1. Introduction

Dense granular systems in nature and industry are often non-monodisperse – i.e. consisting of particles of disparate sizes. In non-monodisperse granular systems, the constituent grains segregate based on size during flow, forming complex patterns (e.g. Shinbrot & Muzzio Reference Shinbrot and Muzzio2000; Gray & Thornton Reference Gray and Thornton2005; Hill & Fan Reference Hill and Fan2008; Fan & Hill Reference Fan and Hill2010; Schlick et al. Reference Schlick, Fan, Isner, Umbanhowar, Ottino and Lueptow2015; Gray Reference Gray2018; Umbanhowar, Lueptow & Ottino Reference Umbanhowar, Lueptow and Ottino2019). The ability to predict the dynamics of segregation is important across applications. For example, in geophysics, granular size segregation can manifest in landslides and debris flows (Johnson et al. Reference Johnson, Kokelaar, Iverson, Logan, LaHusen and Gray2012), in which larger grains segregate to the top of the flow, potentially causing more damage, while in industry, size segregation can be an undesirable effect when blending granular constituents of various sizes.

The current understanding is that there are two driving forces for size segregation in dense granular flows. The first is pressure gradients, which are typically induced by gravity. In pressure-gradient-driven size segregation, small particles move more readily through the interstitial spaces that open and close during flow through a process referred to in the literature as ‘kinetic sieving’, leading to a system stratified along the direction of pressure gradients (Savage & Lun Reference Savage and Lun1988; Gray & Thornton Reference Gray and Thornton2005; Gray & Chugunov Reference Gray and Chugunov2006; Thornton et al. Reference Thornton, Weinhart, Luding and Bokhove2012; Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014). While pressure-gradient-driven segregation has been the focus of significant study, Hill and coworkers (Hill & Fan Reference Hill and Fan2008; Fan & Hill Reference Fan and Hill2010, Reference Fan and Hill2011b; Hill & Tan Reference Hill and Tan2014) demonstrated that grains can also segregate in inhomogeneous flows along directions orthogonal to gravitationally induced pressure gradients, driven instead by gradients in the shear strain rate. As an example, this mechanism has been observed in the split-bottom cell experiments of Hill & Fan (Reference Hill and Fan2008). In these experiments, not only do the larger particles segregate to the top of the cell, but they also segregate perpendicular to the direction of pressure gradients towards more rapidly shearing regions. Shear-strain-rate-gradient-driven segregation has received comparatively less attention in modelling efforts.

Due to the complexity of flow and segregation patterns, developing a general, predictive, continuum model for coupled size segregation and flow in dense granular materials remains an open challenge. Although much progress has been made over recent decades (e.g. Savage & Lun Reference Savage and Lun1988; Gray & Thornton Reference Gray and Thornton2005; Gray & Chugunov Reference Gray and Chugunov2006; Fan & Hill Reference Fan and Hill2011b; Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014; Tunuguntla, Weinhart & Thornton Reference Tunuguntla, Weinhart and Thornton2017; Gray Reference Gray2018; Umbanhowar et al. Reference Umbanhowar, Lueptow and Ottino2019), the development of continuum models that are capable of simultaneously predicting the evolution of both segregation and flow fields, based solely on the geometry of the flow configuration, applied loads and boundary/initial conditions is still in its infancy. Instead, most continuum models for size segregation require some flow field quantity, such as the velocity or stress fluctuation field, to be measured first from experiments or discrete element method (DEM) simulations and then used as model input. A crucial reason for the incompleteness of current models is the lack of a dense granular flow rheology theory that may be coupled to segregation models. A widely used class of viscoplastic models for steady, dense granular flow is based on the ![]() $\mu (I)$ rheology (MiDi Reference MiDi2004; da Cruz et al. Reference da Cruz, Emam, Prochnow, Roux and Chevoir2005; Jop, Forterre & Pouliquen Reference Jop, Forterre and Pouliquen2005; Srivastava et al. Reference Srivastava, Silbert, Grest and Lechman2021), where

$\mu (I)$ rheology (MiDi Reference MiDi2004; da Cruz et al. Reference da Cruz, Emam, Prochnow, Roux and Chevoir2005; Jop, Forterre & Pouliquen Reference Jop, Forterre and Pouliquen2005; Srivastava et al. Reference Srivastava, Silbert, Grest and Lechman2021), where ![]() $\mu$ is the stress ratio and

$\mu$ is the stress ratio and ![]() $I$ is the inertial number. One recent work that couples rheology and segregation in dense granular flows is that of Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021), which combines a regularized version of the

$I$ is the inertial number. One recent work that couples rheology and segregation in dense granular flows is that of Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021), which combines a regularized version of the ![]() $\mu (I)$ rheology (Barker & Gray Reference Barker and Gray2017) with a model for gravity-driven segregation. However, it has been well documented in the literature (e.g. Kamrin Reference Kamrin2019) that the

$\mu (I)$ rheology (Barker & Gray Reference Barker and Gray2017) with a model for gravity-driven segregation. However, it has been well documented in the literature (e.g. Kamrin Reference Kamrin2019) that the ![]() $\mu (I)$ rheology, even in its regularized form, can break down in the presence of spatial flow inhomogeneity, which can be attributed to non-local effects not accounted for in the

$\mu (I)$ rheology, even in its regularized form, can break down in the presence of spatial flow inhomogeneity, which can be attributed to non-local effects not accounted for in the ![]() $\mu (I)$ rheology.

$\mu (I)$ rheology.

To address this point, significant effort has gone into the development of size-dependent, non-local continuum constitutive theories for dense granular flow rheology, and coupling a non-local rheological model with a segregation model provides a route to robust, simultaneous prediction of flow and segregation fields. In this paper, we focus on the non-local granular fluidity (NGF) model of Kamrin and coworkers (Kamrin & Koval Reference Kamrin and Koval2012; Henann & Kamrin Reference Henann and Kamrin2013; Kamrin Reference Kamrin2019), which has been successfully applied to predicting dense flows of monodisperse grains in a wide variety of flow geometries. Then, the overarching aim of this paper is to formulate a continuum theory for simultaneous prediction of flow and size segregation in dense granular systems by integrating the NGF model with a phenomenological size-segregation model. This is a broad goal, and in this paper, we narrow our focus to several simpler, quasi-one-dimensional flow configurations. In most real-world flows, both the pressure-gradient-driven and shear-strain-rate-gradient-driven segregation mechanisms are present, making it difficult to disentangle them. Therefore, our plan for this paper is to isolate and examine the shear-strain-rate-gradient-driven mechanism. Specifically, we study the shear-strain-rate-gradient-driven segregation mechanism by considering flows of dense, bidisperse systems of both disks and spheres in two flow geometries in which the pressure field is spatially uniform: (i) vertical chute flow and (ii) annular shear flow. Therefore, shear-strain-rate gradients are the sole drivers of segregation. In order to inform continuum model development, we perform DEM simulations using the open-source software LAMMPS (Plimpton Reference Plimpton1995), which function as ‘numerical experiments’. The coupled continuum model that we develop is then validated by comparing its predictions of the transient evolution of the segregation field and the steady-state flow field against additional DEM simulation results.

This paper is organized as follows. In § 2, we discuss the continuum model that we use to describe flow and size segregation in bidisperse, dense granular materials. Specifically, §§ 2.1 and 2.2 introduce the mixture theory framework used to describe dense, bidisperse granular mixtures, and in § 2.3, we briefly revisit the ![]() $\mu (I)$ rheology and the NGF model for monodisperse granular systems and discuss their extension to bidisperse systems. Then, in § 2.4, we propose a model for shear-strain-rate-gradient-driven size segregation. In §§ 3 and 4, we consider granular diffusion and shear-strain-rate-gradient-driven segregation, respectively, and independently determine the two dimensionless material parameters that appear in the size-segregation model for both disks and spheres. Then, in § 5, the proposed segregation model is coupled with the NGF model and applied to both vertical chute flow and annular shear flow to predict the transient evolution of the segregation dynamics, and the predicted continuum fields are compared against DEM measurements. In the end, our model demonstrates a level of fidelity in simultaneously predicting the flow and segregation dynamics that has not been previously achieved. We close with a discussion of the segregation model and some concluding remarks in § 6.

$\mu (I)$ rheology and the NGF model for monodisperse granular systems and discuss their extension to bidisperse systems. Then, in § 2.4, we propose a model for shear-strain-rate-gradient-driven size segregation. In §§ 3 and 4, we consider granular diffusion and shear-strain-rate-gradient-driven segregation, respectively, and independently determine the two dimensionless material parameters that appear in the size-segregation model for both disks and spheres. Then, in § 5, the proposed segregation model is coupled with the NGF model and applied to both vertical chute flow and annular shear flow to predict the transient evolution of the segregation dynamics, and the predicted continuum fields are compared against DEM measurements. In the end, our model demonstrates a level of fidelity in simultaneously predicting the flow and segregation dynamics that has not been previously achieved. We close with a discussion of the segregation model and some concluding remarks in § 6.

2. Continuum framework

In this section, we discuss the continuum framework used to describe dense, bidisperse granular systems and propose constitutive equations for rheology and size segregation. Throughout, we utilize a mixture-theory-based approach, which is common in continuum modelling of dense, bidisperse mixtures (e.g. Gray & Thornton Reference Gray and Thornton2005; Gray & Chugunov Reference Gray and Chugunov2006; Fan & Hill Reference Fan and Hill2011b; Gray Reference Gray2018; Umbanhowar et al. Reference Umbanhowar, Lueptow and Ottino2019; Bancroft & Johnson Reference Bancroft and Johnson2021; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021; Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2021), and we use standard component notation, which supposes an underlying set of Cartesian basis vectors ![]() $\{\boldsymbol {e}_i|i=1,2,3\}$, and in which the components of vectors,

$\{\boldsymbol {e}_i|i=1,2,3\}$, and in which the components of vectors, ![]() $\boldsymbol {v}$, and tensors,

$\boldsymbol {v}$, and tensors, ![]() $\boldsymbol {\sigma }$, are denoted by

$\boldsymbol {\sigma }$, are denoted by ![]() $v_i$ and

$v_i$ and ![]() $\sigma _{ij}$, respectively. The Einstein summation convention is employed, and the Kronecker delta,

$\sigma _{ij}$, respectively. The Einstein summation convention is employed, and the Kronecker delta, ![]() $\delta _{ij}$, is utilized to denote the components of the identity tensor.

$\delta _{ij}$, is utilized to denote the components of the identity tensor.

2.1. Bidisperse systems

We consider granular mixtures consisting of particles with two sizes – large grains with an average diameter of ![]() $d^{l}$ and small grains with an average diameter of

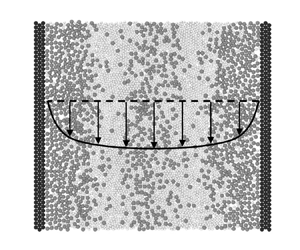

$d^{l}$ and small grains with an average diameter of ![]() $d^{s}$. We consider both two-dimensional systems of disks, as illustrated in figure 1, and three-dimensional systems of spheres. To eliminate the effect of density-based segregation (e.g. Tripathi & Khakhar Reference Tripathi and Khakhar2013) and isolate size-based segregation, all particles are made of the same material with mass density

$d^{s}$. We consider both two-dimensional systems of disks, as illustrated in figure 1, and three-dimensional systems of spheres. To eliminate the effect of density-based segregation (e.g. Tripathi & Khakhar Reference Tripathi and Khakhar2013) and isolate size-based segregation, all particles are made of the same material with mass density ![]() $\rho _{s}$, which represents the area density for disks and the volume density for spheres. Throughout, we utilize the notational convention in which we denote large-grain quantities using a superscript

$\rho _{s}$, which represents the area density for disks and the volume density for spheres. Throughout, we utilize the notational convention in which we denote large-grain quantities using a superscript ![]() ${l}$ and small-grain quantities using a superscript

${l}$ and small-grain quantities using a superscript ![]() ${s}$. The species-specific solid fractions – i.e. the areas occupied by each species per unit total area for disks and the volumes occupied by each species per unit total volume for spheres – are

${s}$. The species-specific solid fractions – i.e. the areas occupied by each species per unit total area for disks and the volumes occupied by each species per unit total volume for spheres – are ![]() $\phi ^{l}$ and

$\phi ^{l}$ and ![]() $\phi ^{s}$, respectively, and the total solid fraction is

$\phi ^{s}$, respectively, and the total solid fraction is ![]() $\phi = \phi ^{l} + \phi ^{s}$. The concentration of each species then follows as

$\phi = \phi ^{l} + \phi ^{s}$. The concentration of each species then follows as ![]() $c^{l} = \phi ^{l}/\phi$ and

$c^{l} = \phi ^{l}/\phi$ and ![]() $c^{s} = \phi ^{s}/\phi$, so that

$c^{s} = \phi ^{s}/\phi$, so that ![]() $c^{l} + c^{s} = 1$. The average mixture grain size is defined as the sizes of both species weighted by their concentrations,

$c^{l} + c^{s} = 1$. The average mixture grain size is defined as the sizes of both species weighted by their concentrations, ![]() $\bar {d} = c^{l}d^{l} + c^{s}d^{s}$. We make the common idealization that the total area for dense systems of disks or total volume for dense systems of spheres does not change (Savage Reference Savage1998; Gray & Thornton Reference Gray and Thornton2005; Gray & Chugunov Reference Gray and Chugunov2006; Fan & Hill Reference Fan and Hill2011b), and therefore

$\bar {d} = c^{l}d^{l} + c^{s}d^{s}$. We make the common idealization that the total area for dense systems of disks or total volume for dense systems of spheres does not change (Savage Reference Savage1998; Gray & Thornton Reference Gray and Thornton2005; Gray & Chugunov Reference Gray and Chugunov2006; Fan & Hill Reference Fan and Hill2011b), and therefore ![]() $\phi$ is idealized as constant at each point in space and at each instant in time during the segregation process. We have verified in our DEM simulations that area (or volume) dilatation at flow initiation occurs over a much shorter time scale than the process of segregation, and that, subsequently, the solid fraction field is approximately uniform both spatially and temporally. Moreover, we have verified that dilatancy-driven secondary flows (e.g. Dsouza & Nott Reference Dsouza and Nott2021) are not observed in the dense flows considered in this work. Therefore, the idealization of a constant solid fraction is reasonable. Throughout this study, we use

$\phi$ is idealized as constant at each point in space and at each instant in time during the segregation process. We have verified in our DEM simulations that area (or volume) dilatation at flow initiation occurs over a much shorter time scale than the process of segregation, and that, subsequently, the solid fraction field is approximately uniform both spatially and temporally. Moreover, we have verified that dilatancy-driven secondary flows (e.g. Dsouza & Nott Reference Dsouza and Nott2021) are not observed in the dense flows considered in this work. Therefore, the idealization of a constant solid fraction is reasonable. Throughout this study, we use ![]() $\phi =0.8$ for disks, and

$\phi =0.8$ for disks, and ![]() $\phi =0.6$ for spheres.

$\phi =0.6$ for spheres.

Figure 1. A representative schematic of a dense, bidisperse granular system consisting of two-dimensional disks.

Regarding the kinematics of flow, each species has an associated partial velocity, ![]() $v_i^{l}$ and

$v_i^{l}$ and ![]() $v_i^{s}$, and the mixture velocity is given by

$v_i^{s}$, and the mixture velocity is given by ![]() $v_i = c^{l}v_i^{l} + c^{s}v_i^{s}$. The mixture strain-rate tensor is then defined using the mixture velocity in the standard way:

$v_i = c^{l}v_i^{l} + c^{s}v_i^{s}$. The mixture strain-rate tensor is then defined using the mixture velocity in the standard way: ![]() ${\mathsf{D}}_{ij} = (1/2)(\partial v_i/\partial x_j + \partial v_j/\partial x_i)$, where

${\mathsf{D}}_{ij} = (1/2)(\partial v_i/\partial x_j + \partial v_j/\partial x_i)$, where ![]() ${\mathsf{D}}_{kk}=0$ since we have assumed that the mixture area (or volume) does not change. The equivalent shear strain rate is defined as

${\mathsf{D}}_{kk}=0$ since we have assumed that the mixture area (or volume) does not change. The equivalent shear strain rate is defined as ![]() $\dot {\gamma } = (2{\mathsf{D}}_{ij}{\mathsf{D}}_{ij})^{1/2}$.

$\dot {\gamma } = (2{\mathsf{D}}_{ij}{\mathsf{D}}_{ij})^{1/2}$.

Then, the relative area (or volume) flux for each grain type, ![]() $\nu ={l}$ or

$\nu ={l}$ or ![]() ${s}$, is defined through the difference between its partial velocity and the mixture velocity as

${s}$, is defined through the difference between its partial velocity and the mixture velocity as ![]() $w_i^{\nu } = c^{\nu } ( v_i^{\nu }-v_i )$, so that

$w_i^{\nu } = c^{\nu } ( v_i^{\nu }-v_i )$, so that ![]() $w_i^{l} + w_i^{s}=0$. Conservation of mass for each species requires that

$w_i^{l} + w_i^{s}=0$. Conservation of mass for each species requires that ![]() ${\rm D}{c}^{\nu }/{\rm D}t + \partial w_i^{\nu }/\partial x_i = 0$, where

${\rm D}{c}^{\nu }/{\rm D}t + \partial w_i^{\nu }/\partial x_i = 0$, where ![]() ${\rm D}(\bullet )/{\rm D}t$ is the material time derivative. Due to the fact that

${\rm D}(\bullet )/{\rm D}t$ is the material time derivative. Due to the fact that ![]() $c^{l} + c^{s} = 1$, only one of

$c^{l} + c^{s} = 1$, only one of ![]() $c^{l}$ and

$c^{l}$ and ![]() $c^{s}$ is independent. Therefore, we utilize

$c^{s}$ is independent. Therefore, we utilize ![]() $c^{l}$ as the field variable that describes the dynamics of size segregation in the following discussion, and the evolution of

$c^{l}$ as the field variable that describes the dynamics of size segregation in the following discussion, and the evolution of ![]() $c^{l}$ is governed by its conservation of mass equation

$c^{l}$ is governed by its conservation of mass equation

2.2. Stress and the equations of motion

We recognize that the symmetric Cauchy stress tensor ![]() $\sigma _{ij} = \sigma _{ji}$ represents the Cauchy stress of the mixture, rather than the partial stress of either species. Regarding stress-related quantities for the granular mixture, we define the pressure

$\sigma _{ij} = \sigma _{ji}$ represents the Cauchy stress of the mixture, rather than the partial stress of either species. Regarding stress-related quantities for the granular mixture, we define the pressure ![]() $P=-(1/3)\sigma _{kk}$, the stress deviator

$P=-(1/3)\sigma _{kk}$, the stress deviator ![]() $\sigma _{ij}' = \sigma _{ij} + P\delta _{ij}$, the equivalent shear stress

$\sigma _{ij}' = \sigma _{ij} + P\delta _{ij}$, the equivalent shear stress ![]() $\tau = (\sigma _{ij}'\sigma _{ij}'/2)^{1/2}$ and the stress ratio

$\tau = (\sigma _{ij}'\sigma _{ij}'/2)^{1/2}$ and the stress ratio ![]() $\mu =\tau /P$. The Cauchy stress is then governed by the standard equations of motion

$\mu =\tau /P$. The Cauchy stress is then governed by the standard equations of motion

where ![]() $\phi$ is the constant total solid fraction, and

$\phi$ is the constant total solid fraction, and ![]() $b_i$ is the non-inertial body force per unit volume (typically gravitational). In order to close the system of equations, we require (i) rheological constitutive equations for the Cauchy stress

$b_i$ is the non-inertial body force per unit volume (typically gravitational). In order to close the system of equations, we require (i) rheological constitutive equations for the Cauchy stress ![]() $\sigma _{ij}$ and (ii) a constitutive equation for the flux

$\sigma _{ij}$ and (ii) a constitutive equation for the flux ![]() $w_i^{l}$, each of which is discussed in the following subsections.

$w_i^{l}$, each of which is discussed in the following subsections.

2.3. Rheological constitutive equations for bidisperse mixtures

In this section, we discuss the rheology of dense, bidisperse granular mixtures. Our strategy for formulating rheological constitutive equations for bidisperse mixtures is to relate mixture-related quantities, such as the Cauchy stress ![]() $\sigma _{ij}$ and the strain-rate tensor

$\sigma _{ij}$ and the strain-rate tensor ![]() ${\mathsf{D}}_{ij}$, instead of specifying constitutive equations for species-specific partial stresses and then combining them to obtain the mixture stress.

${\mathsf{D}}_{ij}$, instead of specifying constitutive equations for species-specific partial stresses and then combining them to obtain the mixture stress.

The starting point of this discussion is the local inertial, or ![]() $\mu (I)$, rheology (MiDi Reference MiDi2004; da Cruz et al. Reference da Cruz, Emam, Prochnow, Roux and Chevoir2005; Jop et al. Reference Jop, Forterre and Pouliquen2005), which follows from dimensional arguments. For a dense, monodisperse system of dry, stiff grains with mean grain diameter

$\mu (I)$, rheology (MiDi Reference MiDi2004; da Cruz et al. Reference da Cruz, Emam, Prochnow, Roux and Chevoir2005; Jop et al. Reference Jop, Forterre and Pouliquen2005), which follows from dimensional arguments. For a dense, monodisperse system of dry, stiff grains with mean grain diameter ![]() $d$ subjected to homogeneous shearing, the local inertial rheology asserts that the stress ratio

$d$ subjected to homogeneous shearing, the local inertial rheology asserts that the stress ratio ![]() $\mu$ is given through the equivalent shear strain rate

$\mu$ is given through the equivalent shear strain rate ![]() $\dot {\gamma }$ and the pressure

$\dot {\gamma }$ and the pressure ![]() $P$ through the dimensionless relationship

$P$ through the dimensionless relationship ![]() $\mu =\mu _{loc}(I)$, where

$\mu =\mu _{loc}(I)$, where ![]() $I=\dot {\gamma }\sqrt {d^2\rho _{s}/P}$ is the inertial number, representing the ratio of the microscopic time scale associated with particle motion

$I=\dot {\gamma }\sqrt {d^2\rho _{s}/P}$ is the inertial number, representing the ratio of the microscopic time scale associated with particle motion ![]() $\sqrt {d^2\rho _{s}/P}$ to the macroscopic time scale of applied deformation

$\sqrt {d^2\rho _{s}/P}$ to the macroscopic time scale of applied deformation ![]() $1/\dot {\gamma }$. As shown by Rognon et al. (Reference Rognon, Roux, Naaïm and Chevoir2007) and Tripathi & Khakhar (Reference Tripathi and Khakhar2011), the inertial rheology function

$1/\dot {\gamma }$. As shown by Rognon et al. (Reference Rognon, Roux, Naaïm and Chevoir2007) and Tripathi & Khakhar (Reference Tripathi and Khakhar2011), the inertial rheology function ![]() $\mu _{loc}(I)$ may be straightforwardly generalized from monodisperse to bidisperse systems by defining the inertial number for a bidisperse system as

$\mu _{loc}(I)$ may be straightforwardly generalized from monodisperse to bidisperse systems by defining the inertial number for a bidisperse system as ![]() $I = \dot {\gamma }\sqrt {\bar {d}^2\rho _{s}/P}$, where the average mixture grain size for a bidisperse system

$I = \dot {\gamma }\sqrt {\bar {d}^2\rho _{s}/P}$, where the average mixture grain size for a bidisperse system ![]() $\bar {d}$ has been used in place of

$\bar {d}$ has been used in place of ![]() $d$ for a monodisperse system. Then, the same local rheology function

$d$ for a monodisperse system. Then, the same local rheology function ![]() $\mu _{loc}(I)$ utilized for the monodisperse system may be used for bidisperse systems without any changes to the parameters appearing in the fitting function. This approach neglects potential effects of new dimensionless quantities that arise in a bidisperse granular system, such as the grain-size ratio

$\mu _{loc}(I)$ utilized for the monodisperse system may be used for bidisperse systems without any changes to the parameters appearing in the fitting function. This approach neglects potential effects of new dimensionless quantities that arise in a bidisperse granular system, such as the grain-size ratio ![]() $d^{l}/d^{s}$, but has been shown to capture DEM data well (Rognon et al. Reference Rognon, Roux, Naaïm and Chevoir2007; Tripathi & Khakhar Reference Tripathi and Khakhar2011).

$d^{l}/d^{s}$, but has been shown to capture DEM data well (Rognon et al. Reference Rognon, Roux, Naaïm and Chevoir2007; Tripathi & Khakhar Reference Tripathi and Khakhar2011).

To demonstrate this point, consider DEM simulations of homogeneous, simple shearing of a dense, bidisperse system of disks, illustrated in figure 2(a) for the case of ![]() $d^{l}/d^{s}=1.5$ and a system-wide large-grain concentration of

$d^{l}/d^{s}=1.5$ and a system-wide large-grain concentration of ![]() $c^{l}=0.5$. Details of the simulated granular systems, including grain interaction properties, for both two-dimensional disks and three-dimensional spheres are given in Appendix A.1. The large particles are dark grey, and the small particles are light grey. With the system-wide mean grain size denoted by

$c^{l}=0.5$. Details of the simulated granular systems, including grain interaction properties, for both two-dimensional disks and three-dimensional spheres are given in Appendix A.1. The large particles are dark grey, and the small particles are light grey. With the system-wide mean grain size denoted by ![]() $\bar {d}_0 = c^{l}d^{l} + (1-c^{l})d^{s}$, the rectangular domain has a length of

$\bar {d}_0 = c^{l}d^{l} + (1-c^{l})d^{s}$, the rectangular domain has a length of ![]() $L=60\bar {d}_0$ in the

$L=60\bar {d}_0$ in the ![]() $x$-direction and a height of

$x$-direction and a height of ![]() $H=60\bar {d}_0$ in the

$H=60\bar {d}_0$ in the ![]() $z$-direction, which is filled with

$z$-direction, which is filled with ![]() $\sim$5000 flowing grains. Shearing is driven through the relative motion of two parallel, rough walls, which each consist of a thin layer of touching glued grains, denoted as black in figure 2(a). Walls consisting of glued grains are utilized to minimize slip between the walls and the adjacent granular medium and mitigate any potential boundary effects associated with slip. The bottom wall is fixed, and the top wall moves with a velocity

$\sim$5000 flowing grains. Shearing is driven through the relative motion of two parallel, rough walls, which each consist of a thin layer of touching glued grains, denoted as black in figure 2(a). Walls consisting of glued grains are utilized to minimize slip between the walls and the adjacent granular medium and mitigate any potential boundary effects associated with slip. The bottom wall is fixed, and the top wall moves with a velocity ![]() $v_{w}$ along the

$v_{w}$ along the ![]() $x$-direction. Following previous works in the literature (da Cruz et al. Reference da Cruz, Emam, Prochnow, Roux and Chevoir2005; Koval et al. Reference Koval, Roux, Corfdir and Chevoir2009; Kamrin & Koval Reference Kamrin and Koval2012; Zhang & Kamrin Reference Zhang and Kamrin2017; Liu & Henann Reference Liu and Henann2018; Kim & Kamrin Reference Kim and Kamrin2020), the

$x$-direction. Following previous works in the literature (da Cruz et al. Reference da Cruz, Emam, Prochnow, Roux and Chevoir2005; Koval et al. Reference Koval, Roux, Corfdir and Chevoir2009; Kamrin & Koval Reference Kamrin and Koval2012; Zhang & Kamrin Reference Zhang and Kamrin2017; Liu & Henann Reference Liu and Henann2018; Kim & Kamrin Reference Kim and Kamrin2020), the ![]() $z$-position of the top wall is not fixed but continuously adjusted using a feedback scheme so that the normal stress applied by the top wall is maintained at a target value of

$z$-position of the top wall is not fixed but continuously adjusted using a feedback scheme so that the normal stress applied by the top wall is maintained at a target value of ![]() $\sigma _{zz}(z=0)=-P_{w}$. Periodic boundary conditions are applied along the

$\sigma _{zz}(z=0)=-P_{w}$. Periodic boundary conditions are applied along the ![]() $x$-direction. For homogeneous simple shearing, no segregation will occur since the flow is homogeneous and no pressure or strain-rate gradients are present. We utilize the DEM procedures described in detail in Liu & Henann (Reference Liu and Henann2018) in order to extract the relationship between

$x$-direction. For homogeneous simple shearing, no segregation will occur since the flow is homogeneous and no pressure or strain-rate gradients are present. We utilize the DEM procedures described in detail in Liu & Henann (Reference Liu and Henann2018) in order to extract the relationship between ![]() $\mu$ and

$\mu$ and ![]() $I$ for bidisperse mixtures with grain-size ratios of

$I$ for bidisperse mixtures with grain-size ratios of ![]() $d^{l}/d^{s} = 1.5, 2.0, 2.5$ and 3.0 and

$d^{l}/d^{s} = 1.5, 2.0, 2.5$ and 3.0 and ![]() $c^{l}=0.5$. The simulated relationships are plotted in figure 2(b) using triangular symbols of different colours, along with the monodisperse data from Liu & Henann (Reference Liu and Henann2018) plotted as grey circles. The relationship between

$c^{l}=0.5$. The simulated relationships are plotted in figure 2(b) using triangular symbols of different colours, along with the monodisperse data from Liu & Henann (Reference Liu and Henann2018) plotted as grey circles. The relationship between ![]() $\mu$ and

$\mu$ and ![]() $I$ for dense systems of disks is observed to be approximately independent of

$I$ for dense systems of disks is observed to be approximately independent of ![]() $d^{l}/d^{s}$. As for the monodisperse case, the DEM data for bidisperse mixtures of disks may be fitted by a linear, Bingham-like functional form

$d^{l}/d^{s}$. As for the monodisperse case, the DEM data for bidisperse mixtures of disks may be fitted by a linear, Bingham-like functional form

as shown by the solid line in figure 2(b), where ![]() $\mu _{s}=0.272$ and

$\mu _{s}=0.272$ and ![]() $b=1.168$ are the dimensionless material parameters for monodisperse disks (Liu & Henann Reference Liu and Henann2018).

$b=1.168$ are the dimensionless material parameters for monodisperse disks (Liu & Henann Reference Liu and Henann2018).

Figure 2. (a) Configuration for two-dimensional DEM simulations of bidisperse simple shear flow. Upper and lower layers of black grains denote rough walls. Dark grey grains indicate large flowing grains, and light grey grains indicate small flowing grains. A ![]() $10\,\%$ polydispersity is utilized for each species to prevent crystallization. (b) The local inertial rheology (

$10\,\%$ polydispersity is utilized for each species to prevent crystallization. (b) The local inertial rheology (![]() $\mu$ vs

$\mu$ vs ![]() $I = \dot {\gamma }\sqrt {\bar {d}^2\rho _{s}/P}$) for monodisperse as well as bidisperse mixtures of disks for grain-size ratios of

$I = \dot {\gamma }\sqrt {\bar {d}^2\rho _{s}/P}$) for monodisperse as well as bidisperse mixtures of disks for grain-size ratios of ![]() $d^{l}/d^{s} = 1.5$, 2.0, 2.5 and 3.0 and

$d^{l}/d^{s} = 1.5$, 2.0, 2.5 and 3.0 and ![]() $c^{l}=0.5$. The solid black line represents the best fit to the monodisperse DEM data using (2.3) with

$c^{l}=0.5$. The solid black line represents the best fit to the monodisperse DEM data using (2.3) with ![]() $\mu _{s}=0.272$ and

$\mu _{s}=0.272$ and ![]() $b=1.168$. (c) The local inertial rheology for monodisperse and bidisperse mixtures of spheres for grain-size ratios of

$b=1.168$. (c) The local inertial rheology for monodisperse and bidisperse mixtures of spheres for grain-size ratios of ![]() $d^{l}/d^{s} = 1.5$ and 2.0 and

$d^{l}/d^{s} = 1.5$ and 2.0 and ![]() $c^{l} = 0.5$ along with the DEM data of Tripathi & Khakhar (Reference Tripathi and Khakhar2011). The solid black curve represents the best fit to the monodisperse DEM data using (2.4) with

$c^{l} = 0.5$ along with the DEM data of Tripathi & Khakhar (Reference Tripathi and Khakhar2011). The solid black curve represents the best fit to the monodisperse DEM data using (2.4) with ![]() $\mu _{s}=0.37$,

$\mu _{s}=0.37$, ![]() $\mu _2 = 0.95$, and

$\mu _2 = 0.95$, and ![]() $I_0=0.58$.

$I_0=0.58$.

Similarly, we consider DEM simulations of homogeneous, simple shearing of dense, bidisperse systems of spheres. The simulation domain consists of a rectangular box of length ![]() $L=20\bar {d}_0$ in the

$L=20\bar {d}_0$ in the ![]() $x$-direction (i.e. the shearing direction), width

$x$-direction (i.e. the shearing direction), width ![]() $W=10\bar {d}_0$ in the

$W=10\bar {d}_0$ in the ![]() $y$-direction (i.e. the direction perpendicular to the plane of shearing) and height

$y$-direction (i.e. the direction perpendicular to the plane of shearing) and height ![]() $H=40\bar {d}_0$ in the

$H=40\bar {d}_0$ in the ![]() $z$-direction. The domain is filled with

$z$-direction. The domain is filled with ![]() $\sim$10 000 flowing grains, and periodic boundary conditions are applied along both the

$\sim$10 000 flowing grains, and periodic boundary conditions are applied along both the ![]() $x$- and

$x$- and ![]() $y$-directions. The simulation domain is bounded along the

$y$-directions. The simulation domain is bounded along the ![]() $z$-direction by two parallel, rough walls, consisting of touching glued grains, and as for the case of disks, shearing along the

$z$-direction by two parallel, rough walls, consisting of touching glued grains, and as for the case of disks, shearing along the ![]() $x$-direction and normal stress along the

$x$-direction and normal stress along the ![]() $z$-direction are applied by the walls. We perform DEM simulations of steady simple shearing for size ratios of

$z$-direction are applied by the walls. We perform DEM simulations of steady simple shearing for size ratios of ![]() $d^{l}/d^{s} = 1.5$ and

$d^{l}/d^{s} = 1.5$ and ![]() $2.0$ for a system-wide large-grain concentration of

$2.0$ for a system-wide large-grain concentration of ![]() $c^{l}=0.5$ as well as for the monodisperse case over a range of top wall velocities. The

$c^{l}=0.5$ as well as for the monodisperse case over a range of top wall velocities. The ![]() $\mu$ vs

$\mu$ vs ![]() $I$ relationship extracted from DEM simulations for these cases along with data from the prior DEM study of Tripathi & Khakhar (Reference Tripathi and Khakhar2011) collapse quite well, as shown in figure 2(c), showing minimal dependence on

$I$ relationship extracted from DEM simulations for these cases along with data from the prior DEM study of Tripathi & Khakhar (Reference Tripathi and Khakhar2011) collapse quite well, as shown in figure 2(c), showing minimal dependence on ![]() $d^{l}/d^{s}$. This relationship for dense systems of spheres may be fitted using the nonlinear functional form of Jop et al. (Reference Jop, Forterre and Pouliquen2005) for

$d^{l}/d^{s}$. This relationship for dense systems of spheres may be fitted using the nonlinear functional form of Jop et al. (Reference Jop, Forterre and Pouliquen2005) for ![]() $\mu _{loc}(I)$

$\mu _{loc}(I)$

as shown by the solid curve in figure 2(c), where ![]() $\{\mu _{s} = 0.37, \mu _2 = 0.95, I_0 = 0.58\}$ are the dimensionless parameters for frictional spheres. (We note that these parameters are nearly the same as those determined by Zhang & Kamrin (Reference Zhang and Kamrin2017) for monodisperse frictional spheres.) In this way, one may capture the rheology of bidisperse mixtures of both disks and spheres in homogeneous simple shearing without introducing additional fitting functions or adjustable parameters beyond those used for the monodisperse case.

$\{\mu _{s} = 0.37, \mu _2 = 0.95, I_0 = 0.58\}$ are the dimensionless parameters for frictional spheres. (We note that these parameters are nearly the same as those determined by Zhang & Kamrin (Reference Zhang and Kamrin2017) for monodisperse frictional spheres.) In this way, one may capture the rheology of bidisperse mixtures of both disks and spheres in homogeneous simple shearing without introducing additional fitting functions or adjustable parameters beyond those used for the monodisperse case.

Despite the successes of the local inertial rheology in capturing steady, homogeneous shear flow, it has been well established in the literature that a local rheological modelling approach cannot be applied to a broad set of inhomogeneous flows that span the quasi-static and dense inertial flow regimes ![]() $(I\lesssim 10^{-1})$, such as annular shear flow (Koval et al. Reference Koval, Roux, Corfdir and Chevoir2009; Tang et al. Reference Tang, Brzinski, Shearer and Daniels2018), split-bottom flow (Fenistein & van Hecke Reference Fenistein and van Hecke2003) and gravity-driven heap flow (Komatsu et al. Reference Komatsu, Inagaki, Nakagawa and Nasuno2001). In these dense, inhomogeneous flows, significant deviation from a one-to-one constitutive relationship

$(I\lesssim 10^{-1})$, such as annular shear flow (Koval et al. Reference Koval, Roux, Corfdir and Chevoir2009; Tang et al. Reference Tang, Brzinski, Shearer and Daniels2018), split-bottom flow (Fenistein & van Hecke Reference Fenistein and van Hecke2003) and gravity-driven heap flow (Komatsu et al. Reference Komatsu, Inagaki, Nakagawa and Nasuno2001). In these dense, inhomogeneous flows, significant deviation from a one-to-one constitutive relationship ![]() $\mu =\mu _{loc}(I)$ is observed (Koval et al. Reference Koval, Roux, Corfdir and Chevoir2009; Kamrin & Koval Reference Kamrin and Koval2012), stemming from the fact that local rheological modelling does not account for cooperative effects, which become dominant in the quasi-static regime. Therefore, to consider inhomogeneous flows of dense, bidisperse granular systems, it is necessary to generalize a non-local rheological modelling approach to the case of dense, bidisperse mixtures. In the present work, we focus attention on the NGF model of Kamrin & Koval (Reference Kamrin and Koval2012), which has been shown to robustly capture a variety of inhomogeneous, steady flows of monodisperse granular systems (Kamrin Reference Kamrin2019). As is standard in the NGF model, we introduce the granular fluidity

$\mu =\mu _{loc}(I)$ is observed (Koval et al. Reference Koval, Roux, Corfdir and Chevoir2009; Kamrin & Koval Reference Kamrin and Koval2012), stemming from the fact that local rheological modelling does not account for cooperative effects, which become dominant in the quasi-static regime. Therefore, to consider inhomogeneous flows of dense, bidisperse granular systems, it is necessary to generalize a non-local rheological modelling approach to the case of dense, bidisperse mixtures. In the present work, we focus attention on the NGF model of Kamrin & Koval (Reference Kamrin and Koval2012), which has been shown to robustly capture a variety of inhomogeneous, steady flows of monodisperse granular systems (Kamrin Reference Kamrin2019). As is standard in the NGF model, we introduce the granular fluidity ![]() $g$, which is a positive, scalar field quantity, and recognize that

$g$, which is a positive, scalar field quantity, and recognize that ![]() $g$ represents the fluidity of the mixture. (See Zhang & Kamrin (Reference Zhang and Kamrin2017) and Kim & Kamrin (Reference Kim and Kamrin2020) for further discussion of the kinematic description of the granular fluidity field for monodisperse granular systems.) Then, we utilize the steady-state form of the NGF model, which relates the stress state, the strain rate, and the granular fluidity through two constitutive equations: (i) the flow rule and (ii) the non-local rheology.

$g$ represents the fluidity of the mixture. (See Zhang & Kamrin (Reference Zhang and Kamrin2017) and Kim & Kamrin (Reference Kim and Kamrin2020) for further discussion of the kinematic description of the granular fluidity field for monodisperse granular systems.) Then, we utilize the steady-state form of the NGF model, which relates the stress state, the strain rate, and the granular fluidity through two constitutive equations: (i) the flow rule and (ii) the non-local rheology.

First, invoking the common idealization that the Cauchy stress deviator and the strain-rate tensor are co-directional (Rycroft, Kamrin & Bazant Reference Rycroft, Kamrin and Bazant2009), the flow rule relates the Cauchy stress tensor ![]() $\sigma _{ij}$, the strain-rate tensor

$\sigma _{ij}$, the strain-rate tensor ![]() ${\mathsf{D}}_{ij}$ and the granular fluidity through

${\mathsf{D}}_{ij}$ and the granular fluidity through

Taking the magnitude of the deviatoric part of (2.5) and rearranging leads to the following scalar form of the flow rule:

Second, the granular fluidity of the bidisperse mixture is governed by the following differential relation:

where ![]() $g_{loc}(\mu,P)$ is the local fluidity function and

$g_{loc}(\mu,P)$ is the local fluidity function and ![]() $\xi (\mu )$ is the stress-dependent cooperativity length. The grain size enters (2.7) through (i) the time scale associated with microscopic particle motion that appears in the local fluidity function

$\xi (\mu )$ is the stress-dependent cooperativity length. The grain size enters (2.7) through (i) the time scale associated with microscopic particle motion that appears in the local fluidity function ![]() $g_{loc}(\mu,P)$ and (ii) the length scale that scales the cooperativity length

$g_{loc}(\mu,P)$ and (ii) the length scale that scales the cooperativity length ![]() $\xi (\mu )$, and both of these roles must be considered when generalizing the NGF model from monodisperse to bidisperse systems.

$\xi (\mu )$, and both of these roles must be considered when generalizing the NGF model from monodisperse to bidisperse systems.

The local fluidity function gives the granular fluidity during steady, homogeneous shear flow at a given state of stress and is related to the local inertial rheology function ![]() $\mu _{loc}(I)$. Denote the inverted form of the local inertial rheology function

$\mu _{loc}(I)$. Denote the inverted form of the local inertial rheology function ![]() $\mu _{loc}(I)$ as

$\mu _{loc}(I)$ as

which is a function of the stress ratio ![]() $\mu$. Then, following the generalization of the local inertial rheology discussed above, in which the time scale associated with microscopic particle motion is taken to be

$\mu$. Then, following the generalization of the local inertial rheology discussed above, in which the time scale associated with microscopic particle motion is taken to be ![]() $\sqrt {\bar {d}^2\rho _{s}/P}$ for a bidisperse mixture, the local fluidity function is

$\sqrt {\bar {d}^2\rho _{s}/P}$ for a bidisperse mixture, the local fluidity function is ![]() $g_{loc}(\mu,P) = \sqrt {P/\bar {d}^2\rho _{s}}\, I_{loc}(\mu )/\mu$. For the case of bidisperse disks, using (2.3), the local fluidity function is

$g_{loc}(\mu,P) = \sqrt {P/\bar {d}^2\rho _{s}}\, I_{loc}(\mu )/\mu$. For the case of bidisperse disks, using (2.3), the local fluidity function is

\begin{equation} g_{loc}(\mu,P) = \left\{\begin{array}{@{}ll} \sqrt{\dfrac{P}{\bar{d}^2\rho_{s}}} \, \dfrac{(\mu-\mu_{s})}{b\mu} & \text{if $\mu > \mu_{s}$,}\\ 0 & \text{if $\mu\le\mu_{s}$,}\end{array}\right. \end{equation}

\begin{equation} g_{loc}(\mu,P) = \left\{\begin{array}{@{}ll} \sqrt{\dfrac{P}{\bar{d}^2\rho_{s}}} \, \dfrac{(\mu-\mu_{s})}{b\mu} & \text{if $\mu > \mu_{s}$,}\\ 0 & \text{if $\mu\le\mu_{s}$,}\end{array}\right. \end{equation}

with ![]() $\{\mu _{s}=0.272, b=1.168\}$, and for the case of bidisperse spheres, using (2.4), the local fluidity function is

$\{\mu _{s}=0.272, b=1.168\}$, and for the case of bidisperse spheres, using (2.4), the local fluidity function is

\begin{equation} g_{loc}(\mu,P) = \left\{\begin{array}{@{}ll} I_0\sqrt{\dfrac{P}{\bar{d}^2\rho_{s}}}\,\dfrac{(\mu-\mu_{s})}{\mu(\mu_2-\mu)} & \text{if $\mu>\mu_{s}$,}\\[10pt] 0 & \text{if $\mu\le\mu_{s}$,} \end{array} \right. \end{equation}

\begin{equation} g_{loc}(\mu,P) = \left\{\begin{array}{@{}ll} I_0\sqrt{\dfrac{P}{\bar{d}^2\rho_{s}}}\,\dfrac{(\mu-\mu_{s})}{\mu(\mu_2-\mu)} & \text{if $\mu>\mu_{s}$,}\\[10pt] 0 & \text{if $\mu\le\mu_{s}$,} \end{array} \right. \end{equation}

with ![]() $\{\mu _{s} = 0.37, \mu _2 = 0.95, I_0 = 0.58\}$. No additional adjustable parameters beyond those used to describe the local inertial rheology for the monodisperse case are introduced in the local fluidity function.

$\{\mu _{s} = 0.37, \mu _2 = 0.95, I_0 = 0.58\}$. No additional adjustable parameters beyond those used to describe the local inertial rheology for the monodisperse case are introduced in the local fluidity function.

As discussed in several of our previous works (Henann & Kamrin Reference Henann and Kamrin2014; Kamrin & Henann Reference Kamrin and Henann2015; Liu & Henann Reference Liu and Henann2017), the manner in which the cooperativity length ![]() $\xi (\mu )$ depends on the stress ratio

$\xi (\mu )$ depends on the stress ratio ![]() $\mu$ is also connected to the choice of the

$\mu$ is also connected to the choice of the ![]() $\mu _{loc}(I)$ function. Without going into details here, the functional forms for the cooperativity length corresponding to (2.3) and (2.4) are

$\mu _{loc}(I)$ function. Without going into details here, the functional forms for the cooperativity length corresponding to (2.3) and (2.4) are

\begin{equation} \xi(\mu) = \frac{A\bar{d}}{\sqrt{|\mu - \mu_{s}|}}\quad\text{and}\quad \xi(\mu) = A\bar{d}\sqrt{\dfrac{(\mu_2-\mu)}{(\mu_2-\mu_{s})|\mu-\mu_{s}|}}, \end{equation}

\begin{equation} \xi(\mu) = \frac{A\bar{d}}{\sqrt{|\mu - \mu_{s}|}}\quad\text{and}\quad \xi(\mu) = A\bar{d}\sqrt{\dfrac{(\mu_2-\mu)}{(\mu_2-\mu_{s})|\mu-\mu_{s}|}}, \end{equation}

respectively. The parameter ![]() $A$ is a dimensionless material constant, referred to as the non-local amplitude, which quantifies the spatial extent of cooperative effects. In the monodisperse case, the cooperativity length is directly proportional to the grain size

$A$ is a dimensionless material constant, referred to as the non-local amplitude, which quantifies the spatial extent of cooperative effects. In the monodisperse case, the cooperativity length is directly proportional to the grain size ![]() $d$, and motivated by the success in generalizing the local inertial rheology, we follow an analogous approach to generalize the cooperativity length to the bidisperse case. We replace

$d$, and motivated by the success in generalizing the local inertial rheology, we follow an analogous approach to generalize the cooperativity length to the bidisperse case. We replace ![]() $d$ for monodisperse grains with

$d$ for monodisperse grains with ![]() $\bar {d}$ for bidisperse grains, resulting in the expressions for the cooperativity length (2.11a,b), in which

$\bar {d}$ for bidisperse grains, resulting in the expressions for the cooperativity length (2.11a,b), in which ![]() $\xi (\mu )$ is proportional to

$\xi (\mu )$ is proportional to ![]() $\bar {d}$. Regarding the non-local amplitude

$\bar {d}$. Regarding the non-local amplitude ![]() $A$, we also follow an approach that is analogous to the generalization of the local inertial rheology and utilize values of

$A$, we also follow an approach that is analogous to the generalization of the local inertial rheology and utilize values of ![]() $A$ previously determined for monodisperse frictional disks and spheres – namely,

$A$ previously determined for monodisperse frictional disks and spheres – namely, ![]() $A=0.90$ as determined by Liu & Henann (Reference Liu and Henann2018) for monodisperse disks and

$A=0.90$ as determined by Liu & Henann (Reference Liu and Henann2018) for monodisperse disks and ![]() $A=0.43$ as determined by Zhang & Kamrin (Reference Zhang and Kamrin2017) for monodisperse spheres. The generalization of the cooperativity length and the choices of

$A=0.43$ as determined by Zhang & Kamrin (Reference Zhang and Kamrin2017) for monodisperse spheres. The generalization of the cooperativity length and the choices of ![]() $A$ for bisdisperse mixtures will be tested in later sections by comparing flow fields predicted by the NGF model with measured flow fields in DEM simulations of bidisperse, inhomogeneous flows.

$A$ for bisdisperse mixtures will be tested in later sections by comparing flow fields predicted by the NGF model with measured flow fields in DEM simulations of bidisperse, inhomogeneous flows.

2.4. Segregation model

The segregation model consists of the constitutive equation for the large-grain flux ![]() $w_i^{l}$. In the present work, we focus on dense flows in the absence of pressure gradients, and we take the large-grain flux

$w_i^{l}$. In the present work, we focus on dense flows in the absence of pressure gradients, and we take the large-grain flux ![]() $w_i^{l}$ to comprise two contributions: (i) a diffusion flux

$w_i^{l}$ to comprise two contributions: (i) a diffusion flux ![]() $w_i^{diff}$ and (ii) a shear-strain-rate-gradient-driven segregation flux

$w_i^{diff}$ and (ii) a shear-strain-rate-gradient-driven segregation flux ![]() $w_i^{seg}$, so that

$w_i^{seg}$, so that

First, the diffusion flux acts counter to segregation to mix the species and is taken to be given in the standard form, in which the diffusion flux is driven by concentration gradients: ![]() $w_i^{diff} = -D ( \partial c^{l}/\partial x_i )$, where

$w_i^{diff} = -D ( \partial c^{l}/\partial x_i )$, where ![]() $D$ is the binary diffusion coefficient (Utter & Behringer Reference Utter and Behringer2004; Artoni et al. Reference Artoni, Larcher, Jenkins and Richard2021; Bancroft & Johnson Reference Bancroft and Johnson2021). Following prior works (e.g. Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021; Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2021; Trewhela, Ancey & Gray Reference Trewhela, Ancey and Gray2021), based on dimensional arguments, we take the diffusion coefficient for a bidisperse system to be

$D$ is the binary diffusion coefficient (Utter & Behringer Reference Utter and Behringer2004; Artoni et al. Reference Artoni, Larcher, Jenkins and Richard2021; Bancroft & Johnson Reference Bancroft and Johnson2021). Following prior works (e.g. Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021; Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2021; Trewhela, Ancey & Gray Reference Trewhela, Ancey and Gray2021), based on dimensional arguments, we take the diffusion coefficient for a bidisperse system to be

where ![]() $C_{diff}$ is a dimensionless material parameter which remains to be calibrated. Therefore, we have that the diffusion flux is

$C_{diff}$ is a dimensionless material parameter which remains to be calibrated. Therefore, we have that the diffusion flux is

Second, regarding segregation, a major question is what field quantity drives the segregation flux in the absence of pressure gradients. Gradients of a number of kinematic quantities are possible – e.g. strain rate, velocity fluctuations or fluidity. For perspective, we note that recent works (Fan & Hill Reference Fan and Hill2011b; Hill & Tan Reference Hill and Tan2014; Tunuguntla, Thornton & Weinhart Reference Tunuguntla, Thornton and Weinhart2016; Tunuguntla et al. Reference Tunuguntla, Weinhart and Thornton2017) have shown that gradients in kinetic stress, which are defined through the velocity fluctuations, correlate well with segregation flux. In the present work, we adopt the simplest approach and hypothesize that the segregation flux is driven by gradients in the shear strain rate ![]() $\dot {\gamma }$ and take the segregation flux to be given in the following phenomenological form:

$\dot {\gamma }$ and take the segregation flux to be given in the following phenomenological form:

The factor ![]() $c^{l}(1-c^{l})$ ensures that segregation ceases when the bidisperse mixture becomes either all large

$c^{l}(1-c^{l})$ ensures that segregation ceases when the bidisperse mixture becomes either all large ![]() $(c^{l} = 1)$ or all small

$(c^{l} = 1)$ or all small ![]() $(c^{l} = 0)$ grains, and the factor

$(c^{l} = 0)$ grains, and the factor ![]() $\bar {d}^2$ is present for dimensional consistency. The quantity

$\bar {d}^2$ is present for dimensional consistency. The quantity ![]() $C^{S}_{seg}$ is a dimensionless material property. While it is possible for

$C^{S}_{seg}$ is a dimensionless material property. While it is possible for ![]() $C^{S}_{seg}$ to depend on the size ratio

$C^{S}_{seg}$ to depend on the size ratio ![]() $d^{l}/d^{s}$, we will demonstrate that this effect is negligible over the range of size ratios considered in the DEM simulations of § 4 and therefore treat

$d^{l}/d^{s}$, we will demonstrate that this effect is negligible over the range of size ratios considered in the DEM simulations of § 4 and therefore treat ![]() $C^{S}_{seg}$ as a constant, dimensionless material parameter, which will be determined by fitting to DEM simulation results for disks and spheres, respectively.

$C^{S}_{seg}$ as a constant, dimensionless material parameter, which will be determined by fitting to DEM simulation results for disks and spheres, respectively.

Combining (2.14), (2.15) and (2.12) with conservation of mass (2.1), we obtain the following differential relation governing the dynamics of ![]() $c^{l}$:

$c^{l}$:

where ![]() $\{ C_{diff}, C^{S}_{seg} \}$ represent two constant dimensionless material parameters that remain to be determined.

$\{ C_{diff}, C^{S}_{seg} \}$ represent two constant dimensionless material parameters that remain to be determined.

We close this section by noting that the incompressibility constraint, the equations of motion (2.2), the non-local rheology (2.7) and the segregation dynamics equation (2.16) represent a closed system of equations for the velocity field ![]() $v_i$, the pressure field

$v_i$, the pressure field ![]() $P$, the fluidity field

$P$, the fluidity field ![]() $g$ and the large-grain concentration field

$g$ and the large-grain concentration field ![]() $c^{l}$, which may be used to simultaneously predict flow fields and the segregation dynamics in the absence of pressure gradients.

$c^{l}$, which may be used to simultaneously predict flow fields and the segregation dynamics in the absence of pressure gradients.

3. Diffusion flux

In this section, we determine values of ![]() $C_{diff}$ for dense, bidisperse systems of frictional disks and spheres. Consider homogeneous simple shear flow of such a bidisperse mixture, as shown in figure 2(a) for disks. Again, no segregation occurs in this setting, since neither of the segregation driving forces (pressure gradients or shear-strain-rate gradients) are present (Tripathi & Khakhar Reference Tripathi and Khakhar2011). During steady, simple shearing, the motion of individual grains in the direction transverse to flow (the

$C_{diff}$ for dense, bidisperse systems of frictional disks and spheres. Consider homogeneous simple shear flow of such a bidisperse mixture, as shown in figure 2(a) for disks. Again, no segregation occurs in this setting, since neither of the segregation driving forces (pressure gradients or shear-strain-rate gradients) are present (Tripathi & Khakhar Reference Tripathi and Khakhar2011). During steady, simple shearing, the motion of individual grains in the direction transverse to flow (the ![]() $z$-direction in figure 2a) approximates a random walk for both two-dimensional systems of disks and three-dimensional systems of spheres. Therefore, by measuring the mean square displacement (MSD) of a system of

$z$-direction in figure 2a) approximates a random walk for both two-dimensional systems of disks and three-dimensional systems of spheres. Therefore, by measuring the mean square displacement (MSD) of a system of ![]() $N$ particles as a function of time, we may determine the binary diffusion coefficient

$N$ particles as a function of time, we may determine the binary diffusion coefficient ![]() $D$ (e.g. Natarajan, Hunt & Taylor Reference Natarajan, Hunt and Taylor1995; Campbell Reference Campbell1997; Utter & Behringer Reference Utter and Behringer2004; Cai et al. Reference Cai, Xiao, Zheng and Zhao2019; Bancroft & Johnson Reference Bancroft and Johnson2021) through

$D$ (e.g. Natarajan, Hunt & Taylor Reference Natarajan, Hunt and Taylor1995; Campbell Reference Campbell1997; Utter & Behringer Reference Utter and Behringer2004; Cai et al. Reference Cai, Xiao, Zheng and Zhao2019; Bancroft & Johnson Reference Bancroft and Johnson2021) through

\begin{equation} \text{MSD}(t)=\dfrac{1}{N} \sum_{n=1}^N(z_n(t)-z_n(0))^2 = 2Dt, \end{equation}

\begin{equation} \text{MSD}(t)=\dfrac{1}{N} \sum_{n=1}^N(z_n(t)-z_n(0))^2 = 2Dt, \end{equation}

where ![]() $z_n(t)$ is the

$z_n(t)$ is the ![]() $z$-coordinate of the

$z$-coordinate of the ![]() $n$th grain at time

$n$th grain at time ![]() $t$. We simulate homogeneous, steady simple shear flows of disks for grain-size ratios of

$t$. We simulate homogeneous, steady simple shear flows of disks for grain-size ratios of ![]() $d^{l}/d^{s} = 1.5$, 2.0, 2.5 and 3.0 and at various shearing rates. We also simulate homogeneous, steady simple shear flows of spheres for the monodisperse case as well as for grain-size ratios of

$d^{l}/d^{s} = 1.5$, 2.0, 2.5 and 3.0 and at various shearing rates. We also simulate homogeneous, steady simple shear flows of spheres for the monodisperse case as well as for grain-size ratios of ![]() $d^{l}/d^{s} = 1.5$, 2.0 and 2.5 over a range of shearing rates. To avoid wall effects in the calculation of the MSD (3.1), grains that are initially within

$d^{l}/d^{s} = 1.5$, 2.0 and 2.5 over a range of shearing rates. To avoid wall effects in the calculation of the MSD (3.1), grains that are initially within ![]() $15\bar {d}_0$ of either the top or bottom wall in figure 2(a) are excluded from the system of particles used to calculate the MSD for disks, leaving a set of

$15\bar {d}_0$ of either the top or bottom wall in figure 2(a) are excluded from the system of particles used to calculate the MSD for disks, leaving a set of ![]() $N\approx 2400$ grains. For spheres, particles initially within

$N\approx 2400$ grains. For spheres, particles initially within ![]() $5\bar {d}_0$ of the top and bottom walls are excluded, so that a set of

$5\bar {d}_0$ of the top and bottom walls are excluded, so that a set of ![]() $N\approx 9000$ grains are used to calculate the MSD. Both large and small grains are included in the calculation of the MSD for the mixture. After a sufficiently long time, the calculated MSD is linear in time in all cases for both disks and spheres, allowing one to extract the diffusion coefficient

$N\approx 9000$ grains are used to calculate the MSD. Both large and small grains are included in the calculation of the MSD for the mixture. After a sufficiently long time, the calculated MSD is linear in time in all cases for both disks and spheres, allowing one to extract the diffusion coefficient ![]() $D$ for each case.

$D$ for each case.

The diffusion coefficient ![]() $D$ is plotted against

$D$ is plotted against ![]() $\dot {\gamma }\bar {d}^2$ (with both quantities normalized by

$\dot {\gamma }\bar {d}^2$ (with both quantities normalized by ![]() $d^{s} \sqrt {P_{w}/\rho _{s}}$) for disks in figure 3(a) and for spheres in figure 3(b). The DEM data for the binary diffusion coefficient collapse to a nearly linear relation with

$d^{s} \sqrt {P_{w}/\rho _{s}}$) for disks in figure 3(a) and for spheres in figure 3(b). The DEM data for the binary diffusion coefficient collapse to a nearly linear relation with ![]() $D\sim \dot {\gamma }\bar {d}^2$ across the range of size ratios and shearing rates considered. A best fit of the slopes of the linear relations – the solid black lines in figures 3(a) and 3(b) – yields

$D\sim \dot {\gamma }\bar {d}^2$ across the range of size ratios and shearing rates considered. A best fit of the slopes of the linear relations – the solid black lines in figures 3(a) and 3(b) – yields

These results are consistent with previous results in the literature. For example, for dense, frictional spheres, the recent work of Bancroft & Johnson (Reference Bancroft and Johnson2021) found a value of ![]() $C_{diff}\approx 0.05$ with a weak dependence on the inertial number, and Duan et al. (Reference Duan, Umbanhowar, Ottino and Lueptow2021) estimated a value of

$C_{diff}\approx 0.05$ with a weak dependence on the inertial number, and Duan et al. (Reference Duan, Umbanhowar, Ottino and Lueptow2021) estimated a value of ![]() $C_{diff}=0.046$. In order to further assess the fitted value of

$C_{diff}=0.046$. In order to further assess the fitted value of ![]() $C_{diff}$ in a diffusion-dominated setting, we have performed a consistency test for disks by considering simple shearing of an initially fully segregated cell, which is described in Appendix B. In this case, diffusion drives remixing of the two species. Using the fitted value of

$C_{diff}$ in a diffusion-dominated setting, we have performed a consistency test for disks by considering simple shearing of an initially fully segregated cell, which is described in Appendix B. In this case, diffusion drives remixing of the two species. Using the fitted value of ![]() $C_{diff}$ for disks in (3.2), we are able to quantitatively capture the diffusive remixing process, which provides confidence in our fitted value of

$C_{diff}$ for disks in (3.2), we are able to quantitatively capture the diffusive remixing process, which provides confidence in our fitted value of ![]() $C_{diff}$.

$C_{diff}$.

Figure 3. The binary diffusion coefficient ![]() $D$, calculated using the MSD (3.1), vs

$D$, calculated using the MSD (3.1), vs ![]() $\dot {\gamma }\bar {d}^2$ in homogeneous, steady simple shear DEM simulations. (a) Data for bidisperse mixtures of disks for grain-size ratios of

$\dot {\gamma }\bar {d}^2$ in homogeneous, steady simple shear DEM simulations. (a) Data for bidisperse mixtures of disks for grain-size ratios of ![]() $d^{l}/d^{ s} = 1.5, 2.0, 2.5$ and 3.0. Both axes are normalized by

$d^{l}/d^{ s} = 1.5, 2.0, 2.5$ and 3.0. Both axes are normalized by ![]() $d^{s} \sqrt {P_{w}/\rho _{s}}$. Each symbol represents

$d^{s} \sqrt {P_{w}/\rho _{s}}$. Each symbol represents ![]() $D$ calculated from one DEM simulation of a specified size ratio at one shearing rate. The solid line represents the best fit of a linear relation with

$D$ calculated from one DEM simulation of a specified size ratio at one shearing rate. The solid line represents the best fit of a linear relation with ![]() $C_{diff}=0.20$. (b) Data for bidisperse mixtures of spheres for the monodisperse case and for grain-size ratios of

$C_{diff}=0.20$. (b) Data for bidisperse mixtures of spheres for the monodisperse case and for grain-size ratios of ![]() $d^{l}/d^{s} = 1.5, 2.0$ and 2.5. The solid line represents the best fit of a linear relation with

$d^{l}/d^{s} = 1.5, 2.0$ and 2.5. The solid line represents the best fit of a linear relation with ![]() $C_{diff}=0.045$.

$C_{diff}=0.045$.

4. Shear-strain-rate-gradient-driven segregation flux

Having independently determined the material parameter ![]() $C_{diff}$ for both frictional disks and spheres, we next turn to testing the constitutive equation for the shear-strain-rate-gradient-driven segregation flux (2.15) and determining the material parameter

$C_{diff}$ for both frictional disks and spheres, we next turn to testing the constitutive equation for the shear-strain-rate-gradient-driven segregation flux (2.15) and determining the material parameter ![]() $C^{S}_{seg}$ by studying two representative flow configurations in the absence of pressure gradients: (i) vertical chute flow and (ii) annular shear flow.

$C^{S}_{seg}$ by studying two representative flow configurations in the absence of pressure gradients: (i) vertical chute flow and (ii) annular shear flow.

4.1. Vertical chute flow

Consider a dense, bidisperse granular mixture flowing down a long vertical chute with parallel, rough walls separated by a distance ![]() $W$ under the action of gravity

$W$ under the action of gravity ![]() $G$. This flow geometry has been utilized extensively in the literature to study dense flows of monodisperse, frictional disks (Kamrin & Koval Reference Kamrin and Koval2012; Liu & Henann Reference Liu and Henann2018) and spheres (Zhang & Kamrin Reference Zhang and Kamrin2017; Kim & Kamrin Reference Kim and Kamrin2020) as well as flows of bidisperse, frictional spheres (Fan & Hill Reference Fan and Hill2011a,Reference Fan and Hillb). Beginning with the case of bidisperse disks, the DEM set-up is shown in figure 4(a) for

$G$. This flow geometry has been utilized extensively in the literature to study dense flows of monodisperse, frictional disks (Kamrin & Koval Reference Kamrin and Koval2012; Liu & Henann Reference Liu and Henann2018) and spheres (Zhang & Kamrin Reference Zhang and Kamrin2017; Kim & Kamrin Reference Kim and Kamrin2020) as well as flows of bidisperse, frictional spheres (Fan & Hill Reference Fan and Hill2011a,Reference Fan and Hillb). Beginning with the case of bidisperse disks, the DEM set-up is shown in figure 4(a) for ![]() $W=60\bar {d}_0$, where

$W=60\bar {d}_0$, where ![]() $\bar {d}_0$ is the system-wide average grain size. In all cases for disks, we take the chute length to be

$\bar {d}_0$ is the system-wide average grain size. In all cases for disks, we take the chute length to be ![]() $L=60\bar {d}_0$ and apply periodic boundary conditions along the

$L=60\bar {d}_0$ and apply periodic boundary conditions along the ![]() $z$-direction. The parallel, rough walls consist of touching glued large grains, denoted as black in figure 4(a). The left vertical wall is fixed, and the right wall is fixed in the

$z$-direction. The parallel, rough walls consist of touching glued large grains, denoted as black in figure 4(a). The left vertical wall is fixed, and the right wall is fixed in the ![]() $z$-direction but can move slightly in the

$z$-direction but can move slightly in the ![]() $x$-direction so as to maintain a constant compressive normal stress

$x$-direction so as to maintain a constant compressive normal stress ![]() $P_{w}$ on the granular material, utilizing the same wall-position control method described in Liu & Henann (Reference Liu and Henann2018). We have verified that the chute length

$P_{w}$ on the granular material, utilizing the same wall-position control method described in Liu & Henann (Reference Liu and Henann2018). We have verified that the chute length ![]() $L$ is sufficiently large, so that it does not affect the resulting flow and segregation fields and all fields are invariant along the

$L$ is sufficiently large, so that it does not affect the resulting flow and segregation fields and all fields are invariant along the ![]() $z$-direction. In the resulting flow fields, the only non-zero component of the velocity is

$z$-direction. In the resulting flow fields, the only non-zero component of the velocity is ![]() $v_z$, which only depends on the cross-channel coordinate

$v_z$, which only depends on the cross-channel coordinate ![]() $x$. A typical steady velocity field is qualitatively sketched in figure 4(a), illustrating that the shear strain rate is greatest at the walls

$x$. A typical steady velocity field is qualitatively sketched in figure 4(a), illustrating that the shear strain rate is greatest at the walls ![]() $(x = \pm W/2)$.

$(x = \pm W/2)$.

Figure 4. (a) Initial well-mixed configuration for two-dimensional DEM simulation of bidisperse vertical chute flow with ![]() $4327$ flowing grains. The chute width is

$4327$ flowing grains. The chute width is ![]() $W=60\bar {d}_0$. As in figure 2, black grains on both sides represent rough walls. (Only large particles are used as wall grains here.) (b) Segregated configuration after flowing for a total simulation time of

$W=60\bar {d}_0$. As in figure 2, black grains on both sides represent rough walls. (Only large particles are used as wall grains here.) (b) Segregated configuration after flowing for a total simulation time of ![]() $\tilde {t} = t/( d^{s}\sqrt {\rho _{s}/P_{w}} )=4.3 \times 10^5$. (c) Spatio-temporal evolution of the large-grain concentration field. Spatial profiles of (d) the concentration field

$\tilde {t} = t/( d^{s}\sqrt {\rho _{s}/P_{w}} )=4.3 \times 10^5$. (c) Spatio-temporal evolution of the large-grain concentration field. Spatial profiles of (d) the concentration field ![]() $c^{l}$ and (e) the normalized velocity field

$c^{l}$ and (e) the normalized velocity field ![]() $(v_{cen}-v_z)\sqrt {\rho _{s}/P_{w}}$ at three times (

$(v_{cen}-v_z)\sqrt {\rho _{s}/P_{w}}$ at three times (![]() $\tilde {t} =4 \times 10^3$,

$\tilde {t} =4 \times 10^3$, ![]() $4 \times 10^4$ and

$4 \times 10^4$ and ![]() $4 \times 10^5$) as indicated by the horizontal lines in (c).

$4 \times 10^5$) as indicated by the horizontal lines in (c).

In all of our DEM simulations of vertical chute flow of bidisperse disks, we observe that the stress field quickly becomes independent of time, so that macroscopic inertia (i.e. the left-hand side of (2.2)) may be neglected. Moreover, we observe that the normal stresses are approximately equal, i.e. ![]() $\sigma _{zz}\approx \sigma _{xx}$. Therefore, due to the force balance along the

$\sigma _{zz}\approx \sigma _{xx}$. Therefore, due to the force balance along the ![]() $z$-direction, the equivalent shear stress field is

$z$-direction, the equivalent shear stress field is ![]() $\tau (x) = |\sigma _{xz}(x)| = |\sigma _{zx}(x)| = \phi \rho _{s}G|x|$, where

$\tau (x) = |\sigma _{xz}(x)| = |\sigma _{zx}(x)| = \phi \rho _{s}G|x|$, where ![]() $x$ is measured from the centreline of the chute, and due to the force balance along the

$x$ is measured from the centreline of the chute, and due to the force balance along the ![]() $x$-direction, the pressure field is

$x$-direction, the pressure field is ![]() $P(x) = -\sigma _{xx}(x) = P_{w}$. The stress ratio field then follows as

$P(x) = -\sigma _{xx}(x) = P_{w}$. The stress ratio field then follows as

where ![]() $\mu _{w}=\phi \rho _{s}GW/2P_{w}$ is the maximum value of

$\mu _{w}=\phi \rho _{s}GW/2P_{w}$ is the maximum value of ![]() $\mu$, occurring at the walls

$\mu$, occurring at the walls ![]() $(x = \pm W/2)$. We note that while flow is driven by gravity, the pressure field is constant throughout the chute and no pressure gradients are present. Therefore, segregation occurs only due to shear-strain-rate gradients, enabling us to consider this effect in isolation.

$(x = \pm W/2)$. We note that while flow is driven by gravity, the pressure field is constant throughout the chute and no pressure gradients are present. Therefore, segregation occurs only due to shear-strain-rate gradients, enabling us to consider this effect in isolation.

Apart from the grain interaction properties that are held constant throughout this work (Appendix A.1), there are four important dimensionless parameters that fully describe each case of vertical chute flow of dense, bidisperse granular mixtures: (i) ![]() $W/\bar {d}_0$, the dimensionless chute width; (ii)

$W/\bar {d}_0$, the dimensionless chute width; (ii) ![]() $\mu _{w}$, the maximum stress ratio, which occurs at the walls and controls the total flow rate; (iii)

$\mu _{w}$, the maximum stress ratio, which occurs at the walls and controls the total flow rate; (iii) ![]() $c^{l}_0(x)$, the initial large-grain concentration, which is not necessarily constant but can be a spatially varying field; and (iv)

$c^{l}_0(x)$, the initial large-grain concentration, which is not necessarily constant but can be a spatially varying field; and (iv) ![]() $d^{l}/d^{s}$, the bidisperse grain-size ratio. This list of system parameters

$d^{l}/d^{s}$, the bidisperse grain-size ratio. This list of system parameters ![]() $\{W/\bar {d}_0,$

$\{W/\bar {d}_0,$ ![]() $\mu _{w},$

$\mu _{w},$ ![]() $c^{l}_0,$

$c^{l}_0,$ ![]() $d^{l}/d^{s}\}$ specifies the geometry, loads and initial conditions of a given case of vertical chute flow. As a representative base case, we consider the parameter group

$d^{l}/d^{s}\}$ specifies the geometry, loads and initial conditions of a given case of vertical chute flow. As a representative base case, we consider the parameter group ![]() $\{W/\bar {d}_0 = 60,\mu _{w}=0.45,c^{l}_0=0.5,d^{l}/d^{s}=1.5\}$. We then run the corresponding DEM simulation starting from the well-mixed initial configuration shown in figure 4(a) and observe that, after a simulation time of

$\{W/\bar {d}_0 = 60,\mu _{w}=0.45,c^{l}_0=0.5,d^{l}/d^{s}=1.5\}$. We then run the corresponding DEM simulation starting from the well-mixed initial configuration shown in figure 4(a) and observe that, after a simulation time of ![]() $\tilde {t} = t/( d^{s}\sqrt {\rho _{s}/P_{w}} )= 4.3 \times 10^5$, the large, dark-grey grains segregate towards the regions near the walls where the shear strain rate is greatest, while the small, light-grey grains gather in bands just inside these regions, as shown in figure 4(b). A well-mixed core persists along the centre of the vertical chute where the shear strain rate is nearly zero. To obtain a more quantitative picture of the segregation process, we coarse grain the concentration field

$\tilde {t} = t/( d^{s}\sqrt {\rho _{s}/P_{w}} )= 4.3 \times 10^5$, the large, dark-grey grains segregate towards the regions near the walls where the shear strain rate is greatest, while the small, light-grey grains gather in bands just inside these regions, as shown in figure 4(b). A well-mixed core persists along the centre of the vertical chute where the shear strain rate is nearly zero. To obtain a more quantitative picture of the segregation process, we coarse grain the concentration field ![]() $c^{l}$ in both space and time and plot contours of the spatio-temporal evolution of

$c^{l}$ in both space and time and plot contours of the spatio-temporal evolution of ![]() $c^{l}$ in figure 4(c). The large-grain concentration field evolves rapidly in time during the initial stages of the segregation process. Then, over longer times, the evolution becomes slower. Spatial profiles of the concentration and velocity fields at three snapshots in time – specifically,

$c^{l}$ in figure 4(c). The large-grain concentration field evolves rapidly in time during the initial stages of the segregation process. Then, over longer times, the evolution becomes slower. Spatial profiles of the concentration and velocity fields at three snapshots in time – specifically, ![]() $\tilde {t} = t/( d^{s}\sqrt {\rho _{s}/P_{w}} ) =4 \times 10^3$,

$\tilde {t} = t/( d^{s}\sqrt {\rho _{s}/P_{w}} ) =4 \times 10^3$, ![]() $4 \times 10^4$ and

$4 \times 10^4$ and ![]() $4 \times 10^5$ as indicated by the horizontal lines in figure 4(c) – are plotted in figures 4(d) and 4(e). These three snapshots correspond to early, medium, and late times with respect to the segregation process. The spatial

$4 \times 10^5$ as indicated by the horizontal lines in figure 4(c) – are plotted in figures 4(d) and 4(e). These three snapshots correspond to early, medium, and late times with respect to the segregation process. The spatial ![]() $c^{l}$ profiles shown in figure 4(d) demonstrate the transition from a well-mixed state to a segregated state with large-grain-rich and small-grain-rich regions. In figure 4(e), the normalized velocity fields

$c^{l}$ profiles shown in figure 4(d) demonstrate the transition from a well-mixed state to a segregated state with large-grain-rich and small-grain-rich regions. In figure 4(e), the normalized velocity fields ![]() $(v_{cen} - v_z)\sqrt {\rho _{s}/P_{w}}$, relative to the velocity at the centre of the chute,

$(v_{cen} - v_z)\sqrt {\rho _{s}/P_{w}}$, relative to the velocity at the centre of the chute, ![]() $v_{cen} = v_z(x=0)$, show that the velocity field rapidly develops into a steady flow field, even while the segregation process is still ongoing, and the

$v_{cen} = v_z(x=0)$, show that the velocity field rapidly develops into a steady flow field, even while the segregation process is still ongoing, and the ![]() $c^{l}$ field continues to evolve.

$c^{l}$ field continues to evolve.

At long times, near the end of the simulated time window (![]() $\tilde {t} = t/( d^{s}\sqrt {\rho _{ s}/P_{w}} )\gtrsim 3 \times 10^5$), the concentration field evolves very slowly, so that