Article contents

Nano/micro mechanics study of nanoindentation on thin Al/Pd films

Published online by Cambridge University Press: 05 February 2015

Abstract

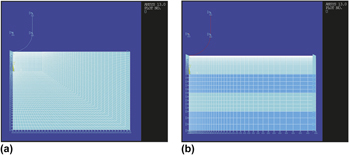

The finite element method is used to simulate indentation with a 100 nm spherical indenter on Al/Pd multilayer thin films and Al and Pd monolayer thin films. The elastic/plastic properties of bulk Al and Pd and the material formulation are obtained by molecular dynamics simulations of tensile and indentation loadings. Hill's plasticity with isotropic hardening is found to best represent the stress–strain response of both bulk Al and Pd. The Pd monolayers appear the hardest and the Al monolayers the softest. The indentation hardness of both monolayered and multilayered films is found to increase with the indentation depth and appears independent of the layer order and thickness in the multilayer films. The hardness values determined by the finite element method simulations are close to those obtained using the well-known formula of Field and Swain. No hardness enhancement in very thin multilayered films (3–5 nm per layer) is evident, in contrast to experimental reports.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2015

References

REFERENCES

- 7

- Cited by