No CrossRef data available.

Article contents

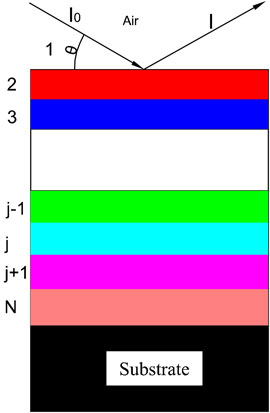

X-ray reflectometry investigation of interfacial structure of CrAlN/TiAlN multilayers

Published online by Cambridge University Press: 27 September 2016

Abstract

TiAlN, CrAlN films and alternate CrAlN/TiAlN multilayers with different repeated bilayer thickness ranging from 10 to 30 nm were prepared by reactive magnetron sputtering. The interface structures of the films were characterized using x-ray reflectometry method. The individual thickness of the repeated bilayers in multilayers and total thickness of the films are close to the nominal thickness and they are more accurate for thicker films. The interface roughness increases as the thickness of the repeated bilayer in mutilayers decreases. The scattering length density profiles of the films suggests that the chemical composition is more accurate for thicker films.

- Type

- Research Letters

- Information

- Copyright

- Copyright © Materials Research Society 2016