Article contents

Tension gradient self-assembly to facilely fabricate polytetrafluoroethylene coatings for oil–water separation

Published online by Cambridge University Press: 23 May 2019

Abstract

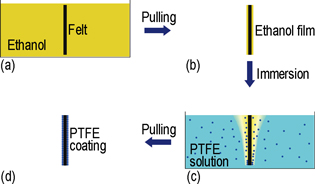

A facile and low-cost method based for tension gradient self-assembly was developed to prepare polytetrafluoroethylene (PTFE) nanofiber coatings on stainless-steel fiber felts. The PTFE particles were used as building blocks and the self-assembly process was analyzed thoroughly. After being sintered, the PTFE particles were transformed into PTFE nanofibers. The felts coated with the PTFE nanofibers exhibited superhydrophobicity and superoleophilicity, and could separate a series of oil–water mixtures with high efficiency and good reusability. The coated felts also presented excellent chemical and thermal stabilities. Over all, this approach could easily fabricate ultra-robust oil–water separation materials suitable for industrial applications.

- Type

- Research Letters

- Information

- Copyright

- Copyright © Materials Research Society 2019

References

- 2

- Cited by