Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Krawczyk, Jacek

Paszkowski, Robert

Bogdanowicz, Włodzimierz

Hanc-Kuczkowska, Aneta

Sieniawski, Jan

and

Terlecki, Bartosz

2019.

Defect Creation in the Root of Single-Crystalline Turbine Blades Made of Ni-Based Superalloy.

Materials,

Vol. 12,

Issue. 6,

p.

870.

Chen, Juan

and

Zhang, Lijun

2019.

Composition-dependent hardness and Young’s modulus in fcc Ni–X (X = Rh, Ta, W, Re, Os, and Ir) alloys: Experimental measurements and CALPHAD modeling.

Journal of Materials Research,

Vol. 34,

Issue. 18,

p.

3104.

Krawczyk, Jacek

Bogdanowicz, Włodzimierz

and

Sieniawski, Jan

2020.

The Number of Subgrain Boundaries in the Airfoils of Heat-Treated Single-Crystalline Turbine Blades.

Materials,

Vol. 14,

Issue. 1,

p.

8.

Strickland, Joel

Tassenberg, Karl

Sheppard, Gareth

Nenchev, Bogdan

Perry, Sam

Li, Jun

Dong, Hongbiao

Burca, Genoveva

Kelleher, Joe

and

Irwin, Steve

2020.

2D single crystal Bragg-dip mapping by time-of-flight energy-resolved neutron imaging on IMAT@ISIS.

Scientific Reports,

Vol. 10,

Issue. 1,

Xu, Wenliang

Wang, Fu

Ma, Dexin

Zhu, Xintao

Li, Dichen

and

Bührig-Polaczek, Andreas

2020.

Sliver defect formation in single crystal Ni-based superalloy castings.

Materials & Design,

Vol. 196,

Issue. ,

p.

109138.

Small, Kathryn A.

and

Taheri, Mitra L.

2021.

Role of Processing in Microstructural Evolution in Inconel 625: A Comparison of Three Additive Manufacturing Techniques.

Metallurgical and Materials Transactions A,

Vol. 52,

Issue. 7,

p.

2811.

Xiao, Jiuhan

Jiang, Weiguo

Han, Dongyu

Li, Kaiwen

Lu, Yuzhang

and

Lou, Langhong

2021.

Effect of the Spacial Dimensions on Solidification Defects in Rejoined Platform of Ni-Based Single-Crystal Superalloy Castings Under Different Withdrawal Rates.

Metallurgical and Materials Transactions A,

Vol. 52,

Issue. 7,

p.

2936.

Rafieazad, Mehran

Fathi, Parisa

Mohammadi, Mohsen

and

Nasiri, Ali

2021.

Effects of Laser-Powder Bed Fusion Process Parameters on the Microstructure and Corrosion Properties of AlSi10Mg Alloy.

Journal of The Electrochemical Society,

Vol. 168,

Issue. 2,

p.

021505.

Chen, Chao

Sun, Jingxia

Diao, Aimin

Yang, Yanhong

Li, Jinguo

and

Zhou, Yizhou

2022.

On the dendrite deformation and evolution mechanism of Ni-based superalloy during directional solidification.

Journal of Alloys and Compounds,

Vol. 891,

Issue. ,

p.

161949.

Xiao, Jiu-han

Jiang, Wei-guo

Han, Dong-yu

Li, Kai-wen

Tong, Guo-jun

Lu, Yu-zhang

and

Lou, Lang-hong

2022.

Evolution mechanism of crystallographic orientation in grain continuator bars of a Ni-based single-crystal superalloy prepared by Bridgman technology during directional solidification.

China Foundry,

Vol. 19,

Issue. 1,

p.

35.

Li, Guizhong

Sun, Dejian

Guo, Linfei

Yuan, Jingshu

Gao, Ka

Jie, Ziqi

Gao, Yang

and

Fan, Lei

2023.

Microstructure evolution and tensile behavior of hot pressed powder metallurgy superalloys.

Journal of Materials Research,

Vol. 38,

Issue. 17,

p.

4118.

Bao, Shuai

Yang, Chao

Li, Zhenshuai

Ye, Peiran

and

Chen, Yungui

2023.

Microstructure and Air Trace Defects of the Rapidly Solidified ZK60 Magnesium Alloy Ribbon.

Materials,

Vol. 17,

Issue. 1,

p.

30.

Liu, Minghao

Zeng, Qi

Zhang, Kai

Zhang, Huawei

Zheng, Wenpeng

Li, Yuanyuan

Hou, Juan

Wang, Jiangwei

Zhu, Yuman

and

Huang, Aijun

2023.

Revealing the interrelation between process parameters and microstructure to promote the mechanical performance for Hastelloy-X.

Vacuum,

Vol. 210,

Issue. ,

p.

111851.

Qin, Jiarun

Yang, Wenchao

Wang, Qiang

Zhou, Yuhan

Fu, Haitao

Zhang, Jun

and

Liu, Lin

2024.

Orientation control of multiple single crystal blades using a novel high-throughput mold via seeding-grain selection technique.

Journal of Materials Research and Technology,

Vol. 29,

Issue. ,

p.

4845.

Wang, Fu

Liu, Yang

Yang, Qiang

Ma, Dexin

and

Li, Dichen

2024.

Microscale stray grains formation in single-crystal turbine blades of Ni-based superalloys.

Journal of Materials Science & Technology,

Vol. 191,

Issue. ,

p.

134.

Fan, Lei

Ran, Denglin

Bai, Yirui

Wang, Fatao

and

Yang, Neng

2024.

Study on casting simulation and wear properties of honeycomb configuration ZTAp-Fe composite.

Wear,

Vol. 538-539,

Issue. ,

p.

205188.

Yang, Luwei

Ren, Neng

Li, Jun

Panwisawas, Chinnapat

Zhang, Yancheng

Xia, Mingxu

Dong, Hongbiao

and

Li, Jianguo

2025.

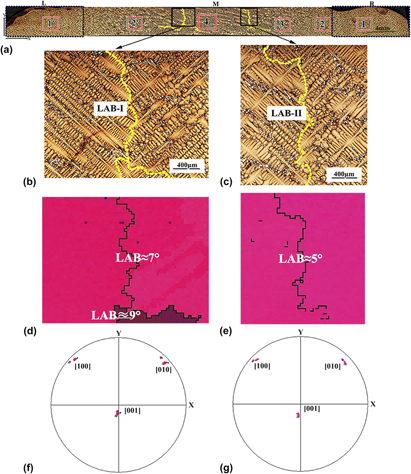

Thermal-solutal convection-induced low-angle grain boundaries in single-crystal nickel-based superalloy solidification.

Journal of Materials Science & Technology,

Vol. 208,

Issue. ,

p.

214.