actively controlling the pitching motion, the foil motion is completely excited by flow-induced instability, using the same mechanism responsible for flutter of airfoils. Recent advances in energy harvesting from flow-induced vibrations or aeroelastic phenomena can be found in the review by Abdelkefi (Reference Abdelkefi2016). The main aim when designing an energy harvesting system is to predict the geometrical and physical properties of the system allowing sustained oscillating limit cycles to emerge (Olivieri et al. Reference Olivieri, Boccalero, Mazzino and Boragno2017). The simple argument to identify such oscillating states is based on a simple resonance condition between the natural frequencies of the flow and structure. But the validity of this resonance condition strongly depends on the solid-to-fluid density ratio. For density ratios close to unity, typical of fluid–structure experiments in water experimental facilities, large-amplitude oscillations can be obtained even far from the resonance condition (see for instance Mittal (Reference Mittal2016) for the vortex-induced vibration of a circular cylinder). Numerical simulations of the evolution equations governing the coupled fluid–solid nonlinear dynamics can be performed to explore the existence of self-sustained oscillating states and to characterize the vibration amplitude that results from the nonlinear saturation. However, the complex dynamics obtained with those temporal simulations is somehow difficult to analyse and the inherent nonlinearity of this approach prevents us from identifying simple linear mechanisms that may be predominant, and explaining the emergence of self-sustained oscillations. One of the objectives of the present study is to use linear stability analyses of the coupled fluid–structure problem so as to predict regions of the parameter space where self-sustained fluid–solid oscillations occur and to characterize their frequency. Such linear analyses have successfully been used to predict and explain the vortex-induced vibrations of rigid bodies (Mittal Reference Mittal2016) or the wake-induced oscillatory paths of rigid bodies freely rising or falling in fluids (Tchoufag, Fabre & Magnaudet Reference Tchoufag, Fabre and Magnaudet2014a; Tchoufag, Magnaudet & Fabre Reference Tchoufag, Magnaudet and Fabre2014b). In the same spirit, we aim here at simulating the self-sustained deformation of elastic splitter plates attached to the rear of a circular cylinder immersed in an incompressible flow and explaining the emergence of those limit cycle solutions based on a linear stability analysis. In the following subsections, we review previous studies, first on the flow past a circular cylinder with rigid and flexible splitter plates, and then on the linear fluid–solid stability analyses of rigid and flexible structures interacting with wake flows.

1.1 Interaction of the circular cylinder wake flow with rigid and flexible splitter plates

Among passive control methods, a rigid splitter plate has been one of the most successful devices to control the vortex shedding behind bluff bodies. The control of the turbulent vortex shedding was experimentally investigated first by Roshko (Reference Roshko1954) and Roshko (Reference Roshko1955) for a circular cylinder at Reynolds number  $Re=5000$ (based on the cylinder diameter

$Re=5000$ (based on the cylinder diameter  $D^{\ast }$ and the uniform inflow velocity

$D^{\ast }$ and the uniform inflow velocity  $U_{\infty }^{\ast }$) and then by Bearman (Reference Bearman1965) for other bluff body wake flows. For higher Reynolds number flows (

$U_{\infty }^{\ast }$) and then by Bearman (Reference Bearman1965) for other bluff body wake flows. For higher Reynolds number flows ( $10\,000<Re<50\,000$), Apelt, West & Szewczyk (Reference Apelt, West and Szewczyk1973) observed that splitter plates have an effect of increasing the base pressure and thus significantly reducing the drag. For lower Reynolds number flows (

$10\,000<Re<50\,000$), Apelt, West & Szewczyk (Reference Apelt, West and Szewczyk1973) observed that splitter plates have an effect of increasing the base pressure and thus significantly reducing the drag. For lower Reynolds number flows ( $140<Re<3600$), Unal & Rockwell (Reference Unal and Rockwell1988) showed that splitter plates reduce the absolute instability responsible for the onset of vortex shedding. Numerical simulations of the two-dimensional incompressible Navier–Stokes equations were performed by Kwon & Choi (Reference Kwon and Choi1996) in the range of lower Reynolds numbers

$140<Re<3600$), Unal & Rockwell (Reference Unal and Rockwell1988) showed that splitter plates reduce the absolute instability responsible for the onset of vortex shedding. Numerical simulations of the two-dimensional incompressible Navier–Stokes equations were performed by Kwon & Choi (Reference Kwon and Choi1996) in the range of lower Reynolds numbers  $80<Re<160$. The vortex shedding completely disappears when the length of the splitter plate is larger than a critical length that is proportional to the Reynolds number. Mittal (Reference Mittal2003) investigated the effect of a ‘slip’ splitter plate, to further understand the control mechanism at play. Other configurations of splitter plates have been considered, such as for instance two splitter plates symmetrically arranged (Bao & Tao Reference Bao and Tao2013).

$80<Re<160$. The vortex shedding completely disappears when the length of the splitter plate is larger than a critical length that is proportional to the Reynolds number. Mittal (Reference Mittal2003) investigated the effect of a ‘slip’ splitter plate, to further understand the control mechanism at play. Other configurations of splitter plates have been considered, such as for instance two splitter plates symmetrically arranged (Bao & Tao Reference Bao and Tao2013).

When the rigid splitter plate is attached to a circular cylinder that is now free to rotate around its axis, a striking symmetry breaking of the configuration may appear depending on the length  $L^{\ast }$ of splitter plate. The cylinder and splitter plate then migrate to a asymmetric equilibrium position, for which the moment exerted by the fluid forces is equal to zero. Such symmetry breaking was first observed experimentally by Cimbala, Garg & Park (Reference Cimbala, Garg and Park1988), Cimbala & Garg (Reference Cimbala and Garg1991) and Cimbala & Chen (Reference Cimbala and Chen1994) for large Reynolds number flows, and more recently by Gu et al. (Reference Gu, Wang, Qiao and Huang2012). At lower Reynolds numbers (

$L^{\ast }$ of splitter plate. The cylinder and splitter plate then migrate to a asymmetric equilibrium position, for which the moment exerted by the fluid forces is equal to zero. Such symmetry breaking was first observed experimentally by Cimbala, Garg & Park (Reference Cimbala, Garg and Park1988), Cimbala & Garg (Reference Cimbala and Garg1991) and Cimbala & Chen (Reference Cimbala and Chen1994) for large Reynolds number flows, and more recently by Gu et al. (Reference Gu, Wang, Qiao and Huang2012). At lower Reynolds numbers ( $Re<100$), two-dimensional numerical simulations of the flow in conjunction with the rotational dynamics of the body were performed by Xu, Sen & Gad-el Hak (Reference Xu, Sen and Gad-el Hak1990) for plate lengths in the range

$Re<100$), two-dimensional numerical simulations of the flow in conjunction with the rotational dynamics of the body were performed by Xu, Sen & Gad-el Hak (Reference Xu, Sen and Gad-el Hak1990) for plate lengths in the range  $0.5<L^{\ast }/D^{\ast }<2$. The symmetry-breaking bifurcation appears when increasing the Reynolds number above a critical value that depends on the ratio between the plate length and cylinder diameter

$0.5<L^{\ast }/D^{\ast }<2$. The symmetry-breaking bifurcation appears when increasing the Reynolds number above a critical value that depends on the ratio between the plate length and cylinder diameter  $L^{\ast }/D^{\ast }$. Further increasing the Reynolds number, Xu, Sen & Gad-el Hak (Reference Xu, Sen and Gad-el Hak1993) identified a supercritical Hopf bifurcation leading to the oscillation of the splitter plate around a asymmetric position. The effect of adding a restoring and dissipative moment at the elastic centre was recently investigated by Lu et al. (Reference Lu, Guo, Tang, Liu, Chen and Xie2016) for the low Reynolds number of

$L^{\ast }/D^{\ast }$. Further increasing the Reynolds number, Xu, Sen & Gad-el Hak (Reference Xu, Sen and Gad-el Hak1993) identified a supercritical Hopf bifurcation leading to the oscillation of the splitter plate around a asymmetric position. The effect of adding a restoring and dissipative moment at the elastic centre was recently investigated by Lu et al. (Reference Lu, Guo, Tang, Liu, Chen and Xie2016) for the low Reynolds number of  $Re=100$. For the same Reynolds number, a similar symmetry-breaking bifurcation was reported by Bagheri, Mazzino & Bottaro (Reference Bagheri, Mazzino and Bottaro2012) for a flexible filament hinged to a circular cylinder. This is a flexible splitter plate with infinitesimally small thickness

$Re=100$. For the same Reynolds number, a similar symmetry-breaking bifurcation was reported by Bagheri, Mazzino & Bottaro (Reference Bagheri, Mazzino and Bottaro2012) for a flexible filament hinged to a circular cylinder. This is a flexible splitter plate with infinitesimally small thickness  $H^{\ast }$, which is allowed to rotate about the hinge point at the base of the cylinder. They reported spontaneous deviations for splitter plates of length

$H^{\ast }$, which is allowed to rotate about the hinge point at the base of the cylinder. They reported spontaneous deviations for splitter plates of length  $L^{\ast }<2D^{\ast }$, as for the rotatable rigid splitter plate (Xu et al. Reference Xu, Sen and Gad-el Hak1990). A semi-empirical model has been later proposed by Lacis et al. (Reference Lacis, Brosse, Ingremeau, Mazzino, Lundell, Kellay and Bagheri2014) to predict the deviation and an analogy with an inverse pendulum was proposed to explain the occurrence of this phenomenon.

$L^{\ast }<2D^{\ast }$, as for the rotatable rigid splitter plate (Xu et al. Reference Xu, Sen and Gad-el Hak1990). A semi-empirical model has been later proposed by Lacis et al. (Reference Lacis, Brosse, Ingremeau, Mazzino, Lundell, Kellay and Bagheri2014) to predict the deviation and an analogy with an inverse pendulum was proposed to explain the occurrence of this phenomenon.

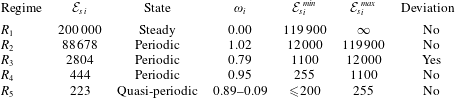

The dynamics of flexible splitter plates, free to continuously deform along their length due to the fluid forces acting on them, was recently investigated experimentally by Shukla, Govardhan & Arakeri (Reference Shukla, Govardhan and Arakeri2013). For a plate of length  $L^{\ast }=5D^{\ast }$, they identified several regimes of splitter plate motions when varying the Reynolds number in the range

$L^{\ast }=5D^{\ast }$, they identified several regimes of splitter plate motions when varying the Reynolds number in the range  $1800<Re<10^{4}$. Two regimes of periodic motions, characterized by a non-dimensional frequency

$1800<Re<10^{4}$. Two regimes of periodic motions, characterized by a non-dimensional frequency  $f^{\ast }D^{\ast }/U_{\infty }^{\ast }\sim 0.15{-}0.2$, were found for low and high Reynolds numbers, and separated by a regime of aperiodic motion. The magnitude of the tip displacement was also found to vary strongly and non-monotonically, especially for the lower values of bending stiffness explored in that study. Meanwhile, Lee & You (Reference Lee and You2013) performed numerical simulations for the low Reynolds number of

$f^{\ast }D^{\ast }/U_{\infty }^{\ast }\sim 0.15{-}0.2$, were found for low and high Reynolds numbers, and separated by a regime of aperiodic motion. The magnitude of the tip displacement was also found to vary strongly and non-monotonically, especially for the lower values of bending stiffness explored in that study. Meanwhile, Lee & You (Reference Lee and You2013) performed numerical simulations for the low Reynolds number of  $Re=100$ while varying the plate’s length and stiffness. For smaller plate lengths, they obtained a non-monotonic variation of the frequency and magnitude of the tip displacement when varying the bending stiffness. In addition, the splitter plate was found to vibrate like a first- (respectively second) bending mode for

$Re=100$ while varying the plate’s length and stiffness. For smaller plate lengths, they obtained a non-monotonic variation of the frequency and magnitude of the tip displacement when varying the bending stiffness. In addition, the splitter plate was found to vibrate like a first- (respectively second) bending mode for  $L^{\ast }=D^{\ast }$ (respectively

$L^{\ast }=D^{\ast }$ (respectively  $L^{\ast }=2D^{\ast }$). For the larger plate’s length

$L^{\ast }=2D^{\ast }$). For the larger plate’s length  $L^{\ast }=3D^{\ast }$, a monotonic variation of the oscillating frequency and magnitude of the tip displacement is reported, and the vibration shape of the splitter plate was a combination of the first- and second-bending mode. Wu, Qiu & Zhao (Reference Wu, Qiu and Zhao2014) investigated the control of the vortex shedding past a circular cylinder at

$L^{\ast }=3D^{\ast }$, a monotonic variation of the oscillating frequency and magnitude of the tip displacement is reported, and the vibration shape of the splitter plate was a combination of the first- and second-bending mode. Wu, Qiu & Zhao (Reference Wu, Qiu and Zhao2014) investigated the control of the vortex shedding past a circular cylinder at  $Re=150$ by using an attached flexible filament of length

$Re=150$ by using an attached flexible filament of length  $D^{\ast }<L^{\ast }<3D^{\ast }$. By varying the flexibility of the filament stiffness, they concluded that the fluctuation of lift force and vortex shedding of a fixed cylinder can be suppressed efficiently. Using a viscoelastic model of the splitter plate attached to the circular cylinder immersed in a channel flow, Mishra et al. (Reference Mishra, Kulkarni, Bhardwaj and Thompson2019) concluded that a careful tuning of the damping may be effectively employed, to suppress flow-induced vibration when it is detrimental to the structure, or to enhance power output for energy extraction applications.

$D^{\ast }<L^{\ast }<3D^{\ast }$. By varying the flexibility of the filament stiffness, they concluded that the fluctuation of lift force and vortex shedding of a fixed cylinder can be suppressed efficiently. Using a viscoelastic model of the splitter plate attached to the circular cylinder immersed in a channel flow, Mishra et al. (Reference Mishra, Kulkarni, Bhardwaj and Thompson2019) concluded that a careful tuning of the damping may be effectively employed, to suppress flow-induced vibration when it is detrimental to the structure, or to enhance power output for energy extraction applications.

If unsteady simulations give the amplitude and frequency of the self-sustained oscillations resulting from the interaction of the flexible splitter plate with the flow, they provide only a limited overview of the underlying destabilizing linear mechanisms at play. For instance, Lee & You (Reference Lee and You2013) concluded that the Strouhal number of vortex shedding or the frequency of plate deflection were difficult to estimate using natural frequencies of the plate’s bending modes. It is therefore unclear whether a resonance condition between the frequency of the hydrodynamic vortex-shedding mode and that of the plate’s bending modes may apply. Moreover, to our knowledge, a global stability analysis of the fluid–structure interaction has never been performed to explain the symmetry breaking of the flexible splitter plate configuration. In the present study, we thus propose to use linear fluid–solid stability analyses so as to better identify and characterize the various regimes of interaction of the splitter plate with the wake flow.

1.2 Linear stability analysis for fluid–rigid and fluid–elastic interactions

Using linear analysis to unravel the mechanism at play in the fluid–structure interaction is not new. Classical aeroelasticity is mainly based on linear analysis, and the flutter and divergence instability of wings can be predicted by considering a linear model of the interaction between the fluid and the solid (Bisplinghoff, Ashley & Halfman Reference Bisplinghoff, Ashley and Halfman1955). The fluid–structure stability analysis refers here to an investigation of the temporal evolution of infinitesimally small perturbations than develop in a time-independent solution of the fluid–structure interaction problem. Conceptually, this is very similar to hydrodynamic stability analysis, but the time-independent solution as well as the temporal perturbations may be both in the flow and the structure. The additional theoretical and numerical difficulty in performing stability analyses in fluid–structure interaction problems is taking into account rigorously the perturbation of the fluid–solid interface motion. Linear stability analysis has been predominantly applied to fluid–solid configurations where the solid is rigid and its dynamics is described by few degrees of freedom. For instance, the transverse displacement of a spring-mounted cylinder facing a uniform flow is simply governed by a damped harmonic oscillator. In most of the following studies, the flow equations can then be rewritten in a frame of reference attached to the rigid solid. To our knowledge, the first linear stability analysis of a spring-mounted rigid body was performed by Cossu & Morino (Reference Cossu and Morino2000) to investigate the vortex-induced vibration of a circular cylinder in a laminar flow regime. They found the existence an unstable fluid–solid eigenmode for sub-critical values of the Reynolds number, i.e. below the critical value given by a purely hydrodynamic stability analysis (Zebib Reference Zebib1987). For these sub-critical Reynolds numbers, Mittal & Singh (Reference Mittal and Singh2005) then showed that results of the linear stability analysis are in good agreement with those of two-dimensional direct numerical simulations. The mechanism of frequency lock-in of the fluid–structure to the natural frequency of the solid (the frequency of the spring in vacuum) was later on investigated with linear stability analysis by Mittal (Reference Mittal2016) for the spring-mounted circular-cylinder flow in a laminar subsonic flow regime, and by Gao, Zhang & Ye (Reference Gao, Zhang and Ye2016), Gao et al. (Reference Gao, Zhang, Li, Liu, Quan, Ye and Jiang2017) for a spring-mounted airfoil in turbulent transonic buffeting flow. The wake-induced oscillatory paths of bodies freely rising or falling in fluids (see Ern et al. (Reference Ern, Risso, Fabre and Magnaudet2012) for a review) have also been investigated using fluid–solid stability analysis. They revealed the essential role of the wake in the path instability of buoyancy-driven disks/thin cylinders (Tchoufag et al. Reference Tchoufag, Fabre and Magnaudet2014a) and of freely rising spheroidal bubble (Tchoufag et al. Reference Tchoufag, Magnaudet and Fabre2014b). Fewer authors have investigated the linear stability of fully deformable structures in flows. The flutter instability of a thin flexible plate in channel flow was first investigated by Shoele & Mittal (Reference Shoele and Mittal2016) using an inviscid flow model, and then by Cisonni et al. (Reference Cisonni, Lucey, Elliott and Heil2017) using a viscous flow model and time-marching simulations. The effect of structural inhomogeneity on the flutter instability of elastic cantilevers was further investigated by Cisonni, Lucey & Elliott (Reference Cisonni, Lucey and Elliott2019). A linear and nonlinear analysis of the dynamics of an inverted-flap flapping in a low Reynolds number flow was also performed by Goza, Colonius & Sader (Reference Goza, Colonius and Sader2018). The effect of a compliant wall on the growth of perturbations developing in a Blasius boundary layer was considered investigated by Tsigklifis & Lucey (Reference Tsigklifis and Lucey2017) with modal and non-modal linear stability analyses of the fluid–structure interaction. In all of these studies, the elastic thin structure was modelled with a one-dimensional elastic beam. The more general case of a finite-thickness structure modelled with the nonlinear Saint Venant–Kirchoff constitutive relation was recently considered by Pfister, Marquet & Carini (Reference Pfister, Marquet and Carini2019) for some of the fluid–solid configurations previously mentioned. The linear stability analysis then relies on a linearization of the nonlinear equations governing the incompressible flow and the elastic structure that are coupled using the arbitrary Lagrangian Eulerian (ALE) method. This approach, that we will follow, has the advantage of preserving a high-quality description of the fluid–solid conform interface, at the price of introducing an arbitrary extension operator for propagating the solid interface deformations onto the fluid domain.

The paper is organized as follows. In § 2, we present first the governing parameters of this fluid–solid configuration and then the mathematical formulation of the fluid–solid interaction. The nonlinear governing equations are briefly introduced before describing the fully coupled as well as the simplified quiescent-fluid and quasi-static linear stability analyses. Simulation results of the unsteady nonlinear dynamics are presented in § 3, where several regimes of interaction, identified when decreasing the plate’s stiffness, are carefully described. Results of various linear stability analyses are finally presented in § 4 so as to better characterize the linear mechanisms at play in the emergence of these nonlinear regimes.

2 Fluid structure configuration and formulations

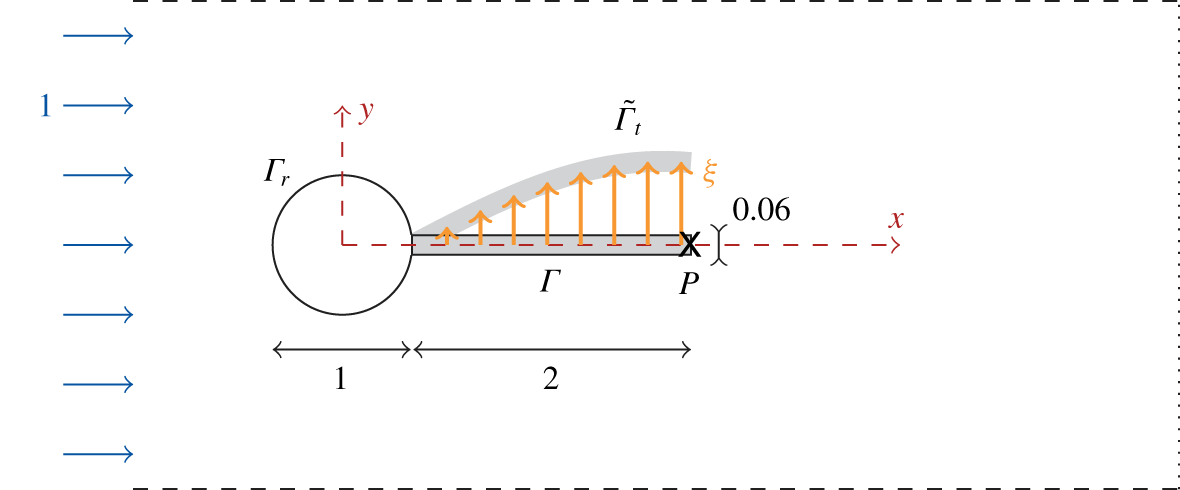

Figure 1. Sketch of the elastic plate (grey, boundary  $\unicode[STIX]{x1D6E4}$ in the reference configuration and

$\unicode[STIX]{x1D6E4}$ in the reference configuration and  $\tilde{\unicode[STIX]{x1D6E4}}_{t}$ in the deformed configuration) clamped on the rigid cylinder (white, boundary

$\tilde{\unicode[STIX]{x1D6E4}}_{t}$ in the deformed configuration) clamped on the rigid cylinder (white, boundary  $\unicode[STIX]{x1D6E4}_{r}$) and immersed in a uniform incoming flow field (blue arrows). Lengths/velocity are made non-dimensional using the inlet velocity and the cylinder’s diameter. The plate’s tip is marked by the point

$\unicode[STIX]{x1D6E4}_{r}$) and immersed in a uniform incoming flow field (blue arrows). Lengths/velocity are made non-dimensional using the inlet velocity and the cylinder’s diameter. The plate’s tip is marked by the point  $P(2.5,0)$.

$P(2.5,0)$.

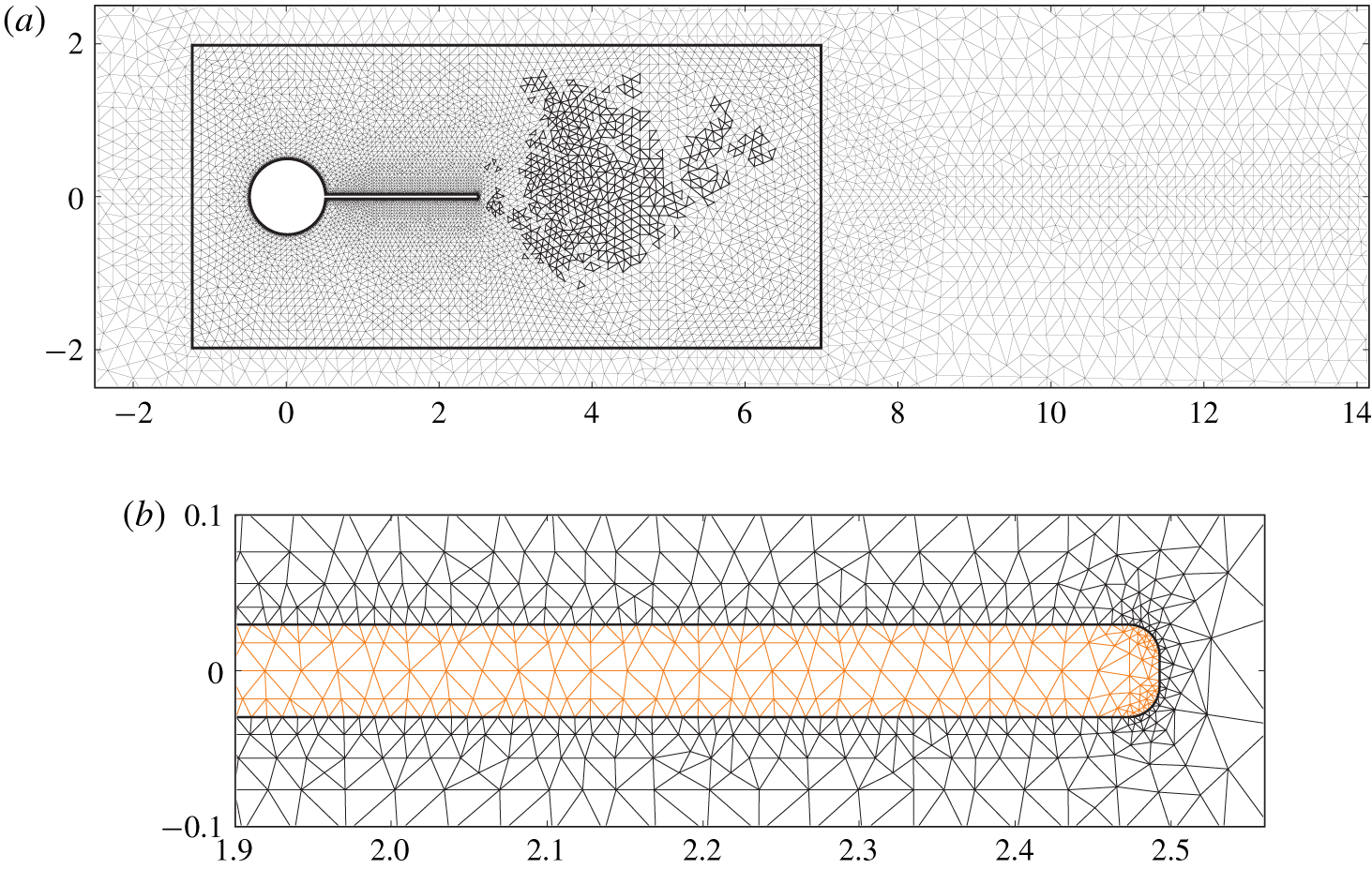

The fluid–structure configuration investigated here is an elastic plate of length  $L^{\ast }$ and thickness

$L^{\ast }$ and thickness  $H^{\ast }$ that is clamped on the rear side of a rigid circular cylinder of diameter

$H^{\ast }$ that is clamped on the rear side of a rigid circular cylinder of diameter  $D^{\ast }$. As shown in figure 1, the plate’s length is rather short and set to

$D^{\ast }$. As shown in figure 1, the plate’s length is rather short and set to  $L^{\ast }=2D^{\ast }$, a value for which a symmetry-breaking bifurcation has been previously reported by Xu et al. (Reference Xu, Sen and Gad-el Hak1990) and Bagheri et al. (Reference Bagheri, Mazzino and Bottaro2012), while the thickness of the plate is set to

$L^{\ast }=2D^{\ast }$, a value for which a symmetry-breaking bifurcation has been previously reported by Xu et al. (Reference Xu, Sen and Gad-el Hak1990) and Bagheri et al. (Reference Bagheri, Mazzino and Bottaro2012), while the thickness of the plate is set to  $H^{\ast }=0.06D^{\ast }$, as in Lee & You (Reference Lee and You2013). The elastic part (displayed in grey colour) deforms under the action of the flow field of uniform inlet velocity

$H^{\ast }=0.06D^{\ast }$, as in Lee & You (Reference Lee and You2013). The elastic part (displayed in grey colour) deforms under the action of the flow field of uniform inlet velocity  $U_{\infty }^{\ast }$. We assume that the viscous flow of density

$U_{\infty }^{\ast }$. We assume that the viscous flow of density  $\unicode[STIX]{x1D70C}_{f}^{\ast }$ and dynamic viscosity

$\unicode[STIX]{x1D70C}_{f}^{\ast }$ and dynamic viscosity  $\unicode[STIX]{x1D702}_{f}^{\ast }$ is incompressible, and that the solid and fluid have the same density, i.e.

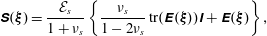

$\unicode[STIX]{x1D702}_{f}^{\ast }$ is incompressible, and that the solid and fluid have the same density, i.e.  $\unicode[STIX]{x1D70C}_{s}^{\ast }=\unicode[STIX]{x1D70C}_{f}^{\ast }$. The homogeneous, isotropic solid is characterized by its Young modulus

$\unicode[STIX]{x1D70C}_{s}^{\ast }=\unicode[STIX]{x1D70C}_{f}^{\ast }$. The homogeneous, isotropic solid is characterized by its Young modulus  $E_{s}^{\ast }$ and Poisson coefficient

$E_{s}^{\ast }$ and Poisson coefficient  $\unicode[STIX]{x1D708}_{s}$. In addition to this non-dimensional coefficient, the fluid–elastic configuration is governed by three non-dimensional parameters, defined here with

$\unicode[STIX]{x1D708}_{s}$. In addition to this non-dimensional coefficient, the fluid–elastic configuration is governed by three non-dimensional parameters, defined here with  $D^{\ast }$ and

$D^{\ast }$ and  $U_{\infty }^{\ast }$ as characteristic length and velocity. These are the Reynolds number, the density ratio and the non-dimensional Young modulus, defined as follows:

$U_{\infty }^{\ast }$ as characteristic length and velocity. These are the Reynolds number, the density ratio and the non-dimensional Young modulus, defined as follows:

$$\begin{eqnarray}{\mathcal{R}}_{e}=\frac{\unicode[STIX]{x1D70C}_{f}^{\ast }U_{\infty }^{\ast }D^{\ast }}{\unicode[STIX]{x1D702}_{f}^{\ast }},\quad {\mathcal{M}}_{s}=\frac{\unicode[STIX]{x1D70C}_{s}^{\ast }}{\unicode[STIX]{x1D70C}_{f}^{\ast }},\quad \text{and}\quad {\mathcal{E}}_{s}=\frac{E_{s}^{\ast }}{\unicode[STIX]{x1D70C}_{f}^{\ast }(U_{\infty }^{\ast })^{2}}.\end{eqnarray}$$

$$\begin{eqnarray}{\mathcal{R}}_{e}=\frac{\unicode[STIX]{x1D70C}_{f}^{\ast }U_{\infty }^{\ast }D^{\ast }}{\unicode[STIX]{x1D702}_{f}^{\ast }},\quad {\mathcal{M}}_{s}=\frac{\unicode[STIX]{x1D70C}_{s}^{\ast }}{\unicode[STIX]{x1D70C}_{f}^{\ast }},\quad \text{and}\quad {\mathcal{E}}_{s}=\frac{E_{s}^{\ast }}{\unicode[STIX]{x1D70C}_{f}^{\ast }(U_{\infty }^{\ast })^{2}}.\end{eqnarray}$$2.1 Nonlinear arbitrary Lagrangian Eulerian formulation

The motion of an elastic solid is classically described in a Lagrangian framework, using the displacement field  $\unicode[STIX]{x1D743}(\boldsymbol{x},t)=\tilde{\boldsymbol{x}}_{t}(\boldsymbol{x},t)-\boldsymbol{x}$, defined as the difference between the position of any material point

$\unicode[STIX]{x1D743}(\boldsymbol{x},t)=\tilde{\boldsymbol{x}}_{t}(\boldsymbol{x},t)-\boldsymbol{x}$, defined as the difference between the position of any material point  $\tilde{\boldsymbol{x}}_{t}$ in the deformed solid domain

$\tilde{\boldsymbol{x}}_{t}$ in the deformed solid domain  $\tilde{\unicode[STIX]{x1D6FA}}_{t}$ and its position

$\tilde{\unicode[STIX]{x1D6FA}}_{t}$ and its position  $\boldsymbol{x}$ in a reference solid configuration

$\boldsymbol{x}$ in a reference solid configuration  $\unicode[STIX]{x1D6FA}_{s}$ (see figure 1). On the other hand, the motion of the fluid is classically described in an Eulerian framework, the governing flow equations being written in the moving domain surrounding the deformed solid. The arbitrary Lagrangian Eulerian method allows for combining of the Eulerian and Lagrangian descriptions of the fluid and solid dynamics (Donea et al. Reference Donea, Huerta, Ponthot, Rodrigez-Ferran, Stein, Borst and Hughes2017). An extension field

$\unicode[STIX]{x1D6FA}_{s}$ (see figure 1). On the other hand, the motion of the fluid is classically described in an Eulerian framework, the governing flow equations being written in the moving domain surrounding the deformed solid. The arbitrary Lagrangian Eulerian method allows for combining of the Eulerian and Lagrangian descriptions of the fluid and solid dynamics (Donea et al. Reference Donea, Huerta, Ponthot, Rodrigez-Ferran, Stein, Borst and Hughes2017). An extension field  $\unicode[STIX]{x1D743}_{e}(\boldsymbol{x},t)$, defined in the reference fluid domain

$\unicode[STIX]{x1D743}_{e}(\boldsymbol{x},t)$, defined in the reference fluid domain  $\unicode[STIX]{x1D6FA}_{f}$, is introduced to account for the deformation for the fluid domain induced by the solid domain. At the fluid–solid interface

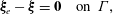

$\unicode[STIX]{x1D6FA}_{f}$, is introduced to account for the deformation for the fluid domain induced by the solid domain. At the fluid–solid interface  $\unicode[STIX]{x1D6E4}$, it is equal to the solid displacement, to obtain a conformal description of this interface. In the reference fluid domain, it satisfies an arbitrary equation which is introduced to smoothly propagate the solid displacement to the fluid domain. Applying the arbitrary Lagrangian Eulerian transformation to the fluid equations, the nonlinear evolution equations governing the fluid–elastic problem are written in the fixed reference domain

$\unicode[STIX]{x1D6E4}$, it is equal to the solid displacement, to obtain a conformal description of this interface. In the reference fluid domain, it satisfies an arbitrary equation which is introduced to smoothly propagate the solid displacement to the fluid domain. Applying the arbitrary Lagrangian Eulerian transformation to the fluid equations, the nonlinear evolution equations governing the fluid–elastic problem are written in the fixed reference domain  $\unicode[STIX]{x1D6FA}=\unicode[STIX]{x1D6FA}_{s}\cup \unicode[STIX]{x1D6FA}_{f}$ – see Le Tallec & Mouro (Reference Le Tallec and Mouro2001).

$\unicode[STIX]{x1D6FA}=\unicode[STIX]{x1D6FA}_{s}\cup \unicode[STIX]{x1D6FA}_{f}$ – see Le Tallec & Mouro (Reference Le Tallec and Mouro2001).

More specifically, we consider here a so-called three-field formulation (Lesoinne & Farhat Reference Lesoinne and Farhat1993) where the fluid–structure solution  $\boldsymbol{q}=(\boldsymbol{q}_{s},\boldsymbol{q}_{e},\boldsymbol{q}_{f})^{\text{T}}$ is decomposed between a solid component

$\boldsymbol{q}=(\boldsymbol{q}_{s},\boldsymbol{q}_{e},\boldsymbol{q}_{f})^{\text{T}}$ is decomposed between a solid component  $\boldsymbol{q}_{s}$, an extension component

$\boldsymbol{q}_{s}$, an extension component  $\boldsymbol{q}_{e}$ and a fluid component

$\boldsymbol{q}_{e}$ and a fluid component  $\boldsymbol{q}_{f}$. The solid component

$\boldsymbol{q}_{f}$. The solid component  $\boldsymbol{q}_{s}=(\unicode[STIX]{x1D743},\boldsymbol{u}_{s})$ gathers the (Lagrangian) solid displacement

$\boldsymbol{q}_{s}=(\unicode[STIX]{x1D743},\boldsymbol{u}_{s})$ gathers the (Lagrangian) solid displacement  $\unicode[STIX]{x1D743}$ field and the solid velocity field defined as

$\unicode[STIX]{x1D743}$ field and the solid velocity field defined as  $\boldsymbol{u}_{s}=\text{d}\unicode[STIX]{x1D743}/\text{d}t$. The fluid component

$\boldsymbol{u}_{s}=\text{d}\unicode[STIX]{x1D743}/\text{d}t$. The fluid component  $\boldsymbol{q}_{f}=(\boldsymbol{u},p,\unicode[STIX]{x1D740})$ gathers the fluid velocity

$\boldsymbol{q}_{f}=(\boldsymbol{u},p,\unicode[STIX]{x1D740})$ gathers the fluid velocity  $\boldsymbol{u}$ and pressure

$\boldsymbol{u}$ and pressure  $p$ fields, as well as the Lagrange multiplier

$p$ fields, as well as the Lagrange multiplier  $\unicode[STIX]{x1D740}$, which is introduced so as to enforce the velocity and stress continuity conditions at the fluid–solid interface (Deparis et al. Reference Deparis, Forti, Grandperrin and Quarteroni2016; Pfister et al. Reference Pfister, Marquet and Carini2019). Finally, the extension variable

$\unicode[STIX]{x1D740}$, which is introduced so as to enforce the velocity and stress continuity conditions at the fluid–solid interface (Deparis et al. Reference Deparis, Forti, Grandperrin and Quarteroni2016; Pfister et al. Reference Pfister, Marquet and Carini2019). Finally, the extension variable  $\boldsymbol{q}_{e}=(\unicode[STIX]{x1D743}_{e},\unicode[STIX]{x1D740}_{e})$ gathers the extension displacement and a second Lagrange multiplier, denoted

$\boldsymbol{q}_{e}=(\unicode[STIX]{x1D743}_{e},\unicode[STIX]{x1D740}_{e})$ gathers the extension displacement and a second Lagrange multiplier, denoted  $\unicode[STIX]{x1D740}_{e}$, that is introduced to enforce the displacement continuity condition at the interface. The fluid–solid evolution equation is formally written here

$\unicode[STIX]{x1D740}_{e}$, that is introduced to enforce the displacement continuity condition at the interface. The fluid–solid evolution equation is formally written here

$$\begin{eqnarray}\unicode[STIX]{x1D63D}(\boldsymbol{q})\frac{\unicode[STIX]{x2202}\boldsymbol{q}}{\unicode[STIX]{x2202}t}=\unicode[STIX]{x1D63C}(\boldsymbol{q}),\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D63D}(\boldsymbol{q})\frac{\unicode[STIX]{x2202}\boldsymbol{q}}{\unicode[STIX]{x2202}t}=\unicode[STIX]{x1D63C}(\boldsymbol{q}),\end{eqnarray}$$ with the block fluid–structure operators  $\unicode[STIX]{x1D63D}$ and

$\unicode[STIX]{x1D63D}$ and  $\unicode[STIX]{x1D63C}$ defined as follows:

$\unicode[STIX]{x1D63C}$ defined as follows:

$$\begin{eqnarray}\unicode[STIX]{x1D63D}(\boldsymbol{q})=\left(\begin{array}{@{}ccc@{}}\unicode[STIX]{x1D63D}_{\boldsymbol{s}} & \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC}\\ \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC}\\ \unicode[STIX]{x1D7EC} & -\unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}(\boldsymbol{q}_{f},\boldsymbol{q}_{e}) & \unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}}(\boldsymbol{q}_{e})\end{array}\right),\quad \unicode[STIX]{x1D63C}(\boldsymbol{q})=\left(\begin{array}{@{}c@{}}\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D668}}(\boldsymbol{q}_{s})+{\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}}}^{\text{T}}\boldsymbol{q}_{f}\\ -\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65A}}\,\boldsymbol{q}_{e}+\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65A}\unicode[STIX]{x1D668}}\,\boldsymbol{q}_{s}\\ \unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}(\boldsymbol{q}_{f},\boldsymbol{q}_{e})+\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}}\boldsymbol{q}_{s}\end{array}\right).\end{eqnarray}$$

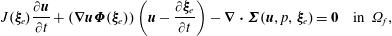

$$\begin{eqnarray}\unicode[STIX]{x1D63D}(\boldsymbol{q})=\left(\begin{array}{@{}ccc@{}}\unicode[STIX]{x1D63D}_{\boldsymbol{s}} & \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC}\\ \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC}\\ \unicode[STIX]{x1D7EC} & -\unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}(\boldsymbol{q}_{f},\boldsymbol{q}_{e}) & \unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}}(\boldsymbol{q}_{e})\end{array}\right),\quad \unicode[STIX]{x1D63C}(\boldsymbol{q})=\left(\begin{array}{@{}c@{}}\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D668}}(\boldsymbol{q}_{s})+{\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}}}^{\text{T}}\boldsymbol{q}_{f}\\ -\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65A}}\,\boldsymbol{q}_{e}+\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65A}\unicode[STIX]{x1D668}}\,\boldsymbol{q}_{s}\\ \unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}(\boldsymbol{q}_{f},\boldsymbol{q}_{e})+\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}}\boldsymbol{q}_{s}\end{array}\right).\end{eqnarray}$$ The first line of this block formulation refers to the (rewritten as first order in time) evolution equation of the structure, modelled in the present study by the Saint-Venant Kirchhoff strain–stress relation, defined by the nonlinear operator  $\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D668}}(\boldsymbol{q}_{s})$ – see appendix A for more details. The solid equation is coupled to the fluid variable by the fluid loads written here as

$\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D668}}(\boldsymbol{q}_{s})$ – see appendix A for more details. The solid equation is coupled to the fluid variable by the fluid loads written here as  ${\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}}}^{\text{T}}\boldsymbol{q}_{f}$. The second line corresponds to the arbitrary equation of the ALE formulation, where the operator

${\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}}}^{\text{T}}\boldsymbol{q}_{f}$. The second line corresponds to the arbitrary equation of the ALE formulation, where the operator  $\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65A}}$ is chosen to smoothly propagate the displacement of the fluid–solid interface into the fluid domain. This is a static problem that is entirely subordinated to the solid interface displacement via the term

$\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65A}}$ is chosen to smoothly propagate the displacement of the fluid–solid interface into the fluid domain. This is a static problem that is entirely subordinated to the solid interface displacement via the term  $\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65A}\unicode[STIX]{x1D668}}\,\boldsymbol{q}_{s}$. Finally, the last line corresponds to the ALE formulation of the incompressible Navier–Stokes equations written in the reference configuration, and denoted here

$\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65A}\unicode[STIX]{x1D668}}\,\boldsymbol{q}_{s}$. Finally, the last line corresponds to the ALE formulation of the incompressible Navier–Stokes equations written in the reference configuration, and denoted here  $\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}(\boldsymbol{q}_{f},\boldsymbol{q}_{e})$ to recall the dependence of the differential operators on the extension field

$\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}(\boldsymbol{q}_{f},\boldsymbol{q}_{e})$ to recall the dependence of the differential operators on the extension field  $\boldsymbol{q}_{e}$. The velocity coupling with the solid appears in the form of the term

$\boldsymbol{q}_{e}$. The velocity coupling with the solid appears in the form of the term  $\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}}\boldsymbol{q}_{s}$. The explicit definitions of these operators and their variational formulations are given in appendix A.

$\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}}\boldsymbol{q}_{s}$. The explicit definitions of these operators and their variational formulations are given in appendix A.

2.2 Linear stability analyses of steady fluid–structure solution

We are interested in investigating the temporal stability of time-independent fluid–structure solutions  $\boldsymbol{Q}=(\boldsymbol{Q}_{s},\boldsymbol{Q}_{e},\boldsymbol{Q}_{f})^{\text{T}}$ of (2.1), that satisfy

$\boldsymbol{Q}=(\boldsymbol{Q}_{s},\boldsymbol{Q}_{e},\boldsymbol{Q}_{f})^{\text{T}}$ of (2.1), that satisfy

$$\begin{eqnarray}\unicode[STIX]{x1D63C}(\boldsymbol{Q})=\mathbf{0}.\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D63C}(\boldsymbol{Q})=\mathbf{0}.\end{eqnarray}$$ The component  $\boldsymbol{Q}_{s}$ then accounts for the static displacement of the structure induced by the steady flow

$\boldsymbol{Q}_{s}$ then accounts for the static displacement of the structure induced by the steady flow  $\boldsymbol{Q}_{f}$ in a fluid domain deformed through

$\boldsymbol{Q}_{f}$ in a fluid domain deformed through  $\boldsymbol{Q}_{e}$.

$\boldsymbol{Q}_{e}$.

The most general approach for investigating the linear stability of an elastic structure immersed in an incompressible flow is presented in § 2.2.1. It relies on the exact linearization of (2.1) and (2.2) around steady solutions. Thus, all the couplings between the fluid and structural perturbations are taken into account. To better distinguish the physical effects at play in the fluid–solid coupling, it may also be interesting to consider two simplified stability analyses. In the quiescent-fluid stability analysis exposed in § 2.2.2, the fluid is assumed to be at rest. By neglecting the effect of the fluid flow on the small vibration of the solid, added-mass effects (including viscous diffusion) can be isolated in the interaction between the fluid and structural perturbations. In the quasi-static analysis exposed in § 2.2.3, the fluid time scale is assumed to be slow compared to the solid time scale. The fluid–solid eigenvalue problem can be then reduced to a solid vibration problem where the fluid effect is taken into account with added-mass, added-damping and added-stiffness operators, as is stated in classical aeroelasticity (Dowell Reference Dowell2004).

2.2.1 Exact fluid–structure stability analysis

The fluid–structure solution is decomposed as

$$\begin{eqnarray}\boldsymbol{q}(\boldsymbol{x},t)=\boldsymbol{Q}(\boldsymbol{x})+\unicode[STIX]{x1D700}(\boldsymbol{q}^{\circ }(\boldsymbol{x})\text{e}^{\unicode[STIX]{x1D706}t}+\text{c.c.}),\end{eqnarray}$$

$$\begin{eqnarray}\boldsymbol{q}(\boldsymbol{x},t)=\boldsymbol{Q}(\boldsymbol{x})+\unicode[STIX]{x1D700}(\boldsymbol{q}^{\circ }(\boldsymbol{x})\text{e}^{\unicode[STIX]{x1D706}t}+\text{c.c.}),\end{eqnarray}$$ where an infinitesimal perturbation ( $\unicode[STIX]{x1D700}\ll 1$) is superimposed on the steady solution and is decomposed in the form of global modes:

$\unicode[STIX]{x1D700}\ll 1$) is superimposed on the steady solution and is decomposed in the form of global modes:  $\boldsymbol{q}^{\circ }=(\boldsymbol{q}_{s}^{\circ },\boldsymbol{q}_{e}^{\circ },\boldsymbol{q}_{f}^{\circ })^{\text{T}}$ is a complex fluid–structure mode whose temporal evolution is exponential and fully defined by the complex scalar

$\boldsymbol{q}^{\circ }=(\boldsymbol{q}_{s}^{\circ },\boldsymbol{q}_{e}^{\circ },\boldsymbol{q}_{f}^{\circ })^{\text{T}}$ is a complex fluid–structure mode whose temporal evolution is exponential and fully defined by the complex scalar  $\unicode[STIX]{x1D706}=\unicode[STIX]{x1D706}^{r}+\text{i}\unicode[STIX]{x1D706}^{i}$. The real part

$\unicode[STIX]{x1D706}=\unicode[STIX]{x1D706}^{r}+\text{i}\unicode[STIX]{x1D706}^{i}$. The real part  $\unicode[STIX]{x1D706}^{r}$ indicates the growth (

$\unicode[STIX]{x1D706}^{r}$ indicates the growth ( $\unicode[STIX]{x1D706}^{r}>0$) or decay (

$\unicode[STIX]{x1D706}^{r}>0$) or decay ( $\unicode[STIX]{x1D706}^{r}<0$) of the mode, while the imaginary part

$\unicode[STIX]{x1D706}^{r}<0$) of the mode, while the imaginary part  $\unicode[STIX]{x1D706}^{i}$ gives its oscillation frequency. The above decomposition is injected into (2.1) and the operators (2.2) are linearized around the steady solutions. Since the reference fluid and solid domains are time independent, the linearization is straightforward but tedious because of spatial derivative operators accounting for the domain motion. We refer to Pfister et al. (Reference Pfister, Marquet and Carini2019) for a detailed derivation and validation of this method. It can be shown that

$\unicode[STIX]{x1D706}^{i}$ gives its oscillation frequency. The above decomposition is injected into (2.1) and the operators (2.2) are linearized around the steady solutions. Since the reference fluid and solid domains are time independent, the linearization is straightforward but tedious because of spatial derivative operators accounting for the domain motion. We refer to Pfister et al. (Reference Pfister, Marquet and Carini2019) for a detailed derivation and validation of this method. It can be shown that  $\unicode[STIX]{x1D706}$ and

$\unicode[STIX]{x1D706}$ and  $\boldsymbol{q}^{\circ }$ are eigenvalues and eigenvectors of the generalized eigenvalue problem

$\boldsymbol{q}^{\circ }$ are eigenvalues and eigenvectors of the generalized eigenvalue problem

$$\begin{eqnarray}\unicode[STIX]{x1D706}\unicode[STIX]{x1D63D}(\boldsymbol{Q})\boldsymbol{q}^{\circ }=\unicode[STIX]{x1D63C}^{\prime }(\boldsymbol{Q})\boldsymbol{q}^{\circ },\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D706}\unicode[STIX]{x1D63D}(\boldsymbol{Q})\boldsymbol{q}^{\circ }=\unicode[STIX]{x1D63C}^{\prime }(\boldsymbol{Q})\boldsymbol{q}^{\circ },\end{eqnarray}$$ where the left-hand side operator  $\unicode[STIX]{x1D63D}$, defined in (2.2), is here evaluated for the steady solution

$\unicode[STIX]{x1D63D}$, defined in (2.2), is here evaluated for the steady solution  $\boldsymbol{Q}$, and the Jacobian operator

$\boldsymbol{Q}$, and the Jacobian operator  $\unicode[STIX]{x1D63C}^{\prime }$ around the steady state writes as follows:

$\unicode[STIX]{x1D63C}^{\prime }$ around the steady state writes as follows:

$$\begin{eqnarray}\unicode[STIX]{x1D63C}^{\prime }(\boldsymbol{Q})=\left(\begin{array}{@{}ccc@{}}\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D668}}^{\prime }(\boldsymbol{Q}_{s}) & \unicode[STIX]{x1D7EC} & {\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}}}^{\text{T}}\\ \unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65A}\unicode[STIX]{x1D668}} & -\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65A}} & \unicode[STIX]{x1D7EC}\\ \unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}} & \unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}^{\prime }(\boldsymbol{Q}_{e},\boldsymbol{Q}_{f}) & \unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime }(\boldsymbol{Q}_{e},\boldsymbol{Q}_{f})\end{array}\right).\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D63C}^{\prime }(\boldsymbol{Q})=\left(\begin{array}{@{}ccc@{}}\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D668}}^{\prime }(\boldsymbol{Q}_{s}) & \unicode[STIX]{x1D7EC} & {\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}}}^{\text{T}}\\ \unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65A}\unicode[STIX]{x1D668}} & -\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65A}} & \unicode[STIX]{x1D7EC}\\ \unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}} & \unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}^{\prime }(\boldsymbol{Q}_{e},\boldsymbol{Q}_{f}) & \unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime }(\boldsymbol{Q}_{e},\boldsymbol{Q}_{f})\end{array}\right).\end{eqnarray}$$ The linearized operators  $\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D668}}^{\prime },\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime }$ and

$\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D668}}^{\prime },\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime }$ and  $\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}^{\prime }$ are obtained by linearization of

$\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}^{\prime }$ are obtained by linearization of  $\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D668}}$ (hyperelastic solid) and

$\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D668}}$ (hyperelastic solid) and  $\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}$ (Navier–Stokes equations written in the reference configuration), respectively. In particular,

$\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}$ (Navier–Stokes equations written in the reference configuration), respectively. In particular,  $\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime }(\boldsymbol{Q}_{e},\boldsymbol{Q}_{f})$ corresponds to the linearized Navier–Stokes equations (with respect to the velocity/pressure) in the reference configuration and thus depend on the extension steady variable

$\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime }(\boldsymbol{Q}_{e},\boldsymbol{Q}_{f})$ corresponds to the linearized Navier–Stokes equations (with respect to the velocity/pressure) in the reference configuration and thus depend on the extension steady variable  $\boldsymbol{Q}_{e}$. The shape derivative operator

$\boldsymbol{Q}_{e}$. The shape derivative operator  $\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}^{\prime }(\boldsymbol{Q}_{e},\boldsymbol{Q}_{f})$ represents the influence of the variations of the domain shape on the fluid momentum and continuity equations. Their expressions are reported in appendix A.

$\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}^{\prime }(\boldsymbol{Q}_{e},\boldsymbol{Q}_{f})$ represents the influence of the variations of the domain shape on the fluid momentum and continuity equations. Their expressions are reported in appendix A.

2.2.2 Quiescent-fluid stability analysis

In this analysis, we investigate small vibrations of an elastic solid in a quiescent fluid. The stability equations can be derived from the generalized eigenvalue problem (2.5) by considering  $\boldsymbol{Q}=(\boldsymbol{Q}_{f},\boldsymbol{Q}_{s},\boldsymbol{Q}_{e})^{\text{T}}=\mathbf{0}$. It can be shown that the shape derivative operators are then identically equal to zero, i.e.

$\boldsymbol{Q}=(\boldsymbol{Q}_{f},\boldsymbol{Q}_{s},\boldsymbol{Q}_{e})^{\text{T}}=\mathbf{0}$. It can be shown that the shape derivative operators are then identically equal to zero, i.e.  $\unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}(\mathbf{0},\mathbf{0})=\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}^{\prime }(\mathbf{0},\mathbf{0})=\mathbf{0}$, and the (second) equation governing the extension perturbation is decoupled from the others. For the quiescent-fluid stability analysis, the eigenvalue problem then reduces to an interaction between the fluid and solid perturbation components, i.e.

$\unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}(\mathbf{0},\mathbf{0})=\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}^{\prime }(\mathbf{0},\mathbf{0})=\mathbf{0}$, and the (second) equation governing the extension perturbation is decoupled from the others. For the quiescent-fluid stability analysis, the eigenvalue problem then reduces to an interaction between the fluid and solid perturbation components, i.e.

$$\begin{eqnarray}\unicode[STIX]{x1D706}\left(\begin{array}{@{}cc@{}}\unicode[STIX]{x1D63D}_{\boldsymbol{s}} & \unicode[STIX]{x1D7EC}\\ \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}}(\mathbf{0})\end{array}\right)\left(\begin{array}{@{}c@{}}\boldsymbol{q}_{s}^{\circ }\\ \boldsymbol{ q}_{f}^{\circ }\end{array}\right)=\left(\begin{array}{@{}cc@{}}\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D668}}^{\prime }(\mathbf{0}) & {\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}}}^{\text{T}}\\ \unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}} & \unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime }(\mathbf{0},\mathbf{0})\end{array}\right)\left(\begin{array}{@{}c@{}}\boldsymbol{q}_{s}^{\circ }\\ \boldsymbol{ q}_{f}^{\circ }\end{array}\right),\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D706}\left(\begin{array}{@{}cc@{}}\unicode[STIX]{x1D63D}_{\boldsymbol{s}} & \unicode[STIX]{x1D7EC}\\ \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}}(\mathbf{0})\end{array}\right)\left(\begin{array}{@{}c@{}}\boldsymbol{q}_{s}^{\circ }\\ \boldsymbol{ q}_{f}^{\circ }\end{array}\right)=\left(\begin{array}{@{}cc@{}}\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D668}}^{\prime }(\mathbf{0}) & {\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}}}^{\text{T}}\\ \unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}} & \unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime }(\mathbf{0},\mathbf{0})\end{array}\right)\left(\begin{array}{@{}c@{}}\boldsymbol{q}_{s}^{\circ }\\ \boldsymbol{ q}_{f}^{\circ }\end{array}\right),\end{eqnarray}$$ where the left-hand side operator is a block diagonal operator with the solid and fluid mass operators. In the right-hand side operator,  $\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D668}}^{\prime }(\mathbf{0})$ is the linearized elasticity operator and

$\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D668}}^{\prime }(\mathbf{0})$ is the linearized elasticity operator and  $\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime }(\mathbf{0},\mathbf{0})$ corresponds to the Stokes operator. Note that neglecting the steady flow does not imply that the fluid has no effect on the perturbed dynamics. The fluid effect at play is that of the momentum transport by the fluid caused by small movements close to the vibrating solid. If the viscosity is neglected in the Stokes operator, the fluid effect can be reduced to an inertia coefficient often referred to as an added-mass coefficient, whose main effect is to lower the vibrating frequency of the structure (de Langre Reference de Langre2002), compared to the case without fluid. Accounting for the viscosity, the fluid effect cannot be simply reduced to an added-mass coefficient effect, since the transport of momentum perturbations is delayed in time as they propagate in space (Maxey & Riley Reference Maxey and Riley1983). The resolution of (2.7) allows us to determine that viscous effect.

$\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime }(\mathbf{0},\mathbf{0})$ corresponds to the Stokes operator. Note that neglecting the steady flow does not imply that the fluid has no effect on the perturbed dynamics. The fluid effect at play is that of the momentum transport by the fluid caused by small movements close to the vibrating solid. If the viscosity is neglected in the Stokes operator, the fluid effect can be reduced to an inertia coefficient often referred to as an added-mass coefficient, whose main effect is to lower the vibrating frequency of the structure (de Langre Reference de Langre2002), compared to the case without fluid. Accounting for the viscosity, the fluid effect cannot be simply reduced to an added-mass coefficient effect, since the transport of momentum perturbations is delayed in time as they propagate in space (Maxey & Riley Reference Maxey and Riley1983). The resolution of (2.7) allows us to determine that viscous effect.

2.2.3 Quasi-static stability analysis

In the quasi-static stability analysis, the solid velocity in  $\boldsymbol{q}_{s}^{\circ }=(\unicode[STIX]{x1D743}^{\circ },\boldsymbol{u}_{s}^{\circ })$ is first explicitly written

$\boldsymbol{q}_{s}^{\circ }=(\unicode[STIX]{x1D743}^{\circ },\boldsymbol{u}_{s}^{\circ })$ is first explicitly written  $\boldsymbol{u}_{s}^{\circ }=\unicode[STIX]{x1D706}\unicode[STIX]{x1D743}^{\circ }$. This gives a second-order eigenvalue problem, equivalent to (2.5)

$\boldsymbol{u}_{s}^{\circ }=\unicode[STIX]{x1D706}\unicode[STIX]{x1D743}^{\circ }$. This gives a second-order eigenvalue problem, equivalent to (2.5)

$$\begin{eqnarray}\displaystyle & & \displaystyle \unicode[STIX]{x1D706}^{2}\left(\begin{array}{@{}ccc@{}}\unicode[STIX]{x1D648}_{\unicode[STIX]{x1D668}} & \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC}\\ \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC}\\ \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC}\end{array}\right)\left(\begin{array}{@{}c@{}}\unicode[STIX]{x1D743}^{\circ }\\ \boldsymbol{q}_{e}^{\circ }\\ \boldsymbol{q}_{f}^{\circ }\end{array}\right)+\unicode[STIX]{x1D706}\left(\begin{array}{@{}ccc@{}}\unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC}\\ \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC}\\ -\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D743}} & -\unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}} & \unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}}\end{array}\right)\left(\begin{array}{@{}c@{}}\unicode[STIX]{x1D743}^{\circ }\\ \boldsymbol{q}_{e}^{\circ }\\ \boldsymbol{q}_{f}^{\circ }\end{array}\right)\nonumber\\ \displaystyle & & \displaystyle \quad =\left(\begin{array}{@{}ccc@{}}-{\displaystyle \frac{{\mathcal{E}}_{s}}{{\mathcal{M}}_{s}}}\unicode[STIX]{x1D646}^{\prime } & \unicode[STIX]{x1D7EC} & {\displaystyle \frac{1}{{\mathcal{M}}_{s}}}{\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D743}}}^{\text{T}}\\ \unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65A}\unicode[STIX]{x1D743}} & -\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65A}} & \unicode[STIX]{x1D7EC}\\ \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}^{\prime } & \unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime }\end{array}\right)\left(\begin{array}{@{}c@{}}\unicode[STIX]{x1D743}^{\circ }\\ \boldsymbol{q}_{e}^{\circ }\\ \boldsymbol{q}_{f}^{\circ }\end{array}\right).\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & & \displaystyle \unicode[STIX]{x1D706}^{2}\left(\begin{array}{@{}ccc@{}}\unicode[STIX]{x1D648}_{\unicode[STIX]{x1D668}} & \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC}\\ \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC}\\ \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC}\end{array}\right)\left(\begin{array}{@{}c@{}}\unicode[STIX]{x1D743}^{\circ }\\ \boldsymbol{q}_{e}^{\circ }\\ \boldsymbol{q}_{f}^{\circ }\end{array}\right)+\unicode[STIX]{x1D706}\left(\begin{array}{@{}ccc@{}}\unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC}\\ \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D7EC}\\ -\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D743}} & -\unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}} & \unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}}\end{array}\right)\left(\begin{array}{@{}c@{}}\unicode[STIX]{x1D743}^{\circ }\\ \boldsymbol{q}_{e}^{\circ }\\ \boldsymbol{q}_{f}^{\circ }\end{array}\right)\nonumber\\ \displaystyle & & \displaystyle \quad =\left(\begin{array}{@{}ccc@{}}-{\displaystyle \frac{{\mathcal{E}}_{s}}{{\mathcal{M}}_{s}}}\unicode[STIX]{x1D646}^{\prime } & \unicode[STIX]{x1D7EC} & {\displaystyle \frac{1}{{\mathcal{M}}_{s}}}{\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D743}}}^{\text{T}}\\ \unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65A}\unicode[STIX]{x1D743}} & -\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65A}} & \unicode[STIX]{x1D7EC}\\ \unicode[STIX]{x1D7EC} & \unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}^{\prime } & \unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime }\end{array}\right)\left(\begin{array}{@{}c@{}}\unicode[STIX]{x1D743}^{\circ }\\ \boldsymbol{q}_{e}^{\circ }\\ \boldsymbol{q}_{f}^{\circ }\end{array}\right).\end{eqnarray}$$ Details of the different operators are given in appendix A. Further eliminating the extension and fluid variables, we eventually obtain an equation for  $\unicode[STIX]{x1D743}^{\circ }$ only

$\unicode[STIX]{x1D743}^{\circ }$ only

$$\begin{eqnarray}\left(\unicode[STIX]{x1D706}^{2}\unicode[STIX]{x1D648}_{\unicode[STIX]{x1D668}}+\frac{{\mathcal{E}}_{s}}{{\mathcal{M}}_{s}}\unicode[STIX]{x1D646}^{\prime }(\boldsymbol{Q}_{s})\right)\unicode[STIX]{x1D743}^{\circ }=\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D668}\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}}(\unicode[STIX]{x1D706};\boldsymbol{Q}_{e},\boldsymbol{Q}_{f})\unicode[STIX]{x1D743}^{\circ }.\end{eqnarray}$$

$$\begin{eqnarray}\left(\unicode[STIX]{x1D706}^{2}\unicode[STIX]{x1D648}_{\unicode[STIX]{x1D668}}+\frac{{\mathcal{E}}_{s}}{{\mathcal{M}}_{s}}\unicode[STIX]{x1D646}^{\prime }(\boldsymbol{Q}_{s})\right)\unicode[STIX]{x1D743}^{\circ }=\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D668}\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}}(\unicode[STIX]{x1D706};\boldsymbol{Q}_{e},\boldsymbol{Q}_{f})\unicode[STIX]{x1D743}^{\circ }.\end{eqnarray}$$In the above formulation, the left-hand side is a solid vibration problem, while the action of the fluid on the solid dynamics is entirely contained in the right-hand side ‘solid-to-fluid-to-solid’ operator

$$\begin{eqnarray}\displaystyle \unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D668}\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}}(\unicode[STIX]{x1D706};\boldsymbol{Q}_{e},\boldsymbol{Q}_{f}) & = & \displaystyle \frac{1}{{\mathcal{M}}_{s}}\underbrace{{\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D743}}}^{\text{T}}}_{(3)}\underbrace{(\unicode[STIX]{x1D706}\unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}}(\boldsymbol{Q}_{e})-\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime }(\boldsymbol{Q}_{f},\boldsymbol{Q}_{e}))^{-1}}_{(2)}\nonumber\\ \displaystyle & & \displaystyle \times \,\cdots \underbrace{(\unicode[STIX]{x1D706}\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D743}}+(\unicode[STIX]{x1D706}\unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}(\boldsymbol{Q}_{f},\boldsymbol{Q}_{e})+\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}^{\prime }(\boldsymbol{Q}_{f},\boldsymbol{Q}_{e}))\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65A}}^{-1}\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65A}\unicode[STIX]{x1D743}})}_{(1)}\qquad\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D668}\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}}(\unicode[STIX]{x1D706};\boldsymbol{Q}_{e},\boldsymbol{Q}_{f}) & = & \displaystyle \frac{1}{{\mathcal{M}}_{s}}\underbrace{{\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D743}}}^{\text{T}}}_{(3)}\underbrace{(\unicode[STIX]{x1D706}\unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}}(\boldsymbol{Q}_{e})-\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime }(\boldsymbol{Q}_{f},\boldsymbol{Q}_{e}))^{-1}}_{(2)}\nonumber\\ \displaystyle & & \displaystyle \times \,\cdots \underbrace{(\unicode[STIX]{x1D706}\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D743}}+(\unicode[STIX]{x1D706}\unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}(\boldsymbol{Q}_{f},\boldsymbol{Q}_{e})+\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}^{\prime }(\boldsymbol{Q}_{f},\boldsymbol{Q}_{e}))\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65A}}^{-1}\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65A}\unicode[STIX]{x1D743}})}_{(1)}\qquad\end{eqnarray}$$ that represents how a linear solid deformation influences the solid modal problem after having ‘travelled’ in the fluid. Indeed, in the first term (1) acting onto the solid displacement  $\unicode[STIX]{x1D743}^{\circ }$, the operator

$\unicode[STIX]{x1D743}^{\circ }$, the operator  $\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65A}}^{-1}\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65A}\unicode[STIX]{x1D743}}$ propagates the solid deformation into the fluid domain, while

$\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65A}}^{-1}\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65A}\unicode[STIX]{x1D743}}$ propagates the solid deformation into the fluid domain, while  $\unicode[STIX]{x1D706}\unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}+\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}^{\prime }$ evaluates into what forcing of the fluid momentum and continuity equation this domain deformation results. The operator

$\unicode[STIX]{x1D706}\unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}+\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D65A}}^{\prime }$ evaluates into what forcing of the fluid momentum and continuity equation this domain deformation results. The operator  $\unicode[STIX]{x1D706}\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D743}}$ extracts the solid velocity at the interface. The output of the operator (1) is therefore the forcing of the fluid induced by the solid deformation. The second term (2) is the fluid resolvent operator that propagates and amplifies this forcing into a fluid perturbation. Finally, the last term (3) extracts the constraints exerted by the fluid onto the solid at the fluid–solid interface. Note that, in the limit

$\unicode[STIX]{x1D706}\unicode[STIX]{x1D644}_{\unicode[STIX]{x1D65B}\unicode[STIX]{x1D743}}$ extracts the solid velocity at the interface. The output of the operator (1) is therefore the forcing of the fluid induced by the solid deformation. The second term (2) is the fluid resolvent operator that propagates and amplifies this forcing into a fluid perturbation. Finally, the last term (3) extracts the constraints exerted by the fluid onto the solid at the fluid–solid interface. Note that, in the limit  ${\mathcal{M}}_{s}\rightarrow +\infty$, i.e. the limit of a ‘very heavy’ solid, this feedback term becomes negligible and the system behaves as a solid oscillator to which the fluid can only respond. So far, the formulation (2.9)–(2.10) is equivalent to (2.5).

${\mathcal{M}}_{s}\rightarrow +\infty$, i.e. the limit of a ‘very heavy’ solid, this feedback term becomes negligible and the system behaves as a solid oscillator to which the fluid can only respond. So far, the formulation (2.9)–(2.10) is equivalent to (2.5).

In the quasi-static approach, we assume that the time scale of the fluid–structure instability is slow and sufficiently close to onset. The eigenvalue  $\unicode[STIX]{x1D706}$ is then close to zero and a Taylor expansion of the fluid resolvent operator gives

$\unicode[STIX]{x1D706}$ is then close to zero and a Taylor expansion of the fluid resolvent operator gives

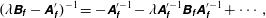

$$\begin{eqnarray}(\unicode[STIX]{x1D706}\unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}}-\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime })^{-1}=-\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime -1}-\unicode[STIX]{x1D706}\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime -1}\unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}}\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime -1}+\cdots \,,\end{eqnarray}$$

$$\begin{eqnarray}(\unicode[STIX]{x1D706}\unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}}-\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime })^{-1}=-\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime -1}-\unicode[STIX]{x1D706}\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime -1}\unicode[STIX]{x1D63D}_{\unicode[STIX]{x1D65B}}\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D65B}}^{\prime -1}+\cdots \,,\end{eqnarray}$$ where we have dropped the dependency of the operators on the steady states so as to simplify the notations. In this development, the first term accounts for a purely static approximation of the linearized fluid dynamics while the second term is a first-order correction that approximates the low-frequency dynamics. Injecting the above expansion of the fluid resolvent into (2.10), we obtain an approximation  $\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D668}\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}}(\unicode[STIX]{x1D706})\simeq \unicode[STIX]{x1D706}^{2}\unicode[STIX]{x1D648}_{a}+\unicode[STIX]{x1D706}\unicode[STIX]{x1D63F}_{a}+\unicode[STIX]{x1D646}_{a}$, where

$\unicode[STIX]{x1D63C}_{\unicode[STIX]{x1D668}\unicode[STIX]{x1D65B}\unicode[STIX]{x1D668}}(\unicode[STIX]{x1D706})\simeq \unicode[STIX]{x1D706}^{2}\unicode[STIX]{x1D648}_{a}+\unicode[STIX]{x1D706}\unicode[STIX]{x1D63F}_{a}+\unicode[STIX]{x1D646}_{a}$, where  $\unicode[STIX]{x1D648}_{a}$,

$\unicode[STIX]{x1D648}_{a}$,  $\unicode[STIX]{x1D63F}_{a}$ and

$\unicode[STIX]{x1D63F}_{a}$ and  $\unicode[STIX]{x1D646}_{a}$ are added-mass, added-damping and added-stiffness operators, respectively. The eigenvalue problem (2.9) can then be written on the form of the quadratic problem

$\unicode[STIX]{x1D646}_{a}$ are added-mass, added-damping and added-stiffness operators, respectively. The eigenvalue problem (2.9) can then be written on the form of the quadratic problem

$$\begin{eqnarray}\left(\unicode[STIX]{x1D706}^{2}(\unicode[STIX]{x1D648}_{\unicode[STIX]{x1D668}}-\unicode[STIX]{x1D648}_{a})-\unicode[STIX]{x1D706}\unicode[STIX]{x1D63F}_{a}+\left(\frac{{\mathcal{E}}_{s}}{{\mathcal{M}}_{s}}\unicode[STIX]{x1D646}^{\prime }-\unicode[STIX]{x1D646}_{a}\right)\right)\unicode[STIX]{x1D743}^{\circ }=\mathbf{0}.\end{eqnarray}$$

$$\begin{eqnarray}\left(\unicode[STIX]{x1D706}^{2}(\unicode[STIX]{x1D648}_{\unicode[STIX]{x1D668}}-\unicode[STIX]{x1D648}_{a})-\unicode[STIX]{x1D706}\unicode[STIX]{x1D63F}_{a}+\left(\frac{{\mathcal{E}}_{s}}{{\mathcal{M}}_{s}}\unicode[STIX]{x1D646}^{\prime }-\unicode[STIX]{x1D646}_{a}\right)\right)\unicode[STIX]{x1D743}^{\circ }=\mathbf{0}.\end{eqnarray}$$To further understand how these added-fluid operators modify the purely structural dynamics, the solid component of the coupled problem is decomposed as

$$\begin{eqnarray}\displaystyle \unicode[STIX]{x1D743}^{\circ }=\mathop{\sum }_{i=1}^{N}\unicode[STIX]{x1D6FC}_{i}\unicode[STIX]{x1D753}_{i}^{\circ }, & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \unicode[STIX]{x1D743}^{\circ }=\mathop{\sum }_{i=1}^{N}\unicode[STIX]{x1D6FC}_{i}\unicode[STIX]{x1D753}_{i}^{\circ }, & & \displaystyle\end{eqnarray}$$ where  $\unicode[STIX]{x1D753}_{i}^{\circ }$ is the

$\unicode[STIX]{x1D753}_{i}^{\circ }$ is the  $i\text{th}$ solid free-vibration mode, vibrating at the frequency

$i\text{th}$ solid free-vibration mode, vibrating at the frequency  $\unicode[STIX]{x1D714}_{s,i}$. They are obtained as eigenvectors/eigenvalues of the solid mass and stiffness operators, i.e.

$\unicode[STIX]{x1D714}_{s,i}$. They are obtained as eigenvectors/eigenvalues of the solid mass and stiffness operators, i.e.

$$\begin{eqnarray}\left\{-\unicode[STIX]{x1D714}_{s,i}^{2}\unicode[STIX]{x1D648}_{\unicode[STIX]{x1D668}}+\frac{{\mathcal{E}}_{s}}{{\mathcal{M}}_{s}}\unicode[STIX]{x1D646}^{\prime }\right\}\unicode[STIX]{x1D753}_{i}^{\circ }=\mathbf{0}.\end{eqnarray}$$

$$\begin{eqnarray}\left\{-\unicode[STIX]{x1D714}_{s,i}^{2}\unicode[STIX]{x1D648}_{\unicode[STIX]{x1D668}}+\frac{{\mathcal{E}}_{s}}{{\mathcal{M}}_{s}}\unicode[STIX]{x1D646}^{\prime }\right\}\unicode[STIX]{x1D753}_{i}^{\circ }=\mathbf{0}.\end{eqnarray}$$ Only real modes are found – whatever the stiffness – if the steady strains are neglected, as will be done in the following. By introducing the decomposition (2.13) into (2.12) and using the orthogonality property of the free-vibrations modes, i.e.  $\unicode[STIX]{x1D753}_{i}^{\circ \text{T}}\unicode[STIX]{x1D648}_{\unicode[STIX]{x1D668}}\unicode[STIX]{x1D753}_{j}^{\circ }=\unicode[STIX]{x1D6FF}_{ij}$, we obtain the reduced-scale eigenvalue problem

$\unicode[STIX]{x1D753}_{i}^{\circ \text{T}}\unicode[STIX]{x1D648}_{\unicode[STIX]{x1D668}}\unicode[STIX]{x1D753}_{j}^{\circ }=\unicode[STIX]{x1D6FF}_{ij}$, we obtain the reduced-scale eigenvalue problem

$$\begin{eqnarray}\left(\unicode[STIX]{x1D706}^{2}(\unicode[STIX]{x1D644}-\hat{\unicode[STIX]{x1D648}}_{a})-\unicode[STIX]{x1D706}\hat{\unicode[STIX]{x1D63F}}_{a}+\left(\frac{{\mathcal{E}}_{s}}{{\mathcal{M}}_{s}}\hat{\unicode[STIX]{x1D646}}-\hat{\unicode[STIX]{x1D646}}_{a}\right)\right)\unicode[STIX]{x1D736}=\mathbf{0}.\end{eqnarray}$$

$$\begin{eqnarray}\left(\unicode[STIX]{x1D706}^{2}(\unicode[STIX]{x1D644}-\hat{\unicode[STIX]{x1D648}}_{a})-\unicode[STIX]{x1D706}\hat{\unicode[STIX]{x1D63F}}_{a}+\left(\frac{{\mathcal{E}}_{s}}{{\mathcal{M}}_{s}}\hat{\unicode[STIX]{x1D646}}-\hat{\unicode[STIX]{x1D646}}_{a}\right)\right)\unicode[STIX]{x1D736}=\mathbf{0}.\end{eqnarray}$$ where  $\unicode[STIX]{x1D736}=[\unicode[STIX]{x1D6FC}_{1},\ldots ,\unicode[STIX]{x1D6FC}_{N}]^{\text{T}}$ is the vector gathering the coefficients of the modal projection,

$\unicode[STIX]{x1D736}=[\unicode[STIX]{x1D6FC}_{1},\ldots ,\unicode[STIX]{x1D6FC}_{N}]^{\text{T}}$ is the vector gathering the coefficients of the modal projection,  $\unicode[STIX]{x1D644}$ is the identity matrix of size

$\unicode[STIX]{x1D644}$ is the identity matrix of size  $N\times N$ and

$N\times N$ and  $\hat{\unicode[STIX]{x1D646}}$ is a diagonal matrix containing the free-vibration frequencies. The projected added-fluid matrices are defined as

$\hat{\unicode[STIX]{x1D646}}$ is a diagonal matrix containing the free-vibration frequencies. The projected added-fluid matrices are defined as  $\hat{\unicode[STIX]{x1D648}}_{a}=\unicode[STIX]{x1D753}^{\text{T}}\unicode[STIX]{x1D648}_{a}\unicode[STIX]{x1D753}$,

$\hat{\unicode[STIX]{x1D648}}_{a}=\unicode[STIX]{x1D753}^{\text{T}}\unicode[STIX]{x1D648}_{a}\unicode[STIX]{x1D753}$,  $\hat{\unicode[STIX]{x1D63F}}_{a}=\unicode[STIX]{x1D753}^{\text{T}}\unicode[STIX]{x1D63F}_{a}\unicode[STIX]{x1D753}$ and

$\hat{\unicode[STIX]{x1D63F}}_{a}=\unicode[STIX]{x1D753}^{\text{T}}\unicode[STIX]{x1D63F}_{a}\unicode[STIX]{x1D753}$ and  $\hat{\unicode[STIX]{x1D646}}_{a}=\unicode[STIX]{x1D753}^{\text{T}}\unicode[STIX]{x1D646}_{a}\unicode[STIX]{x1D753}$, where

$\hat{\unicode[STIX]{x1D646}}_{a}=\unicode[STIX]{x1D753}^{\text{T}}\unicode[STIX]{x1D646}_{a}\unicode[STIX]{x1D753}$, where  $\unicode[STIX]{x1D753}$ is a matrix whose columns are the free-vibration modes

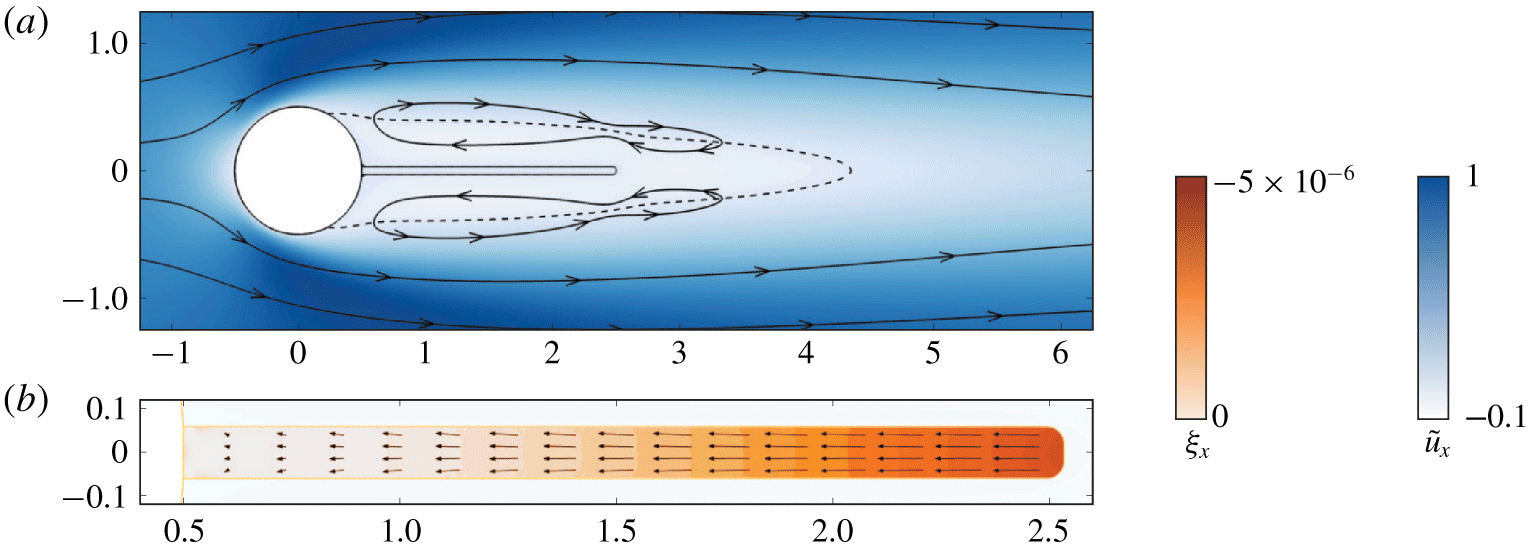

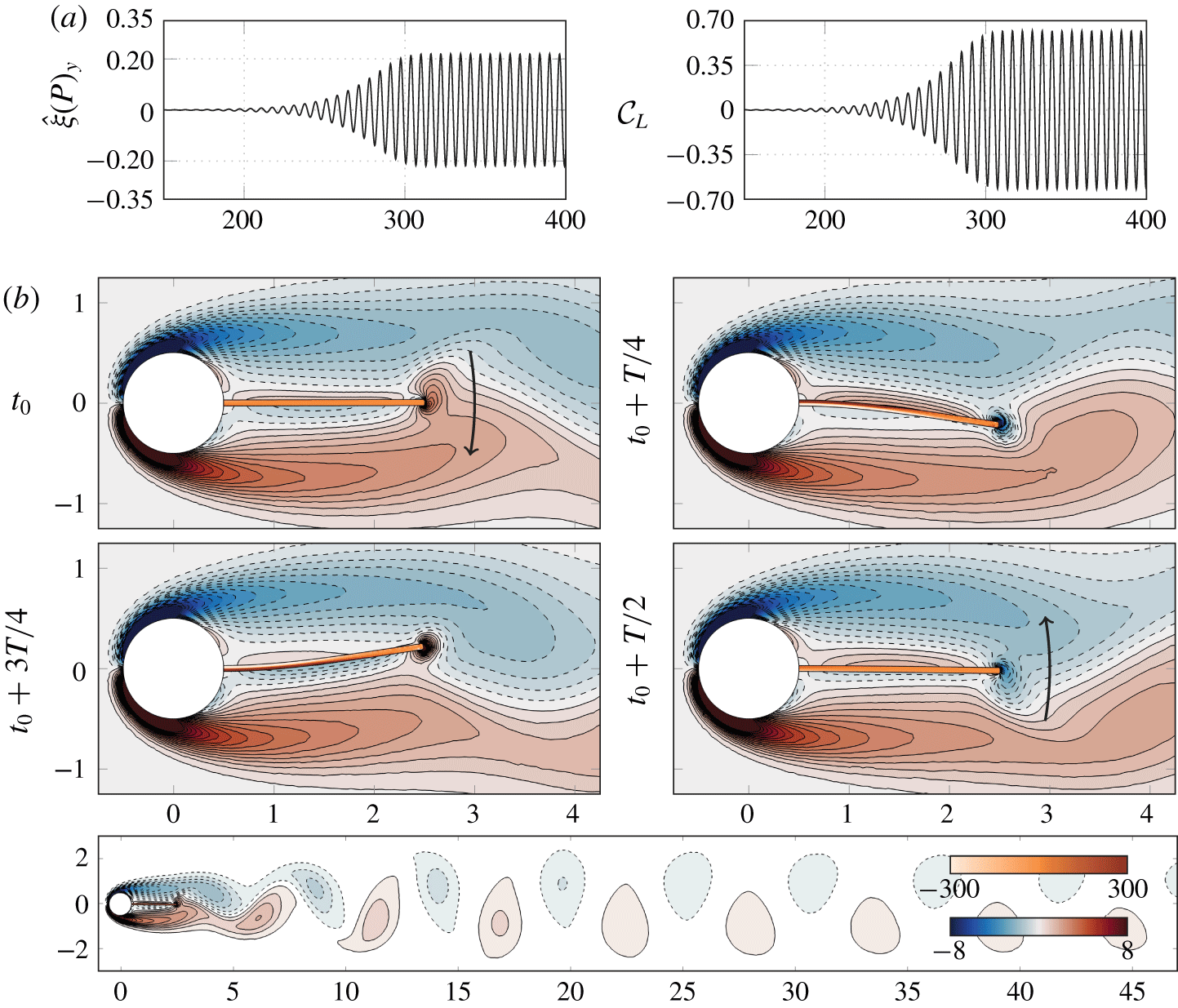

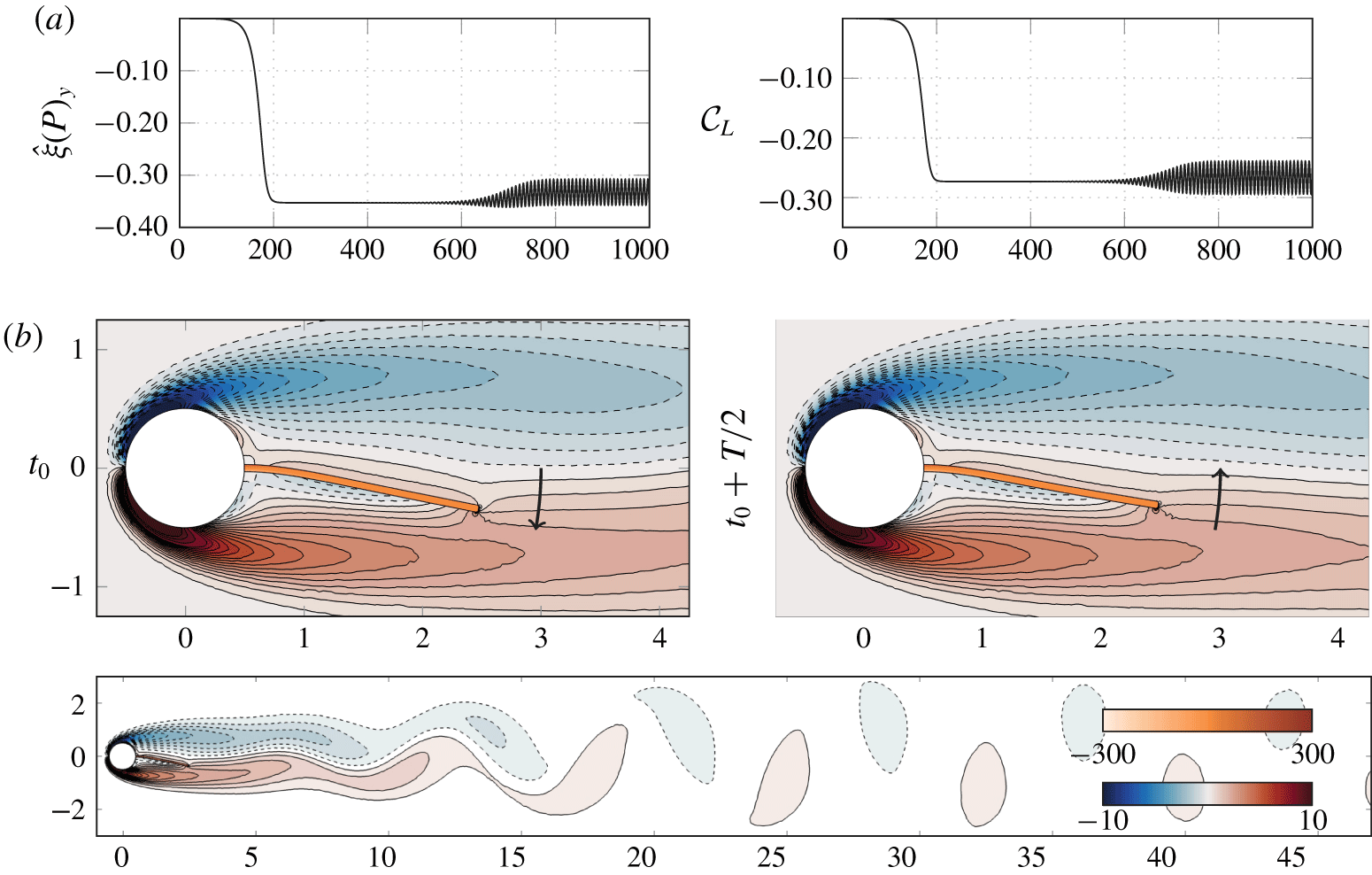

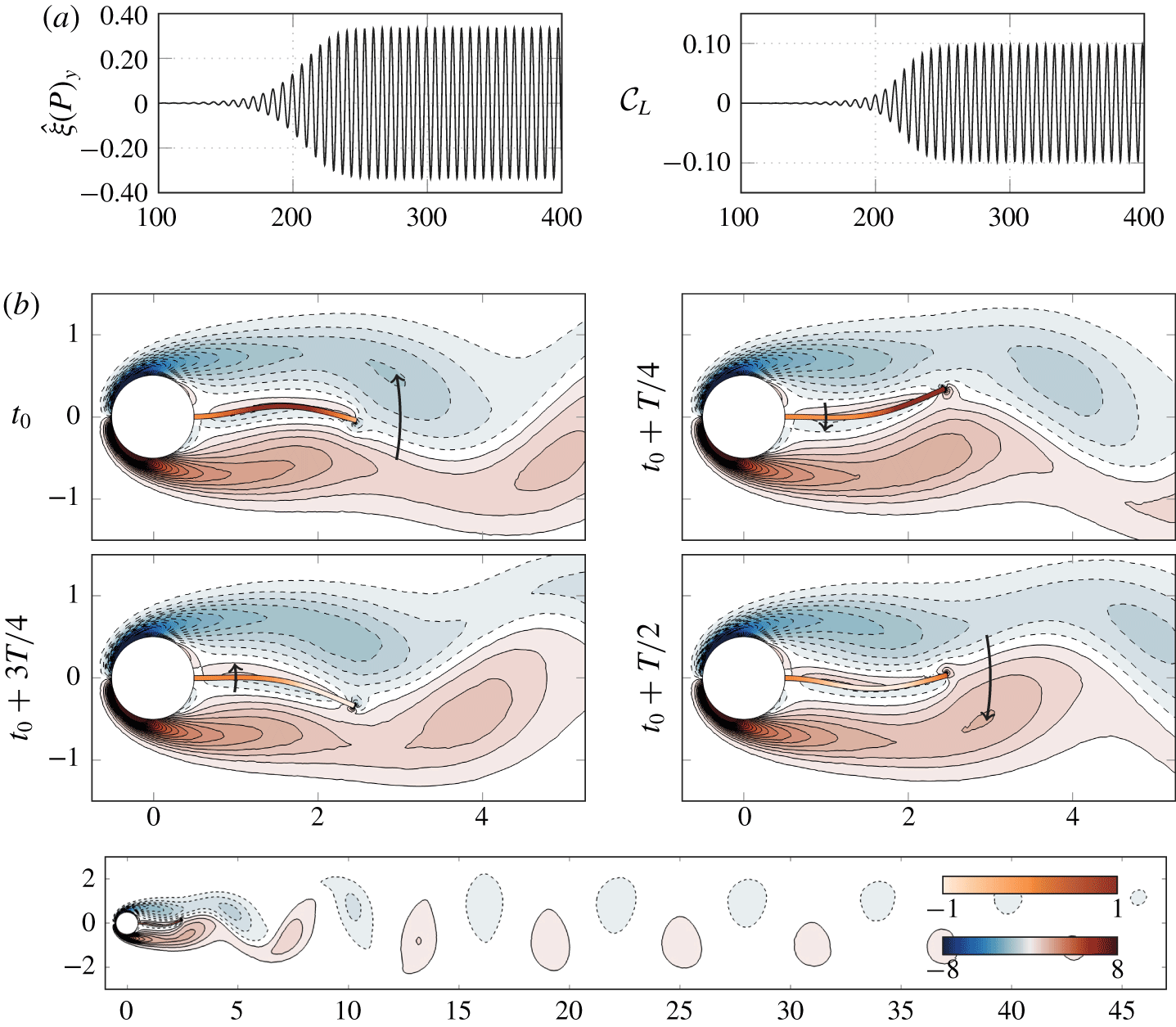

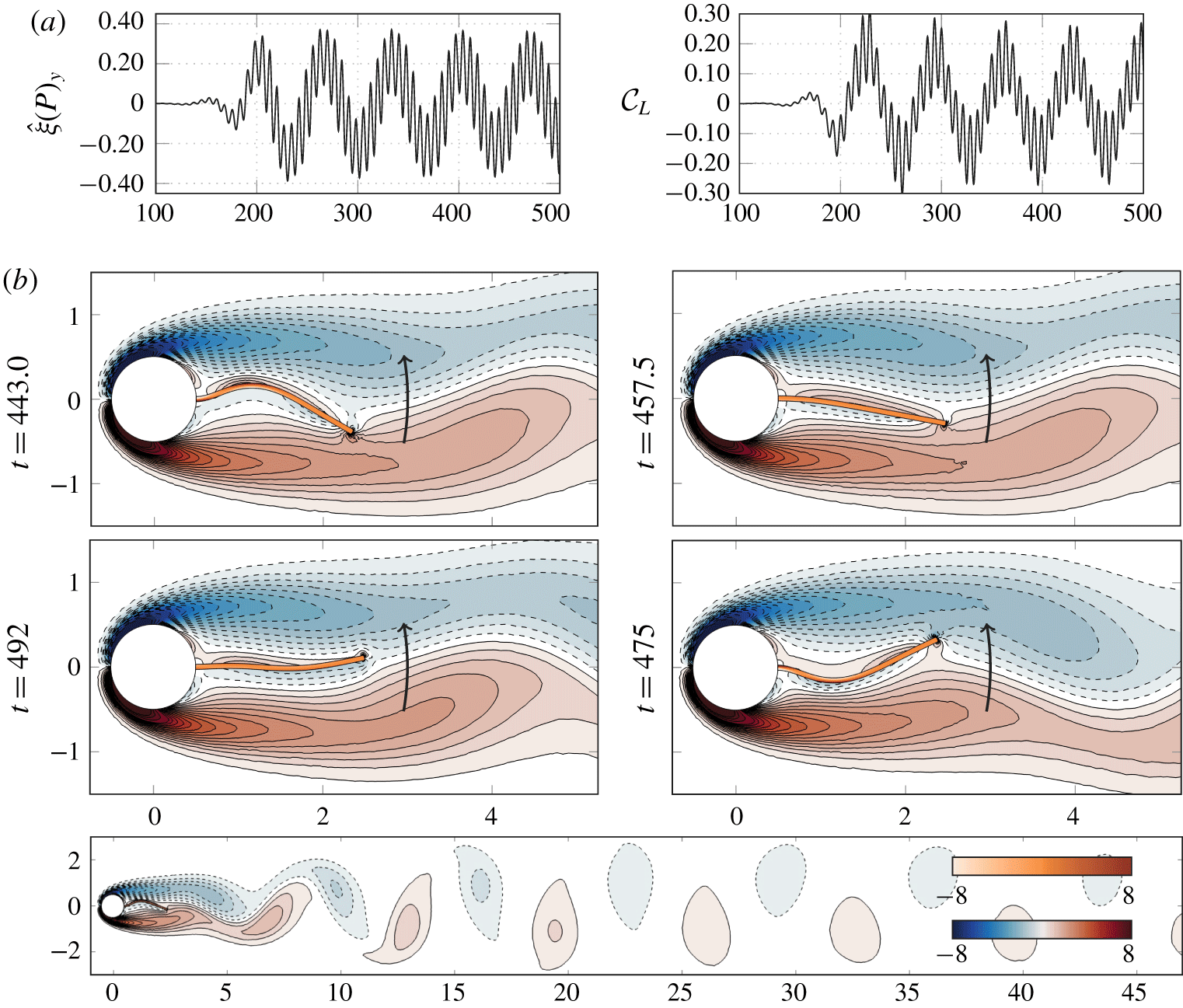

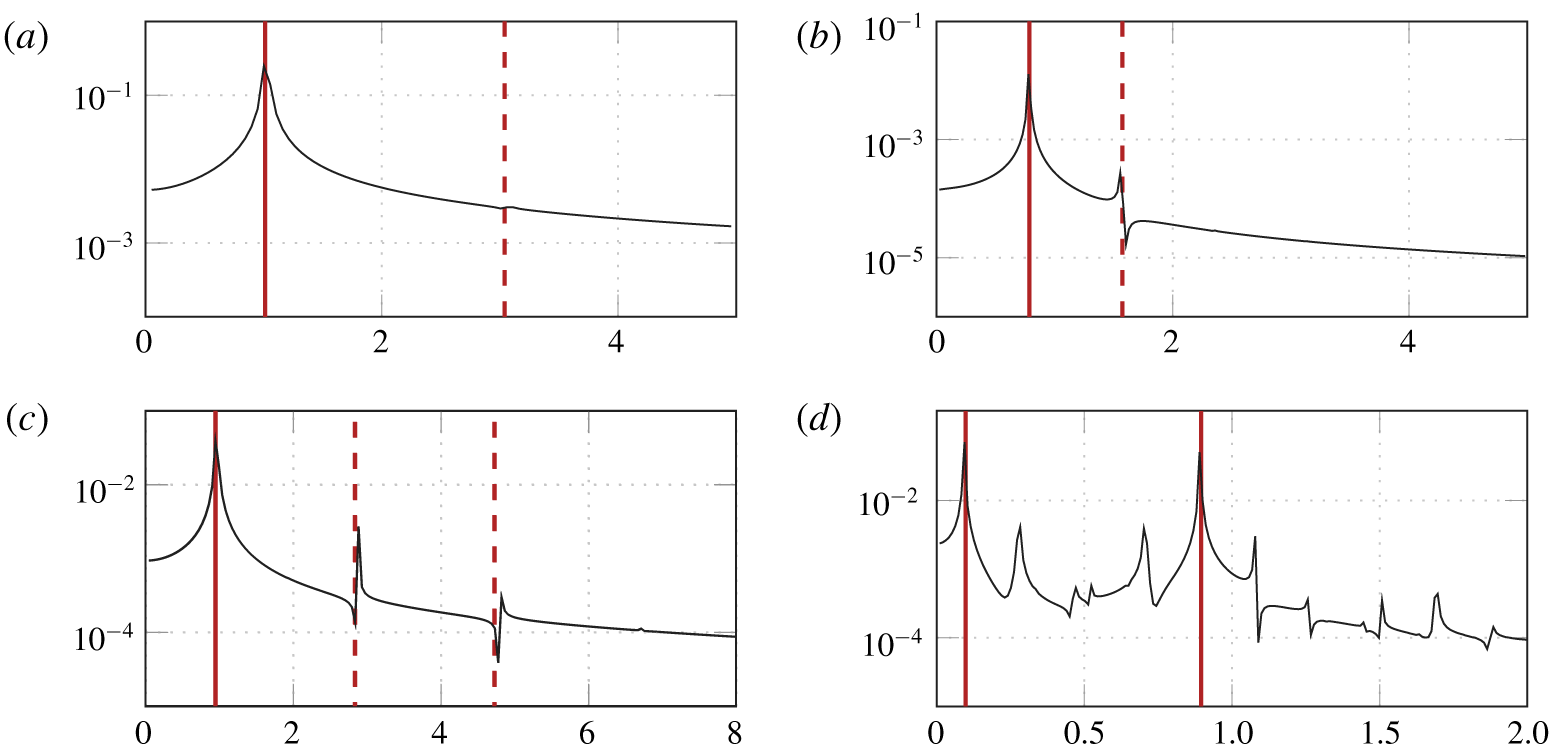

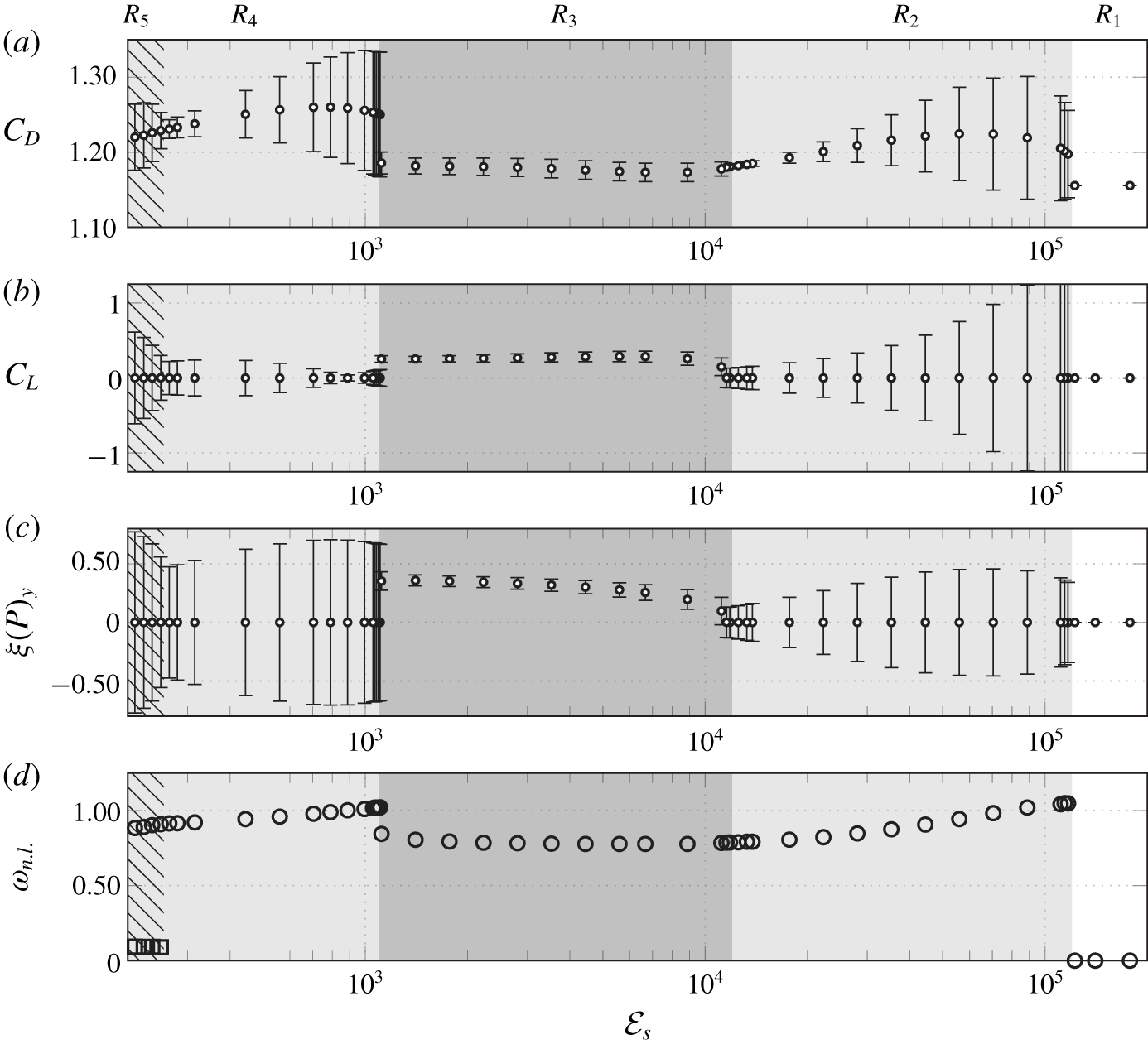

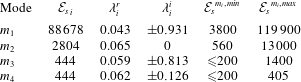

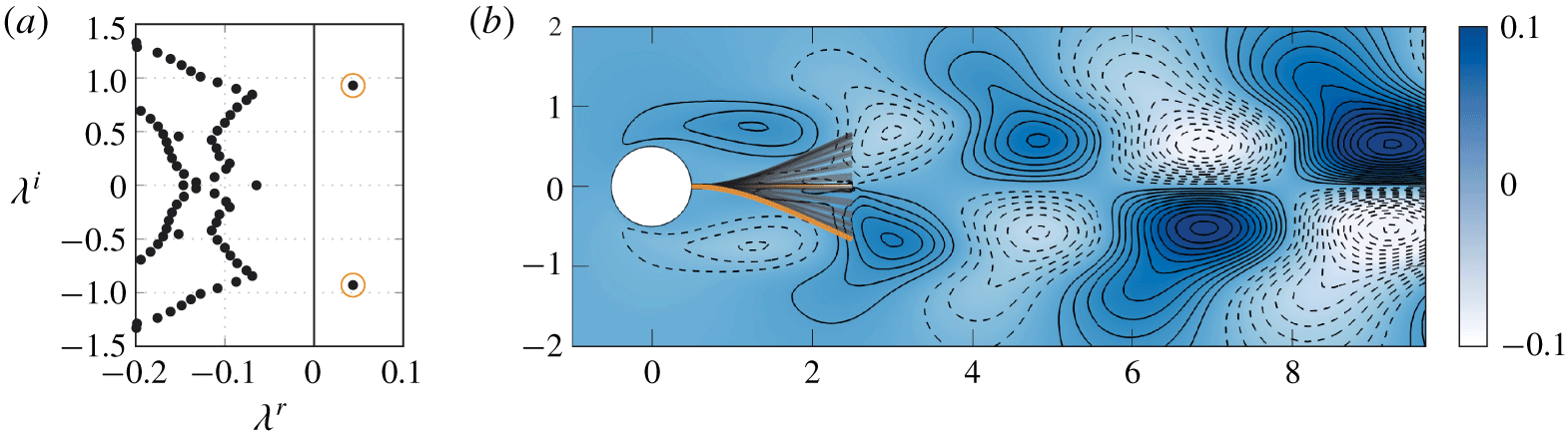

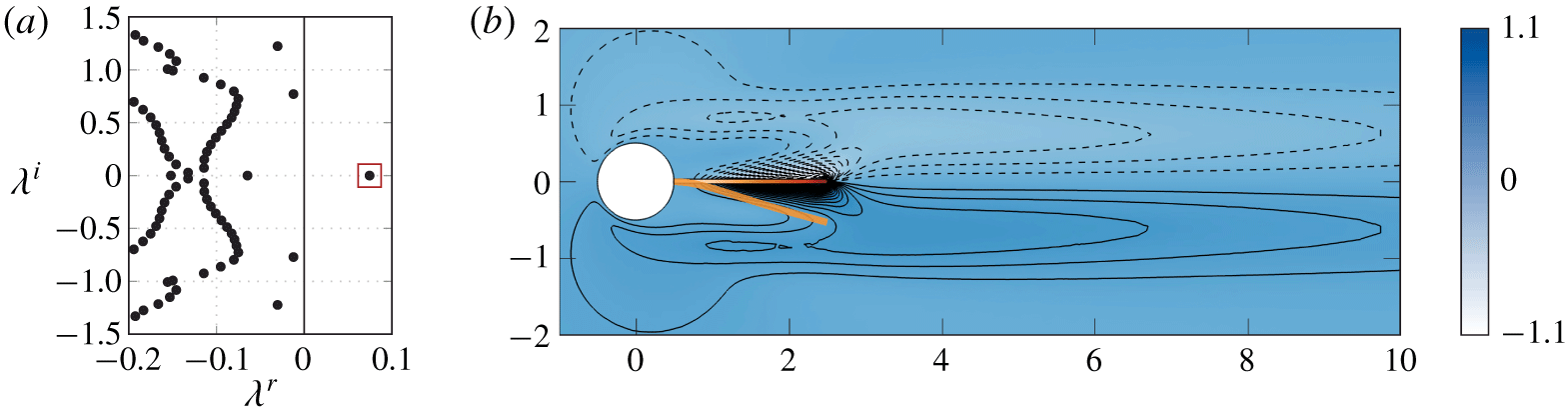

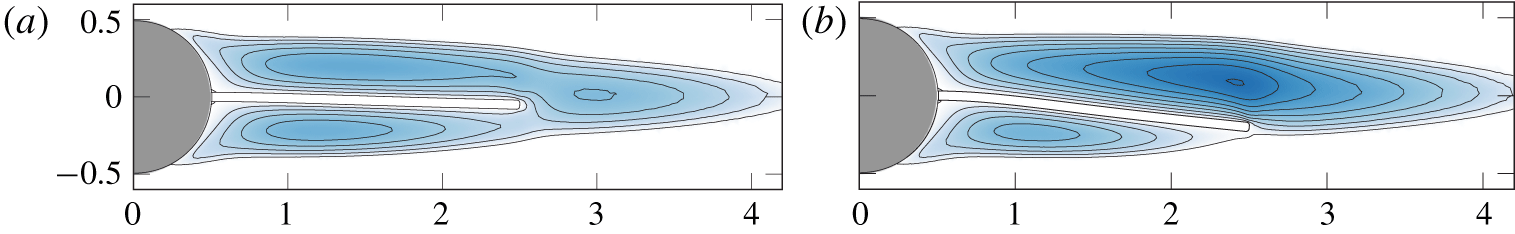

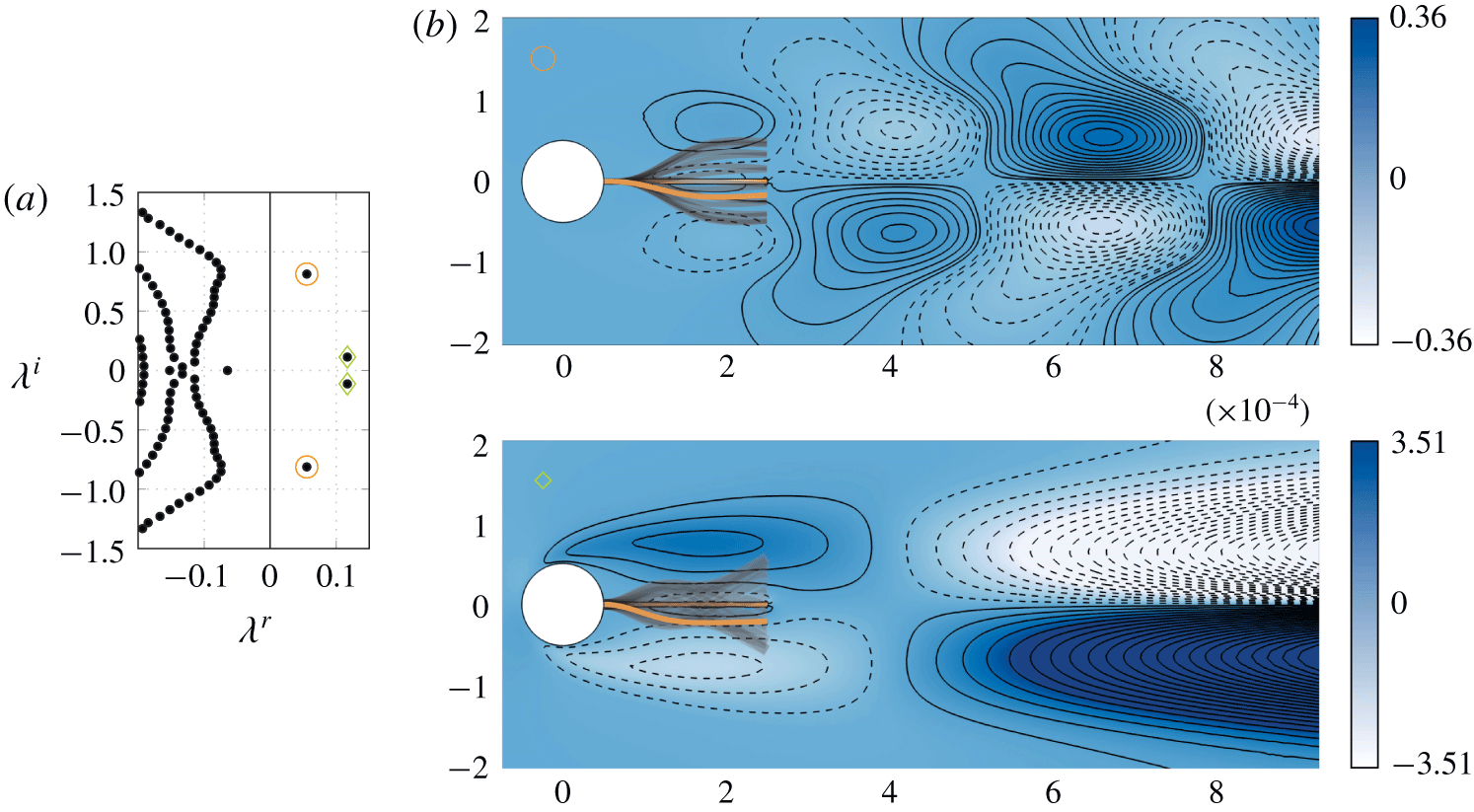

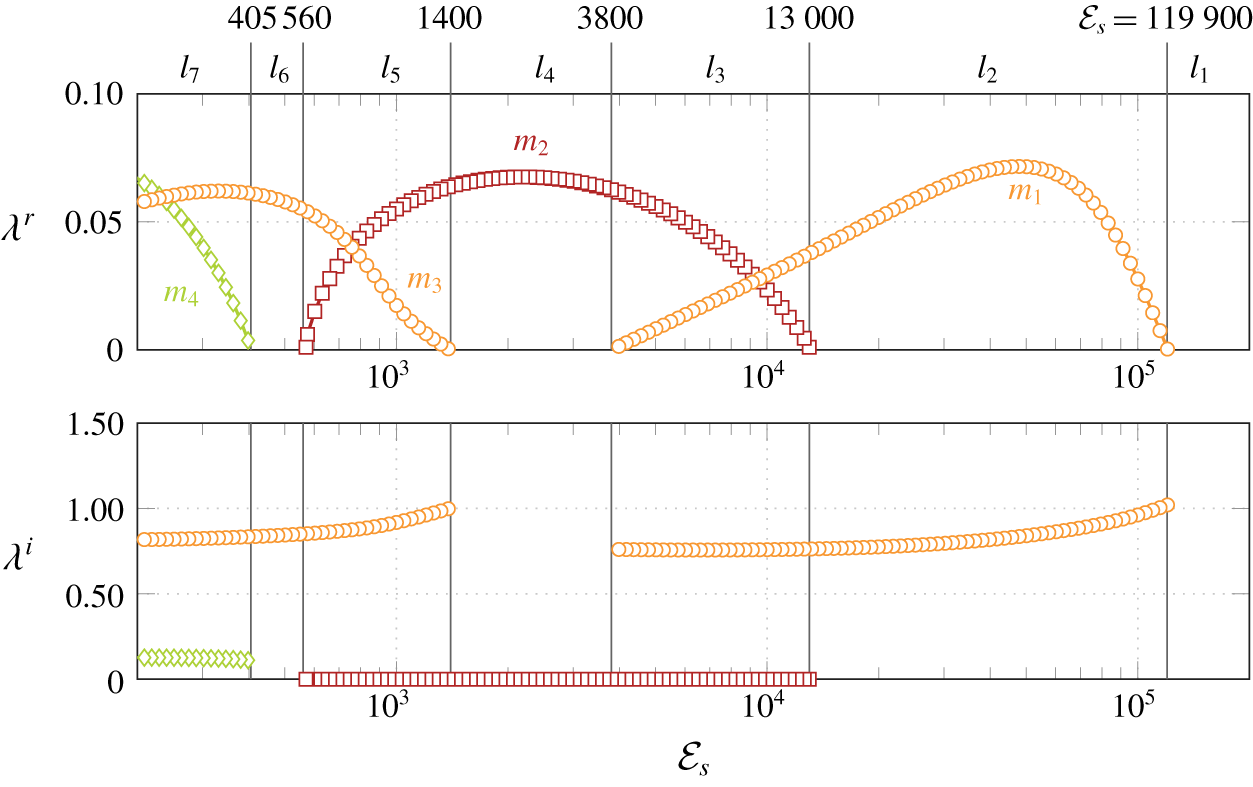

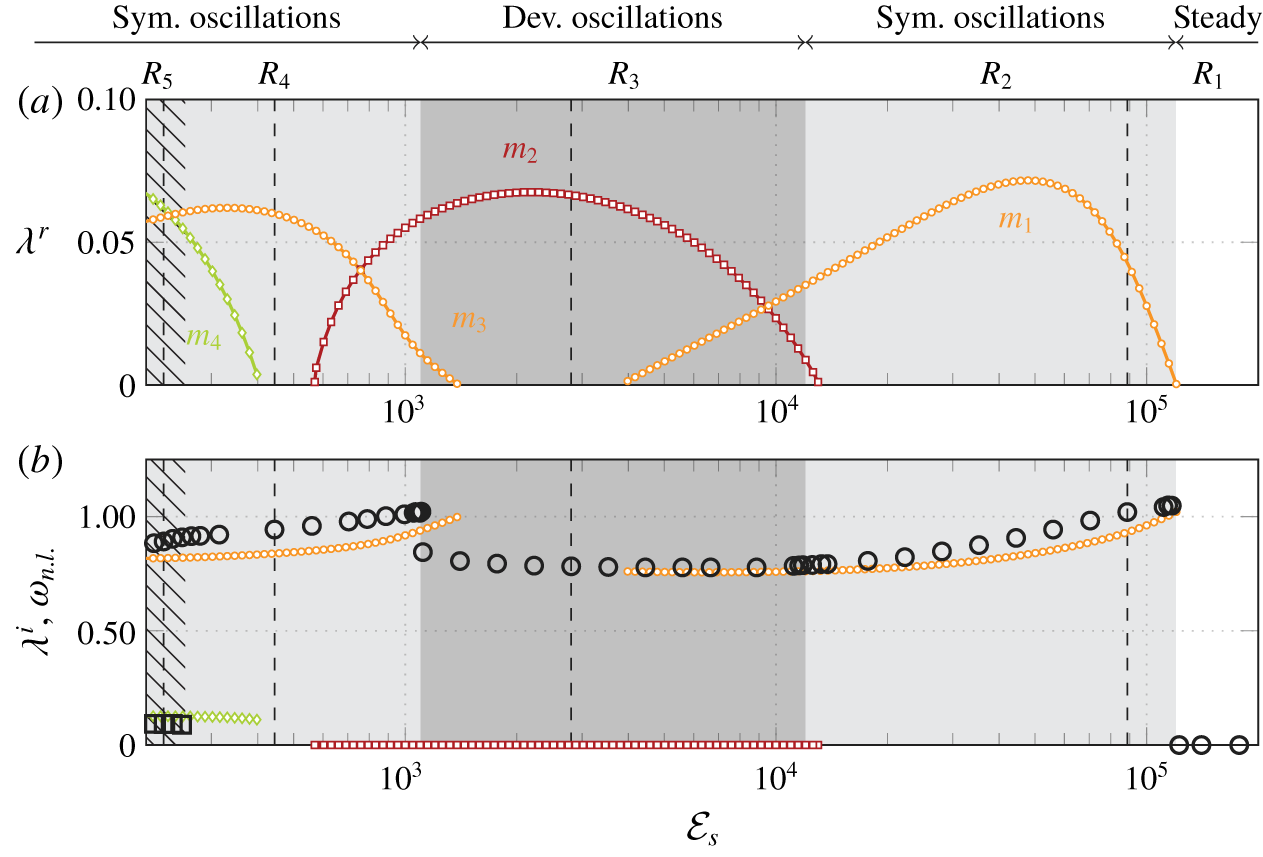

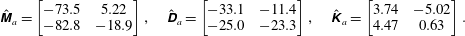

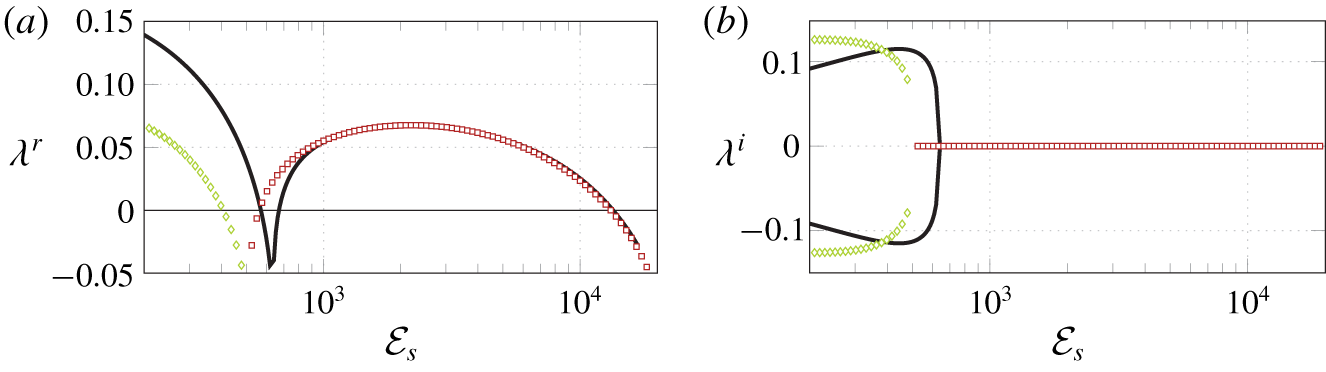

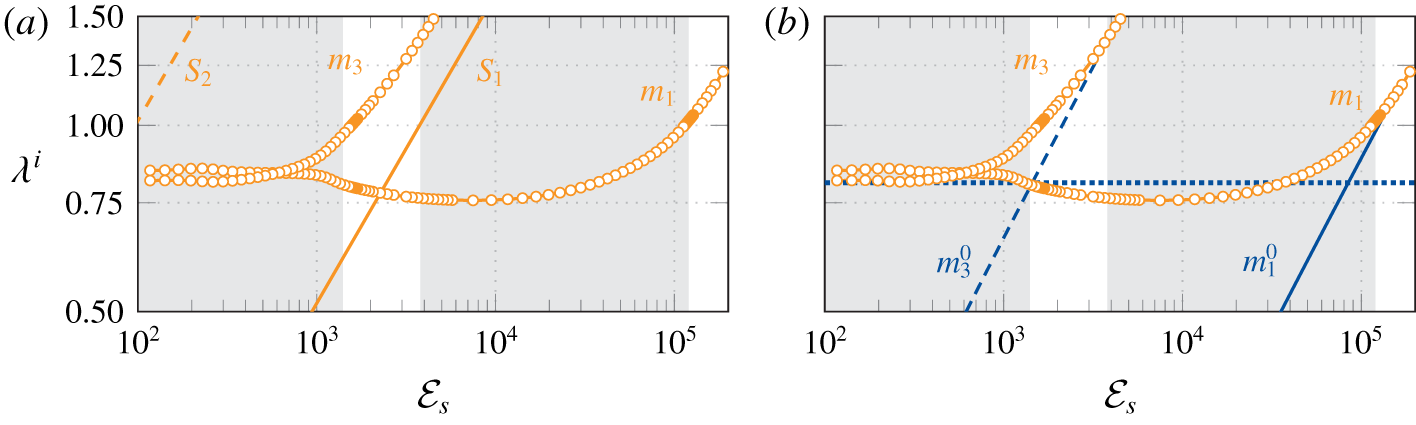

$\unicode[STIX]{x1D753}$ is a matrix whose columns are the free-vibration modes  $\unicode[STIX]{x1D753}_{i}^{\circ }$. This analysis will be applied to analyse the steady and low-frequency fluid–elastic modes. Note that the problem (2.15) is similar to linear flutter equations used for aeroelasticity analyses (Dowell Reference Dowell2004), but are here obtained as a first-order expansion of our fully coupled analysis rather than stated a priori. Moreover, we see that the approach is valid as long as the expansion (2.11) is valid.