Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Kelley, Algernon T.

Serem, Wilson K.

Daniels, Stephanie L.

Englade-Franklin, Lauren E.

Morrison, Gregory

Flurry, Nickolaus

Chan, Julia Y.

and

Garno, Jayne C.

2013.

Vibrational Response of FeNi3 Nanoparticles to the Flux of a Modulated Electromagnetic Field Detected by Contact-Mode Atomic Force Microscopy.

The Journal of Physical Chemistry C,

Vol. 117,

Issue. 36,

p.

18768.

Abellán, Gonzalo

Coronado, Eugenio

Martí‐Gastaldo, Carlos

Ribera, Antonio

and

Otero, Toribio F.

2013.

Magnetic Nanocomposites Formed by FeNi3 Nanoparticles Embedded in Graphene. Application as Supercapacitors.

Particle & Particle Systems Characterization,

Vol. 30,

Issue. 10,

p.

853.

Abellán, Gonzalo

Carrasco, Jose A.

Coronado, Eugenio

and

Prima-García, Helena

2014.

Synthesis of FeNi3 nanoparticles in benzyl alcohol and their electrical and magnetic properties.

Journal of Sol-Gel Science and Technology,

Vol. 70,

Issue. 2,

p.

292.

Slaton, Rahiem Davon

Bae, In-Tae

Lutz, Patrick S.

Pathade, Laxmikant

and

Maye, Mathew M.

2015.

The transformation of α-Fe nanoparticles into multi-domain FeNi–M3O4(M = Fe, Ni) heterostructures by galvanic exchange.

Journal of Materials Chemistry C,

Vol. 3,

Issue. 24,

p.

6367.

Wu, Chenguang

Guo, Hongxia

Cui, Suping

Li, Huaiyang

and

Li, Fan

2015.

Influence of Ce doping on structure, morphology, and photocatalytic activity of three-dimensional ZnO superstructures synthesized via coprecipitation and roasting processes.

Proceedings of the Institution of Mechanical Engineers, Part N: Journal of Nanoengineering and Nanosystems,

Vol. 229,

Issue. 2,

p.

66.

Srakaew, N.

Jantaratana, P.

Nipakul, P.

and

Sirisathitkul, C.

2017.

Structural and magnetic properties of Fe x Ni 100−x alloys synthesized using Al as a reducing metal.

Journal of Magnetism and Magnetic Materials,

Vol. 435,

Issue. ,

p.

201.

Guo, Hongxia

Li, Mingye

Qin, Zhenping

Li, Fan

Zhang, Xuehong

Wu, Wenzheng

and

Cheng, Hua

2021.

Shape-controlled synthesis of flake-like FeNi3 nanoparticles based on sodium lignosulfonate.

Advanced Powder Technology,

Vol. 32,

Issue. 3,

p.

755.

ATAŞ, Mehmet Şahin

and

ALTINTAŞ YILDIRIM, Özlem

2022.

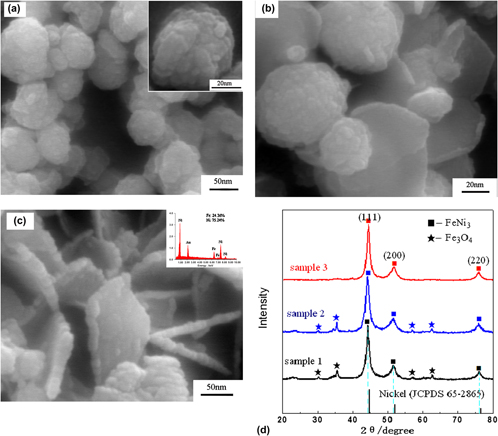

Ni-FeNi3-Fe3O4 METALİK NANOALAŞIMLARIN HİDROTERMAL YÖNTEMLE SENTEZİ VE KARAKTERİZASYONU.

Konya Journal of Engineering Sciences,

Vol. 10,

Issue. 4,

p.

965.

Tan, Li Ping

Padhy, Shakti P.

Tsakadze, Zviad

Chaudhary, V.

and

Ramanujan, R.V.

2022.

Accelerated property evaluation of Ni–Co materials libraries produced by multiple processing techniques.

Journal of Materials Research and Technology,

Vol. 20,

Issue. ,

p.

4186.

Tan, Li Ping

Chaudhary, V.

Tsakadze, Z.

and

Ramanujan, R. V.

2022.

Rapid multiple property determination from bulk materials libraries prepared from chemically synthesized powders.

Scientific Reports,

Vol. 12,

Issue. 1,

Hamalzadeh Ahmadi, F.

Mousavi Ghahfarokhi, S.E.

and

Khani, O.

2023.

The effects of temperature, contact time, and molar ratio of HCl:KMnO4 on the morphology of FeNi3/MnO2 core-shell nanostructure and its application in microwave absorption.

Journal of Magnetism and Magnetic Materials,

Vol. 572,

Issue. ,

p.

170637.

Cai, Haodong

Guo, Jian

Hu, Haobin

Liu, Yang

Jia, Mingyue

Chen, Hongmei

and

Zhou, Gengheng

2024.

Carbon Nanotube/FeNi3 Nanoparticle Composites for Electromagnetic Wave Absorption.

ACS Applied Nano Materials,

Vol. 7,

Issue. 10,

p.

11302.