1. Introduction

Film boiling is encountered in numerous applications such as metal quenching, cryogenics, superconducting devices and nuclear reactor accident analysis. Thus despite the low heat transfer rates observed post heater dryout, the study of hydrodynamics and heat transfer in film boiling with regard to different geometries and operating conditions is essential. Further, the low heat transfer rates present a limiting case of boiling heat transfer, and estimating these becomes crucial from design considerations. Pioneered by some early works for a flat heater geometry (Son & Dhir Reference Son and Dhir1997; Juric & Tryggvason Reference Juric and Tryggvason1998; Welch & Wilson Reference Welch and Wilson2000), direct numerical simulations have gained traction in recent years as an important means to study boiling flows. These involve solving the transport mechanisms directly across the phase interface without resorting to any empiricism. As a result, significant insights can be obtained while alleviating issues such as measurements at small spatiotemporal scales in boiling experiments, and major simplifying assumptions often employed in various theoretical analysis carried out until the present.

Owing to the importance of the flat plate geometry coupled with a relative ease in its computational treatment, many of the earlier numerical models focused on horizontal film boiling. Nonetheless, a circular wire is often the optimal geometric choice as a boiling heater, and also presents itself as an important baseline case for understanding film boiling physics over different complex geometries encountered across practical applications. Despite this only a few direct numerical simulations (Esmaeeli & Tryggvason Reference Esmaeeli and Tryggvason2004; Son & Dhir Reference Son and Dhir2008; Tsui et al. Reference Tsui, Lin, Lai and Wu2014; Singh & Premachandran Reference Singh and Premachandran2018a) have been performed over a cylinder in the context of pool film boiling, with external forced convection film boiling receiving considerably less attention. This can be partly attributed to numerical challenges associated with geometric considerations in the framework of nonlinear phase change simulations. However, recent efforts have been directed towards accurate interface capturing on unstructured grids for two-phase flows (Balcázar et al. Reference Balcázar, Lehmkuhl, Jofre, Rigola and Oliva2016) including phase change (Singh & Premachandran Reference Singh and Premachandran2018a) that have enabled important film boiling results to be obtained in a wider geometrical ambit (Singh & Premachandran Reference Singh and Premachandran2018b, Reference Singh and Premachandran2019, Reference Singh and Premachandran2020). Further, an ellipse represents the simplest deviation from a circular body as a non-canonical form with features such as aspect ratio ![]() $(\varGamma )$ and angle of incidence

$(\varGamma )$ and angle of incidence ![]() $(\theta )$ offering possibilities to study the interfacial dynamics and heat transfer for external flow film boiling in a comprehensive manner. It can also be noted that many important aspects including wake characteristics even for single-phase flow over an ellipse have been brought to the fore only in recent studies (Paul et al. Reference Paul, Prakash, Vengadesan and Pulletikurthi2016; Rao et al. Reference Rao, Leontini, Thompson and Hourigan2017) as compared with an extensive effort dedicated towards understanding flow over a circular cylinder. Additionally, the interfacial dynamics in film boiling is prominently governed by Rayleigh–Taylor and Kelvin–Helmholtz instabilities, which can result in the heat transfer behaviour being counter-intuitive to that expected for single phase flows under certain conditions, as shown in some previous studies (Singh & Premachandran Reference Singh and Premachandran2019, Reference Singh and Premachandran2020) by the present authors. Thus the aim of the present work is to study the flow and heat transfer characteristics in saturated film boiling over an ellipse in the mixed regime (Singh & Premachandran Reference Singh and Premachandran2018b) under different liquid cross-flow configurations, with a suitable computational framework for boiling flows. To the best of authors’ knowledge, this has not been attempted previously, and thus would help in gaining interesting insights.

$(\theta )$ offering possibilities to study the interfacial dynamics and heat transfer for external flow film boiling in a comprehensive manner. It can also be noted that many important aspects including wake characteristics even for single-phase flow over an ellipse have been brought to the fore only in recent studies (Paul et al. Reference Paul, Prakash, Vengadesan and Pulletikurthi2016; Rao et al. Reference Rao, Leontini, Thompson and Hourigan2017) as compared with an extensive effort dedicated towards understanding flow over a circular cylinder. Additionally, the interfacial dynamics in film boiling is prominently governed by Rayleigh–Taylor and Kelvin–Helmholtz instabilities, which can result in the heat transfer behaviour being counter-intuitive to that expected for single phase flows under certain conditions, as shown in some previous studies (Singh & Premachandran Reference Singh and Premachandran2019, Reference Singh and Premachandran2020) by the present authors. Thus the aim of the present work is to study the flow and heat transfer characteristics in saturated film boiling over an ellipse in the mixed regime (Singh & Premachandran Reference Singh and Premachandran2018b) under different liquid cross-flow configurations, with a suitable computational framework for boiling flows. To the best of authors’ knowledge, this has not been attempted previously, and thus would help in gaining interesting insights.

The significance of mixed regime stems from the often overlooked aspect pertaining to the effect of gravity in flow film boiling over a bluff body, which cannot be neglected under certain conditions. The relative importance of buoyancy and flow inertia is characterized by the Froude number, ![]() $Fr=U^{2}/gD$, where

$Fr=U^{2}/gD$, where ![]() $U$ is the liquid cross-flow velocity and

$U$ is the liquid cross-flow velocity and ![]() $D$ is the characteristic dimension. Still, most of the experimental studies for forced convection film boiling over a circular cylinder focused only on the inertia dominated regime. At the same time, the challenges associated with the analytical treatment of the problem become more pronounced under comparable influence of buoyancy and inertia leading to almost all prior theoretical studies neglecting the effect of gravity. The mixed regime of film boiling over a circular cylinder has been explicitly identified only in the studies of Bromley, LeRoy & Robbers (Reference Bromley, LeRoy and Robbers1953) and Ito, Nishikawa & Shigechi (Reference Ito, Nishikawa and Shigechi1981). However, these studies differed in the prediction for the onset of the mixed regime in terms of the Froude number. Also, no conclusive heat transfer results were provided by either study in the mixed regime thereby leaving a discernible gap in the literature. Bromley et al. (Reference Bromley, LeRoy and Robbers1953) proposed semiempirical heat transfer correlations only for pool film boiling and purely forced convection film boiling. Ito et al. (Reference Ito, Nishikawa and Shigechi1981) noted that a similarity solution in the mixed regime was not possible and used an integral method for the two-phase boundary layer in their analysis. They also established a definitive relationship between the Nusselt number and other non-dimensional parameters only in the buoyancy or inertia dominated regimes, while noting anomalous heat transfer behaviour when both the forces were comparable. Here it can be mentioned that the aforementioned gaps can be suitably addressed through computations of film boiling. As such, the present authors performed direct numerical simulations in the mixed regime of saturated film boiling over a horizontal circular cylinder under different liquid flow configurations in recent studies (Singh & Premachandran Reference Singh and Premachandran2018b, Reference Singh and Premachandran2019), where the effect of different film boiling parameters was analysed and all the relevant aspects discussed in detail. It was shown that a complex interplay of buoyancy and inertia governed the interfacial dynamics and heat transfer in the mixed regime, in addition to surface tension, vapour properties and wall superheat. A comprehensive heat transfer correlation was proposed for upward cross-flow (Singh & Premachandran Reference Singh and Premachandran2018b), while a reduction factor (Singh & Premachandran Reference Singh and Premachandran2019) as a function of the Froude number was proposed to quantify the heat transfer with horizontal cross-flow of liquid.

$D$ is the characteristic dimension. Still, most of the experimental studies for forced convection film boiling over a circular cylinder focused only on the inertia dominated regime. At the same time, the challenges associated with the analytical treatment of the problem become more pronounced under comparable influence of buoyancy and inertia leading to almost all prior theoretical studies neglecting the effect of gravity. The mixed regime of film boiling over a circular cylinder has been explicitly identified only in the studies of Bromley, LeRoy & Robbers (Reference Bromley, LeRoy and Robbers1953) and Ito, Nishikawa & Shigechi (Reference Ito, Nishikawa and Shigechi1981). However, these studies differed in the prediction for the onset of the mixed regime in terms of the Froude number. Also, no conclusive heat transfer results were provided by either study in the mixed regime thereby leaving a discernible gap in the literature. Bromley et al. (Reference Bromley, LeRoy and Robbers1953) proposed semiempirical heat transfer correlations only for pool film boiling and purely forced convection film boiling. Ito et al. (Reference Ito, Nishikawa and Shigechi1981) noted that a similarity solution in the mixed regime was not possible and used an integral method for the two-phase boundary layer in their analysis. They also established a definitive relationship between the Nusselt number and other non-dimensional parameters only in the buoyancy or inertia dominated regimes, while noting anomalous heat transfer behaviour when both the forces were comparable. Here it can be mentioned that the aforementioned gaps can be suitably addressed through computations of film boiling. As such, the present authors performed direct numerical simulations in the mixed regime of saturated film boiling over a horizontal circular cylinder under different liquid flow configurations in recent studies (Singh & Premachandran Reference Singh and Premachandran2018b, Reference Singh and Premachandran2019), where the effect of different film boiling parameters was analysed and all the relevant aspects discussed in detail. It was shown that a complex interplay of buoyancy and inertia governed the interfacial dynamics and heat transfer in the mixed regime, in addition to surface tension, vapour properties and wall superheat. A comprehensive heat transfer correlation was proposed for upward cross-flow (Singh & Premachandran Reference Singh and Premachandran2018b), while a reduction factor (Singh & Premachandran Reference Singh and Premachandran2019) as a function of the Froude number was proposed to quantify the heat transfer with horizontal cross-flow of liquid.

With regard to an elliptical cylinder, only a few analytical studies have been performed in the purview of natural convection film boiling. Nakayama & Koyama (Reference Nakayama and Koyama1986) theoretically studied heat transfer in saturated pool film boiling over arbitrary geometries using an integral formulation for two-phase boundary layer. They considered the inertial and convective effects in the film along with interfacial shear, while not incorporating surface tension in their analysis. Amongst the results for several different geometries, only local heat transfer variation with two different aspect ratios of an ellipse was presented. Subsequently, the effect of surface tension was considered in their analytical model by Yang & Hsu (Reference Yang and Hsu1997), who studied the problem with the major axis of the isothermal elliptical cylinder oriented along gravity. They presented the mean heat transfer results with variation in several different parameters such as wall superheat, surface tension, liquid viscosity and eccentricity of the ellipse. The vapour flow adjacent to the heater surface can become turbulent at high Grashof number values as noted by Sarma et al. (Reference Sarma, Subrahmanyam, Rao and Bergles2001) for a horizontal cylinder. As such Hu, Wang & Chen (Reference Hu, Wang and Chen2008) analytically studied turbulent film boiling over an ellipse under free convection considering radiation effects. Despite these analyses determining some important aspects, it can be seen that a pertinent gap exists in the literature even for natural convection film boiling physics over elliptical cylinders, in contrast to many experimental, theoretical and numerical investigations performed for circular cylinders. Noting this, Sadeghi, Shadloo & Hooman (Reference Sadeghi, Shadloo and Hooman2016) numerically studied bubble dynamics and heat transfer in saturated pool film boiling over an elliptical tube with different aspect ratios using the volume of fluid method. Additionally, they proposed a correlation for Nusselt number involving a polynomial expression for aspect ratio of the ellipse. Furthermore, to the best of authors’ knowledge, no prior detailed investigation has focused on ascertaining film boiling behaviour with a forced flow of liquid over an elliptical tube. This entails a critical gap in the literature regarding interesting interfacial dynamics and heat transfer that can be observed under such conditions, and forms an important aspect of the present work.

Significant mathematical difficulties are associated with the analytical prediction of interfacial behaviour including vapour flow separation and wake dynamics in flow film boiling over bluff bodies under different operating conditions. This is the case even for circular cylinders, especially when the effect of gravity is considerable in addition to flow inertia. Kaul & Witte (Reference Kaul and Witte1987) predicted vapour wake profiles over a cylinder using cavitation theory from purely inertial considerations. As such their model was observed to deviate significantly from experimental data where the effect of gravity was notable. Direct numerical simulations can aid in gaining detailed insights about such aspects of film boiling dynamics, while also alleviating major simplifying assumptions employed in various theoretical studies. A direct consequence of the difficulty in obtaining wake profiles is a substantial gap in the understanding of vapour wake heat transfer, which has been neglected in most classical film boiling analyses for a cylinder. Such studies have modelled the heat transfer based on the front stagnation region only leading to discrepancies from empirical data in several studies (Bromley et al. Reference Bromley, LeRoy and Robbers1953; Witte & Orozco Reference Witte and Orozco1984; Chou, Sankaran & Witte Reference Chou, Sankaran and Witte1995). The wake heat transfer can thus be significant under certain conditions, especially for an elliptical cylinder with different angles of incidence to the liquid flow. This is directly accounted for in the present simulations as also other often overlooked aspects in forced convection film boiling analyses such as inertial and convective effects in the vapour film, surface tension, and mutual interaction of the liquid and vapour wakes. While the liquid flow expectedly drives the vapour wake evolution, the vapour wake structure itself can cause the liquid pressure field to deviate from the potential flow assumption, which has been employed in previous analyses again primarily owing to unknown wake profiles. Hence, it can be deduced from the aforementioned discussion that direct numerical simulations present a significant and unique opportunity to understand film boiling physics over an ellipse in the mixed regime.

The aim of the present work is thus to numerically investigate the mixed regime of saturated film boiling over an elliptical cylinder under different geometric conditions defined by the aspect ratio ![]() $(\varGamma )$ and angle of incidence

$(\varGamma )$ and angle of incidence ![]() $(\theta )$ to the flow. Additionally, the present study considers both upward and horizontal cross-flow of liquid as shown in the problem schematic in figure 1. The cross-flow direction has been shown to be non-trivial in the mixed regime in recent studies for a circular cylinder by the authors (Singh & Premachandran Reference Singh and Premachandran2018b, Reference Singh and Premachandran2019), with markedly different interface evolution, vapour wake structure and heat transfer obtained for different orientations. Direct numerical simulations have been performed for the liquid flow Reynolds number varying in the range

$(\theta )$ to the flow. Additionally, the present study considers both upward and horizontal cross-flow of liquid as shown in the problem schematic in figure 1. The cross-flow direction has been shown to be non-trivial in the mixed regime in recent studies for a circular cylinder by the authors (Singh & Premachandran Reference Singh and Premachandran2018b, Reference Singh and Premachandran2019), with markedly different interface evolution, vapour wake structure and heat transfer obtained for different orientations. Direct numerical simulations have been performed for the liquid flow Reynolds number varying in the range ![]() $10 \leq Re_{l} \leq 170$, which along with other relevant parameters ascribe to the mixed regime of the Froude number. To this effect, a computational framework developed by the present authors for phase change problems on two-dimensional unstructured grids based on the coupled level set and volume of fluid (CLSVOF) interface capturing algorithm (Singh & Premachandran Reference Singh and Premachandran2018a) is used. The problem formulation and numerical methodology have been presented in § 2. The interface morphology and heat transfer as determined under the effect of cross-flow velocity as well as orientation, and wall superheat along with the geometrical parameters of the ellipse is discussed in detail in §§ 3.1–3.3. The mutual interaction of liquid and vapour wakes in the mixed regime is discussed in § 3.4. Based on the simulation results, a correlation for heat transfer is presented in terms of a shape factor

$10 \leq Re_{l} \leq 170$, which along with other relevant parameters ascribe to the mixed regime of the Froude number. To this effect, a computational framework developed by the present authors for phase change problems on two-dimensional unstructured grids based on the coupled level set and volume of fluid (CLSVOF) interface capturing algorithm (Singh & Premachandran Reference Singh and Premachandran2018a) is used. The problem formulation and numerical methodology have been presented in § 2. The interface morphology and heat transfer as determined under the effect of cross-flow velocity as well as orientation, and wall superheat along with the geometrical parameters of the ellipse is discussed in detail in §§ 3.1–3.3. The mutual interaction of liquid and vapour wakes in the mixed regime is discussed in § 3.4. Based on the simulation results, a correlation for heat transfer is presented in terms of a shape factor ![]() $(\psi )$ for elliptical cylinders in § 3.5. Finally, the key conclusions from the present study are summarized in § 4.

$(\psi )$ for elliptical cylinders in § 3.5. Finally, the key conclusions from the present study are summarized in § 4.

Figure 1. Problem schematic for the mixed regime of saturated film boiling over an elliptical cylinder: (![]() $a$) upward cross-flow and (

$a$) upward cross-flow and (![]() $b$) horizontal cross-flow.

$b$) horizontal cross-flow.

Lack of any prior investigation with regard to the above aspects lays the foundation for the present work. Through this work, some completely new inferences on film boiling physics in liquid cross-flow over bluff bodies will be outlined that are counter-intuitive to our previous understanding of the phenomenon, and would be difficult to readily ascertain from experiments or analytical models. As such, the observations from the present simulations could also serve as reference for real applications or future empirical studies that may be required to further the relevant body of research. The present analysis is envisaged to plug a major gap towards the understanding of flow film boiling in the mixed regime with a non-canonical heater profile.

2. Methodology

2.1. Governing equations and CLSVOF method

The mass, momentum and energy conservation equations are solved in a single fluid formulation for both the phases while suitably accounting for the property variations across the liquid–vapour interface, surface tension and phase change. An in-house numerical framework developed by the present authors (Singh & Premachandran Reference Singh and Premachandran2018a) for phase change problems on two-dimensional unstructured grids is employed to perform the simulations. The solver is based on the CLSVOF method and has been parallelized using OpenMP to utilize multiple cores on a shared memory system and reduce the computational time. It has been validated in detail against a number of benchmark problems (Singh & Premachandran Reference Singh and Premachandran2018a), and also adopted in some recent studies (Singh & Premachandran Reference Singh and Premachandran2018b, Reference Singh and Premachandran2019, Reference Singh and Premachandran2020) to obtain important results and physical insights for film boiling. For the sake of completeness, the salient features of the numerical method are presented succinctly along with the governing equations in this section.

Apart from the unsteady interfacial dynamics, the flow is considered to be laminar and incompressible. The continuity equation in any single phase region is given as

where ![]() $\boldsymbol {v}$ represents the fluid velocity vector. However, for a two-phase computational cell, with its boundary denoted as

$\boldsymbol {v}$ represents the fluid velocity vector. However, for a two-phase computational cell, with its boundary denoted as ![]() $S_c$ and having a part of the interface

$S_c$ and having a part of the interface ![]() $S_{int}(t)$ between the two phases, the continuity equation is modified as (Welch & Wilson Reference Welch and Wilson2000)

$S_{int}(t)$ between the two phases, the continuity equation is modified as (Welch & Wilson Reference Welch and Wilson2000)

where ![]() $\Vert \cdot \Vert$ represents the jump in the variable across the phase interface. The interface with the unit normal

$\Vert \cdot \Vert$ represents the jump in the variable across the phase interface. The interface with the unit normal ![]() $\boldsymbol {n}$ pointing into the liquid phase moves with a velocity

$\boldsymbol {n}$ pointing into the liquid phase moves with a velocity ![]() $\boldsymbol {v}_{int}$. Further, the mass and energy jump conditions at the phase interface are given as

$\boldsymbol {v}_{int}$. Further, the mass and energy jump conditions at the phase interface are given as

where ![]() $\rho$ is the fluid density,

$\rho$ is the fluid density, ![]() $\dot {m}$ represents the mass flux across the phase interface,

$\dot {m}$ represents the mass flux across the phase interface, ![]() $h_{lv}$ is the latent heat of vaporization and

$h_{lv}$ is the latent heat of vaporization and ![]() $\boldsymbol {q}_{int}^{''}$ denotes the heat flux vector at the interface. By incorporating these jump conditions, the continuity equation for the two-phase cells in a boiling flow is written as (Welch & Wilson Reference Welch and Wilson2000)

$\boldsymbol {q}_{int}^{''}$ denotes the heat flux vector at the interface. By incorporating these jump conditions, the continuity equation for the two-phase cells in a boiling flow is written as (Welch & Wilson Reference Welch and Wilson2000)

\begin{equation} \int_{S_c}\boldsymbol{v}\boldsymbol{\cdot}\boldsymbol{n}\,\mathrm{d}S + \int_{S_{int}(t)}\left(\frac{1}{\rho_{l}}-\frac{1}{\rho_{v}}\right)\frac{\Vert\boldsymbol{q}_{int}^{''}\Vert\boldsymbol{\cdot}\boldsymbol{n}}{h_{lv}}\,\mathrm{d}S = 0, \end{equation}

\begin{equation} \int_{S_c}\boldsymbol{v}\boldsymbol{\cdot}\boldsymbol{n}\,\mathrm{d}S + \int_{S_{int}(t)}\left(\frac{1}{\rho_{l}}-\frac{1}{\rho_{v}}\right)\frac{\Vert\boldsymbol{q}_{int}^{''}\Vert\boldsymbol{\cdot}\boldsymbol{n}}{h_{lv}}\,\mathrm{d}S = 0, \end{equation}where the subscripts l and v denote liquid and vapour phases, respectively.

The Navier–Stokes equations in the conservative form are written as

for the entire flow field. Here ![]() $P$ denotes the pressure field,

$P$ denotes the pressure field, ![]() $\boldsymbol {\tau } = \mu (\boldsymbol {\nabla }\boldsymbol {v} + \boldsymbol {\nabla }\boldsymbol {v}^{T})$ is the deviatoric stress tensor for a Newtonian fluid and

$\boldsymbol {\tau } = \mu (\boldsymbol {\nabla }\boldsymbol {v} + \boldsymbol {\nabla }\boldsymbol {v}^{T})$ is the deviatoric stress tensor for a Newtonian fluid and ![]() $\boldsymbol {g}$ represents the acceleration due to gravity. Here

$\boldsymbol {g}$ represents the acceleration due to gravity. Here ![]() $\boldsymbol {f}_{st}$ is the surface tension force per unit volume that acts only in the interfacial region and is treated as a body force following the continuum surface force model of Brackbill, Kothe & Zemach (Reference Brackbill, Kothe and Zemach1992). Neglecting any variations in the surface tension coefficient

$\boldsymbol {f}_{st}$ is the surface tension force per unit volume that acts only in the interfacial region and is treated as a body force following the continuum surface force model of Brackbill, Kothe & Zemach (Reference Brackbill, Kothe and Zemach1992). Neglecting any variations in the surface tension coefficient ![]() $\sigma$, it is expressed as

$\sigma$, it is expressed as ![]() $\boldsymbol {f}_{st}= \sigma \kappa \boldsymbol {n}\delta$, where

$\boldsymbol {f}_{st}= \sigma \kappa \boldsymbol {n}\delta$, where ![]() $\delta$ is a delta function centred at the interface and

$\delta$ is a delta function centred at the interface and ![]() $\kappa$ is the interfacial curvature.

$\kappa$ is the interfacial curvature.

The temperature field (![]() $T$) is determined by solving the energy equation only in the vapour phase as

$T$) is determined by solving the energy equation only in the vapour phase as

This follows directly from the fact that saturated boiling is investigated in the present study with the liquid and the interface temperature considered to be constant at the saturation temperature (Son & Dhir Reference Son and Dhir1998; Welch & Wilson Reference Welch and Wilson2000). The properties appearing in (2.6) and (2.7) can be identified as dynamic viscosity (![]() $\mu$), specific heat (

$\mu$), specific heat (![]() $c_p$) and thermal conductivity (

$c_p$) and thermal conductivity (![]() $k$).

$k$).

Upon calculation of the instantaneous velocity and temperature fields, the CLSVOF algorithm that incorporates accurate geometric procedures for interface advection and reconstruction is invoked to capture the interface on the Eulerian finite volume grid. The colour function or the volume fraction ![]() $F$, with a value of zero in the liquid, is advected in space at each time step as

$F$, with a value of zero in the liquid, is advected in space at each time step as

The above equation, where ![]() $F_{mt}$ denotes the rate of generation of volume fraction due to mass transfer at the interface, is solved in an unsplit manner using the edge matched flux polygon advection (EMFPA) algorithm proposed by López et al. (Reference López, Hernández, Gómez and Faura2004). Within the EMFPA algorithm, the cell vertex velocities are directly used to construct the flux polygons, while a scaling factor derived from cell face velocities is used to correct the advected flux through each face. The level set (

$F_{mt}$ denotes the rate of generation of volume fraction due to mass transfer at the interface, is solved in an unsplit manner using the edge matched flux polygon advection (EMFPA) algorithm proposed by López et al. (Reference López, Hernández, Gómez and Faura2004). Within the EMFPA algorithm, the cell vertex velocities are directly used to construct the flux polygons, while a scaling factor derived from cell face velocities is used to correct the advected flux through each face. The level set (![]() $\phi$) advection equation (Son & Dhir Reference Son and Dhir1998) is written as

$\phi$) advection equation (Son & Dhir Reference Son and Dhir1998) is written as

where ![]() $\boldsymbol {v}_{int} = \boldsymbol {v} + \boldsymbol {v}_{mt}$ is the sum of cell fluid velocity and interfacial velocity due to mass transfer. A total variational diminishing (TVD) scheme for unstructured grids (Darwish & Moukalled Reference Darwish and Moukalled2003) along with a Min-Mod flux limiter function is used to solve (2.9). The interface normal is subsequently calculated as

$\boldsymbol {v}_{int} = \boldsymbol {v} + \boldsymbol {v}_{mt}$ is the sum of cell fluid velocity and interfacial velocity due to mass transfer. A total variational diminishing (TVD) scheme for unstructured grids (Darwish & Moukalled Reference Darwish and Moukalled2003) along with a Min-Mod flux limiter function is used to solve (2.9). The interface normal is subsequently calculated as

Upon calculation of the interface normal and the volume fraction, a piecewise linear interface is geometrically reconstructed in each two-phase cell using an analytical procedure for volume reinforcement by López & Hernández (Reference López and Hernández2008). For the level set field to remain a signed distance function, it is geometrically reinitialized using the reconstructed phase interface at the end of each time step. The reinitialization procedure on unstructured grids has been described in a previous study by the present authors (Singh & Premachandran Reference Singh and Premachandran2018b).

The smoothed Heaviside function, ![]() $H(\phi )$ is employed to prevent any numerical instability arising from discontinuous properties at the liquid–vapour interface. The calculation procedure for

$H(\phi )$ is employed to prevent any numerical instability arising from discontinuous properties at the liquid–vapour interface. The calculation procedure for ![]() $H(\phi )$ with a varying grid size across the domain is outlined in previous studies (Singh & Premachandran Reference Singh and Premachandran2018b, Reference Singh and Premachandran2019). As such any fluid property

$H(\phi )$ with a varying grid size across the domain is outlined in previous studies (Singh & Premachandran Reference Singh and Premachandran2018b, Reference Singh and Premachandran2019). As such any fluid property ![]() $\chi$ is calculated as follows:

$\chi$ is calculated as follows:

Further, the present algorithm uses the gradient of the Heaviside function to ascertain the term ![]() $\boldsymbol {n}\delta$ appearing in the expression for surface tension force, which is eventually determined as

$\boldsymbol {n}\delta$ appearing in the expression for surface tension force, which is eventually determined as

The interfacial curvature is calculated as

The gradients of ![]() $\phi$ and

$\phi$ and ![]() $H(\phi )$ are calculated using the multidimensional Taylor series expansion based second-order accurate scheme (Lehnhäuser & Schäfer Reference Lehnhäuser and Schäfer2002) for unstructured grids.

$H(\phi )$ are calculated using the multidimensional Taylor series expansion based second-order accurate scheme (Lehnhäuser & Schäfer Reference Lehnhäuser and Schäfer2002) for unstructured grids.

The heat flux at the phase interface is calculated to determine the interfacial mass transfer as

where ![]() $T_v$ and

$T_v$ and ![]() $T_l$ are the temperatures of the vapour and liquid phases at a normal distance

$T_l$ are the temperatures of the vapour and liquid phases at a normal distance ![]() $\Delta n$ from the interface. In the present study under saturation conditions, the heat flux is calculated only in the vapour phase.

$\Delta n$ from the interface. In the present study under saturation conditions, the heat flux is calculated only in the vapour phase.

The finite volume method is used to solve the governing equations on collocated unstructured grids. The SIMPLE algorithm (Patankar Reference Patankar1980) is invoked for pressure and velocity coupling while the convective terms in the momentum and energy equations are discretized using a second-order upwind scheme (Mathur & Murthy Reference Mathur and Murthy1997) for unstructured grids. The time integration is performed using the Euler explicit scheme. Based on the smallest grid size in the computational domain encountered near the heated elliptical cylinder, time step restrictions are imposed on account of Courant–Friedrichs–Lewy (CFL) condition, gravity, viscosity and the explicit treatment of the surface tension force (Singh & Premachandran Reference Singh and Premachandran2018b, Reference Singh and Premachandran2019).

2.2. Problem formulation

2.2.1. Computational domain and boundary conditions

The layout of the computational domain for both the flow orientations considered in this study is presented in figure 2 along with the boundary conditions. The heated elliptical cylinder has an aspect ratio ![]() $\varGamma = b/a$, where

$\varGamma = b/a$, where ![]() $a$ and

$a$ and ![]() $b$ denote its semimajor and semiminor axis, respectively, as also shown in figure 1. It is situated in a cross-flow of saturated liquid with the free stream flow aiding buoyancy for the case of upward cross-flow (figure 2

$b$ denote its semimajor and semiminor axis, respectively, as also shown in figure 1. It is situated in a cross-flow of saturated liquid with the free stream flow aiding buoyancy for the case of upward cross-flow (figure 2![]() $a$), while being orthogonal to the gravity field for horizontal cross-flow configuration (figure 2

$a$), while being orthogonal to the gravity field for horizontal cross-flow configuration (figure 2![]() $b$). The flow inlet is situated 20

$b$). The flow inlet is situated 20![]() $b$ upstream of the cylinder where the liquid enters with a uniform velocity

$b$ upstream of the cylinder where the liquid enters with a uniform velocity ![]() $U$ at a temperature

$U$ at a temperature ![]() $T_{sat}$. The velocity

$T_{sat}$. The velocity ![]() $U$ is determined based on the liquid flow Reynolds number (

$U$ is determined based on the liquid flow Reynolds number (![]() $Re_l$) considered in the simulations. At the outlet section normal to the free stream situated at a distance of 40

$Re_l$) considered in the simulations. At the outlet section normal to the free stream situated at a distance of 40![]() $b$ downstream of the elliptical cylinder, Neumann boundary conditions are prescribed for all the variables, while the Dirichlet boundary condition is specified for pressure. With

$b$ downstream of the elliptical cylinder, Neumann boundary conditions are prescribed for all the variables, while the Dirichlet boundary condition is specified for pressure. With ![]() $u$ and

$u$ and ![]() $v$ representing the velocity components in the

$v$ representing the velocity components in the ![]() $x$ and

$x$ and ![]() $y$ directions, respectively, and in accordance with the layout shown in figure 2, the Neumann boundary conditions are expressed as

$y$ directions, respectively, and in accordance with the layout shown in figure 2, the Neumann boundary conditions are expressed as ![]() $\partial u / \partial y = \partial v / \partial y = \partial T / \partial y = 0$ for upward cross-flow, and

$\partial u / \partial y = \partial v / \partial y = \partial T / \partial y = 0$ for upward cross-flow, and ![]() $\partial u / \partial x = \partial v / \partial x = \partial T / \partial x = 0$ for horizontal cross-flow.

$\partial u / \partial x = \partial v / \partial x = \partial T / \partial x = 0$ for horizontal cross-flow.

Figure 2. Computational domain with boundary conditions: (![]() $a$) upward cross-flow and (

$a$) upward cross-flow and (![]() $b$) horizontal cross-flow.

$b$) horizontal cross-flow.

For upward flow configuration, symmetry boundary conditions ![]() $(u=0, \partial v / \partial x = 0)$ are prescribed at the domain boundaries aligned to the free stream direction and positioned on either side at a distance of 20

$(u=0, \partial v / \partial x = 0)$ are prescribed at the domain boundaries aligned to the free stream direction and positioned on either side at a distance of 20![]() $b$ from the central heater axis. This leads to a blockage ratio of 0.05 at

$b$ from the central heater axis. This leads to a blockage ratio of 0.05 at ![]() $\theta =0^{\circ }$, which is in line with the previous studies for a circular cylinder pertaining to film boiling in the mixed regime (Singh & Premachandran Reference Singh and Premachandran2018b) and single phase forced and mixed convection (Sarkar, Dalal & Biswas Reference Sarkar, Dalal and Biswas2011). Even for other angles and all aspect ratios considered in the present work, the blockage broadly conforms to the study performed by Jackson (Reference Jackson1987) for different bodies including elliptical cylinders, and mitigates any significant confinement effect on the flow field. Similarly for horizontal cross-flow, the bottom boundary at 20

$\theta =0^{\circ }$, which is in line with the previous studies for a circular cylinder pertaining to film boiling in the mixed regime (Singh & Premachandran Reference Singh and Premachandran2018b) and single phase forced and mixed convection (Sarkar, Dalal & Biswas Reference Sarkar, Dalal and Biswas2011). Even for other angles and all aspect ratios considered in the present work, the blockage broadly conforms to the study performed by Jackson (Reference Jackson1987) for different bodies including elliptical cylinders, and mitigates any significant confinement effect on the flow field. Similarly for horizontal cross-flow, the bottom boundary at 20![]() $b$ distance from the heater axis is considered as a free-slip boundary

$b$ distance from the heater axis is considered as a free-slip boundary ![]() $( \partial u / \partial y = 0,v=0)$. However, at the top boundary located at a larger distance of 30

$( \partial u / \partial y = 0,v=0)$. However, at the top boundary located at a larger distance of 30![]() $b$ from the heater axis, symmetry condition is prescribed only up to a distance of 20

$b$ from the heater axis, symmetry condition is prescribed only up to a distance of 20![]() $b$ from the inlet, while the remaining portion is considered to be a free outlet as shown in figure 2(

$b$ from the inlet, while the remaining portion is considered to be a free outlet as shown in figure 2(![]() $b$). This is done to ensure that vapour bubbles can freely move out of the domain even from the top boundary, which can be expected at the low

$b$). This is done to ensure that vapour bubbles can freely move out of the domain even from the top boundary, which can be expected at the low ![]() $Re_l$ values used in this study, and thus prevent any unphysical behaviour to arise in the domain. A similar choice of boundary condition has been followed in previous studies for a circular cylinder (Singh & Premachandran Reference Singh and Premachandran2019) and two-phase mixing layer (Ling et al. Reference Ling, Fuster, Tryggvason and Zaleski2019). Thus bubbles can freely move out even under buoyancy dominated conditions, with the domain size being much larger than considered by Sadeghi et al. (Reference Sadeghi, Shadloo and Hooman2016) for natural convection film boiling over an ellipse.

$Re_l$ values used in this study, and thus prevent any unphysical behaviour to arise in the domain. A similar choice of boundary condition has been followed in previous studies for a circular cylinder (Singh & Premachandran Reference Singh and Premachandran2019) and two-phase mixing layer (Ling et al. Reference Ling, Fuster, Tryggvason and Zaleski2019). Thus bubbles can freely move out even under buoyancy dominated conditions, with the domain size being much larger than considered by Sadeghi et al. (Reference Sadeghi, Shadloo and Hooman2016) for natural convection film boiling over an ellipse.

The surface of the elliptical cylinder is considered to be isothermal in the present simulations where the temperature is specified as ![]() $T_w = T_{sat} + \Delta T$. Here

$T_w = T_{sat} + \Delta T$. Here ![]() $\Delta T$ is the wall superheat. Further, no-slip conditions (

$\Delta T$ is the wall superheat. Further, no-slip conditions (![]() $u=0, v=0$) are prescribed for the velocity components. At the commencement of each simulation, a thin vapour film is initialized over the heater surface blanketing it from the surrounding liquid. The thickness of the vapour layer is specified uniformly as 0.1 times the minor axis, where a linear temperature distribution is initially specified with temperature varying from

$u=0, v=0$) are prescribed for the velocity components. At the commencement of each simulation, a thin vapour film is initialized over the heater surface blanketing it from the surrounding liquid. The thickness of the vapour layer is specified uniformly as 0.1 times the minor axis, where a linear temperature distribution is initially specified with temperature varying from ![]() $T_w$ at the wall to

$T_w$ at the wall to ![]() $T_{sat}$ at the phase interface. The simulations are subsequently run for a long time such that multiple ebullition cycles are established while being governed by the hydrodynamics of the case being investigated, thereby ensuring that the initial conditions do not affect the interface evolution and heat transfer.

$T_{sat}$ at the phase interface. The simulations are subsequently run for a long time such that multiple ebullition cycles are established while being governed by the hydrodynamics of the case being investigated, thereby ensuring that the initial conditions do not affect the interface evolution and heat transfer.

2.2.2. Fluid properties and physical parameters

Water at near-critical conditions is considered as the boiling fluid for the present simulations with constant properties assumed in each phase corresponding to saturation conditions. The corresponding liquid and vapour properties (Singh & Premachandran Reference Singh and Premachandran2018a) are presented in table 1, with the reduced pressure ![]() $p / p_c=0.99$, and

$p / p_c=0.99$, and ![]() $p_c$ denoting the critical pressure. Low values of the liquid cross-flow Reynolds number

$p_c$ denoting the critical pressure. Low values of the liquid cross-flow Reynolds number ![]() $(Re_l=\rho _{l}UD/\mu _l)$ in the range 10–170 are considered such that film boiling occurs in the mixed regime where the flow inertia is accompanied by a significant effect of buoyancy. The selected values of

$(Re_l=\rho _{l}UD/\mu _l)$ in the range 10–170 are considered such that film boiling occurs in the mixed regime where the flow inertia is accompanied by a significant effect of buoyancy. The selected values of ![]() $Re_l$ also conform to the critical limits reported for flow transition to a three-dimensional nature in single phase flow over an ellipse with different aspect ratios (Thompson et al. Reference Thompson, Radi, Rao, Sheridan and Hourigan2014; Paul et al. Reference Paul, Prakash, Vengadesan and Pulletikurthi2016), which is necessary with regard to the present two-dimensional numerical model and different angles of incidence investigated including

$Re_l$ also conform to the critical limits reported for flow transition to a three-dimensional nature in single phase flow over an ellipse with different aspect ratios (Thompson et al. Reference Thompson, Radi, Rao, Sheridan and Hourigan2014; Paul et al. Reference Paul, Prakash, Vengadesan and Pulletikurthi2016), which is necessary with regard to the present two-dimensional numerical model and different angles of incidence investigated including ![]() $\theta =90^{\circ }$. At this stage it is important to define the characteristic geometric dimension

$\theta =90^{\circ }$. At this stage it is important to define the characteristic geometric dimension ![]() $D$ used to calculate the various non-dimensional parameters in this study. While this is simply the diameter for a circular cylinder (

$D$ used to calculate the various non-dimensional parameters in this study. While this is simply the diameter for a circular cylinder (![]() $\varGamma =1$), it is considered as the length presented by the elliptical body normal to the flow and given as (Jackson Reference Jackson1987)

$\varGamma =1$), it is considered as the length presented by the elliptical body normal to the flow and given as (Jackson Reference Jackson1987)

\begin{equation} D= 2b\cos\theta\left(1+\left(\frac{a}{b}\right)^{2}\tan^{2}\theta\right)^{{1}/{2}}. \end{equation}

\begin{equation} D= 2b\cos\theta\left(1+\left(\frac{a}{b}\right)^{2}\tan^{2}\theta\right)^{{1}/{2}}. \end{equation}Table 1. Liquid and vapour properties for water at near-critical conditions ![]() $(p_{sat} = 21.9\ \mathrm {MPa}, T_{sat} = 646\ \mathrm {K}).$

$(p_{sat} = 21.9\ \mathrm {MPa}, T_{sat} = 646\ \mathrm {K}).$ ![]() $\left (\sigma =0.07\ \mathrm {mN}\,\mathrm {m}^{-1}, h_{lv}=276.4\ \mathrm {kJ}\,\mathrm {kg}^{-1}.\right )$

$\left (\sigma =0.07\ \mathrm {mN}\,\mathrm {m}^{-1}, h_{lv}=276.4\ \mathrm {kJ}\,\mathrm {kg}^{-1}.\right )$

A careful choice of the fluid properties and the free stream velocity magnitudes thus determined lead to low values of the Froude number, with ![]() $\sqrt {Fr}\leq 2$ in almost all the simulations involving different aspect ratios and orientations of the elliptical cylinder. This ascertains a combined influence of buoyancy and inertia on the film boiling behaviour, for which other relevant parameters are the Grashof number (

$\sqrt {Fr}\leq 2$ in almost all the simulations involving different aspect ratios and orientations of the elliptical cylinder. This ascertains a combined influence of buoyancy and inertia on the film boiling behaviour, for which other relevant parameters are the Grashof number (![]() $Gr$) and the vapour Prandtl number (

$Gr$) and the vapour Prandtl number (![]() $Pr_v$). While the Grashof number is defined as

$Pr_v$). While the Grashof number is defined as ![]() $Gr=\rho _v(\rho _l-\rho _v)gD^{3}/{\mu _v}^{2}$ and varies with the elliptical geometry, the vapour Prandtl number given as

$Gr=\rho _v(\rho _l-\rho _v)gD^{3}/{\mu _v}^{2}$ and varies with the elliptical geometry, the vapour Prandtl number given as ![]() $Pr_v=\mu _v c_{pv}/k_v$ has a fixed value of 21.18 based on the fluid properties. Further, the aspect ratio (

$Pr_v=\mu _v c_{pv}/k_v$ has a fixed value of 21.18 based on the fluid properties. Further, the aspect ratio (![]() $\varGamma$) and the angle of incidence (

$\varGamma$) and the angle of incidence (![]() $\theta$) for the elliptical cylinder are varied in a wide range to gain interesting insights regarding interface evolution and heat transfer for both upward and horizontal liquid cross-flow orientations in a comprehensive manner. In all the simulations, the minor axis of the ellipse is fixed with respect to the characteristic capillary length scale

$\theta$) for the elliptical cylinder are varied in a wide range to gain interesting insights regarding interface evolution and heat transfer for both upward and horizontal liquid cross-flow orientations in a comprehensive manner. In all the simulations, the minor axis of the ellipse is fixed with respect to the characteristic capillary length scale ![]() $\lambda _o$ such that

$\lambda _o$ such that ![]() $2b/\lambda _o=1$ or

$2b/\lambda _o=1$ or ![]() $b/\lambda _o=0.5$. Here, the capillary length scale is defined as

$b/\lambda _o=0.5$. Here, the capillary length scale is defined as ![]() $\lambda _o = \sqrt {\sigma / (\rho _l - \rho _v)g}$. The values of

$\lambda _o = \sqrt {\sigma / (\rho _l - \rho _v)g}$. The values of ![]() $\varGamma$ along with

$\varGamma$ along with ![]() $b/\lambda _o$ considered in this study primarily result in conditions where surface tension also governs the hydrodynamics, in addition to a competing influence of buoyancy and inertia, and is duly considered in the simulations. This can also be ascertained by specifically calculating the Bond number, which can be defined as

$b/\lambda _o$ considered in this study primarily result in conditions where surface tension also governs the hydrodynamics, in addition to a competing influence of buoyancy and inertia, and is duly considered in the simulations. This can also be ascertained by specifically calculating the Bond number, which can be defined as ![]() $Bo=(\rho _l-\rho _v)ga^{2}/\sigma$ (Yang & Hsu Reference Yang and Hsu1997). Additionally, the effect of wall superheat (

$Bo=(\rho _l-\rho _v)ga^{2}/\sigma$ (Yang & Hsu Reference Yang and Hsu1997). Additionally, the effect of wall superheat (![]() $\Delta T$) is also studied in detail, which is specified in non-dimensional terms throughout the study as

$\Delta T$) is also studied in detail, which is specified in non-dimensional terms throughout the study as ![]() $Ja_v/Pr_v$, with

$Ja_v/Pr_v$, with ![]() $Ja_v=c_{pv} \Delta T/h_{lv}$ representing the Jacob number. The values of the various parameters considered in the present simulations are summarized in table 2. Corresponding to the conditions in the present simulations and a circular geometry, the radiation contribution to the total heat transfer coefficient has been shown to be quite small in previous studies by the present authors (Singh & Premachandran Reference Singh and Premachandran2018b, Reference Singh and Premachandran2019) when considering a well-polished heater surface. Thus radiation heat transfer is safely neglected in the present study also.

$Ja_v=c_{pv} \Delta T/h_{lv}$ representing the Jacob number. The values of the various parameters considered in the present simulations are summarized in table 2. Corresponding to the conditions in the present simulations and a circular geometry, the radiation contribution to the total heat transfer coefficient has been shown to be quite small in previous studies by the present authors (Singh & Premachandran Reference Singh and Premachandran2018b, Reference Singh and Premachandran2019) when considering a well-polished heater surface. Thus radiation heat transfer is safely neglected in the present study also.

Table 2. Range of different parameters considered in the study. Other fixed parameters are ![]() $Pr_v=21.18$ and

$Pr_v=21.18$ and ![]() $2b/\lambda _o=1.$ Results for

$2b/\lambda _o=1.$ Results for ![]() $\varGamma =1$ have been adopted from Singh & Premachandran (Reference Singh and Premachandran2018b, Reference Singh and Premachandran2019).

$\varGamma =1$ have been adopted from Singh & Premachandran (Reference Singh and Premachandran2018b, Reference Singh and Premachandran2019).

A summary of the simulation runs in this study is as follows. Firstly, corresponding to ![]() $\varGamma =0.6$ and

$\varGamma =0.6$ and ![]() $\theta =0^{\circ }$, four different values of

$\theta =0^{\circ }$, four different values of ![]() $Re_l$, viz., 10, 50, 100 and 170 are considered to study the effect of free stream velocity, while the non-dimensional wall superheat,

$Re_l$, viz., 10, 50, 100 and 170 are considered to study the effect of free stream velocity, while the non-dimensional wall superheat, ![]() $Ja_v/Pr_v$, is varied from 0.3 to 1.2 in increments of 0.3 at each

$Ja_v/Pr_v$, is varied from 0.3 to 1.2 in increments of 0.3 at each ![]() $Re_l$. Subsequently, two other aspect ratios, viz.,

$Re_l$. Subsequently, two other aspect ratios, viz., ![]() $\varGamma = 0.4$ and 0.8 are considered with similar variation in

$\varGamma = 0.4$ and 0.8 are considered with similar variation in ![]() $Re_l$ but fixed values of

$Re_l$ but fixed values of ![]() $\theta =0^{0}$ and

$\theta =0^{0}$ and ![]() $Ja_v/Pr_v=0.6$. Finally, the effect of heater orientation is investigated by considering three different values of

$Ja_v/Pr_v=0.6$. Finally, the effect of heater orientation is investigated by considering three different values of ![]() $\theta$, viz.,

$\theta$, viz., ![]() $30^{\circ }, 60^{\circ }$ and

$30^{\circ }, 60^{\circ }$ and ![]() $90^{\circ }$ corresponding to each heater aspect ratio. This set of simulations is extended to two levels of wall superheat,

$90^{\circ }$ corresponding to each heater aspect ratio. This set of simulations is extended to two levels of wall superheat, ![]() $Ja_v/Pr_v=0.6$ and 1.2, and different

$Ja_v/Pr_v=0.6$ and 1.2, and different ![]() $Re_l$ values in the range 10–170. All the cases specified above have been investigated for both upward and horizontal cross-flow of saturated liquid. This results in a total of 118 simulations as a part of this study while a comparison with circular heater geometry (

$Re_l$ values in the range 10–170. All the cases specified above have been investigated for both upward and horizontal cross-flow of saturated liquid. This results in a total of 118 simulations as a part of this study while a comparison with circular heater geometry (![]() $\varGamma = 1$) (Singh & Premachandran Reference Singh and Premachandran2018b, Reference Singh and Premachandran2019) under similar conditions is also included in the analysis.

$\varGamma = 1$) (Singh & Premachandran Reference Singh and Premachandran2018b, Reference Singh and Premachandran2019) under similar conditions is also included in the analysis.

An important part of the present study is the quantification of heat transfer, which is done in terms of the Nusselt number. The local Nusselt number (![]() $Nu$) is calculated using the temperature gradient normal to the heater wall as

$Nu$) is calculated using the temperature gradient normal to the heater wall as

The space-averaged Nusselt number (![]() $\overline {Nu}$) is calculated by integrating the local

$\overline {Nu}$) is calculated by integrating the local ![]() $Nu$ values over the surface of the elliptical cylinder as

$Nu$ values over the surface of the elliptical cylinder as

The time–space averaged Nusselt number (![]() $\overline {Nu_T}$), referred to simply as the time-averaged Nusselt number in the subsequent text, is calculated by averaging over a time period

$\overline {Nu_T}$), referred to simply as the time-averaged Nusselt number in the subsequent text, is calculated by averaging over a time period ![]() $T$ as

$T$ as

2.2.3. Validation of the numerical model

The present numerical framework based on the CLSVOF interface capturing method has been extensively validated qualitatively as well as quantitatively in an earlier work (Singh & Premachandran Reference Singh and Premachandran2018a) for both structured and unstructured grids. A number of standard advection test cases, two-phase flow problems and phase change problems including film boiling and condensation were considered to establish the accuracy of interface advection and reconstruction, surface tension and phase change calculations.

Subsequently, the numerical solver has been employed to study the mixed regime of film boiling over a circular heater geometry with upward and horizontal cross-flow (Singh & Premachandran Reference Singh and Premachandran2018b, Reference Singh and Premachandran2019) configurations, and a comprehensive heat transfer model has been developed based on the simulation results. The model predictions have further been compared with some of the available empirical data in the mixed regime of saturated film boiling for upward cross-flow corresponding to benzene at atmospheric conditions (Bromley et al. Reference Bromley, LeRoy and Robbers1953) and water at 294 kPa (Liu & Fukuda Reference Liu and Fukuda2008). The values of ![]() $D/\lambda _o$ for the two sets of data are calculated as 6.05 and 2.1, respectively. The comparison is presented in table 3 showing a deviation within

$D/\lambda _o$ for the two sets of data are calculated as 6.05 and 2.1, respectively. The comparison is presented in table 3 showing a deviation within ![]() ${\pm }10\,\%$ in most of the cases, which is an excellent agreement for boiling data. It can be noted that the convective heat transfer has been compared in table 3 with the property values calculated at the average film temperature to match the experimental conditions. At the same time, the interfacial dynamics has not been presented in the aforementioned empirical studies. With regard to horizontal cross-flow configuration, it was shown by means of a reduction factor that for conditions approaching natural convection or purely inertial film boiling regime the results were similar to the established results for upward cross-flow, thereby enforcing the validity of the simulations. Additionally the present solver has been used to obtain important results for a wavy horizontal heater (Singh & Premachandran Reference Singh and Premachandran2020), where validation against an available Nusselt number correlation for a flat heater has been presented. For the present problem, while a direct comparison is limited by the availability of empirical data for film boiling over an ellipse in the mixed regime, to the best of authors’ knowledge, the above discussion lends substantial credence to the use of the present numerical method to perform the simulations.

${\pm }10\,\%$ in most of the cases, which is an excellent agreement for boiling data. It can be noted that the convective heat transfer has been compared in table 3 with the property values calculated at the average film temperature to match the experimental conditions. At the same time, the interfacial dynamics has not been presented in the aforementioned empirical studies. With regard to horizontal cross-flow configuration, it was shown by means of a reduction factor that for conditions approaching natural convection or purely inertial film boiling regime the results were similar to the established results for upward cross-flow, thereby enforcing the validity of the simulations. Additionally the present solver has been used to obtain important results for a wavy horizontal heater (Singh & Premachandran Reference Singh and Premachandran2020), where validation against an available Nusselt number correlation for a flat heater has been presented. For the present problem, while a direct comparison is limited by the availability of empirical data for film boiling over an ellipse in the mixed regime, to the best of authors’ knowledge, the above discussion lends substantial credence to the use of the present numerical method to perform the simulations.

Table 3. Comparison of heat transfer predictions in upward cross-flow (![]() $\varGamma =1$; Singh & Premachandran (Reference Singh and Premachandran2018b)) obtained using the present numerical method with the literature for different conditions in the mixed regime.

$\varGamma =1$; Singh & Premachandran (Reference Singh and Premachandran2018b)) obtained using the present numerical method with the literature for different conditions in the mixed regime.

2.2.4. Grid convergence study

The computational domain in the present simulations is discretized using quadrangular cells, and the grid layout is depicted in figure 3(![]() $a$) for upward cross-flow configuration. A non-uniform mesh is used to achieve the desired level of refinement in different parts of the domain such as near the heater wall and downstream of the heater. A similar mesh layout is also employed in the domain for horizontal cross-flow, with the mesh also refined diagonally across the domain where the vapour is expected to move with orthogonal flow and gravity fields. The grid size is finest adjacent to the elliptical heater to capture the thin vapour film as can be seen in the close-up view shown in figure 3(

$a$) for upward cross-flow configuration. A non-uniform mesh is used to achieve the desired level of refinement in different parts of the domain such as near the heater wall and downstream of the heater. A similar mesh layout is also employed in the domain for horizontal cross-flow, with the mesh also refined diagonally across the domain where the vapour is expected to move with orthogonal flow and gravity fields. The grid size is finest adjacent to the elliptical heater to capture the thin vapour film as can be seen in the close-up view shown in figure 3(![]() $b$). Further, the grid is stretched along the major axis to accommodate a decrease in the aspect ratio of the ellipse for different simulations.

$b$). Further, the grid is stretched along the major axis to accommodate a decrease in the aspect ratio of the ellipse for different simulations.

Figure 3. Finite volume mesh used for the computations (shown here for upward cross-flow): (![]() $a$) full domain and (

$a$) full domain and (![]() $b$) close-up view near the elliptical cylinder.

$b$) close-up view near the elliptical cylinder.

The grid convergence for mixed regime of film boiling over a circular cylinder (![]() $\varGamma =1$) has been presented in previous studies by the present authors (Singh & Premachandran Reference Singh and Premachandran2018b, Reference Singh and Premachandran2019). Nonetheless, it is established for the elliptical geometry by considering three different meshes, as presented here for upward cross-flow. The relevant details such as number of cells in the entire domain (

$\varGamma =1$) has been presented in previous studies by the present authors (Singh & Premachandran Reference Singh and Premachandran2018b, Reference Singh and Premachandran2019). Nonetheless, it is established for the elliptical geometry by considering three different meshes, as presented here for upward cross-flow. The relevant details such as number of cells in the entire domain (![]() $N_{cell}$) and on the ellipse surface (

$N_{cell}$) and on the ellipse surface (![]() $E_{cell}$) are presented in table 3. While there is grid stretching along the major axis, the grid size adjacent to the heater wall for the three meshes is maintained to be nearly 0.02, 0.01 and 0.005 times the minor axis, respectively, as listed in table 4. Corresponding to

$E_{cell}$) are presented in table 3. While there is grid stretching along the major axis, the grid size adjacent to the heater wall for the three meshes is maintained to be nearly 0.02, 0.01 and 0.005 times the minor axis, respectively, as listed in table 4. Corresponding to ![]() $\varGamma =0.6$,

$\varGamma =0.6$, ![]() $\theta =0^{\circ }$ and

$\theta =0^{\circ }$ and ![]() $Ja_v/Pr_v=0.6$, the time-averaged Nusselt number (

$Ja_v/Pr_v=0.6$, the time-averaged Nusselt number (![]() $\overline {Nu_T}$) values obtained with each mesh for two different

$\overline {Nu_T}$) values obtained with each mesh for two different ![]() $Re_l$ values, viz., 50 and 170 are included in table 4, while the time period of the periodic ebullition cycle (

$Re_l$ values, viz., 50 and 170 are included in table 4, while the time period of the periodic ebullition cycle (![]() $t_c$) is also listed alongside for

$t_c$) is also listed alongside for ![]() $Re_l=50$. Additionally, for both values of

$Re_l=50$. Additionally, for both values of ![]() $Re_l$, the interface morphology at

$Re_l$, the interface morphology at ![]() $t=0.125\ \textrm {s}$ is compared with regard to different grids in figure 4. From these results, it can be inferred that the mesh M2 presents an optimum resolution with regard to computational cost and grid independence, which is selected for the subsequent computations. For horizontal cross-flow, a mesh with

$t=0.125\ \textrm {s}$ is compared with regard to different grids in figure 4. From these results, it can be inferred that the mesh M2 presents an optimum resolution with regard to computational cost and grid independence, which is selected for the subsequent computations. For horizontal cross-flow, a mesh with ![]() $N_{cell}=74\,265$ and

$N_{cell}=74\,265$ and ![]() $E_{cell}=228$ is suitably employed for the simulations. Concomitantly, it is confirmed that the mesh selected for each flow configuration is able to resolve the thin vapour film near the heater wall for the various cases considered in the present study.

$E_{cell}=228$ is suitably employed for the simulations. Concomitantly, it is confirmed that the mesh selected for each flow configuration is able to resolve the thin vapour film near the heater wall for the various cases considered in the present study.

Figure 4. Interface morphology obtained with upward liquid cross-flow at time ![]() $t = 0.125\ \textrm {s}$ corresponding to different grids and parameters mentioned in table 3: (

$t = 0.125\ \textrm {s}$ corresponding to different grids and parameters mentioned in table 3: (![]() $a$)

$a$) ![]() $Re_l=50$ and (

$Re_l=50$ and (![]() $b$)

$b$) ![]() $Re_l=170$.

$Re_l=170$.

Table 4. Grid independence study (upward cross-flow, ![]() $\varGamma =0.6$,

$\varGamma =0.6$, ![]() $\theta =0^{\circ }$,

$\theta =0^{\circ }$, ![]() $Ja_v/Pr_v=0.6$).

$Ja_v/Pr_v=0.6$).

3. Results and discussion

With a careful choice of different parameters that are coupled on account of fluid properties, flow velocity and elliptical heater geometry, mixed regime of film boiling is ascertained in the present computations entailing a significant effect of buoyancy in addition to flow inertia. With regard to interface evolution and heat transfer as influenced by various hydrodynamic, thermal and geometric parameters, a detailed investigation is presented in §§ 3.1–3.3, considering aiding as well as orthogonal configurations of gravity and flow fields under saturation conditions. Subsequently, the vapour and liquid wake dynamics is discussed in § 3.4 while highlighting their mutual interaction. Finally, a shape factor (![]() $\psi$) based on the geometrical parameters of the elliptical heater is conceived and determined in § 3.5 to correlate the heat transfer quantified through the present simulations.

$\psi$) based on the geometrical parameters of the elliptical heater is conceived and determined in § 3.5 to correlate the heat transfer quantified through the present simulations.

3.1. Effect of liquid cross-flow velocity, orientation and wall superheat

Four different values of ![]() $Re_l$, viz., 10, 50, 100 and 170 are considered to study the effect of free stream velocity in both upward and horizontal cross-flow of saturated liquid. The major axis of the elliptical heater is aligned to the flow direction (

$Re_l$, viz., 10, 50, 100 and 170 are considered to study the effect of free stream velocity in both upward and horizontal cross-flow of saturated liquid. The major axis of the elliptical heater is aligned to the flow direction (![]() $\theta =0^{\circ }$) in these simulations while the aspect ratio is fixed as

$\theta =0^{\circ }$) in these simulations while the aspect ratio is fixed as ![]() $\varGamma =0.6$. Correspondingly, the square root of the Froude number is calculated as 0.12, 0.6, 1.2 and 2.04, respectively, for different

$\varGamma =0.6$. Correspondingly, the square root of the Froude number is calculated as 0.12, 0.6, 1.2 and 2.04, respectively, for different ![]() $Re_l$ that signifies a successively growing influence of flow inertia. The non-dimensional wall superheat,

$Re_l$ that signifies a successively growing influence of flow inertia. The non-dimensional wall superheat, ![]() $Ja_v/Pr_v$ , is varied from 0.3 to 1.2 at each

$Ja_v/Pr_v$ , is varied from 0.3 to 1.2 at each ![]() $Re_l$, and is an important parameter affecting the interfacial dynamics by controlling the rate of vapour generation that is subsequently infused into the vapour wake.

$Re_l$, and is an important parameter affecting the interfacial dynamics by controlling the rate of vapour generation that is subsequently infused into the vapour wake.

The effect of different upward cross-flow velocities on the interface evolution at ![]() $Ja_v/Pr_v=0.6$ is presented in figure 5. A periodic ebullition is observed at

$Ja_v/Pr_v=0.6$ is presented in figure 5. A periodic ebullition is observed at ![]() $Re_l=10$ as shown in figure 5(

$Re_l=10$ as shown in figure 5(![]() $a$), involving various stages such as bubble growth at the top of the heater, necking and pinch-off, recoil of the remaining vapour mass, and subsequent undulations leading to the next bubble formation and release cycle. Such a quasi-steady nature is characteristic of natural convection film boiling where bubble removal is governed by Rayleigh–Taylor instability. This is expected to be the case with a dominant effect of buoyancy at a low value of Fr. A similar interface evolution is also seen at

$a$), involving various stages such as bubble growth at the top of the heater, necking and pinch-off, recoil of the remaining vapour mass, and subsequent undulations leading to the next bubble formation and release cycle. Such a quasi-steady nature is characteristic of natural convection film boiling where bubble removal is governed by Rayleigh–Taylor instability. This is expected to be the case with a dominant effect of buoyancy at a low value of Fr. A similar interface evolution is also seen at ![]() $Re_l=50$ from figure 5(

$Re_l=50$ from figure 5(![]() $b$). However, an increase in the bubble release frequency is observed that indicates an additional effect of flow inertia on vapour removal, although being quite subtle with respect to the interface morphology. At

$b$). However, an increase in the bubble release frequency is observed that indicates an additional effect of flow inertia on vapour removal, although being quite subtle with respect to the interface morphology. At ![]() $Re_l=100$, the influence of inertia becomes more prominent with the vapour wake dynamics visibly affected by the liquid flow, as shown in figure 5(

$Re_l=100$, the influence of inertia becomes more prominent with the vapour wake dynamics visibly affected by the liquid flow, as shown in figure 5(![]() $c$). A combined effect of inertia and buoyancy results in a larger pinch-off distance (

$c$). A combined effect of inertia and buoyancy results in a larger pinch-off distance (![]() $t=0.74\ \textrm {s}$) along with a thinner film at the bottom of the cylinder. Further, a loss of the periodic nature of film boiling can be seen accompanied by a random detachment of bubbles from the vapour wake. Upon further increase in flow velocity at

$t=0.74\ \textrm {s}$) along with a thinner film at the bottom of the cylinder. Further, a loss of the periodic nature of film boiling can be seen accompanied by a random detachment of bubbles from the vapour wake. Upon further increase in flow velocity at ![]() $Re_l=170$, a thin film is wrapped around the bottom half of the cylinder, and a steady and thick vapour wake along with a trailing column is formed behind the elliptical cylinder. Further, small bubbles are observed to release from the top of the vapour mass. While such a steady interface morphology indicates a suppression of vortex shedding at the

$Re_l=170$, a thin film is wrapped around the bottom half of the cylinder, and a steady and thick vapour wake along with a trailing column is formed behind the elliptical cylinder. Further, small bubbles are observed to release from the top of the vapour mass. While such a steady interface morphology indicates a suppression of vortex shedding at the ![]() $Re_l$ value under consideration, it is also inherently different from that observed for a circular cylinder (

$Re_l$ value under consideration, it is also inherently different from that observed for a circular cylinder (![]() $\varGamma =1$) under similar conditions (Singh & Premachandran Reference Singh and Premachandran2018b). This shows the effect of elliptical geometry in the present configuration on vapour removal in terms of accentuating the rate at which kinetic energy of the vapour is carried into the wake.

$\varGamma =1$) under similar conditions (Singh & Premachandran Reference Singh and Premachandran2018b). This shows the effect of elliptical geometry in the present configuration on vapour removal in terms of accentuating the rate at which kinetic energy of the vapour is carried into the wake.

Figure 5. Interface evolution with different upward liquid cross-flow velocities over an elliptical cylinder ![]() $(b / \lambda _o = 0.5,\varGamma =0.6)$ for water

$(b / \lambda _o = 0.5,\varGamma =0.6)$ for water ![]() $(p / p_c = 0.99)$ at

$(p / p_c = 0.99)$ at ![]() $Ja_v / Pr_v = 0.6$ and

$Ja_v / Pr_v = 0.6$ and ![]() $\theta =0^{\circ }$: (

$\theta =0^{\circ }$: (![]() $a$)

$a$) ![]() $Re_l = 10$ (

$Re_l = 10$ (![]() $\sqrt {Fr} = 0.12$), (

$\sqrt {Fr} = 0.12$), (![]() $b$)

$b$) ![]() $Re_l = 50$ (

$Re_l = 50$ (![]() $\sqrt {Fr}= 0.6$), (

$\sqrt {Fr}= 0.6$), (![]() $c$)

$c$) ![]() $Re_l = 100$ (

$Re_l = 100$ (![]() $\sqrt {Fr}=1.2$) and (

$\sqrt {Fr}=1.2$) and (![]() $d$)

$d$) ![]() $Re_l = 170$ (

$Re_l = 170$ (![]() $\sqrt {Fr} = 2.04$).

$\sqrt {Fr} = 2.04$).

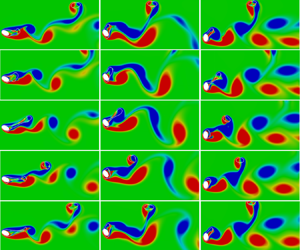

Figure 6 shows the effect of free stream velocity on interface evolution in horizontal cross-flow at ![]() $Ja_v/Pr_v =0.6$. From figure 6(

$Ja_v/Pr_v =0.6$. From figure 6(![]() $a$) at

$a$) at ![]() $Re_l=10$, similar phases of interface evolution are observed as for upward cross-flow with buoyancy predominantly determining the vapour morphology. However, a much thicker film can be seen in the bottom portion of the cylinder, which can be attributed to a constriction in the vapour removal due to buoyancy, and is discussed in § 3.2. This also leads to a much lower bubble release frequency compared with upward flow orientation. Nonetheless, the voluminous vapour mass at the top of the elliptical heater is observed to be slightly deflected sideways even with a minimal effect of liquid flow. At

$Re_l=10$, similar phases of interface evolution are observed as for upward cross-flow with buoyancy predominantly determining the vapour morphology. However, a much thicker film can be seen in the bottom portion of the cylinder, which can be attributed to a constriction in the vapour removal due to buoyancy, and is discussed in § 3.2. This also leads to a much lower bubble release frequency compared with upward flow orientation. Nonetheless, the voluminous vapour mass at the top of the elliptical heater is observed to be slightly deflected sideways even with a minimal effect of liquid flow. At ![]() $Re_l=50$, the effect of flow inertia can be clearly visualized from figure 6(

$Re_l=50$, the effect of flow inertia can be clearly visualized from figure 6(![]() $b$) with the bubbles releasing from the top right-hand portion of the heater at a higher frequency, while the role of buoyancy is verified from the periodic nature of ebullition. Such a competing effect of inertia and buoyancy causes a recirculation in the vapour film leading to a vapour bulge at the bottom of the heater, as analysed in an earlier study for

$b$) with the bubbles releasing from the top right-hand portion of the heater at a higher frequency, while the role of buoyancy is verified from the periodic nature of ebullition. Such a competing effect of inertia and buoyancy causes a recirculation in the vapour film leading to a vapour bulge at the bottom of the heater, as analysed in an earlier study for ![]() $\varGamma =1$ (Singh & Premachandran Reference Singh and Premachandran2019). However, with the present aspect ratio of 0.6, the bulge is more prominent as compared with a circular cylinder due to the ellipse orientation blocking vapour passage against a significant influence of buoyancy at

$\varGamma =1$ (Singh & Premachandran Reference Singh and Premachandran2019). However, with the present aspect ratio of 0.6, the bulge is more prominent as compared with a circular cylinder due to the ellipse orientation blocking vapour passage against a significant influence of buoyancy at ![]() $\sqrt {Fr}=0.6$. At

$\sqrt {Fr}=0.6$. At ![]() $Re_l=100$, the vapour wake shifts entirely to the rear of the elliptical cylinder as shown in figure 6(

$Re_l=100$, the vapour wake shifts entirely to the rear of the elliptical cylinder as shown in figure 6(![]() $c$). While the vapour wake shows a slight tendency to rise even with a weak effect of gravity, the overall vapour morphology along with a random detachment of bubbles from the tail end of the wake indicates that the aperiodic interface evolution is primarily governed by flow inertia in contrast to Rayleigh–Taylor instability at lower velocities. Upon further increase in cross-flow velocity, it is seen from figure 6(

$c$). While the vapour wake shows a slight tendency to rise even with a weak effect of gravity, the overall vapour morphology along with a random detachment of bubbles from the tail end of the wake indicates that the aperiodic interface evolution is primarily governed by flow inertia in contrast to Rayleigh–Taylor instability at lower velocities. Upon further increase in cross-flow velocity, it is seen from figure 6(![]() $d$) at

$d$) at ![]() $Re_l=170$ that the vapour wake is again formed at the cylinder rear with the front stagnation region covered with a thin and steady film. However, an interesting build-up of the instability is observed in distinct phases, as also marked in Figure 6(