Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Zhao, N.

Zhong, Y.

Huang, M.L.

Ma, H.T.

and

Dong, W.

2016.

Dissolution and precipitation kinetics of Cu6Sn5 intermetallics in Cu/Sn/Cu micro interconnects under temperature gradient.

Intermetallics,

Vol. 79,

Issue. ,

p.

28.

Zhao, Ning

Deng, Jianfeng

Zhong, Yi

Huang, Mingliang

and

Ma, Haitao

2016.

Interfacial reaction of Ni/Sn-9Zn/Ni solder joint undergoing liquid-solid thermomigration.

p.

273.

Zhong, Y.

Zhao, N.

Ma, H.T.

Dong, W.

and

Huang, M.L.

2017.

Retardation of thermomigration-induced Cu substrate consumption in Pb-free solder joints by Zn addition.

Journal of Alloys and Compounds,

Vol. 695,

Issue. ,

p.

1436.

Zhong, Yi

Zhao, Ning

Dong, Wei

Ma, Haitao

Huang, Mingliang

Yin, Luqiao

and

Wong, Chingping

2017.

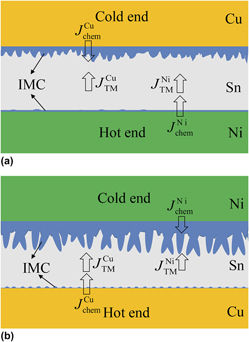

Coupling effect of thermomigration and cross-interaction on evolution of intermetallic compounds in Cu/Sn/Ni ultrafine interconnects undergoing TLP bonding.

Journal of Materials Research,

Vol. 32,

Issue. 16,

p.

3128.

Zhao, Ning

Wang, Mingyao

Zhong, Yi

Ma, Haitao

Wang, Yunpeng

and

Wong, Ching-Ping

2017.

Study on interfacial reactions in Cu/Sn-9Zn/Ni micro solder joints under temperature gradient.

p.

1478.

Zhao, Ning

Deng, Jianfeng

Zhong, Yi

Ma, Haitao

Wang, Yunpeng

and

Wong, Ching-ping

2017.

Effect of Zn content on interfacial reactions of Ni/Sn–xZn/Ni joints under temperature gradient.

Journal of Materials Research,

Vol. 32,

Issue. 18,

p.

3555.

Zhong, Y.

Zhao, N.

Ma, H. T.

Dong, W.

Huang, M. L.

and

Wong, C. P.

2017.

Low Temperature Ni/Sn/Ni Transient Liquid Phase Bonding for High Temperature Packaging Applications by Imposing Temperature Gradient.

p.

411.

Zhao, N.

Deng, J. F.

Zhong, Y.

Huang, M. L.

and

Ma, H. T.

2017.

Abnormal Intermetallic Compound Evolution in Ni/Sn/Ni and Ni/Sn-9Zn/Ni Micro Solder Joints Under Thermomigration.

Journal of Electronic Materials,

Vol. 46,

Issue. 4,

p.

1931.

Guo, Bingfeng

Kunwar, Anil

Jiang, Chengrong

Zhao, Ning

Sun, Junhao

Chen, Jun

Wang, Yunpeng

Huang, Mingliang

and

Ma, Haitao

2018.

Synchrotron radiation imaging study on the rapid IMC growth of Sn–xAg solders with Cu and Ni substrates during the heat preservation stage.

Journal of Materials Science: Materials in Electronics,

Vol. 29,

Issue. 1,

p.

589.

Zhong, Y.

Zhao, N.

Dong, W.

Wang, Y.P.

and

Ma, H.T.

2018.

In situ study on the effect of Cu5Zn8 intermetallic layer on the Cu-Ni cross-interaction in Cu/Sn-9Zn/Ni interconnect under temperature gradient.

Materials Chemistry and Physics,

Vol. 216,

Issue. ,

p.

130.

Zhao, N.

Wang, M. Y.

Zhong, Y.

Ma, H. T.

Wang, Y. P.

and

Wong, C. P.

2018.

Effect of Zn content on Cu–Ni cross-interaction in Cu/Sn–xZn/Ni micro solder joints.

Journal of Materials Science: Materials in Electronics,

Vol. 29,

Issue. 6,

p.

5064.

Wang, Y. W.

Shih, W. L.

Hung, H. T.

and

Kao, C. R.

2019.

Reaction Within Ni/Sn/Cu Microjoints for Chip-Stacking Applications.

Journal of Electronic Materials,

Vol. 48,

Issue. 1,

p.

25.

Zhu, Ze

Chan, Yan-cheong

and

Wu, Fengshun

2019.

Effect of alternating current (AC) stressing on the microstructure and mechanical properties of low-silver content solder interconnect.

Microelectronics Reliability,

Vol. 92,

Issue. ,

p.

12.

Yang, Li

Zhou, Shiyuan

Zhang, Yaocheng

Xiong, Yifeng

Jiang, Wei

and

Shen, Sai

2020.

Microstructure and mechanical property of Cu/In–45Cu/Ni solder joints formed by transient liquid phase bonding.

Journal of Materials Research,

Vol. 35,

Issue. 21,

p.

2848.

Tian, Ye

Fang, Heng

Ren, Ning

Zhao, Yatao

Chen, Boli

Wu, Fengshun

and

Paik, Kyung-Wook

2020.

Reliable single-phase micro-joints with high melting point for 3D TSV chip stacking.

Journal of Alloys and Compounds,

Vol. 828,

Issue. ,

p.

154468.

Zhang, Peng

Xue, Songbai

and

Wang, Jianhao

2020.

New challenges of miniaturization of electronic devices: Electromigration and thermomigration in lead-free solder joints.

Materials & Design,

Vol. 192,

Issue. ,

p.

108726.

Ding, Zongye

Zhang, Naifang

Yu, Liao

Lu, Wenquan

Li, Jianguo

and

Hu, Qiaodan

2021.

Recent Progress in Metallurgical Bonding Mechanisms at the Liquid/Solid Interface of Dissimilar Metals Investigated via in situ X-ray Imaging Technologies.

Acta Metallurgica Sinica (English Letters),

Vol. 34,

Issue. 2,

p.

145.

Lai, Yanqing

Chen, Shi

Ren, Xiaolei

Qiao, Yuanyuan

and

Zhao, Ning

2022.

Growth behavior and morphology evolution of interfacial (Cu,Ni)6Sn5 in (001)Cu/Sn/Ni micro solder joints.

Materials Characterization,

Vol. 186,

Issue. ,

p.

111803.

Liang, Shuibao

Kunwar, Anil

Liu, Changqing

Jiang, Han

and

Zhou, Zhaoxia

2022.

Preferential growth of intermetallics under temperature gradient at Cu–Sn interface during transient liquid phase bonding: insights from phase field simulation.

Journal of Materials Research and Technology,

Vol. 19,

Issue. ,

p.

345.

Chao, Chen-Sung

Wu, Zih-You

Lee, Yin-Ku

Huang, Pin-Wei

Chang, Shou-Yi

Tsai, Su-Yueh

and

Duh, Jenq-Gong

2023.

Enhancing mechanical properties via the dual effect of Ni addition and temperature gradient for 5 μm Cu/Sn-3.0Ag-0.5Cu/Cu transient liquid phase bonding.

Materials Science and Engineering: A,

Vol. 870,

Issue. ,

p.

144863.