Article contents

Transmission electron microscopy study of the microstructural evolution during high-temperature and low-stress (011) [11] shear creep deformation of the superalloy single crystal LEK 94

Published online by Cambridge University Press: 15 September 2017

Abstract

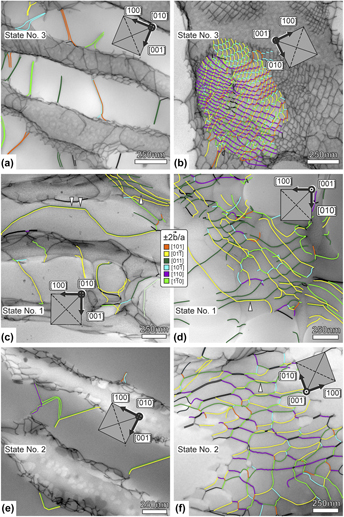

The present work describes the shear creep behavior of the superalloy LEK 94 at temperatures between 980 and 1050 °C and shear stresses between 50 and 140 MPa for loading on the macroscopic crystallographic shear system (MCSS) (011)

$\left[ {01\bar 1} \right]$

. The strain rate versus strain curves show short primary and extended secondary creep regimes. We find an apparent activation energy for creep of Q

app = 466 kJ/mol and a Norton-law stress exponent of n = 6. With scanning transmission electron microscopy, we characterize three material states that differ in temperature, applied stress, and accumulated strain/time. Rafting develops perpendicular to the maximum principal stress direction, γ channels fill with dislocations, superdislocations cut γ′ particles, and dislocation networks form at γ/γ′ interfaces. Our findings are in agreement with previous results for high-temperature and low-stress [001] and [110] tensile creep testing, and for shear creep testing of the superalloys CMSX-4 and CMSX-6 on the MCSSs (111)

$\left[ {01\bar 1} \right]$

. The strain rate versus strain curves show short primary and extended secondary creep regimes. We find an apparent activation energy for creep of Q

app = 466 kJ/mol and a Norton-law stress exponent of n = 6. With scanning transmission electron microscopy, we characterize three material states that differ in temperature, applied stress, and accumulated strain/time. Rafting develops perpendicular to the maximum principal stress direction, γ channels fill with dislocations, superdislocations cut γ′ particles, and dislocation networks form at γ/γ′ interfaces. Our findings are in agreement with previous results for high-temperature and low-stress [001] and [110] tensile creep testing, and for shear creep testing of the superalloys CMSX-4 and CMSX-6 on the MCSSs (111)

$\left[ {01\bar 1} \right]$

and (001)[100]. The parameters that characterize the evolving γ/γ′ microstructure and the evolving dislocation substructures depend on creep temperature, stress, strain, and time.

$\left[ {01\bar 1} \right]$

and (001)[100]. The parameters that characterize the evolving γ/γ′ microstructure and the evolving dislocation substructures depend on creep temperature, stress, strain, and time.

- Type

- Articles

- Information

- Journal of Materials Research , Volume 32 , Issue 24: Focus Issue: Mechanical Properties and Microstructure of Advanced Metallic Alloys—in Honor of Prof. Haël Mughrabi PART B , 28 December 2017 , pp. 4491 - 4502

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

This author contributed equally to this work.

This author was an editor of this journal during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editor-manuscripts/.

Contributing Editor: Mathias Göken

References

REFERENCES

- 4

- Cited by