1. Introduction

Combustion in high-mass-flux chambers is the practical and major method for energy conversion for mechanical power and heating. Inherently, the high mass-flow rate leads to turbulent flow. Thereby, many length and time scales appear in the physics, making serious challenges for both computational and experimental analyses. For computations where the smallest scales typically cannot be resolved, the method of large-eddy simulation (LES) is employed wherein the smaller scales are filtered via integration over a window size commensurate with the computational mesh size that allows affordable computations. Consequently, the essential, rate-controlling, physical and chemical processes that occur on shorter scales than the filter size must be modelled. Those subgrid models must be properly coupled to the resolved LES flow field.

Current flamelet models that are used for LES or Reynolds-averaged Navier–Stokes (RANS) methods have some advantages. Typically, the flamelet equations are a system of ordinary differential equations (ODEs) that can be solved offline with solutions available in tabular form or through neural networks. The flamelet models can handle multi-species, multi-step oxidation kinetics without requiring small time steps during the solution of the resolved-scale fluid dynamics. Thus, for several reasons, savings of computational resources can be huge compared with direct numerical simulation. We aim here to retain these very attractive features while removing some less desirable features. Already, some progress has been made in extending the fundamental flamelet theory beyond its long-term limitation of a single-flame structure, two-dimensional (or axisymmetric) configuration and use of the uniform-density assumption. However, those advances still must be applied to LES or RANS. In addition, the flamelet theory must be advanced to consider shear strain and vorticity at the small scale of the flamelet; these are the vital forgotten physics in current flamelet modelling. Furthermore, the strain rates in the flamelet model are far from properly connected to the strain rates at the resolved scale. Attempts at corrections of these weaknesses are made here.

The focus here is on the types of turbulent flames found in the shear-driven flows of practical combustors. Thereby, we address flamelets as originally described by Williams (Reference Williams1975), namely ‘highly sheared small diffusion flamelets’ and ‘forming a turbulent flame brush which appears on the average to fill’ the flow domain. Our discussion will not cover some interesting work on corrugated or wrinkled flames. The goals in this paper are to improve the flamelet model by including several important physical effects that are commonly neglected in present models and to identify other issues, related to the coupling between the subgrid-scale physics and the resolved-scale (or time-averaged) physics, that require further study.

1.1. Existing flamelet theory

There is need to understand the laminar mixing and combustion that commonly occur within the smallest turbulent eddies. These laminar flamelet subdomains experience significant strain of all types: shear, tensile and compressive. Some important works exist here but typically for either counterflows with only normal strain or simple vortex structures in two dimensions or axisymmetry and often with a constant-density approximation; see Linan (Reference Linan1974), Marble (Reference Marble1985), Karagozian & Marble (Reference Karagozian and Marble1986), Cetegen & Sirignano (Reference Cetegen and Sirignano1988), Cetegen & Sirignano (Reference Cetegen and Sirignano1990), Peters (Reference Peters2000) and Pierce & Moin (Reference Pierce and Moin2004). Linan and Peters focused on the counterflow configuration. Williams (Reference Williams1975) first established the concept of laminar flamelets in a turbulent diffusion flame structure. Karagozian and Marble examined a three-dimensional flow with radial inward velocity, axial jetting and a vortex centred on the axis. The flame sheet wrapped around the axis due to the vorticity. An interesting review of the early flamelet theory is given by Williams (Reference Williams2000). Generally, flamelet studies have focused on either premixed or non-premixed flames; a unifying approach to premixed, non-premixed and multi-branched flames has not been developed. That unifying approach is taken here.

Most flamelet studies have not directly considered vorticity interaction with the flamelet; see, for example, Linan (Reference Linan1974), Peters (Reference Peters2000), Williams (Reference Williams2000) and Pierce & Moin (Reference Pierce and Moin2004). Mueller (Reference Mueller2020) presented the flamelet model in a somewhat different mathematical framework but without the addition of new physical description. Williams (Reference Williams1975) first recognized the advantage of separating rotation (due to vorticity) and stretching by transformation to a rotating, non-Newtonian reference frame. He did not, however, examine the momentum consequences in the new reference frame which will be examined later here. The other works that have examined vortex–flame interaction have not separated the effects of stretching and rotation; see Marble (Reference Marble1985), Karagozian & Marble (Reference Karagozian and Marble1986), Cetegen & Sirignano (Reference Cetegen and Sirignano1988), Cetegen & Sirignano (Reference Cetegen and Sirignano1990) and Meneveau & Poinsot (Reference Meneveau and Poinsot1991).

Again, with the above-mentioned emphasis on turbulent flames in shear-driven flows as defined by Williams (Reference Williams1975), some interesting work on corrugated or wrinkled premixed laminar flames is not detailed here. The reader is guided to Swaminathan & Grout (Reference Swaminathan and Grout2006), Steinberg & Driscoll (Reference Steinberg and Driscoll2009), Chakraborty & Swaminathan (Reference Chakraborty and Swaminathan2007) and Mura & Champion (Reference Mura and Champion2009) for examples of those studies.

The two-dimensional planar or axisymmetric counterflow configuration has become a foundation for the flamelet model. Local conversion to a coordinate system based on the principal strain-rate directions can provide the counterflow configuration in a general flow. Furthermore, the quasi-steady counterflow can be analysed by ODEs because the dependence on the transverse coordinate is either constant or linear, depending on the variable. Pierce and Moin modified the non-premixed flamelet counterflow configuration by fixing domain size and forcing flux to zero at the boundaries. Flamelet theory as a closure model for turbulent combustion is typically based on the tracking of two variables: a normalized conserved scalar and the strain rate. The latter is generally given indirectly through a progress variable. Mixture fraction is traditionally used for the conserved scalar.

The flamelet model has become a popular subgrid model for gas-fuelled combustors. Some development is also underway for the use of flamelets in spray combustion, but here we focus on the former type. The flamelet model for LES developed by Pierce & Moin (Reference Pierce and Moin2004) was a substantial advancement through the introduction of the flamelet progress variable (FPV). Their approach has also been used by Ihme, Schmitt & Pitsch (Reference Ihme, Schmitt and Pitsch2009), Nguyen, Popov & Sirignano (Reference Nguyen, Popov and Sirignano2018), Nguyen & Sirignano (Reference Nguyen and Sirignano2018, Reference Nguyen and Sirignano2019) and others. Other works are based on the use of the original form developed by Peters (Reference Peters2000). Pierce and Moin extended that work in two ways. Firstly, the inclusion of both the upper and middle branches of the curve of flame temperature versus scalar dissipation rate allowed better representation of the unsteady details in turbulent combustion such as extinction and reignition. Secondly, they created a progress variable as a function (of the scalar dissipation rate) which is governed by a partial differential equation (added to the LES equations) with a chemical-rate source term determined through the flamelet model. Nguyen & Sirignano (Reference Nguyen and Sirignano2018) found that the inclusion of both branches for flame stability resulted in better agreement with experiment. Note that Nguyen & Sirignano (Reference Nguyen and Sirignano2018) addressed rocket combustion instability which places a greater demand on the flamelet model than most other applications. In addition to the velocity fluctuations due to turbulence, it becomes necessary to address very large fluctuations in velocity, pressure and temperature due to the nonlinear acoustics.

There are concerns with the existing model. While there is clear utility for the FPV approach, there are concurrently clear signs of incompleteness in the flamelet model and contradiction between the tenets of the model and the LES results produced with the model. A few examples of problems that require resolution are provided here. Firstly, the design of the flamelet model uses a counterflow configuration where only normal strain is imposed on the flame region by the ambient flow. Yet, the LES results show that the flame is embedded in a flow field with substantial shear strain rate, i.e. a flow with vorticity. Secondly, the current models assume that the inflowing streams in the counterflow are irrotational; yet, we know that the smaller scales in turbulent combustion are highly rotational. Thirdly, the classical flamelet model is two-dimensional (or axisymmetric) whereas it has been used in flows that are clearly three-dimensional. The model considers only a single-branched diffusion flame while its coupled use in LES commonly predicts multi-branched flames in qualitative agreement with experimental evidence. A fourth issue involves the quasi-steady assumption for the flamelet model that is used in a highly unsteady LES flow with a broadband noise.

These models are built around the postulate that the flamelets are always non-premixed (i.e. diffusion) flames or premixed flames. However, evidence of both non-premixed and premixed flames has been found in LES and experimental results. In fact, they can coexist in a multi-branched structure. Nguyen et al. (Reference Nguyen, Popov and Sirignano2018) and Nguyen & Sirignano (Reference Nguyen and Sirignano2018, Reference Nguyen and Sirignano2019) employed the Pierce & Moin (Reference Pierce and Moin2004) flamelet approach in the simulation of a single-injector rocket engine. They showed the importance of flamelets subject to high strain rates. However, contradictions occurred in that both premixed flames and non-premixed flames appeared in the predictions. In fact, they report multi-branched flames; in particular, the combination is often seen of a fuel-lean premixed flame branch with a branch consisting of a merged diffusion flame and fuel-rich premixed flame.

Note that the mixture fraction has been used widely as an independent variable to display non-premixed flamelet scalar variations; this cannot be useful for premixed flames. Sirignano (Reference Sirignano2021a) has shown that any conserved scalar can serve well as an independent variable to present scalar results for non-premixed and multi-branched flamelets.

Experiments and asymptotic analysis by Hamins, Thridandam & Seshadri (Reference Hamins, Thridandam and Seshadri1985) showed that a partially premixed fuel-lean flame and a diffusion flame can coexist in a counterflow with opposing streams of heptane vapour and methane–oxygen–nitrogen mixture. Thus, a need exists for flamelet theory to address both premixed and non-premixed flames. Recently, Rajamanickam et al. (Reference Rajamanickam, Coenen, Sanchez and Williams2019) provided an interesting three-dimensional triple-flame analysis, describing the effect of imposed normal strain on a multi-branched flame. While it did not consider shear strain, it was a helpful step followed by the work of Sirignano (Reference Sirignano2021c) where both shear strain and normal strain were considered.

The classical counterflow treatment by Linan (Reference Linan1974) and Peters (Reference Peters2000) has two opposing streams, fuel or fuel plus a chemically inert gas and oxidizer or oxidizer plus an inert gas. They considered uniform density. That critical assumption was relaxed by Sirignano (Reference Sirignano2019) for reacting flows and heated flows. Sirignano (Reference Sirignano2021a,Reference Sirignanoc) with one-step kinetics and López-Cámara, Jordà Juanós & Sirignano (Reference López-Cámara, Jordà Juanós and Sirignano2020) with detailed kinetics address that single diffusion flame case. In addition, situations are addressed where the inflowing streams from ![]() $y_{\infty }$ and

$y_{\infty }$ and ![]() $y_{-\infty }$ may consist of a combustible mixture of fuel and oxidizer, thereby allowing another flame or two besides the simple diffusion flame to coexist. Sirignano (Reference Sirignano2021a) provides a counterflow analysis with three-dimensional strain and shows the possibility for a variety of flame configurations to exist depending on the compositions of the inflowing streams: (i) three flames including fuel-lean partially premixed, non-premixed (i.e. diffusion-controlled) and fuel-rich partially premixed; (ii) non-premixed and fuel-rich partially premixed; (iii) fuel-lean partially premixed and non-premixed; (iv) non-premixed; and (v) premixed. López-Cámara et al. (Reference López-Cámara, Jordà Juanós and Sirignano2020) extended the counterflow analysis to consider detailed kinetics for methane–oxygen detailed chemical kinetics and confirmed that combinations of premixed and non-premixed flames could exist in a multi-flame counterflow.

$y_{-\infty }$ may consist of a combustible mixture of fuel and oxidizer, thereby allowing another flame or two besides the simple diffusion flame to coexist. Sirignano (Reference Sirignano2021a) provides a counterflow analysis with three-dimensional strain and shows the possibility for a variety of flame configurations to exist depending on the compositions of the inflowing streams: (i) three flames including fuel-lean partially premixed, non-premixed (i.e. diffusion-controlled) and fuel-rich partially premixed; (ii) non-premixed and fuel-rich partially premixed; (iii) fuel-lean partially premixed and non-premixed; (iv) non-premixed; and (v) premixed. López-Cámara et al. (Reference López-Cámara, Jordà Juanós and Sirignano2020) extended the counterflow analysis to consider detailed kinetics for methane–oxygen detailed chemical kinetics and confirmed that combinations of premixed and non-premixed flames could exist in a multi-flame counterflow.

1.2. Relative orientations of principal strain axes, vorticity and scalar gradients

Both normal strain rate and shear strain rate are important. There is a strong need to study mixing and combustion in three-dimensional flows with both imposed normal strain and shear strain and therein imposed vorticity with global circulation. Shear strain can, in general, be decomposed into a normal strain and a rotation (whose rate is half of the vorticity magnitude). For example, a rectangular shape that is changed by shear strain can be viewed as a combination of deformation to a parallelogram caused by normal strain perpendicular to the diagonal and rotation of the diagonal caused by vorticity. The behaviour due to the strain and rotation becomes especially important on the smallest scales of turbulence where mixing and chemical reaction occur. The magnitudes of strain rate and vorticity increase as the eddy size (or wavelength) decreases in the turbulence energy cascade process. The Kolmogorov scale size is determined by the dissipation rate of turbulence kinetic energy and dynamic viscosity and is the smallest turbulence length scale. The final molecular mixing and chemical reaction in the combustion process occur on a still smaller scale, where there will be an axis (or direction) of principal compressive normal strain and an orthogonal axis for principal tensile strain; the third orthogonal axis could be either tensile or compressive. These axes would rotate under shear strain (or equivalently vorticity). Similarly, the direction of the scalar gradient rotates under shear. A useful flamelet model must have a statistically accurate representation of the relative orientations on this smallest scale of the vorticity vector, scalar gradients and the directions of the three principal axes for strain rate. Several studies exist that are helpful in understanding this important alignment issue.

Generally and always for incompressible flow, one principal strain rate ![]() $\gamma$ locally will be compressive (corresponding to inflow in a counterflow configuration), another principal strain rate

$\gamma$ locally will be compressive (corresponding to inflow in a counterflow configuration), another principal strain rate ![]() $\alpha$ will be tensile (also named extensional and corresponding to outflow) and the third can be either extensional or compressive and will have an intermediate strain rate

$\alpha$ will be tensile (also named extensional and corresponding to outflow) and the third can be either extensional or compressive and will have an intermediate strain rate ![]() $\beta$ of lower magnitude than the other like strain rate. Specifically,

$\beta$ of lower magnitude than the other like strain rate. Specifically, ![]() $\alpha > \beta > \gamma, \;\alpha > 0 , \; \gamma <0$ and, for incompressible flow,

$\alpha > \beta > \gamma, \;\alpha > 0 , \; \gamma <0$ and, for incompressible flow, ![]() $\alpha + \beta + \gamma = 0$. If the intermediate strain rate

$\alpha + \beta + \gamma = 0$. If the intermediate strain rate ![]() $\beta < 0$, there is inflow from two directions with outflow in one direction; a contracting jet flow occurs locally. Conversely, with

$\beta < 0$, there is inflow from two directions with outflow in one direction; a contracting jet flow occurs locally. Conversely, with ![]() $\beta > 0$, there is outflow in two directions and inflow in one direction; a counterflow or, in other words, the head-on collision of two opposed jets occurs. Betchov (Reference Betchov1956) has shown that, for homogeneous, isotropic turbulence in an incompressible flow, the situation with

$\beta > 0$, there is outflow in two directions and inflow in one direction; a counterflow or, in other words, the head-on collision of two opposed jets occurs. Betchov (Reference Betchov1956) has shown that, for homogeneous, isotropic turbulence in an incompressible flow, the situation with ![]() $\beta > 0$ and resulting counterflow is the most important for production of vorticity and the turbulence energy cascade to smaller scales.

$\beta > 0$ and resulting counterflow is the most important for production of vorticity and the turbulence energy cascade to smaller scales.

Several interesting findings result from direct numerical simulations for incompressible flows. Both Ashurst et al. (Reference Ashurst, Kerstein, Kerr and Gibson1987) and Nomura & Elghobashi (Reference Nomura and Elghobashi1992) compared a case of homogeneous sheared turbulence with a case of isotropic turbulence. They report that the vorticity alignment with the intermediate strain direction is most probable in both cases but especially in the case with shear. Furthermore, the intermediate strain rate is most likely to be extensive (positive) implying a counterflow configuration. Dresselhaus & Tabor (Reference Dresselhaus and Tabor1991) use a kinematic approach to study the stretching of material and vorticity in a fluid flow and predict the tendency towards alignment of the intermediate strain direction with the vorticity. If the vorticity had strong alignment with the major compressive or major tensile strain direction, the magnitude of helicity, the dot product of velocity ![]() $\boldsymbol {u}$ and vorticity

$\boldsymbol {u}$ and vorticity ![]() $\boldsymbol {\omega }$, would be large. Kerr (Reference Kerr1987) reports that large values of helicity are not found in the turbulence cascade process. Ashurst et al. (Reference Ashurst, Kerstein, Kerr and Gibson1987) note further that the positive intermediate strain rate has a significantly smaller magnitude than either of the other two principal strain rates. Furthermore, the time for alignment of the vorticity with that intermediate direction is short compared to the eddy-turnover time.

$\boldsymbol {\omega }$, would be large. Kerr (Reference Kerr1987) reports that large values of helicity are not found in the turbulence cascade process. Ashurst et al. (Reference Ashurst, Kerstein, Kerr and Gibson1987) note further that the positive intermediate strain rate has a significantly smaller magnitude than either of the other two principal strain rates. Furthermore, the time for alignment of the vorticity with that intermediate direction is short compared to the eddy-turnover time.

Nomura & Elghobashi (Reference Nomura and Elghobashi1993) studied reacting flow and show that in regions of exothermic reaction and variable density, alignment of the vorticity with the most tensile strain direction can occur. Still though as the strain rates increase, the intermediate direction becomes more favoured for alignment with vorticity; that direction is also preferred in regions where mixing occurs without substantial divergence of the velocity due to chemical reaction.

We may also expect that a material interface most probably aligns to be normal to the direction of the compressive normal strain. That is, the scalar gradient and the direction of compressive strain are aligned; see Ashurst et al. (Reference Ashurst, Kerstein, Kerr and Gibson1987), Nomura & Elghobashi (Reference Nomura and Elghobashi1992), Nomura & Elghobashi (Reference Nomura and Elghobashi1993) and Boratav, Elghobashi & Zhong (Reference Boratav, Elghobashi and Zhong1996, Reference Boratav, Elghobashi and Zhong1998). Authors agree that the most common intermittent vortex structures in regions of high strain rate are sheets or ribbons rather than tubes.

An important issue for flamelet modelling is the relative magnitudes of the vorticity and the rates of principal normal strain. For homogeneous, incompressible turbulence, Betchov (Reference Betchov1956) showed that, for the average across all length scales, these quantities are of the same order of magnitude. Of course, the smallest scales contribute more to the average since the velocity derivatives are larger on those scales. Also, for shear flows, we expect that the turbulence at the smaller scales will be isotropic and behave more like the homogeneous flow. In our analysis for variable-density, reacting shear flows, we assume the same order-of-magnitude similarity between vorticity and the rates of principal normal strain applies for the smallest scales.

Based on those understandings concerning vector orientations, Sirignano (Reference Sirignano2021c) extended flamelet theory in a second significant aspect beyond the inclusion of both premixed and non-premixed flame structures; namely, a model was created of a three-dimensional field with both shear and normal strains. The three-dimensional problem is reduced to a two-dimensional form and then, for the counterflow or mixing-layer flow, to a one-dimensional similar form. The system of ODEs is presented for the thermochemical variables and the velocity components. Conserved scalars are determined and can become the independent variable if they behave in a monotonic fashion. Sirignano (Reference Sirignano2021c) also was able to use a velocity component as the independent variable for the flamelet model with shear strain and vorticity. The validity of the similar solution form for mixing layers with certain thin reaction zones was discussed using concepts from singular perturbation theory. The chemical-kinetic model appears as a source term for an ODE. These new findings are very helpful in improving the foundations for flamelet theory and its use in subgrid modelling for turbulent combustion. Still, however, there has not been a flamelet model that connects well the scales on the resolved LES level to the subgrid scales at the level of the flame structure.

Based on the observations of the needed improvements, the aim here is to develop a flamelet model that (i) determines rather than prescribes the existence of non-premixed flames, premixed flames or multi-branched flame structures; (ii) determines directly the effect of shear strain and vorticity on the flames; (iii) applies directly the resolved-scale strain rates and vorticity to the subgrid level without the use of a contrived progress variable; (iv) employs a three-dimensional flamelet model; and (v) considers the effect of variable density. Furthermore, some discussion and primitive analysis of the in situ function of the flamelet model in a turbulent shear flow is presented. The analysis uses one-step kinetics to avoid complications in this initial study; however, a clear template will exist for the employment of multi-step kinetics. The choice for the in situ study will be a mixing layer with the use of mixing-length theory. Here, the goal is not to advance the portion of the analysis for the resolved scale; rather, the coupling with the subgrid closure model will be made clear.

In § 2, the scaling and connections between the resolved shear flow and the flamelet behaviour on the subgrid scale are discussed. Section 3 has the description of a new subgrid flame model that better handles connection with strain and vorticity on the resolved scale, three-dimensional character and multi-branched flame structure. The application of the subgrid flamelet with a resolved shear flow is addressed in § 4. Concluding comments are made in § 5.

2. Scaling between flamelet scale and resolved scale

Current flamelet theory for use in LES or RANS makes no substantial attempt to scale properly between the small scale of the flamelet and the larger flow scales which pertain to the computational fluid dynamics analysis. A theoretical basis is needed to prescribe how to determine vorticity, strain rates and scalar gradients on the flamelet scale given those properties on the resolved scale. Certainly, as mentioned in § 1.2, a body of helpful literature exists on this subject; it is considered here. Specifically, we avoid the creation of arbitrary variables such as the FPV used in many publications. The FPV is actually not a good measure of progress. In order to relate increasing temperature during combustion to the flamelet theory, scalar dissipation rate is obliged to increase as the FPV increases. Instead, scalar dissipation rate on the flamelet scale should be related to temporally varying and spatially varying scalar and velocity gradients and not to temperature magnitude. The existing theory will not allow a hot gas to experience reductions in dissipation rates related to reductions in the values of velocity and scalar gradients which surely is not consistent with general flow patterns in turbulent combustors. Here, a new method is developed for determining burning rate from the flamelet theory and applying it to the resolved scale for LES or to the averaged flow field for RANS. During the burning process, temperature is able to increase even if strain rate and the associated scalar dissipation rate might be decreasing.

2.1. Scaling of velocity, strain rate and vorticity

Here, at first, we use approximate concepts which perhaps are reasonably well suited for a use of mixing-length theory to describe the time-averaged turbulent flow in a shear layer. The aim is to provide a simple framework for the first application and test of a new flamelet theory. More sophisticated and modern statistical approaches can be found (e.g. Pope Reference Pope2000), and can be used in the future for examination of turbulent flows using RANS or LES.

The shear-driven flow on the larger scale can be characterized by a length ![]() $\delta$ and a time-averaged velocity difference

$\delta$ and a time-averaged velocity difference ![]() $\Delta U$ across that particular length that ultimately relate to the magnitudes of the largest eddy size and the turbulence kinetic energy. Then, the velocity, length and time scales for the resolved scales are

$\Delta U$ across that particular length that ultimately relate to the magnitudes of the largest eddy size and the turbulence kinetic energy. Then, the velocity, length and time scales for the resolved scales are ![]() $\Delta U$,

$\Delta U$, ![]() $\delta$ and

$\delta$ and ![]() $\delta /\Delta U$, respectively. The root-mean-square velocity fluctuation

$\delta /\Delta U$, respectively. The root-mean-square velocity fluctuation ![]() $u'$, the turbulence kinetic energy

$u'$, the turbulence kinetic energy ![]() $k$ and the rate of dissipation of turbulence kinetic energy

$k$ and the rate of dissipation of turbulence kinetic energy ![]() $\epsilon$ will have magnitudes of the order of

$\epsilon$ will have magnitudes of the order of ![]() $\Delta U$,

$\Delta U$, ![]() $\Delta U^2$ and

$\Delta U^2$ and ![]() $\Delta U^3/\delta$, respectively. The Kolmogorov scale is the smallest scale in the turbulence energy cascade where the inertial and viscous effects balance each other (Pope Reference Pope2000; White Reference White2005). On that smallest scale, the characteristic velocity, length and time scales become

$\Delta U^3/\delta$, respectively. The Kolmogorov scale is the smallest scale in the turbulence energy cascade where the inertial and viscous effects balance each other (Pope Reference Pope2000; White Reference White2005). On that smallest scale, the characteristic velocity, length and time scales become ![]() $u_{\kappa } = (\nu \epsilon )^{1/4}$,

$u_{\kappa } = (\nu \epsilon )^{1/4}$, ![]() $\kappa = (\nu ^3/\epsilon )^{1/4}$ and

$\kappa = (\nu ^3/\epsilon )^{1/4}$ and ![]() $t_{\kappa } = (\nu / \epsilon )^{1/2},$ respectively, where

$t_{\kappa } = (\nu / \epsilon )^{1/2},$ respectively, where ![]() $\nu$ is the kinematic viscosity of the fluid. One can use these Kolmogorov scales to be the scales for flamelet analysis; a more refined approach might be to use the rate of dissipation for scalar quantities

$\nu$ is the kinematic viscosity of the fluid. One can use these Kolmogorov scales to be the scales for flamelet analysis; a more refined approach might be to use the rate of dissipation for scalar quantities ![]() $\epsilon _c$ discussed by Elghobashi & Launder (Reference Elghobashi and Launder1983) instead of

$\epsilon _c$ discussed by Elghobashi & Launder (Reference Elghobashi and Launder1983) instead of ![]() $\epsilon$.

$\epsilon$.

We estimate a Reynolds number for the resolved flow using ![]() $Re \equiv \Delta U \delta /\nu$. Vorticity, rate of normal strain and rate of shear strain will be

$Re \equiv \Delta U \delta /\nu$. Vorticity, rate of normal strain and rate of shear strain will be ![]() $O(\Delta U/\delta )$. We estimate the magnitudes of rate of strain and vorticity on the flamelet scale to be given as

$O(\Delta U/\delta )$. We estimate the magnitudes of rate of strain and vorticity on the flamelet scale to be given as

Clearly, for high ![]() $Re$ values, we may expect vorticity and rate of strain on the flamelet scale to be orders higher than found on the resolved scale. This scaling and the connection of the strain rates and vorticity on different scales have not been addressed in prior flamelet modelling.

$Re$ values, we may expect vorticity and rate of strain on the flamelet scale to be orders higher than found on the resolved scale. This scaling and the connection of the strain rates and vorticity on different scales have not been addressed in prior flamelet modelling.

Note that different estimates of a relevant resolved-scale or averaged-flow Reynolds number are used at later points in this discussion. The intention, however, is to maintain the same order of magnitude.

If we examine a time-averaged shear flow, the quantity ![]() $\Delta U/\delta$ can be replaced by the magnitude of a velocity gradient for the averaged flow treated through RANS simulations following a mixing-length concept. For LES, that quantity can be related to a velocity gradient on the smallest resolved scale, following an approach similar to the Smagorinsky model for Reynolds stress. Specifically,

$\Delta U/\delta$ can be replaced by the magnitude of a velocity gradient for the averaged flow treated through RANS simulations following a mixing-length concept. For LES, that quantity can be related to a velocity gradient on the smallest resolved scale, following an approach similar to the Smagorinsky model for Reynolds stress. Specifically,

$$\begin{gather} \frac{\Delta U}{\delta} \equiv \left|\frac{\partial u}{\partial x}\right| ; \quad Re \equiv \left|\frac{\partial u}{\partial x}\right| \frac{\delta^2}{\nu} ;\nonumber\\ \left|\frac{\partial u_{\kappa}}{\partial \kappa}\right| = \left|\frac{\partial u}{\partial x}\right|Re^{1/2} = \left|\frac{\partial u}{\partial x}\right|^{3/2}\frac{\delta}{\nu^{1/2}} = \frac{S_{rs}^{*3/2} \delta}{\nu^{1/2}}. \end{gather}$$

$$\begin{gather} \frac{\Delta U}{\delta} \equiv \left|\frac{\partial u}{\partial x}\right| ; \quad Re \equiv \left|\frac{\partial u}{\partial x}\right| \frac{\delta^2}{\nu} ;\nonumber\\ \left|\frac{\partial u_{\kappa}}{\partial \kappa}\right| = \left|\frac{\partial u}{\partial x}\right|Re^{1/2} = \left|\frac{\partial u}{\partial x}\right|^{3/2}\frac{\delta}{\nu^{1/2}} = \frac{S_{rs}^{*3/2} \delta}{\nu^{1/2}}. \end{gather}$$

Here, one can make a choice about the interpretation of the resolved scale strain rate ![]() $S^{*}_{rs} \equiv |\partial u / \partial x|$. The largest component of shear strain rate on the resolved scale or for the time-averaged flow is recommended for use. Strain rate

$S^{*}_{rs} \equiv |\partial u / \partial x|$. The largest component of shear strain rate on the resolved scale or for the time-averaged flow is recommended for use. Strain rate ![]() $S^{*}_{rs}$ can vary with location in the flow and, for unsteady RANS and LES, can vary with time as well. The quantity

$S^{*}_{rs}$ can vary with location in the flow and, for unsteady RANS and LES, can vary with time as well. The quantity ![]() $\partial u_{\kappa }/\partial \kappa$ will be imposed as the compressive normal strain rate in the flamelet model; it will be a negative number

$\partial u_{\kappa }/\partial \kappa$ will be imposed as the compressive normal strain rate in the flamelet model; it will be a negative number ![]() $-(S^*_1 + S^*_2)$. Thus, (2.2a–c) can relate the normal strain rate on the flamelet scale to the strain rate on the resolved scale or for the time-averaged flow. In the case with the two-equation RANS model using

$-(S^*_1 + S^*_2)$. Thus, (2.2a–c) can relate the normal strain rate on the flamelet scale to the strain rate on the resolved scale or for the time-averaged flow. In the case with the two-equation RANS model using ![]() $k, \epsilon$ theory, (2.1a,b) will yield

$k, \epsilon$ theory, (2.1a,b) will yield ![]() $S^* = (\epsilon / \delta ^2)^{1/3}$.

$S^* = (\epsilon / \delta ^2)^{1/3}$.

A relation must be created between the dimensional vorticity ![]() $\omega ^*$ on the resolved scale and the dimensional vorticity

$\omega ^*$ on the resolved scale and the dimensional vorticity ![]() $\omega ^*_{\kappa }$ on the flamelet subgrid scale. (Note that, in the development of the flamelet model, the subgrid

$\omega ^*_{\kappa }$ on the flamelet subgrid scale. (Note that, in the development of the flamelet model, the subgrid ![]() $\omega _{\kappa }$ is dimensionless.) A reasonable relationship, mimicking the strain rate relation, is given as

$\omega _{\kappa }$ is dimensionless.) A reasonable relationship, mimicking the strain rate relation, is given as ![]() $\omega ^*_{\kappa } = \omega ^{*3/2}\delta / \nu ^{1/2} = O(\omega ^* Re^{1/2}) \gg \omega ^*.$

$\omega ^*_{\kappa } = \omega ^{*3/2}\delta / \nu ^{1/2} = O(\omega ^* Re^{1/2}) \gg \omega ^*.$

2.2. Scaling of the scalar properties

The inflow boundary conditions for the scalar quantities in the flamelet calculation must be determined from the resolved scale behaviour. The scalar gradients are much larger on the flamelet scale due to the dynamics of the turbulent flow. As a first approximation, consider that the scalar gradients scale in proportion to the strain rates. For example, using the mass fraction of species ![]() $m$, we state the rough approximation:

$m$, we state the rough approximation:

\begin{equation} \frac{\dfrac{ \partial Y_{m, \kappa}} {\partial \kappa}}{\dfrac{ \partial Y_m} {\partial x} }= \frac{\dfrac{ \partial u_{\kappa}} {\partial \kappa} }{\dfrac{ \partial u} {\partial x} }= Re^{1/2}, \end{equation}

\begin{equation} \frac{\dfrac{ \partial Y_{m, \kappa}} {\partial \kappa}}{\dfrac{ \partial Y_m} {\partial x} }= \frac{\dfrac{ \partial u_{\kappa}} {\partial \kappa} }{\dfrac{ \partial u} {\partial x} }= Re^{1/2}, \end{equation}

where the subscript ![]() $\kappa$ designates the flamelet scale. The domain sizes between the Kolmogorov scale and the resolved scale as

$\kappa$ designates the flamelet scale. The domain sizes between the Kolmogorov scale and the resolved scale as ![]() $\kappa = \delta Re^{-3/4}$. Setting the change in scalar value across the given domain as the product of domain size and its gradient, the result is

$\kappa = \delta Re^{-3/4}$. Setting the change in scalar value across the given domain as the product of domain size and its gradient, the result is ![]() $\Delta Y_{m, \kappa } = \Delta Y_m Re^{-1/4}$. So, the variation in scalar properties across the smallest eddy is smaller than the variation across the larger eddies. Although the gradient of the scalar property is much greater on the flamelet scale due to turbulent mixing, the variation across the flamelet domain is smaller due to the greatly reduced domain size. Changes in enthalpy

$\Delta Y_{m, \kappa } = \Delta Y_m Re^{-1/4}$. So, the variation in scalar properties across the smallest eddy is smaller than the variation across the larger eddies. Although the gradient of the scalar property is much greater on the flamelet scale due to turbulent mixing, the variation across the flamelet domain is smaller due to the greatly reduced domain size. Changes in enthalpy ![]() $h$ and density

$h$ and density ![]() $\rho$ can be determined following the same pattern. The important implication is that, in general, the partial premixing on the smaller scales should be greater than experienced on the largest scales.

$\rho$ can be determined following the same pattern. The important implication is that, in general, the partial premixing on the smaller scales should be greater than experienced on the largest scales.

If, on the resolved scale at a particular point ![]() $\boldsymbol {x}, t$, the scalar property is

$\boldsymbol {x}, t$, the scalar property is ![]() $Y_m$, the bounding values for the inflow of the flamelet counterflow will be taken as

$Y_m$, the bounding values for the inflow of the flamelet counterflow will be taken as ![]() $Y_{m, \kappa, \infty } = Y_{m}(\boldsymbol {x},t) + \Delta Y_{m, \kappa }$ and

$Y_{m, \kappa, \infty } = Y_{m}(\boldsymbol {x},t) + \Delta Y_{m, \kappa }$ and ![]() $Y_{m, \kappa, - \infty } = Y_{m}(\boldsymbol {x},t) - \Delta Y_{m, \kappa }$. Again, the boundary values for other scalars can be handled identically. A consequence here will be that the incoming streams of the flamelet counterflow are more likely to be fuel-rich or fuel-lean than pure fuel or pure oxidizer. Multi-branched flame structures of the type found by Hamins et al. (Reference Hamins, Thridandam and Seshadri1985), Rajamanickam et al. (Reference Rajamanickam, Coenen, Sanchez and Williams2019), Sirignano (Reference Sirignano2019, Reference Sirignano2021c) and López-Cámara et al. (Reference López-Cámara, Jordà Juanós and Sirignano2020) can be expected.

$Y_{m, \kappa, - \infty } = Y_{m}(\boldsymbol {x},t) - \Delta Y_{m, \kappa }$. Again, the boundary values for other scalars can be handled identically. A consequence here will be that the incoming streams of the flamelet counterflow are more likely to be fuel-rich or fuel-lean than pure fuel or pure oxidizer. Multi-branched flame structures of the type found by Hamins et al. (Reference Hamins, Thridandam and Seshadri1985), Rajamanickam et al. (Reference Rajamanickam, Coenen, Sanchez and Williams2019), Sirignano (Reference Sirignano2019, Reference Sirignano2021c) and López-Cámara et al. (Reference López-Cámara, Jordà Juanós and Sirignano2020) can be expected.

2.3. Scaling of energy release rate and species consumption and production rates

The resolved scale will require input from the flamelet model for the quantities giving consumption (or production) rates per unit volume for the chemical species and energy release rate per unit volume due to chemical reaction and perhaps also viscous dissipation rate. The production and consumption rates within the flame are substantially higher than the average values over the counterflow volume. It is the average over the counterflow volume that should be used in the resolved-scale calculations. The same approach should be used for the viscous dissipation rate in high-speed flows where that is considered to be important. These quantities to be used on the resolved scale are given as integrals over the flamelet scale by (3.24).

The dimensional form of the rates indicates that the integrated chemical rates are proportional to the magnitude of the compressive strain rate ![]() $S^*\equiv S^*_1 + S^*_2$ for the counterflow. The portion of the dimensional energy release rate due to viscous dissipation is proportional to

$S^*\equiv S^*_1 + S^*_2$ for the counterflow. The portion of the dimensional energy release rate due to viscous dissipation is proportional to ![]() $S^{*2}$. That subgrid strain rate is much larger than the strain rate on the resolved scale as indicated by (2.3). The scalar gradients have similar scaling relation between the subgrid and the resolved scale. They impact diffusion and therefore, in diffusion-controlled combustion, they determine burning rates.

$S^{*2}$. That subgrid strain rate is much larger than the strain rate on the resolved scale as indicated by (2.3). The scalar gradients have similar scaling relation between the subgrid and the resolved scale. They impact diffusion and therefore, in diffusion-controlled combustion, they determine burning rates.

3. Subgrid flamelet analysis

We formulate the problem in a quasi-steady three-dimensional form. The following alignments are assumed. The direction of major compressive principal strain is orthogonal to the vorticity vector direction. Specifically, the intermediate principal strain direction is aligned with the vorticity while the scalar gradient aligns with the principal compressive strain direction. These assumptions are consistent with the statistical findings of Nomura & Elghobashi (Reference Nomura and Elghobashi1993).

3.1. Coordinate transformation

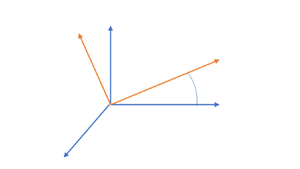

A transformation displayed in figure 1 is made from the Newtonian frame with rotating material (due to vorticity) to a rotating, non-Newtonian frame. Let the vorticity direction be the ![]() $z'$ direction in an orthogonal framework. Any

$z'$ direction in an orthogonal framework. Any ![]() $x', y'$ plane contains the directions of scalar gradients, major principal axis for compressive strain and major principal axis for tensile strain. Note that the

$x', y'$ plane contains the directions of scalar gradients, major principal axis for compressive strain and major principal axis for tensile strain. Note that the ![]() $x',y', z'$ directions are not correlated with coordinates on the resolved scale. Here,

$x',y', z'$ directions are not correlated with coordinates on the resolved scale. Here, ![]() $\omega _{\kappa }$ is the vorticity magnitude on this subgrid (Kolmogorov) scale. Directions

$\omega _{\kappa }$ is the vorticity magnitude on this subgrid (Kolmogorov) scale. Directions ![]() $x', y', z'$ are transformed to

$x', y', z'$ are transformed to ![]() $\xi, \chi, z'$ wherein the material rotation is removed from the

$\xi, \chi, z'$ wherein the material rotation is removed from the ![]() $\xi, \chi$ plane by having it rotate at angular velocity

$\xi, \chi$ plane by having it rotate at angular velocity ![]() ${\rm d}\theta /{\rm d}t = \omega _{\kappa }/2$ relative to

${\rm d}\theta /{\rm d}t = \omega _{\kappa }/2$ relative to ![]() $x', y'$. Here,

$x', y'$. Here, ![]() $\theta$ is the angle between the

$\theta$ is the angle between the ![]() $x'$ and

$x'$ and ![]() $\xi$ axes and simultaneously the angle between the

$\xi$ axes and simultaneously the angle between the ![]() $y'$ and

$y'$ and ![]() $\chi$ axes. Clearly, we take the subgrid domain to be sufficiently small to consider a uniform value of

$\chi$ axes. Clearly, we take the subgrid domain to be sufficiently small to consider a uniform value of ![]() $\omega$ across it.

$\omega$ across it.

Figure 1. Transformation to ![]() $\xi, \chi, z'$ rotating coordinate system from

$\xi, \chi, z'$ rotating coordinate system from ![]() $x', y', z'$ Newtonian system. Angle

$x', y', z'$ Newtonian system. Angle ![]() $\theta$ increases in the counterclockwise direction.

$\theta$ increases in the counterclockwise direction.

The following relations apply:

\begin{equation} \left. \begin{aligned} \xi & = x' \cos \theta + y' \sin\theta ; \quad \chi = y' \cos \theta - x' \sin\theta;\\ \frac{\partial \xi}{\partial x'} & = \cos \theta ; \quad\frac{\partial \xi}{\partial y'}= \sin\theta ; \quad \frac{\partial \chi}{\partial x'} ={-} \sin \theta ; \quad \frac{\partial \chi}{\partial y'} = \cos \theta ;\\ u_{\xi} & = u \cos \theta + v \sin \theta + \chi\frac{\omega_{\kappa}}{2} ; \quad u_{\chi} = v\cos \theta -u \sin \theta - \xi\frac{\omega_{\kappa}}{2} ;\\ \frac{\partial u}{\partial x'} & = \frac{\partial u}{\partial \xi}\cos \theta - \frac{\partial u}{\partial \chi}\sin \theta ; \quad \frac{\partial u}{\partial y'} = \frac{\partial u}{\partial \xi}\sin \theta + \frac{\partial u}{\partial \chi}\cos \theta ;\\ \frac{\partial v}{\partial x'} & = \frac{\partial v}{\partial \xi}\cos \theta - \frac{\partial v}{\partial \chi}\sin \theta ; \quad \frac{\partial v}{\partial y'} = \frac{\partial v}{\partial \xi}\sin \theta + \frac{\partial v}{\partial \chi}\cos \theta . \end{aligned} \right\} \end{equation}

\begin{equation} \left. \begin{aligned} \xi & = x' \cos \theta + y' \sin\theta ; \quad \chi = y' \cos \theta - x' \sin\theta;\\ \frac{\partial \xi}{\partial x'} & = \cos \theta ; \quad\frac{\partial \xi}{\partial y'}= \sin\theta ; \quad \frac{\partial \chi}{\partial x'} ={-} \sin \theta ; \quad \frac{\partial \chi}{\partial y'} = \cos \theta ;\\ u_{\xi} & = u \cos \theta + v \sin \theta + \chi\frac{\omega_{\kappa}}{2} ; \quad u_{\chi} = v\cos \theta -u \sin \theta - \xi\frac{\omega_{\kappa}}{2} ;\\ \frac{\partial u}{\partial x'} & = \frac{\partial u}{\partial \xi}\cos \theta - \frac{\partial u}{\partial \chi}\sin \theta ; \quad \frac{\partial u}{\partial y'} = \frac{\partial u}{\partial \xi}\sin \theta + \frac{\partial u}{\partial \chi}\cos \theta ;\\ \frac{\partial v}{\partial x'} & = \frac{\partial v}{\partial \xi}\cos \theta - \frac{\partial v}{\partial \chi}\sin \theta ; \quad \frac{\partial v}{\partial y'} = \frac{\partial v}{\partial \xi}\sin \theta + \frac{\partial v}{\partial \chi}\cos \theta . \end{aligned} \right\} \end{equation}Since

it follows that

Namely, the flow in the rotating frame of reference does not have the vorticity imposed on it. However, two points must be understood. Firstly, the frame is not Newtonian and a reversed (centrifugal) force is imposed. Secondly, the expansions due to combustion and energy release can produce new vorticity but it will integrate to zero globally. The inflowing free-stream vorticity in the transformed coordinates is zero. Thus, in similar fashion to classical counterflow, the vorticity develops as an odd function so that the circulation on a contour surrounding the flow domain remains with zero value. This creation of vorticity is related to gas expansion with density variation; however, that expansion has a symmetry that yields an antisymmetry in the vorticity.

3.2. Governing equations

The governing equations for unsteady three-dimensional flow in the non-Newtonian frame can be written with ![]() $u_i = u_{\xi }, u_{\chi }, w ; \; x_i = \xi, \chi, z$. The centrifugal acceleration

$u_i = u_{\xi }, u_{\chi }, w ; \; x_i = \xi, \chi, z$. The centrifugal acceleration ![]() $a_i = \xi \omega _{\kappa }^2/4 , \chi \omega _{\kappa }^2 /4, 0$. The quantities

$a_i = \xi \omega _{\kappa }^2/4 , \chi \omega _{\kappa }^2 /4, 0$. The quantities ![]() $p, \rho, h, h_m, Y_m, \dot {\omega }, \mu, \lambda, D$ and

$p, \rho, h, h_m, Y_m, \dot {\omega }, \mu, \lambda, D$ and ![]() $c_p$ are pressure, density, specific enthalpy, heat of formation of species

$c_p$ are pressure, density, specific enthalpy, heat of formation of species ![]() $m$, mass fraction of species

$m$, mass fraction of species ![]() $m$, chemical reaction rate of species

$m$, chemical reaction rate of species ![]() $m$, dynamic viscosity, thermal conductivity, mass diffusivity and specific heat, respectively. Furthermore,

$m$, dynamic viscosity, thermal conductivity, mass diffusivity and specific heat, respectively. Furthermore, ![]() $\tau _{ij}$ is the viscous stress tensor and the Lewis number

$\tau _{ij}$ is the viscous stress tensor and the Lewis number ![]() $Le \equiv \lambda /(\rho D c_p )$.

$Le \equiv \lambda /(\rho D c_p )$.

where, following the Stokes hypothesis for a Newtonian fluid,

\begin{gather} \rho \frac{\partial h}{\partial t} + \rho u_j\frac{\partial h}{\partial x_j} - \frac{\partial p}{\partial t} - u_j\frac{\partial p}{\partial x_j} = \frac{\partial}{\partial x_j} \left( \frac{\lambda}{c_p} \frac{\partial h}{\partial x_j} \right) \nonumber\\ + \frac{\partial}{\partial x_j} \left( \rho D (1 - Le) \varSigma^N_{m=1}h_m \frac{\partial Y_m}{\partial x_j} \right) - \rho \varSigma^N_{m=1}h_{f,m} \dot{\omega}_m + \tau_{ij}\frac{\partial u_i}{\partial x_j}, \end{gather}

\begin{gather} \rho \frac{\partial h}{\partial t} + \rho u_j\frac{\partial h}{\partial x_j} - \frac{\partial p}{\partial t} - u_j\frac{\partial p}{\partial x_j} = \frac{\partial}{\partial x_j} \left( \frac{\lambda}{c_p} \frac{\partial h}{\partial x_j} \right) \nonumber\\ + \frac{\partial}{\partial x_j} \left( \rho D (1 - Le) \varSigma^N_{m=1}h_m \frac{\partial Y_m}{\partial x_j} \right) - \rho \varSigma^N_{m=1}h_{f,m} \dot{\omega}_m + \tau_{ij}\frac{\partial u_i}{\partial x_j}, \end{gather}Equations (3.4)–(3.8) together with the equation of state and the relations describing fluid physicochemical properties give a complete description of behaviour in the non-Newtonian reference frame. These equations are used in the remainder of this section.

Equation (3.7) is a thermodynamic statement wherein, following a material element, we are stating the differential relation ![]() $\rho \,\textrm {d}h - \textrm {d}p = \rho T \,\textrm {d}s$. The terms on the right-hand side of (3.7) are entropy-producing terms. An alternative form of the energy equation can be developed to govern the total

$\rho \,\textrm {d}h - \textrm {d}p = \rho T \,\textrm {d}s$. The terms on the right-hand side of (3.7) are entropy-producing terms. An alternative form of the energy equation can be developed to govern the total ![]() $H$ of the specific enthalpy, specific chemical energy and kinetic energy per unit mass. That is,

$H$ of the specific enthalpy, specific chemical energy and kinetic energy per unit mass. That is, ![]() $H \equiv h + \varSigma _{m=1}^NY_m h_{f,m} +u_k u_k/2$. Specifically, the vector dot product of

$H \equiv h + \varSigma _{m=1}^NY_m h_{f,m} +u_k u_k/2$. Specifically, the vector dot product of ![]() $u_i$ with (3.5) is used to substitute for

$u_i$ with (3.5) is used to substitute for ![]() $u_j \partial p/ \partial x_j$ in (3.7) and (3.8) is used to substitute for

$u_j \partial p/ \partial x_j$ in (3.7) and (3.8) is used to substitute for ![]() $\dot {\omega }_m$ there. The Lewis number

$\dot {\omega }_m$ there. The Lewis number ![]() $Le =1$ is considered. It follows that

$Le =1$ is considered. It follows that

The energy source term ![]() $\rho u_j a_j = \rho (\omega _{\kappa }/2)^2(\xi u_{\xi } + \chi u_{\chi })$. If we neglect terms of the order of the kinetic energy per mass, this effect disappears. We might still retain the viscous dissipation rate

$\rho u_j a_j = \rho (\omega _{\kappa }/2)^2(\xi u_{\xi } + \chi u_{\chi })$. If we neglect terms of the order of the kinetic energy per mass, this effect disappears. We might still retain the viscous dissipation rate ![]() $\tau _{ij} \partial u_i/\partial x_j$ for special cases where large strain rates are expected on the subgrid scale, as suggested by Drozda, Quinlan & Drummond (Reference Drozda, Quinlan and Drummond2020). The viscous dissipation rate will have exactly the same value whether it is calculated in the Newtonian frame or the rotating frame; this result is expected because it relates to the thermodynamics where the laws are independent of the reference frame. The resulting equation becomes

$\tau _{ij} \partial u_i/\partial x_j$ for special cases where large strain rates are expected on the subgrid scale, as suggested by Drozda, Quinlan & Drummond (Reference Drozda, Quinlan and Drummond2020). The viscous dissipation rate will have exactly the same value whether it is calculated in the Newtonian frame or the rotating frame; this result is expected because it relates to the thermodynamics where the laws are independent of the reference frame. The resulting equation becomes

$$\begin{gather} \rho \frac{\partial h}{\partial t} + \rho u_j\frac{\partial h}{\partial x_j} - \frac{\partial p}{\partial t} \approx \frac{\partial}{\partial x_j} \left( \frac{\lambda}{c_p} \frac{\partial h}{\partial x_j} \right) + \frac{\partial}{\partial x_j} \left( \rho D (1 - Le) \varSigma^N_{m=1}h_m \frac{\partial Y_m}{\partial x_j} \right) \nonumber\\ -\rho \varSigma^N_{m=1}h_{f,m} \dot{\omega}_m + \tau_{ij}\frac{\partial u_i}{\partial x_j}. \end{gather}$$

$$\begin{gather} \rho \frac{\partial h}{\partial t} + \rho u_j\frac{\partial h}{\partial x_j} - \frac{\partial p}{\partial t} \approx \frac{\partial}{\partial x_j} \left( \frac{\lambda}{c_p} \frac{\partial h}{\partial x_j} \right) + \frac{\partial}{\partial x_j} \left( \rho D (1 - Le) \varSigma^N_{m=1}h_m \frac{\partial Y_m}{\partial x_j} \right) \nonumber\\ -\rho \varSigma^N_{m=1}h_{f,m} \dot{\omega}_m + \tau_{ij}\frac{\partial u_i}{\partial x_j}. \end{gather}$$

Here, we define the non-dimensional Prandtl, Schmidt and Lewis numbers: ![]() $Pr \equiv c_p \mu / \lambda$;

$Pr \equiv c_p \mu / \lambda$; ![]() $Sc \equiv \mu / (\rho D)$; and

$Sc \equiv \mu / (\rho D)$; and ![]() $Le \equiv Sc/ Pr$.

$Le \equiv Sc/ Pr$.

The non-dimensional forms of the above equations remain identical to the above forms if we choose certain reference values for normalization. In the remainder of this article, the non-dimensional forms of the above equations are considered. The superscript ![]() $^*$ is used to designate a dimensional property. The variables

$^*$ is used to designate a dimensional property. The variables ![]() $u_i^*, t^*, x_i^*, \rho ^*, h^*, p^*$ and

$u_i^*, t^*, x_i^*, \rho ^*, h^*, p^*$ and ![]() $\dot {\omega }_m^* ,$ and properties

$\dot {\omega }_m^* ,$ and properties ![]() $\mu ^*, \lambda ^*/ c_p^*$ and

$\mu ^*, \lambda ^*/ c_p^*$ and ![]() $D^*$ are normalized respectively by

$D^*$ are normalized respectively by ![]() $[(S_1^* +S_2^*) \mu _{\infty }^*/ \rho _{\infty }^*]^{1/2}, (S_1^* + S_2^*)^{-1}, [ \mu _{\infty }^*/ (\rho _{\infty }^*(S_1^* +S_2^*))]^{1/2}, \rho _{\infty }^*, (S_1^* +S_2^*) \mu _{\infty }^*/ \rho _{\infty }^*,$

$[(S_1^* +S_2^*) \mu _{\infty }^*/ \rho _{\infty }^*]^{1/2}, (S_1^* + S_2^*)^{-1}, [ \mu _{\infty }^*/ (\rho _{\infty }^*(S_1^* +S_2^*))]^{1/2}, \rho _{\infty }^*, (S_1^* +S_2^*) \mu _{\infty }^*/ \rho _{\infty }^*,$ ![]() $(S_1^* + S_2^*)\mu _{\infty }^*, (S_1^* + S_2^*), \mu _{\infty }^*, \mu _{\infty }^*$ and

$(S_1^* + S_2^*)\mu _{\infty }^*, (S_1^* + S_2^*), \mu _{\infty }^*, \mu _{\infty }^*$ and ![]() $\mu _{\infty }^*/ \rho _{\infty }^*$. The dimensional strain rates

$\mu _{\infty }^*/ \rho _{\infty }^*$. The dimensional strain rates ![]() $S^*_1$ and

$S^*_1$ and ![]() $S^*_2$ and vorticity

$S^*_2$ and vorticity ![]() $\omega _{\kappa }^*$ are normalized by

$\omega _{\kappa }^*$ are normalized by ![]() $S^*_1 + S^*_2$. It is understood that, for unsteady flow, the reference values for strain rates and far-stream variables and properties used for normalization are constants; for example, averages might be taken for fluctuating conditions. Note that the reference length

$S^*_1 + S^*_2$. It is understood that, for unsteady flow, the reference values for strain rates and far-stream variables and properties used for normalization are constants; for example, averages might be taken for fluctuating conditions. Note that the reference length ![]() $[ \mu _{\infty }^*/ (\rho _{\infty }^*(S_1^* +S_2^*))]^{1/2}$ is the estimate for the magnitude of the viscous-layer thickness. In the following flamelet analysis, the vorticity

$[ \mu _{\infty }^*/ (\rho _{\infty }^*(S_1^* +S_2^*))]^{1/2}$ is the estimate for the magnitude of the viscous-layer thickness. In the following flamelet analysis, the vorticity ![]() $\omega _{\kappa }$ and the velocity derivatives

$\omega _{\kappa }$ and the velocity derivatives ![]() $\partial u_i/ \partial x_j$ are non-dimensional quantities; their dimensional values can be obtained through multiplication by

$\partial u_i/ \partial x_j$ are non-dimensional quantities; their dimensional values can be obtained through multiplication by ![]() $S^*_1 + S^*_2$. In § 2, the algorithms are given that relate dimensional vorticity and velocity derivatives on the resolved scale to dimensional vorticity and velocity derivatives on the subgrid scale.

$S^*_1 + S^*_2$. In § 2, the algorithms are given that relate dimensional vorticity and velocity derivatives on the resolved scale to dimensional vorticity and velocity derivatives on the subgrid scale.

3.3. Similar form for the velocity and pressure

The stagnation point in the steady counterflow is taken as the origin ![]() $\xi = \chi =z=0$. Along the line

$\xi = \chi =z=0$. Along the line ![]() $\xi =z=0$ normal to the interface, we can expect the first derivatives of

$\xi =z=0$ normal to the interface, we can expect the first derivatives of ![]() $u_{\chi }, \rho, h, T$ and

$u_{\chi }, \rho, h, T$ and ![]() $Y_m$ with respect to either

$Y_m$ with respect to either ![]() $\xi$ or

$\xi$ or ![]() $z$ to be zero-valued. For unsteady cases, only symmetric situations are considered so that the stagnation point remains at the origin and the interface remains at

$z$ to be zero-valued. For unsteady cases, only symmetric situations are considered so that the stagnation point remains at the origin and the interface remains at ![]() $\chi =0$. The velocity components

$\chi =0$. The velocity components ![]() $u_{\xi }$ and

$u_{\xi }$ and ![]() $w$ are odd functions of

$w$ are odd functions of ![]() $\xi$ and

$\xi$ and ![]() $z$, respectively, going through zero and changing sign at that line. Consequently, upon neglect of terms of

$z$, respectively, going through zero and changing sign at that line. Consequently, upon neglect of terms of ![]() $O(\xi ^2)$ and

$O(\xi ^2)$ and ![]() $O(z^2)$, the variables

$O(z^2)$, the variables ![]() $u_{\chi }, \rho, h, T$ and

$u_{\chi }, \rho, h, T$ and ![]() $Y_m$ can be considered to be functions only of

$Y_m$ can be considered to be functions only of ![]() $t$ and

$t$ and ![]() $\chi$. For steady flow, the density-weighted Illingworth (Reference Illingworth1949) transformation of

$\chi$. For steady flow, the density-weighted Illingworth (Reference Illingworth1949) transformation of ![]() $\chi$ can be used to replace

$\chi$ can be used to replace ![]() $\chi$ with

$\chi$ with ![]() $\eta \equiv \int ^{\chi }_0 \rho (\chi ') \,\textrm {d}\chi '$. Neglect of the same order of terms implies that

$\eta \equiv \int ^{\chi }_0 \rho (\chi ') \,\textrm {d}\chi '$. Neglect of the same order of terms implies that ![]() $u_{\xi }= S_1 \xi (\textrm {d}f_1/\textrm {d}\eta )$ and

$u_{\xi }= S_1 \xi (\textrm {d}f_1/\textrm {d}\eta )$ and ![]() $w= S_2 z(\textrm {d}f_2/\textrm {d}\eta )$. Note that

$w= S_2 z(\textrm {d}f_2/\textrm {d}\eta )$. Note that ![]() $u_{\xi }$ is independent of

$u_{\xi }$ is independent of ![]() $z$ and

$z$ and ![]() $w$ is independent of

$w$ is independent of ![]() $\xi$ in this case where no shear strain is imposed on the incoming stream(s). At the edge of the viscous layer at large positive

$\xi$ in this case where no shear strain is imposed on the incoming stream(s). At the edge of the viscous layer at large positive ![]() $\eta$,

$\eta$, ![]() $\textrm {d}f_1/\textrm {d} \eta \rightarrow 1, \textrm {d}f_2/\textrm {d} \eta \rightarrow 1, f_1 \rightarrow \eta$ and

$\textrm {d}f_1/\textrm {d} \eta \rightarrow 1, \textrm {d}f_2/\textrm {d} \eta \rightarrow 1, f_1 \rightarrow \eta$ and ![]() $f_2 \rightarrow \eta$. Ordinary differential equations are created here through the variable

$f_2 \rightarrow \eta$. Ordinary differential equations are created here through the variable ![]() $\eta$ and the convenient definition is made that

$\eta$ and the convenient definition is made that ![]() $( )' \equiv \textrm {d}( )/\textrm {d}\eta$. Note that other transformations of the

$( )' \equiv \textrm {d}( )/\textrm {d}\eta$. Note that other transformations of the ![]() $\chi$ coordinate can be made, e.g. weighting by transport properties (Linan et al. Reference Linan, Martinez-Ruiz, Vera and Sanchez2017; Weiss et al. Reference Weiss, Vera, Linan, Sanchez and Williams2018) rather than density.

$\chi$ coordinate can be made, e.g. weighting by transport properties (Linan et al. Reference Linan, Martinez-Ruiz, Vera and Sanchez2017; Weiss et al. Reference Weiss, Vera, Linan, Sanchez and Williams2018) rather than density.

In the non-dimensional form given by (3.4)–(3.10), the dimensional strain rates ![]() $S_1^*$ and

$S_1^*$ and ![]() $S_2^*$ are each normalized by the dimensional sum

$S_2^*$ are each normalized by the dimensional sum ![]() $S_1^* + S_2^*$. Thus, the non-dimensional relation is

$S_1^* + S_2^*$. Thus, the non-dimensional relation is ![]() $S_2 = 1 - S_1$ and only one independent non-dimensional strain-rate parameter is needed. Nevertheless, two strain rates are presented above and in the following analysis with the understanding that one depends on the other such that

$S_2 = 1 - S_1$ and only one independent non-dimensional strain-rate parameter is needed. Nevertheless, two strain rates are presented above and in the following analysis with the understanding that one depends on the other such that ![]() $S_1 + S_2 = 1$. Values of

$S_1 + S_2 = 1$. Values of ![]() $S_1 + S_2$ are explicitly stated in our analysis without substitution of the unity value. This choice clarifies whether a particular term when converted to a dimensional form depends on

$S_1 + S_2$ are explicitly stated in our analysis without substitution of the unity value. This choice clarifies whether a particular term when converted to a dimensional form depends on ![]() $S_1^*, S_2^*$ or the sum of the two strain rates.

$S_1^*, S_2^*$ or the sum of the two strain rates.

For steady state, the continuity equation (3.4) is readily integrated to give

For derivatives of variables that are functions of ![]() $\eta$ only, the prime is used to indicate differentiation with respect to

$\eta$ only, the prime is used to indicate differentiation with respect to ![]() $\eta$. Then,

$\eta$. Then,

Thus, the incoming inviscid flow outside the boundary layer is described by ![]() $u_{\chi }=-(S_1 + S_2)\eta$ for positive

$u_{\chi }=-(S_1 + S_2)\eta$ for positive ![]() $\eta$ and

$\eta$ and ![]() $u_{\chi }=-(S_1 + S_2)\eta / \rho _{-\infty }$ for negative

$u_{\chi }=-(S_1 + S_2)\eta / \rho _{-\infty }$ for negative ![]() $\eta$. Note that the same result is found for the unsteady or steady incompressible state where there is no need to use

$\eta$. Note that the same result is found for the unsteady or steady incompressible state where there is no need to use ![]() $\eta$ in place of

$\eta$ in place of ![]() $\chi$ since

$\chi$ since ![]() $\rho =1$ everywhere. Then,

$\rho =1$ everywhere. Then, ![]() $u_{\chi } = -(S_1 + S_2 ) \chi$ for the external incoming flow.

$u_{\chi } = -(S_1 + S_2 ) \chi$ for the external incoming flow.

Equations (3.11) and (3.12) may be substituted into (3.5) to determine the pressure gradient:

\begin{equation} \left. \begin{aligned} \frac{\partial p}{\partial \xi} & = \rho [ \rho \mu S_1 f_1''' + S_1 f_1'' (\rho \mu)' +(S_1 f_1 + S_2f_2)S_1 f_1'' + \left(\frac{\omega_{\kappa}}{2} \right)^2 - (S_1f_1')^2]\xi ,\\ \frac{\partial p}{\partial \eta} & = \frac{4}{3} ( \rho \mu u_{\chi}')' \!-\!\frac{2}{3}(S_1f_1' \!+\! S_2 f_2')\mu' \!+\!\frac{ \mu}{3}(S_1 f_1'' \!+\! S_2 f_2'') + \left(\frac{\omega_{\kappa}}{2} \right)^2\chi +(S_1 f_1 + S_2 f_2)u_{\chi}' ,\\ \frac{\partial p}{\partial z} & = \rho [ \rho \mu S_2 f_2''' + S_2 f_2'' (\rho \mu)' +(S_1 f_1 + S_2f_2)S_2 f_2''- (S_2f_2')^2]z . \end{aligned} \right\} \end{equation}

\begin{equation} \left. \begin{aligned} \frac{\partial p}{\partial \xi} & = \rho [ \rho \mu S_1 f_1''' + S_1 f_1'' (\rho \mu)' +(S_1 f_1 + S_2f_2)S_1 f_1'' + \left(\frac{\omega_{\kappa}}{2} \right)^2 - (S_1f_1')^2]\xi ,\\ \frac{\partial p}{\partial \eta} & = \frac{4}{3} ( \rho \mu u_{\chi}')' \!-\!\frac{2}{3}(S_1f_1' \!+\! S_2 f_2')\mu' \!+\!\frac{ \mu}{3}(S_1 f_1'' \!+\! S_2 f_2'') + \left(\frac{\omega_{\kappa}}{2} \right)^2\chi +(S_1 f_1 + S_2 f_2)u_{\chi}' ,\\ \frac{\partial p}{\partial z} & = \rho [ \rho \mu S_2 f_2''' + S_2 f_2'' (\rho \mu)' +(S_1 f_1 + S_2f_2)S_2 f_2''- (S_2f_2')^2]z . \end{aligned} \right\} \end{equation}

It follows from the ![]() $\eta$ pressure gradient in (3.13) that

$\eta$ pressure gradient in (3.13) that ![]() $\partial p/ \partial \eta$ is a function only of

$\partial p/ \partial \eta$ is a function only of ![]() $\eta$. Therefore,

$\eta$. Therefore, ![]() $\partial ^2 p/ \partial \xi \partial \eta = 0$ and

$\partial ^2 p/ \partial \xi \partial \eta = 0$ and ![]() $\partial ^2 p/ \partial z \partial \eta = 0$. Now, the coefficient of

$\partial ^2 p/ \partial z \partial \eta = 0$. Now, the coefficient of ![]() $\xi$ on the right-hand side of the

$\xi$ on the right-hand side of the ![]() $\xi$ pressure gradient in (3.13) must be constant. The same conclusion is made for the coefficient of

$\xi$ pressure gradient in (3.13) must be constant. The same conclusion is made for the coefficient of ![]() $z$ on the right-hand side of the

$z$ on the right-hand side of the ![]() $z$ pressure gradient in (3.13). At

$z$ pressure gradient in (3.13). At ![]() $\eta =\infty$,

$\eta =\infty$, ![]() $f_1' =f_2'=1$ and

$f_1' =f_2'=1$ and ![]() $f_1'' = f_2'' = f_1''' = f_2''' =0$ which allows the two constants to be determined. Specifically, we obtain

$f_1'' = f_2'' = f_1''' = f_2''' =0$ which allows the two constants to be determined. Specifically, we obtain

\begin{equation} \left. \begin{gathered} \rho \mu f_1''' + f_1'' (\rho \mu)'+(S_1 f_1 + S_2f_2) f_1'' + S_1\left(\frac{1}{\rho} -(f_1')^2\right) +\frac{\omega_{\kappa}^2}{4S_1}\left(1 - \frac{1}{\rho}\right)= 0 ,\\ \rho \mu f_2''' + f_2'' (\rho \mu)'+(S_1 f_1 + S_2f_2) f_2'' + S_2\left(\frac{1}{\rho}-(f_2')^2\right) = 0. \end{gathered} \right\} \end{equation}

\begin{equation} \left. \begin{gathered} \rho \mu f_1''' + f_1'' (\rho \mu)'+(S_1 f_1 + S_2f_2) f_1'' + S_1\left(\frac{1}{\rho} -(f_1')^2\right) +\frac{\omega_{\kappa}^2}{4S_1}\left(1 - \frac{1}{\rho}\right)= 0 ,\\ \rho \mu f_2''' + f_2'' (\rho \mu)'+(S_1 f_1 + S_2f_2) f_2'' + S_2\left(\frac{1}{\rho}-(f_2')^2\right) = 0. \end{gathered} \right\} \end{equation}

The boundary conditions will use the assumption that two velocity components asymptote to the constant values ![]() $u_{\xi }(\infty ), u_{\xi }(-\infty ), w(\infty )$ and

$u_{\xi }(\infty ), u_{\xi }(-\infty ), w(\infty )$ and ![]() $w(-\infty )$ at large magnitudes of

$w(-\infty )$ at large magnitudes of ![]() $\eta$. The stream function bounding the two incoming streams is arbitrarily given a zero value and placed at

$\eta$. The stream function bounding the two incoming streams is arbitrarily given a zero value and placed at ![]() $\eta =0$.

$\eta =0$.

\begin{equation} \left. \begin{gathered} f'_1(\infty) = 1 ; \quad f'_1(-\infty)= \sqrt{\frac{1}{\rho(-\infty)}+ \left(\frac{\omega_{\kappa}}{2 S_1}\right)^2 \left( 1 - \frac{1}{\rho(-\infty)} \right) } ; \quad f_1(0) = 0 ;\\ f'_2(\infty) = 1 ; \quad f'_2(-\infty)= \frac{1}{\sqrt{\rho(-\infty)}}; \quad f_2(0) =0. \end{gathered} \right\} \end{equation}

\begin{equation} \left. \begin{gathered} f'_1(\infty) = 1 ; \quad f'_1(-\infty)= \sqrt{\frac{1}{\rho(-\infty)}+ \left(\frac{\omega_{\kappa}}{2 S_1}\right)^2 \left( 1 - \frac{1}{\rho(-\infty)} \right) } ; \quad f_1(0) = 0 ;\\ f'_2(\infty) = 1 ; \quad f'_2(-\infty)= \frac{1}{\sqrt{\rho(-\infty)}}; \quad f_2(0) =0. \end{gathered} \right\} \end{equation} In the incompressible case where density is uniform throughout the flow, i.e. ![]() $\rho =1$, the solutions become simply that

$\rho =1$, the solutions become simply that ![]() $f'_1(\eta )=1$ and

$f'_1(\eta )=1$ and ![]() $f'_2(\eta ) =1$ everywhere. When density varies through the flow because of heating or variation of composition,

$f'_2(\eta ) =1$ everywhere. When density varies through the flow because of heating or variation of composition, ![]() $u_{\xi }$ and

$u_{\xi }$ and ![]() $w$ vary with

$w$ vary with ![]() $\chi$, thereby creating a shear stress and vorticity albeit that the frame transformation removed vorticity and shear from the incoming flow. The vorticity will be created in an antisymmetric manner since the two velocity components are odd functions of

$\chi$, thereby creating a shear stress and vorticity albeit that the frame transformation removed vorticity and shear from the incoming flow. The vorticity will be created in an antisymmetric manner since the two velocity components are odd functions of ![]() $\xi$ and

$\xi$ and ![]() $z$, respectively. Thereby, the circulation remains zero for the transformed counterflow.

$z$, respectively. Thereby, the circulation remains zero for the transformed counterflow.

For steady flows, ![]() $S_1 + S_2 =1$. The dependence of

$S_1 + S_2 =1$. The dependence of ![]() $u_{\chi }$ on

$u_{\chi }$ on ![]() $f\equiv S_1f_1 + S_2 f_2$ is shown by (3.11). Thus, the function

$f\equiv S_1f_1 + S_2 f_2$ is shown by (3.11). Thus, the function ![]() $f$ will be important in determining both the field for

$f$ will be important in determining both the field for ![]() $u_{\chi }$ and the scalar fields. From (3.14), an equation for

$u_{\chi }$ and the scalar fields. From (3.14), an equation for ![]() $f$ can be formed:

$f$ can be formed:

Consequently, ![]() $f$ as well as

$f$ as well as ![]() $f_1$ and

$f_1$ and ![]() $f_2$ depend on both

$f_2$ depend on both ![]() $S_1$ and

$S_1$ and ![]() $S_2$, not merely on

$S_2$, not merely on ![]() $S_1 + S_2$. That is, the particular distribution of the normal strain rate between the two transverse direction matters. Functions

$S_1 + S_2$. That is, the particular distribution of the normal strain rate between the two transverse direction matters. Functions ![]() $f$ and

$f$ and ![]() $f_1$ also depend directly on

$f_1$ also depend directly on ![]() $\omega _{\kappa }$ (unless

$\omega _{\kappa }$ (unless ![]() $S_1 = 0$). Function

$S_1 = 0$). Function ![]() $f_2$ depends on

$f_2$ depends on ![]() $\omega _{\kappa }$ through its coupling with

$\omega _{\kappa }$ through its coupling with ![]() $f_1$. In our calculations, we consider a planar case (

$f_1$. In our calculations, we consider a planar case (![]() $S_1 = 1.0 , S_2 = 0$) where the product

$S_1 = 1.0 , S_2 = 0$) where the product ![]() $S_1S_2$ is minimized and the vorticity vector is normal to the plane with strain. The case where

$S_1S_2$ is minimized and the vorticity vector is normal to the plane with strain. The case where ![]() $S_1 = S_2 = 0.5$ has the maximum value for the product

$S_1 = S_2 = 0.5$ has the maximum value for the product ![]() $S_1 S_2$ would be axisymmetric if

$S_1 S_2$ would be axisymmetric if ![]() $\omega = 0$. However, symmetry is lost if the rotation exists.

$\omega = 0$. However, symmetry is lost if the rotation exists.

In the outer flow where variability of viscosity and density may be neglected and ![]() $u_{\chi } \rightarrow \eta / \rho _{\infty }$ as

$u_{\chi } \rightarrow \eta / \rho _{\infty }$ as ![]() $\eta \rightarrow \infty$, the

$\eta \rightarrow \infty$, the ![]() $\chi$-momentum equation from (3.13) becomes

$\chi$-momentum equation from (3.13) becomes

\begin{equation} \left. \begin{aligned} \frac{\partial }{\partial \eta} \left[p - \frac{4\rho \mu}{3}u_{\chi}' \right] & \rightarrow (S_1 f_1 + S_2 f_2)u_{\chi}' + \left( \frac{\omega_{\kappa}}{2}\right)^2 \chi \rightarrow (S_1 + S_2 )\eta u_{\chi}' + \left(\frac{\omega_{\kappa}}{2}\right)^2 \frac{\eta}{\rho_{\infty}} ,\\ \frac{\partial p}{\partial \eta} & \rightarrow \left[\left(\frac{\omega_{\kappa}}{2}\right)^2 -(S_1 + S_2)^2 \right] \frac{\eta}{\rho_{\infty}}. \end{aligned} \right\} \end{equation}

\begin{equation} \left. \begin{aligned} \frac{\partial }{\partial \eta} \left[p - \frac{4\rho \mu}{3}u_{\chi}' \right] & \rightarrow (S_1 f_1 + S_2 f_2)u_{\chi}' + \left( \frac{\omega_{\kappa}}{2}\right)^2 \chi \rightarrow (S_1 + S_2 )\eta u_{\chi}' + \left(\frac{\omega_{\kappa}}{2}\right)^2 \frac{\eta}{\rho_{\infty}} ,\\ \frac{\partial p}{\partial \eta} & \rightarrow \left[\left(\frac{\omega_{\kappa}}{2}\right)^2 -(S_1 + S_2)^2 \right] \frac{\eta}{\rho_{\infty}}. \end{aligned} \right\} \end{equation}The negative pressure gradient will be reduced by the centrifugal effect. Essentially, the pressure gradient serves to decelerate the incoming stream in a counterflow; here, it is helped by the imposed acceleration.

The variable-density-and-viscosity case requires some couplings with (3.7) and (3.8) and with an equation of state and fluid-property laws which affect ![]() $\rho$ and

$\rho$ and ![]() $\mu$.

$\mu$.

The pressure derivative can be determined by substituting from (3.11) and (3.12) into (3.13):

\begin{align} \frac{\partial p}{\partial \eta} &=\frac{4}{3}\left( \rho \mu\left[ \frac{S_1 f_1(\eta) + S_2 f_2(\eta)}{\rho^2 } \rho'-\frac{S_1 f_1'(\eta)+ S_2 f_2'(\eta)}{\rho} \right]\right)' + \left(\frac{\omega_{\kappa}}{2} \right)^2\chi \nonumber\\ &\quad +\frac{ \mu}{3}(S_1 f_1'' + S_2 f_2'')-\frac{2}{3}(S_1f_1' + S_2 f_2')\mu' \nonumber\\ &\quad +(S_1 f_1 + S_2 f_2)\left[\frac{S_1 f_1(\eta) + S_2 f_2(\eta)}{\rho^2 } \rho'-\frac{S_1 f_1'(\eta)+ S_2 f_2'(\eta)}{\rho}\right] , \nonumber\\ p(x, \eta, z) &= p_{ref} + \frac{4\mu(\eta)}{3\rho(\eta)} \left[ (S_1 f_1(\eta) + S_2 f_2(\eta)) \rho' -\rho(\eta)(S_1 f_1'(\eta)+ S_2 f_2'(\eta))\right] \nonumber\\ &\quad + \frac{4 \mu(0)}{3}(S_1f_1'(0) + S_2f_2'(0)) \nonumber\\ &\quad + \int_{0}^{\eta}\left[\frac{\mu(\zeta)}{3}(S_1 f_1''(\zeta) + S_2 f_2''(\zeta)) -\frac{2}{3}(S_1f_1'(\zeta) + S_2 f_2'(\zeta))\mu' \right] \,{\rm d}\zeta \nonumber\\ &\quad +\int_{0}^{\eta}(S_1 f_1(\zeta) + S_2 f_2(\zeta))\left[\frac{S_1 f_1(\zeta) + S_2 f_2(\zeta)}{\rho(\zeta)^2 } \rho' -\frac{S_1 f_1'(\zeta)+ S_2 f_2'(\zeta)}{\rho(\zeta)}\right] \,{\rm d}\zeta \nonumber\\ &\quad- \frac{S_1^2 x^2}{2} - \frac{S_2^2 z^2}{2} + \left(\frac{\omega_{\kappa}}{2} \right)^2 \int_0^{\eta} \chi(\zeta) \,{\rm d}\zeta . \end{align}

\begin{align} \frac{\partial p}{\partial \eta} &=\frac{4}{3}\left( \rho \mu\left[ \frac{S_1 f_1(\eta) + S_2 f_2(\eta)}{\rho^2 } \rho'-\frac{S_1 f_1'(\eta)+ S_2 f_2'(\eta)}{\rho} \right]\right)' + \left(\frac{\omega_{\kappa}}{2} \right)^2\chi \nonumber\\ &\quad +\frac{ \mu}{3}(S_1 f_1'' + S_2 f_2'')-\frac{2}{3}(S_1f_1' + S_2 f_2')\mu' \nonumber\\ &\quad +(S_1 f_1 + S_2 f_2)\left[\frac{S_1 f_1(\eta) + S_2 f_2(\eta)}{\rho^2 } \rho'-\frac{S_1 f_1'(\eta)+ S_2 f_2'(\eta)}{\rho}\right] , \nonumber\\ p(x, \eta, z) &= p_{ref} + \frac{4\mu(\eta)}{3\rho(\eta)} \left[ (S_1 f_1(\eta) + S_2 f_2(\eta)) \rho' -\rho(\eta)(S_1 f_1'(\eta)+ S_2 f_2'(\eta))\right] \nonumber\\ &\quad + \frac{4 \mu(0)}{3}(S_1f_1'(0) + S_2f_2'(0)) \nonumber\\ &\quad + \int_{0}^{\eta}\left[\frac{\mu(\zeta)}{3}(S_1 f_1''(\zeta) + S_2 f_2''(\zeta)) -\frac{2}{3}(S_1f_1'(\zeta) + S_2 f_2'(\zeta))\mu' \right] \,{\rm d}\zeta \nonumber\\ &\quad +\int_{0}^{\eta}(S_1 f_1(\zeta) + S_2 f_2(\zeta))\left[\frac{S_1 f_1(\zeta) + S_2 f_2(\zeta)}{\rho(\zeta)^2 } \rho' -\frac{S_1 f_1'(\zeta)+ S_2 f_2'(\zeta)}{\rho(\zeta)}\right] \,{\rm d}\zeta \nonumber\\ &\quad- \frac{S_1^2 x^2}{2} - \frac{S_2^2 z^2}{2} + \left(\frac{\omega_{\kappa}}{2} \right)^2 \int_0^{\eta} \chi(\zeta) \,{\rm d}\zeta . \end{align} The viscous dissipation ![]() $\varPhi$ can be determined as follows:

$\varPhi$ can be determined as follows: