No CrossRef data available.

Article contents

Synthesis of polypropylene-graft-norbornene by reactive extrusion and its rheological behavior

Published online by Cambridge University Press: 29 June 2020

Abstract

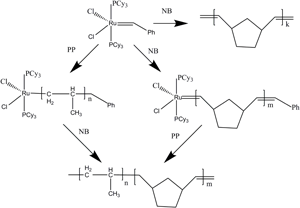

To overcome the steric effect of norbornene (NB), first-generation Grubbs’ catalyst (GC1) was used as the catalyst to graft NB onto the polypropylene (PP) chain by reactive extrusion. Instead of harsh reaction conditions, such as anhydrous, which was the general method to synthesize NB polymers, this convenient method would be easier to industrialize. The mechanism of grafting was studied by using Fourier Transform InfraRed spectra and differential scanning calorimetry. It was found that GC1 could initiate the ring-opening metathesis polymerization of NB to obtain short NB chain-grafted PP-g-NB. The rheological behavior showed that the grafted NB short chains on PP-g-NB increase the shear thinning of the polymers and decrease the system viscosity.

- Type

- Research Letters

- Information

- Copyright

- Copyright © Materials Research Society, 2020