Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Wang, Tong

Yin, Yajun

Zhou, Jianxin

Shen, Xu

and

Wang, Min

2018.

Optimal riser design method based on geometric reasoning method and fruit fly optimization algorithm in CAD.

The International Journal of Advanced Manufacturing Technology,

Vol. 96,

Issue. 1-4,

p.

53.

Liu, Peng Fei

Chen, Wen Jun

Li, Jun Jun

Zhou, Ru Long

and

Zhang, Bo

2018.

Iron-Based Amorphous Magnetic Properties by Ni Content Tuning and Isothermal Treatment.

Materials Science Forum,

Vol. 913,

Issue. ,

p.

661.

Zhu, Man

Zhang, Mao

Yao, Lijuan

Nan, Ruihua

Jian, Zengyun

and

Chang, Fang'e

2019.

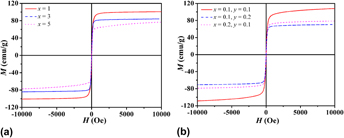

Effect of Mo substitution for Nb on the glass-forming ability, magnetic properties, and electrical resistivity in Fe80(Nb1–xMox)5B15 (x=0–0.75) amorphous ribbons.

Vacuum,

Vol. 163,

Issue. ,

p.

368.

Lopachak, Mariia

Kovbuz, Myroslava

Hertsyk, Oksana

Hula, Tetiana

Boichyshyn, Lidiya

and

Khrushcyk, Khrystyna

2020.

Influence of Fe/Co Substitution and Nb Doping on Thermal Stability of Fe/Co-Si -B Alloys.

p.

01NMM06-1.

Boichyshyn, L. M.

Hertsyk, О. М.

Lopachak, М. М.

Kovbuz, М. О.

Hula, Т. H.

and

Pandyak, N. L.

2020.

Electrochemical Properties of Ternary Amorphous Alloys Based on Iron and Cobalt in Alkali Solutions.

Materials Science,

Vol. 55,

Issue. 5,

p.

703.

Yao, Lijuan

Zhu, Man

Li, Kun

Jian, Zengyun

and

Chang, Fang’e

2020.

Glass formation, nanocrystallisation and magnetic properties of the (Fe1–xCox)79Nb3B18 (x = 0, 0.15, 0.3, 0.45, 0.6, 0.75) metallic glasses.

International Journal of Materials Research,

Vol. 111,

Issue. 7,

p.

600.

Zhu, Man

Zhang, Chi

Xu, Tao

Yao, Lijuan

Liu, Yongqin

Cai, Mengmeng

and

Jian, Zengyun

2021.

Glass formation, magnetic properties, and electrical resistivity of the multi-component FeNbBCuNiCo amorphous alloys.

International Journal of Materials Research,

Vol. 112,

Issue. 2,

p.

137.

Hertsyk, О. М.

Kovbuz, М. О.

Hula, Т. H.

Korniy, S. А.

Yezerska, O. A.

and

Pandiak, N. L.

2021.

Corrosion Resistance of Modified Amorphous Alloys Based on Iron in Sulfuric Acid.

Materials Science,

Vol. 56,

Issue. 6,

p.

755.

Warski, Tymon

Radon, Adrian

Zackiewicz, Przemyslaw

Wlodarczyk, Patryk

Polak, Marcin

Wojcik, Anna

Maziarz, Wojciech

Kolano-Burian, Aleksandra

and

Hawelek, Lukasz

2021.

Influence of Cu Content on Structure, Thermal Stability and Magnetic Properties in Fe72−xNi8Nb4CuxSi2B14 Alloys.

Materials,

Vol. 14,

Issue. 4,

p.

726.

Wang, Tong

Zhou, Jianxin

Wang, Lei

Zhang, Zelin

Zhang, Huan

and

Xia, Xuhui

2023.

Research and Development of Gating and Riser Process Optimization Integrated System for Steel Casting.

International Journal of Metalcasting,

Vol. 17,

Issue. 4,

p.

2452.

Tiwari, Saurabh

Ryu, Wook Ha

Kim, Kyung Jun

and

Park, Eun Soo

2023.

Development of (Fe-Co-Ni)-Si-B metallic glass catalyst for promoting degradation of acid orange II azo-dye.

Journal of Alloys and Compounds,

Vol. 961,

Issue. ,

p.

171027.