Article contents

The fatigue failure analysis and fatigue life prediction model of FV520B-I as a function of surface roughness in HCF regime

Published online by Cambridge University Press: 05 January 2017

Abstract

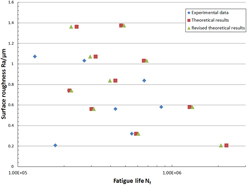

The high-cycle fatigue (HCF) behavior is significantly affected by surface roughness, especially for high strength metal FV520B-I. However, with surface roughness effect, neither the fatigue property, nor the high-cycle fatigue life model about FV520B-I with surface roughness has been reported. In this paper, designed fatigue experiment using the specimen with different surface roughness is presented to study the effectiveness of the roughness to the fatigue. The observations of the fatigue crack initiation sites and the crack propagation. Then the high cycle fatigue behavior of FV520B-I affected by surface roughness is analyzed. The existing very-high-cycle fatigue life model is not well-fit for high-cycle fatigue model of FV520B-I. A NEW high-cycle fatigue life prediction model of FV520B-I, taking surface roughness as a main effective variable is proposed. The model is built up by a comprehensive use of experimental data and the traditional fatigue modeling theory. The new finding between the fatigue strength coefficient and stress amplitude, with surface roughness, is adopted, leading to a NEW modified life prediction model. Study on fatigue model of FV520B-I with surface roughness is a very beneficial effort in fatigue theory and fatigue engineering development.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

References

REFERENCES

- 11

- Cited by