Article contents

Implications of the idea of effective tip shape on nanoindentation unloading curves: AFM measurements and FE simulation

Published online by Cambridge University Press: 26 August 2011

Abstract

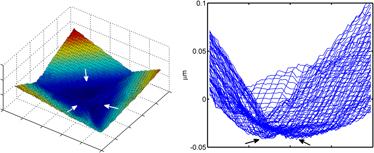

The analysis of nanoindentation force data are based on Sneddon’s solution for a linear elastic half space with a rigid axisymmetric indenter. Berkovich indenters commonly used in indentation experiments are normally modeled as cones. The idea of effective tip shape was presented to better explain the behavior of the unloading curve and pressure distribution under the tip in real experiments. We examine the concept of effective tip in three dimensions by importing real indenter metrology by atomic force microscope directly into finite element analysis and simulate fused silica indentation experiments. We show that fitting the elastic reloading curves overestimates the elastic modulus of fused silica. This is explained by studying the pressure distribution at maximum depth under the effective tip. While the effective tip describes the problem geometrically, it is believed that neglecting the deformed zone in the indented material is responsible for over estimating the modulus value.

Keywords

- Type

- Articles

- Information

- Journal of Materials Research , Volume 27 , Issue 1: Focus Issue: Instrumented Indentation , 14 January 2012 , pp. 126 - 131

- Copyright

- Copyright © Materials Research Society 2011

References

REFERENCES

- 9

- Cited by