Article contents

Influence of the injection temperature on the size of Ni–Pt polyhedral nanoparticles synthesized by the hot-injection method

Published online by Cambridge University Press: 08 November 2017

Abstract

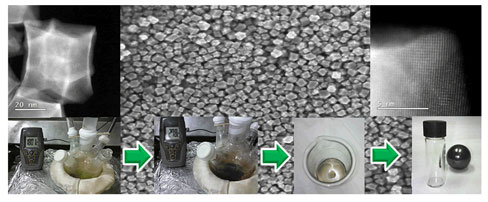

Ni–Pt polyhedral nanoparticles were synthesized through a thermochemical route by the hot-injection method using Oleylamine (Oam) and Oleic acid (Oac) solvents as simultaneous stabilizing and reducing agents. Several syntheses were performed to study the effect of the hot-injection temperature on nanoparticle size distribution. Results revealed that the injection of precursors in a mixture of Oam and Oac at 180 °C produced paramagnetic nanoparticles with an approximate size of 27 nm; these particles have uniformly defined polyhedral structures and show greater Pt accumulation on the edges and corners. Ni–Pt polyhedral nanoparticles with larger sizes and high polydispersity were obtained as the injection temperature was increased closer to the reduction temperature.

- Type

- Research Letters

- Information

- Copyright

- Copyright © Materials Research Society 2017

References

- 4

- Cited by