1. Introduction

Turbulent particle-laden flows are of relevance to many engineering applications such as gas turbine engine combustors used for aircraft propulsion, cyclones used for particle separation, industrial driers and slurry pumps, see the works of Crowe et al. (Reference Crowe, Schwarzkopf, Sommerfeld and Tsuji2011), Kuerten (Reference Kuerten2016) and Zhao et al. (Reference Zhao, Zhao, Zhang, Li and Geng2021). Thus, several theoretical, numerical and experimental investigations have been carried out over the past decades, and many review papers have been published, see for example those of Poelma & Ooms (Reference Poelma and Ooms2006), Balachandar & Eaton (Reference Balachandar and Eaton2010) and Brandt & Coletti (Reference Brandt and Coletti2022). Review of these studies suggests that, among many non-dimensional parameters, the Stokes number (which is the ratio of particle to flow time scale, as defined by, for example, Crowe et al. Reference Crowe, Schwarzkopf, Sommerfeld and Tsuji2011) primarily influences the characteristics of the turbulent particle-laden flows. Although past investigations are of significant importance as they provide insight into relatively small and moderate Stokes number flows (![]() $St\lesssim 10$), the Stokes number of particle-laden flows relevant to some engineering applications such as sprays in gas turbine engine combustors, is relatively large (

$St\lesssim 10$), the Stokes number of particle-laden flows relevant to some engineering applications such as sprays in gas turbine engine combustors, is relatively large (![]() $St \gtrsim 10$). The present study is motivated by the need for understanding the spray characteristics at relatively large Stokes numbers. As elaborated by Baker et al. (Reference Baker, Frankel, Mani and Coletti2017) and Boddapati, Manish & Sahu (Reference Boddapati, Manish and Sahu2020), the interaction of the particles and the background turbulent flow leads to the formation of regions with relatively large and small number of particles, which are referred to as clusters and voids, respectively, and are relevant to the present study. A brief review of the literature related to the clusters and voids is provided below.

$St \gtrsim 10$). The present study is motivated by the need for understanding the spray characteristics at relatively large Stokes numbers. As elaborated by Baker et al. (Reference Baker, Frankel, Mani and Coletti2017) and Boddapati, Manish & Sahu (Reference Boddapati, Manish and Sahu2020), the interaction of the particles and the background turbulent flow leads to the formation of regions with relatively large and small number of particles, which are referred to as clusters and voids, respectively, and are relevant to the present study. A brief review of the literature related to the clusters and voids is provided below.

The inertial bias and sweep-stick mechanisms are proposed in the literature to elaborate the formation of clusters and voids in turbulent flows. The former suggests that during a particle and eddy interaction, the large eddies centrifuge out the particles and accumulate them in regions that feature small vorticities and large strain rates, as explained by Maxey (Reference Maxey1987), Squires & Eaton (Reference Squires and Eaton1991) and Wang & Maxey (Reference Wang and Maxey1993). Compared with the inertial bias mechanism, the sweep-stick mechanism suggests that the vorticity and strain rate fields may not be sufficient in explaining the positioning of the particles and hence formation of the clusters, see the work of Goto & Vassilicos (Reference Goto and Vassilicos2008). The sweep-stick mechanism suggests that particles with ![]() $St \gtrsim 1$ tend to be positioned in the spatial locations with zero acceleration. Then, these particles are carried by large eddies in the flow, see the works of Goto & Vassilicos (Reference Goto and Vassilicos2006), Monchaux, Bourgoin & Cartellier (Reference Monchaux, Bourgoin and Cartellier2012), Mora et al. (Reference Mora, Bourgoin, Mininni and Obligado2021) and Hassaini & Coletti (Reference Hassaini and Coletti2022).

$St \gtrsim 1$ tend to be positioned in the spatial locations with zero acceleration. Then, these particles are carried by large eddies in the flow, see the works of Goto & Vassilicos (Reference Goto and Vassilicos2006), Monchaux, Bourgoin & Cartellier (Reference Monchaux, Bourgoin and Cartellier2012), Mora et al. (Reference Mora, Bourgoin, Mininni and Obligado2021) and Hassaini & Coletti (Reference Hassaini and Coletti2022).

Various tools and methods have been developed to identify the clusters and voids from the spatial distribution of the particles. For example, Monchaux, Bourgoin & Cartellier (Reference Monchaux, Bourgoin and Cartellier2010), Tagawa et al. (Reference Tagawa, Mercado, Prakash, Calzavarini, Sun and Lohse2012) and Frankel et al. (Reference Frankel, Pouransari, Coletti and Mani2016) utilized the Voronoï cells, Andrade, Hardalupas & Charalampous (Reference Andrade, Hardalupas and Charalampous2022) used the combined graph and Voronoï cells, Fessler, Kulick & Eaton (Reference Fessler, Kulick and Eaton1994) and Villafañe-Roca et al. (Reference Villafañe-Roca, Esmaily-Moghadam, Banko and Eaton2016) implemented the box-counting method, and Salazar et al. (Reference Salazar, De Jong, Cao, Woodward, Meng and Collins2008), Saw et al. (Reference Saw, Shaw, Ayyalasomayajula, Chuang and Gylfason2008) and Sahu, Hardalupas & Taylor (Reference Sahu, Hardalupas and Taylor2016) applied the radial distribution functions to identify the clusters. The Voronoï cells (relevant to the present investigation) can allow for estimating the degree of clustering, which is defined (see for example Boddapati et al. Reference Boddapati, Manish and Sahu2020) as the root mean square (RMS) of the normalized Voronoï cells area (![]() $\sigma$) divided by that if the droplets were distributed following a random Poisson process (RPP),

$\sigma$) divided by that if the droplets were distributed following a random Poisson process (RPP), ![]() $\sigma _{\rm RPP}$, minus unity. The studies of Monchaux et al. (Reference Monchaux, Bourgoin and Cartellier2010), Obligado et al. (Reference Obligado, Teitelbaum, Cartellier, Mininni and Bourgoin2014) and Sumbekova et al. (Reference Sumbekova, Cartellier, Aliseda and Bourgoin2017) showed that the degree of clustering is influenced by three non-dimensional parameters that are the Stokes number (

$\sigma _{\rm RPP}$, minus unity. The studies of Monchaux et al. (Reference Monchaux, Bourgoin and Cartellier2010), Obligado et al. (Reference Obligado, Teitelbaum, Cartellier, Mininni and Bourgoin2014) and Sumbekova et al. (Reference Sumbekova, Cartellier, Aliseda and Bourgoin2017) showed that the degree of clustering is influenced by three non-dimensional parameters that are the Stokes number (![]() $St$) estimated based on the Kolmogorov time scale, Taylor-length-scale-based Reynolds number (

$St$) estimated based on the Kolmogorov time scale, Taylor-length-scale-based Reynolds number (![]() $Re_\lambda$) and the droplets volume fraction (

$Re_\lambda$) and the droplets volume fraction (![]() $\phi _{{\rm v}}$). Monchaux et al. (Reference Monchaux, Bourgoin and Cartellier2010) and Obligado et al. (Reference Obligado, Teitelbaum, Cartellier, Mininni and Bourgoin2014) showed that for relatively small values of the Stokes number (

$\phi _{{\rm v}}$). Monchaux et al. (Reference Monchaux, Bourgoin and Cartellier2010) and Obligado et al. (Reference Obligado, Teitelbaum, Cartellier, Mininni and Bourgoin2014) showed that for relatively small values of the Stokes number (![]() $St \lesssim 10$) and for relatively small values of the Taylor-length-scale-based Reynolds number (

$St \lesssim 10$) and for relatively small values of the Taylor-length-scale-based Reynolds number (![]() $Re_\lambda \lesssim 200$), the degree of clustering increases by increasing the Stokes number and maximizes at

$Re_\lambda \lesssim 200$), the degree of clustering increases by increasing the Stokes number and maximizes at ![]() $St\approx 2\unicode{x2013}4$. Further increasing the Stokes number decreases the degree of clustering. Compared with those of Monchaux et al. (Reference Monchaux, Bourgoin and Cartellier2010) and Obligado et al. (Reference Obligado, Teitelbaum, Cartellier, Mininni and Bourgoin2014), the study of Sumbekova et al. (Reference Sumbekova, Cartellier, Aliseda and Bourgoin2017) showed that, for relatively small values of the Stokes number but relatively large values of the Taylor-length-scale-based Reynolds number (

$St\approx 2\unicode{x2013}4$. Further increasing the Stokes number decreases the degree of clustering. Compared with those of Monchaux et al. (Reference Monchaux, Bourgoin and Cartellier2010) and Obligado et al. (Reference Obligado, Teitelbaum, Cartellier, Mininni and Bourgoin2014), the study of Sumbekova et al. (Reference Sumbekova, Cartellier, Aliseda and Bourgoin2017) showed that, for relatively small values of the Stokes number but relatively large values of the Taylor-length-scale-based Reynolds number (![]() $Re_\lambda \gtrsim 200$),

$Re_\lambda \gtrsim 200$), ![]() $St$ does not greatly influence the degree of clustering, however, this parameter scales with

$St$ does not greatly influence the degree of clustering, however, this parameter scales with ![]() $Re_\lambda$ and the square root of

$Re_\lambda$ and the square root of ![]() $\phi _{{\rm v}}$. The studies of Sumbekova et al. (Reference Sumbekova, Cartellier, Aliseda and Bourgoin2017), Obligado et al. (Reference Obligado, Teitelbaum, Cartellier, Mininni and Bourgoin2014) and Monchaux et al. (Reference Monchaux, Bourgoin and Cartellier2010) showed that the probability density function (PDF) of the cluster and void areas feature power-law correlations with the exponents of the power-law ranging from approximately

$\phi _{{\rm v}}$. The studies of Sumbekova et al. (Reference Sumbekova, Cartellier, Aliseda and Bourgoin2017), Obligado et al. (Reference Obligado, Teitelbaum, Cartellier, Mininni and Bourgoin2014) and Monchaux et al. (Reference Monchaux, Bourgoin and Cartellier2010) showed that the probability density function (PDF) of the cluster and void areas feature power-law correlations with the exponents of the power-law ranging from approximately ![]() $-$1.5 to

$-$1.5 to ![]() $-$2.1 and

$-$2.1 and ![]() $-$1.7 to

$-$1.7 to ![]() $-$1.9, respectively. Sumbekova et al. (Reference Sumbekova, Cartellier, Aliseda and Bourgoin2017) showed that the PDFs of the cluster and void areas normalized by their corresponding mean value feature a power-law decay with an exponent of

$-$1.9, respectively. Sumbekova et al. (Reference Sumbekova, Cartellier, Aliseda and Bourgoin2017) showed that the PDFs of the cluster and void areas normalized by their corresponding mean value feature a power-law decay with an exponent of ![]() $-$5/3 for normalized cluster and void areas ranging from approximately 0.2 to 10.

$-$5/3 for normalized cluster and void areas ranging from approximately 0.2 to 10.

In addition to the PDFs of the cluster and void areas, the length scales of the clusters and voids and how they relate the length scales of the turbulent flow have been studied. The characteristic length scales of the clusters and voids are defined as the square root of the cluster and void mean areas, respectively. The studies of Aliseda et al. (Reference Aliseda, Cartellier, Hainaux and Lasheras2002), Obligado et al. (Reference Obligado, Teitelbaum, Cartellier, Mininni and Bourgoin2014), Sumbekova et al. (Reference Sumbekova, Cartellier, Aliseda and Bourgoin2017), Sahu et al. (Reference Sahu, Hardalupas and Taylor2016) and Boddapati et al. (Reference Boddapati, Manish and Sahu2020) showed that the cluster length scale is approximately 5–90 times the Kolmogorov length scale. For voids, Sumbekova et al. (Reference Sumbekova, Cartellier, Aliseda and Bourgoin2017) showed that the length scale can increase to approximately 200 times the Kolmogorov length scale. Power-law formulations were developed by Sumbekova et al. (Reference Sumbekova, Cartellier, Aliseda and Bourgoin2017) and it was shown that the normalized cluster length scale is proportional to ![]() $St^{-0.25}Re_\lambda ^{4.7}\phi _{{\rm v}}^{1.2}$. Also, Sumbekova et al. (Reference Sumbekova, Cartellier, Aliseda and Bourgoin2017) showed that, despite the Stokes number does not significantly influence the normalized voids length scale, this positively relates to

$St^{-0.25}Re_\lambda ^{4.7}\phi _{{\rm v}}^{1.2}$. Also, Sumbekova et al. (Reference Sumbekova, Cartellier, Aliseda and Bourgoin2017) showed that, despite the Stokes number does not significantly influence the normalized voids length scale, this positively relates to ![]() $Re_\lambda$ and

$Re_\lambda$ and ![]() $\phi _{{\rm v}}$.

$\phi _{{\rm v}}$.

Although the generated knowledge from the particle-laden flow studies (with a brief review presented above) is of significant importance, as it allows to understand the clustering characteristics of droplets corresponding to relatively small Stokes numbers (![]() $St < 10$), some engineering application feature droplets with large Stokes numbers. In such applications, it is of significant importance to understand the distribution of the droplet diameter and their number density within a given cluster and for

$St < 10$), some engineering application feature droplets with large Stokes numbers. In such applications, it is of significant importance to understand the distribution of the droplet diameter and their number density within a given cluster and for ![]() $St > 10$. For example, for spray combustion-related applications (which feature Stokes numbers in excess of 10), the mean distance between the fuel droplets and their number density within a given cluster can influence the droplet evaporation rate as well as the flame location and the temperature distribution, see for example the works of Sahu, Hardalupas & Taylor (Reference Sahu, Hardalupas and Taylor2018), Hardalupas, Taylor & Whitelaw (Reference Hardalupas, Taylor and Whitelaw1994), Akamatsu et al. (Reference Akamatsu, Miutani, Katsuki, Tsushima and Cho1996), Pandurangan & Sahu (Reference Pandurangan and Sahu2022) and Weiss et al. (Reference Weiss, Bhopalam, Meyer and Jenny2021). The objective of the present study is to investigate the effect of the Stokes number on both the geometrical (e.g. clusters and voids length scales) as well as the joint characteristics of the droplets and clusters/voids for

$St > 10$. For example, for spray combustion-related applications (which feature Stokes numbers in excess of 10), the mean distance between the fuel droplets and their number density within a given cluster can influence the droplet evaporation rate as well as the flame location and the temperature distribution, see for example the works of Sahu, Hardalupas & Taylor (Reference Sahu, Hardalupas and Taylor2018), Hardalupas, Taylor & Whitelaw (Reference Hardalupas, Taylor and Whitelaw1994), Akamatsu et al. (Reference Akamatsu, Miutani, Katsuki, Tsushima and Cho1996), Pandurangan & Sahu (Reference Pandurangan and Sahu2022) and Weiss et al. (Reference Weiss, Bhopalam, Meyer and Jenny2021). The objective of the present study is to investigate the effect of the Stokes number on both the geometrical (e.g. clusters and voids length scales) as well as the joint characteristics of the droplets and clusters/voids for ![]() $St > 10$. In the following, the methodology, data reduction, results and concluding remarks are presented in §§ 2–5, respectively.

$St > 10$. In the following, the methodology, data reduction, results and concluding remarks are presented in §§ 2–5, respectively.

2. Experimental methodology

The experimental set-up, the utilized diagnostics and the tested conditions are presented in this section.

2.1. Experimental set-up

The experimental set-up consists of a liquid delivery and flow apparatuses, which are shown in figure 1 as items (1–3) and item (4), respectively. A nitrogen bottle, item (1) in the figure, as well as a dual-valve MCRH 2000 ALICAT pressure controller, item (2), were used to purge water inside a pressure vessel, item (3). Then, water flowed into the flow apparatus, see the blue arrow in figure 1. In addition to water, a compressor was used to provide air into the flow apparatus, see the black arrow in figure 1. The air flow rate was controlled using an MCRH 5000 ALICAT mass flow controller.

Figure 1. Experimental set-up. Items (1–3) are a nitrogen bottle, a pressure controller and a pressurized water vessel. Item (4) is the nozzle section of the flow apparatus. Item (5) is a 532 nm Nd:YAG laser. Items (6–8) are the laser sheet forming optics and optomechanics. Items (9) and (10) are a Nova S12 camera and lens as well as a Zyla camera and lens for simultaneous Mie scattering and interferometric laser imaging for droplet sizing (ILIDS) measurements.

The flow apparatus is composed of a diffuser section (with an area ratio of 4), a settling chamber (which is equipped with five equally spaced mesh screens), a contraction section (with an area ratio of 7) and a nozzle (with an inner diameter of 48.4 mm). Further details regarding the apparatus are provided by Mohammadnejad, Saca & Kheirkhah (Reference Mohammadnejad, Saca and Kheirkhah2022), Kheirkhah & Gülder (Reference Kheirkhah and Gülder2015) and Kheirkhah (Reference Kheirkhah2016). The nozzle section of the flow apparatus is shown in figure 2. In the present study, this section was modified to allow for producing a spray subjected to turbulent co-flow of air. The nozzle includes a 6.4 mm outer diameter tube (which carries water), a spray injector, a turbulence generation mechanism and a ring-shaped tube-holder, which was press-fit against the inner wall of the nozzle and the outer wall of the tube using four bars and a collar. The injector was a pressure swirl atomizer from Delavan (model 6330609), which produced a polydisperse spray. The spray flow rate depends on the vessel pressure, and separate calibration experiments were performed to obtain the relation between the vessel pressure and the spray flow rate, as discussed in Appendix A.

Figure 2. (a) and (b) Three-dimensional (3-D) drawing of the flow apparatus nozzle section for the second and third turbulence generation mechanisms, respectively.

Three turbulence generation mechanisms were used in the present study. Either no perforated plate, one perforate plate (see figure 2a) or two perforated plates attached back-to-back (see figure 2b) were utilized. The outer diameter of each perforated plates is 48.4 mm, matching the inner diameter of the nozzle. Each perforated plate features 3.9 mm diameter holes arranged in a hexagonal pattern. For the first turbulence generation mechanism, the perforated plates in figure 2 were removed. For the third turbulence generation mechanism, the plates were rotated by 60![]() $^{\circ }$ with respect to one another, similar to that in the study of Kheirkhah & Gülder (Reference Kheirkhah and Gülder2014). For the second turbulence generation mechanism, the planes containing the holes, and for the third turbulence generation mechanism, the centre plane of the two perforated plates, were positioned 76.0 mm upstream of the nozzle exit plane, similar to the studies of Kheirkhah & Gülder (Reference Kheirkhah and Gülder2015) and Kheirkhah (Reference Kheirkhah2016).

$^{\circ }$ with respect to one another, similar to that in the study of Kheirkhah & Gülder (Reference Kheirkhah and Gülder2014). For the second turbulence generation mechanism, the planes containing the holes, and for the third turbulence generation mechanism, the centre plane of the two perforated plates, were positioned 76.0 mm upstream of the nozzle exit plane, similar to the studies of Kheirkhah & Gülder (Reference Kheirkhah and Gülder2015) and Kheirkhah (Reference Kheirkhah2016).

2.2. Diagnostics

Separate hotwire anemometry (HWA) as well as simultaneous Mie scattering and interferometric laser imaging for droplet sizing (ILIDS) were performed. The hotwire anemometry was used to characterize the background turbulent flow. A schematic of the diagnostics used in the present study is shown in figure 1. The hardware configuration for the HWA is identical to that used by Mohammadnejad et al. (Reference Mohammadnejad, Saca and Kheirkhah2022); so a separate illustration is not presented in figure 1. For all test conditions, the HWA data were acquired at a frequency of 100 kHz and for 90 s, corresponding to 9 000 000 data points. The simultaneous Mie scattering and ILIDS images were collected at a frequency of 10 Hz and for a duration of 80 s, corresponding to 800 image pairs. Further details regarding the HWA, Mie scattering and ILIDS diagnostics are provided in the following.

2.2.1. Hotwire anemometry

The hardware of the HWA system consists of a probe (model 55P01 from Dantec), a probe support (model 9055H0261 from Dantec) and two motorized translational stages (MTS50-Z8 from Thorlabs). The probe is a single wire sensor, which is 3 mm long (with an active sensor length of 1.25 mm) and has a diameter of 5 ![]() $\mathrm {\mu }$m. A mini-constant temperature anemometry (mini-CTA) circuit (model 9054T0421 from Dantec) maintains the wire temperature, with an overheat ratio of 0.7. The motorized translational stages featured a 50 mm range of operation, which was sufficient for the present study. Further details regarding the HWA system as well as the calibration procedure are provided by Mohammadnejad et al. (Reference Mohammadnejad, Saca and Kheirkhah2022).

$\mathrm {\mu }$m. A mini-constant temperature anemometry (mini-CTA) circuit (model 9054T0421 from Dantec) maintains the wire temperature, with an overheat ratio of 0.7. The motorized translational stages featured a 50 mm range of operation, which was sufficient for the present study. Further details regarding the HWA system as well as the calibration procedure are provided by Mohammadnejad et al. (Reference Mohammadnejad, Saca and Kheirkhah2022).

A Cartesian coordinate system was used in the present investigation. The origin of the coordinate system is at the exit plane of the nozzle section and at the nozzle centreline, as shown in figure 3. The ![]() $z$-axis coincides with the nozzle centreline. The

$z$-axis coincides with the nozzle centreline. The ![]() $x$-axis is normal to the

$x$-axis is normal to the ![]() $z$-axis and is parallel with the laser sheet shown in figure 1. HWA was performed at

$z$-axis and is parallel with the laser sheet shown in figure 1. HWA was performed at ![]() $z = 35.0$ mm and at horizontal locations spaced by 5.0 mm along the

$z = 35.0$ mm and at horizontal locations spaced by 5.0 mm along the ![]() $x$-axis, ranging from

$x$-axis, ranging from ![]() $x = -20.0$ to 20.0 mm as shown by the red cross data symbols in figure 3.

$x = -20.0$ to 20.0 mm as shown by the red cross data symbols in figure 3.

Figure 3. Coordinate system and the measurements locations. The red cross data points present the locations at which the hotwire anemometry was performed. The dashed black and dash–dotted blue squares are the regions of interest for the Mie scattering and ILIDS measurements, respectively. The minimum vertical distance for the above measurements is 35.0 mm from the nozzle exit plane, and this distance shown in the figure is not to scale.

2.2.2. Mie scattering

The Mie scattering hardware consists of a pulsed Nd:YAG laser (Lab-Series-170 from Spectra Physics, shown by item (5) in figure 1), the sheet forming optics (see items (6–8)) and a camera equipped with collection optics (item (9)). The laser produces a 1064 nm beam, which is converted to a 532 nm beam using a harmonic generator. The laser was operated at a reduced (compared to its maximum) but fixed energy to avoid saturation in the collected Mie scattering images. The laser beam was 8.0 mm in diameter, which was converted to a 40 mm high and 1 mm thick laser sheet using a plano-concave cylindrical lens with a focal length of ![]() $-$100 mm, a plano-convex cylindrical lens with a focal length of 500 mm and a cylindrical lens with a focal length of 1000 mm, see items (6–8) in figure 1. The centreline of the collimated laser sheet was positioned at

$-$100 mm, a plano-convex cylindrical lens with a focal length of 500 mm and a cylindrical lens with a focal length of 1000 mm, see items (6–8) in figure 1. The centreline of the collimated laser sheet was positioned at ![]() $z=55.0$ mm. The Mie scattering images were acquired using a Photron Fastcam Nova S12 camera equipped with a Macro Sigma lens, which had a focal length of

$z=55.0$ mm. The Mie scattering images were acquired using a Photron Fastcam Nova S12 camera equipped with a Macro Sigma lens, which had a focal length of ![]() $f =105$ mm and its aperture size was set to

$f =105$ mm and its aperture size was set to ![]() $f/2.8$. A bandpass filter with a centre wavelength and full width at half maximum of 532 and 20 nm was mounted on the camera lens. By adjusting the working distance of the camera, a field of view of 70.0 mm along the

$f/2.8$. A bandpass filter with a centre wavelength and full width at half maximum of 532 and 20 nm was mounted on the camera lens. By adjusting the working distance of the camera, a field of view of 70.0 mm along the ![]() $x$-axis and 70.0 mm along the

$x$-axis and 70.0 mm along the ![]() $z$-axis was obtained, which corresponds to a pixel resolution of

$z$-axis was obtained, which corresponds to a pixel resolution of ![]() $70\,\mathrm {mm}/1024\,\mathrm {pixels}=68\,\mathrm {\mu }\mathrm {m}\,\mathrm {pixel}^{-1}$. For analysis and presentation purposes, the above field of view was cropped to a

$70\,\mathrm {mm}/1024\,\mathrm {pixels}=68\,\mathrm {\mu }\mathrm {m}\,\mathrm {pixel}^{-1}$. For analysis and presentation purposes, the above field of view was cropped to a ![]() $50.0\,{\rm mm}\times 50.0\,{\rm mm}$ square, which is shown by the black dashed box in figure 3. It is noted that since the above field of view is close to the injector, the air entrainment may occur and the background turbulent air flow may be anisotropic. A field of view that is located farther from the injector could facilitate reducing the effect of the air entrainment into the spray on the reported results and/or improve the background turbulent flow isotropy. However, the present study employed an injector that is used for reacting flow applications for which the majority of the turbulence and droplet interaction takes place close to the injector. In fact, at distances larger than 85 mm and for reacting conditions (not discussed here), the droplets are evaporated, burned and do not exist. For this reason, a field of view that is close to the injector is chosen. At distances smaller than 35 mm, the spray was too dense and the images were influenced by the laser reflection from the injector; as a result, the analysis of the Mie scattering images was not feasible.

$50.0\,{\rm mm}\times 50.0\,{\rm mm}$ square, which is shown by the black dashed box in figure 3. It is noted that since the above field of view is close to the injector, the air entrainment may occur and the background turbulent air flow may be anisotropic. A field of view that is located farther from the injector could facilitate reducing the effect of the air entrainment into the spray on the reported results and/or improve the background turbulent flow isotropy. However, the present study employed an injector that is used for reacting flow applications for which the majority of the turbulence and droplet interaction takes place close to the injector. In fact, at distances larger than 85 mm and for reacting conditions (not discussed here), the droplets are evaporated, burned and do not exist. For this reason, a field of view that is close to the injector is chosen. At distances smaller than 35 mm, the spray was too dense and the images were influenced by the laser reflection from the injector; as a result, the analysis of the Mie scattering images was not feasible.

2.2.3. Interferometric laser imaging for droplet sizing

ILIDS was performed to measure the droplets diameter, similar to that done by Qieni et al. (Reference Qieni, Kan, Baozhen and Xiang2016), Bocanegra Evans et al. (Reference Bocanegra Evans, Dam, van der Voort, Bertens and van de Water2015) and Garcia-Magarino et al. (Reference Garcia-Magarino, Sor, Bardera and Munoz-Campillejo2021). In ILIDS, the droplet diameter is measured by analysing the interference pattern of the reflected and first-order refracted rays scattered from spherical droplets that are illuminated by a laser. The ILIDS hardware includes the laser and the laser-sheet forming optics, see items (5–8) in figure 1, which are identical to those used for the Mie scattering technique as well as a scientific complementary metal-oxide semiconductor (sCMOS) camera equipped with a Macro sigma lens (![]() $\,f = 105$ mm and aperture size of

$\,f = 105$ mm and aperture size of ![]() $f/2.8$) and a high-precision rotary stage, see item (10). The camera is a 5.5 Zyla from Andor, which has a

$f/2.8$) and a high-precision rotary stage, see item (10). The camera is a 5.5 Zyla from Andor, which has a ![]() $2560\,{\rm pixels}\times 2160\,{\rm pixels}$ sensor. The ILIDS field of view was 29.4 mm along the

$2560\,{\rm pixels}\times 2160\,{\rm pixels}$ sensor. The ILIDS field of view was 29.4 mm along the ![]() $x$-axis and 24.6 mm along the

$x$-axis and 24.6 mm along the ![]() $z$-axis, which led to a pixel resolution of

$z$-axis, which led to a pixel resolution of ![]() $29.4\,\mathrm {mm}/2560\,\mathrm {pixels} = 11.4\,\mathrm {\mu }\mathrm {m}\,\mathrm {pixel}^{-1}$. Using the rotary stage, the angle between the axis normal to the camera sensor and the direction of the laser sheet,

$29.4\,\mathrm {mm}/2560\,\mathrm {pixels} = 11.4\,\mathrm {\mu }\mathrm {m}\,\mathrm {pixel}^{-1}$. Using the rotary stage, the angle between the axis normal to the camera sensor and the direction of the laser sheet, ![]() $\theta$, was adjusted. Sahu (Reference Sahu2011) utilized the Mie scattering theory and obtained the variations of the intensities of the first-order refraction and reflected light versus the scattering angle for water droplets. For these droplets, they showed that the above intensities are equal at approximately

$\theta$, was adjusted. Sahu (Reference Sahu2011) utilized the Mie scattering theory and obtained the variations of the intensities of the first-order refraction and reflected light versus the scattering angle for water droplets. For these droplets, they showed that the above intensities are equal at approximately ![]() $\theta =69^{\circ }$, creating interference patterns with a maximized amplitude which leads to the best clarity of the fringe patterns. In the present study, and similar to those performed by Sahu (Reference Sahu2011) and Sahu et al. (Reference Sahu, Hardalupas and Taylor2016),

$\theta =69^{\circ }$, creating interference patterns with a maximized amplitude which leads to the best clarity of the fringe patterns. In the present study, and similar to those performed by Sahu (Reference Sahu2011) and Sahu et al. (Reference Sahu, Hardalupas and Taylor2016), ![]() $\theta$ was set to 69

$\theta$ was set to 69![]() $^{\circ }$. Finally, the formulation by Hayashi, Ichiyanagi & Hishida (Reference Hayashi, Ichiyanagi and Hishida2012) and Thimothée et al. (Reference Thimothée, Chauveau, Halter and Gökalp2016) was used to estimate the droplet diameter, which is given by

$^{\circ }$. Finally, the formulation by Hayashi, Ichiyanagi & Hishida (Reference Hayashi, Ichiyanagi and Hishida2012) and Thimothée et al. (Reference Thimothée, Chauveau, Halter and Gökalp2016) was used to estimate the droplet diameter, which is given by

\begin{equation} d=\frac{2\lambda_\mathrm{L} N}{\alpha}\left[\cos\left(\frac{\theta}{2}\right)+ \frac{m\sin\left(\dfrac{\theta}{2}\right)}{\sqrt{m^{2}-2m\cos\left(\dfrac{\theta}{2}\right)+1}}\right]^{{-}1}, \end{equation}

\begin{equation} d=\frac{2\lambda_\mathrm{L} N}{\alpha}\left[\cos\left(\frac{\theta}{2}\right)+ \frac{m\sin\left(\dfrac{\theta}{2}\right)}{\sqrt{m^{2}-2m\cos\left(\dfrac{\theta}{2}\right)+1}}\right]^{{-}1}, \end{equation}

where ![]() $\lambda _{{\rm L}}$ is the wavelength of the laser and is 532 nm. In (2.1),

$\lambda _{{\rm L}}$ is the wavelength of the laser and is 532 nm. In (2.1), ![]() $m$ is the droplets index of refraction, which equals 1.33 for water, and

$m$ is the droplets index of refraction, which equals 1.33 for water, and ![]() $\alpha$ is the collection angle of the scattered light. The collection angle depends on the utilized lens diameter (

$\alpha$ is the collection angle of the scattered light. The collection angle depends on the utilized lens diameter (![]() $d_{{\rm l}}$, which is 60 mm), and the distance between the camera lens and the projected location of the droplets in the measurement plane (

$d_{{\rm l}}$, which is 60 mm), and the distance between the camera lens and the projected location of the droplets in the measurement plane (![]() $c$). Specifically, the collection angle is calculated using

$c$). Specifically, the collection angle is calculated using ![]() $\alpha =2\arctan [d_{{\rm l}}/(2c)]$. In the present study, while

$\alpha =2\arctan [d_{{\rm l}}/(2c)]$. In the present study, while ![]() $d_{{\rm l}}$ is fixed,

$d_{{\rm l}}$ is fixed, ![]() $c$ can vary from 195 to 205 mm. Thus, the collection angle is not constant across the image plane. Here, a fixed value of

$c$ can vary from 195 to 205 mm. Thus, the collection angle is not constant across the image plane. Here, a fixed value of ![]() $c = 200$ mm was used which can lead to an error in the calculation of the droplet diameter. This error was quantified, and it was obtained that the maximum error due to the variation of

$c = 200$ mm was used which can lead to an error in the calculation of the droplet diameter. This error was quantified, and it was obtained that the maximum error due to the variation of ![]() $c$ is less than 2.5 %.

$c$ is less than 2.5 %.

In (2.1), ![]() $N$ is the number of the fringes and is estimated using the procedure discussed in the next section. Substituting

$N$ is the number of the fringes and is estimated using the procedure discussed in the next section. Substituting ![]() $N=1$ and the values of

$N=1$ and the values of ![]() $\lambda _{{\rm L}}$,

$\lambda _{{\rm L}}$, ![]() $m$,

$m$, ![]() $\theta$ and

$\theta$ and ![]() $\alpha$ in (2.1), the droplet diameter per fringe is obtained, which is 1.97

$\alpha$ in (2.1), the droplet diameter per fringe is obtained, which is 1.97 ![]() $\mathrm {\mu }$m. Since at least two fringes are required for the detection of the droplets, the minimum measurable diameter of the droplets is twice the diameter per fringe which is

$\mathrm {\mu }$m. Since at least two fringes are required for the detection of the droplets, the minimum measurable diameter of the droplets is twice the diameter per fringe which is ![]() $2\times 1.97\,\mathrm {\mu }{\rm m} \approx 4\,\mathrm {\mu }$m. Also, considering the widths of the fringes, the maximum resolvable diameter is estimated and equals 150

$2\times 1.97\,\mathrm {\mu }{\rm m} \approx 4\,\mathrm {\mu }$m. Also, considering the widths of the fringes, the maximum resolvable diameter is estimated and equals 150 ![]() $\mathrm {\mu }$m. Challenges exist in performing simultaneous ILIDS and Mie scattering measurements as well as interpreting the results, which need to be addressed. Since the viewing angle of the ILIDS camera is different than that of the Mie scattering camera, simultaneous measurement of the location of the droplets using the Mie scattering and ILIDS techniques require registering the ILIDS images to the Mie scattering images. Even after the registration of the ILIDS image to the Mie scattering image, since the ILIDS images are out-of-focus, the centres of the droplets identified from the ILIDS images are not identical to those obtained form the Mie scattering images. Furthermore, due to the limitations of the ILIDS technique, the number of droplets detected in each frame of the ILIDS does not equate to that of the Mie scattering technique. The above potentially lead to uncertainty in estimating the joint characteristics of the droplets and clusters/voids. Details for addressing/assessing the issues related to the droplets centre discrepancy and average diameter uncertainty for the calculation of the joint characteristics are discussed in Appendices B and C, respectively.

$\mathrm {\mu }$m. Challenges exist in performing simultaneous ILIDS and Mie scattering measurements as well as interpreting the results, which need to be addressed. Since the viewing angle of the ILIDS camera is different than that of the Mie scattering camera, simultaneous measurement of the location of the droplets using the Mie scattering and ILIDS techniques require registering the ILIDS images to the Mie scattering images. Even after the registration of the ILIDS image to the Mie scattering image, since the ILIDS images are out-of-focus, the centres of the droplets identified from the ILIDS images are not identical to those obtained form the Mie scattering images. Furthermore, due to the limitations of the ILIDS technique, the number of droplets detected in each frame of the ILIDS does not equate to that of the Mie scattering technique. The above potentially lead to uncertainty in estimating the joint characteristics of the droplets and clusters/voids. Details for addressing/assessing the issues related to the droplets centre discrepancy and average diameter uncertainty for the calculation of the joint characteristics are discussed in Appendices B and C, respectively.

2.3. Test conditions

In total, 13 experimental conditions were tested, with the corresponding details tabulated in table 1. The first row in the table highlights the test condition for which no co-flow is used and the spray is issued into the quiescent air. The first column in the table presents the utilized turbulence generation (TG) mechanism, with 0PP, 1PP and 2PP referring to zero, one and two perforated plates, respectively. For each turbulence generation mechanism, the mean bulk flow velocities of 3.5, 7.0, 10.5 and 14.0 m s![]() $^{-1}$ were tested. The bulk Reynolds number was calculated using

$^{-1}$ were tested. The bulk Reynolds number was calculated using ![]() $Re_{D}=UD/\nu$, with

$Re_{D}=UD/\nu$, with ![]() $D$ being the nozzle diameter and

$D$ being the nozzle diameter and ![]() $\nu$ being the air kinematic viscosity estimated at the laboratory temperature. The values of

$\nu$ being the air kinematic viscosity estimated at the laboratory temperature. The values of ![]() $Re_D$ are tabulated in the third column of table 1. The RMS of the streamwise velocity (

$Re_D$ are tabulated in the third column of table 1. The RMS of the streamwise velocity (![]() $u'_0$) and the integral length scale (

$u'_0$) and the integral length scale (![]() $\varLambda$) estimated at

$\varLambda$) estimated at ![]() $x=0$ and

$x=0$ and ![]() $z = 35.0$ mm are listed in the fourth and fifth columns of table 1, respectively. The integral length scale was calculated using the Taylor's frozen turbulence hypothesis, see the work of Taylor (Reference Taylor1938), and following the procedure detailed by Mohammadnejad et al. (Reference Mohammadnejad, Saca and Kheirkhah2022). Specifically, the integral length scale was calculated as the multiplication of the mean bulk flow velocity and the integral of the streamwise velocity auto-correlation from

$z = 35.0$ mm are listed in the fourth and fifth columns of table 1, respectively. The integral length scale was calculated using the Taylor's frozen turbulence hypothesis, see the work of Taylor (Reference Taylor1938), and following the procedure detailed by Mohammadnejad et al. (Reference Mohammadnejad, Saca and Kheirkhah2022). Specifically, the integral length scale was calculated as the multiplication of the mean bulk flow velocity and the integral of the streamwise velocity auto-correlation from ![]() $t=0$ to the first time that the auto-correlation becomes zero. The Taylor (

$t=0$ to the first time that the auto-correlation becomes zero. The Taylor (![]() $\lambda$) and Kolmogorov (

$\lambda$) and Kolmogorov (![]() $\eta$) length scales were calculated using

$\eta$) length scales were calculated using ![]() $\lambda = \varLambda (u^\prime _0 \varLambda /\nu )^{-0.5}$ and

$\lambda = \varLambda (u^\prime _0 \varLambda /\nu )^{-0.5}$ and ![]() $\eta = \varLambda (u^\prime _0 \varLambda /\nu )^{-0.75}$. The values of

$\eta = \varLambda (u^\prime _0 \varLambda /\nu )^{-0.75}$. The values of ![]() $\lambda$ and

$\lambda$ and ![]() $\eta$ are tabulated in the sixth and seventh columns of table 1. For all test conditions, the most probable droplet diameters (

$\eta$ are tabulated in the sixth and seventh columns of table 1. For all test conditions, the most probable droplet diameters (![]() $d^*$) were obtained using the ILIDS diagnostic and are listed in the eighth column of the table. Further details regarding the size distribution of the droplets are discussed in § 4.1.

$d^*$) were obtained using the ILIDS diagnostic and are listed in the eighth column of the table. Further details regarding the size distribution of the droplets are discussed in § 4.1.

Table 1. Test conditions. TG stands for the turbulence generating mechanism. 0PP, 1PP and 2PP are the acronyms for zero, one and two perforated plates, respectively.

The Taylor-length-scale-based Reynolds number, the Stokes number and the liquid volume fraction are non-dimensional parameters that can potentially influence the interaction of the droplets with the background turbulent flow. The Taylor-length-scale-based Reynolds number was estimated using ![]() $Re_\lambda = u^\prime _0 \lambda /\nu$, with the corresponding values listed in the ninth column of table 1. In the present study,

$Re_\lambda = u^\prime _0 \lambda /\nu$, with the corresponding values listed in the ninth column of table 1. In the present study, ![]() $Re_\lambda$ varies from approximately 10 to 36, which corresponds to relatively small values. Following Reade & Collins (Reference Reade and Collins2000), the Stokes number was calculated using

$Re_\lambda$ varies from approximately 10 to 36, which corresponds to relatively small values. Following Reade & Collins (Reference Reade and Collins2000), the Stokes number was calculated using

where ![]() $\rho _{{\rm W}}$ and

$\rho _{{\rm W}}$ and ![]() $\rho _{{\rm A}}$ are the water and air densities, respectively, both estimated at the laboratory temperature. In (2.2),

$\rho _{{\rm A}}$ are the water and air densities, respectively, both estimated at the laboratory temperature. In (2.2), ![]() $d$ is the droplet diameter. In the present study,

$d$ is the droplet diameter. In the present study, ![]() $d$ was selected as the most probable droplet diameter for estimation of the Stokes number, with the rationale for this selection discussed later. The values of

$d$ was selected as the most probable droplet diameter for estimation of the Stokes number, with the rationale for this selection discussed later. The values of ![]() $St$ are tabulated in table 1 and range from approximately 3 to 25, which are relatively large compared to those of the studies that were performed in multi-phase wind tunnels. It is worth highlighting that, in addition to the most probable droplet diameter, the Sauter mean diameter was also estimated for all test conditions following the formulation given by Lefebvre & McDonell (Reference Lefebvre and McDonell2017). The Stokes number estimated based on the Sauter mean diameter and the Kolmogorov length scale varied from 17 to 150 and positively correlated with the Stokes number estimated based on the most probable droplet diameter and the Kolmogorov length scale. Additionally, instead of the Kolmogorov length scale, the Stokes number was also estimated based on the integral length scale. It was obtained that the Stokes numbers estimated based on both length scales positively correlate. Given the above correlations, presentation of the results using the Stokes number estimated based on either of the length scales or either of the diameters yielded similar conclusions. Nonetheless, facilitating comparisons with the past investigations, e.g. those of Sumbekova et al. (Reference Sumbekova, Cartellier, Aliseda and Bourgoin2017), Obligado et al. (Reference Obligado, Teitelbaum, Cartellier, Mininni and Bourgoin2014) and Monchaux et al. (Reference Monchaux, Bourgoin and Cartellier2010), the Stokes number estimated based on the most probable droplet diameter and the Kolmogorov length scale was used in the discussions and analyses.

$St$ are tabulated in table 1 and range from approximately 3 to 25, which are relatively large compared to those of the studies that were performed in multi-phase wind tunnels. It is worth highlighting that, in addition to the most probable droplet diameter, the Sauter mean diameter was also estimated for all test conditions following the formulation given by Lefebvre & McDonell (Reference Lefebvre and McDonell2017). The Stokes number estimated based on the Sauter mean diameter and the Kolmogorov length scale varied from 17 to 150 and positively correlated with the Stokes number estimated based on the most probable droplet diameter and the Kolmogorov length scale. Additionally, instead of the Kolmogorov length scale, the Stokes number was also estimated based on the integral length scale. It was obtained that the Stokes numbers estimated based on both length scales positively correlate. Given the above correlations, presentation of the results using the Stokes number estimated based on either of the length scales or either of the diameters yielded similar conclusions. Nonetheless, facilitating comparisons with the past investigations, e.g. those of Sumbekova et al. (Reference Sumbekova, Cartellier, Aliseda and Bourgoin2017), Obligado et al. (Reference Obligado, Teitelbaum, Cartellier, Mininni and Bourgoin2014) and Monchaux et al. (Reference Monchaux, Bourgoin and Cartellier2010), the Stokes number estimated based on the most probable droplet diameter and the Kolmogorov length scale was used in the discussions and analyses.

Following the definition provided by Elghobashi (Reference Elghobashi1994), the liquid volume fraction was calculated from

where ![]() $n$ is the mean number of droplets within the volume of the region of interest (ROI),

$n$ is the mean number of droplets within the volume of the region of interest (ROI), ![]() $V_{{\rm ROI}}$. In (2.3),

$V_{{\rm ROI}}$. In (2.3), ![]() $V_{{\rm d}}$ is the droplet volume. For each test condition,

$V_{{\rm d}}$ is the droplet volume. For each test condition, ![]() $n$ was estimated using the Mie scattering technique and averaged over all collected Mie scattering images.

$n$ was estimated using the Mie scattering technique and averaged over all collected Mie scattering images. ![]() $V_{{\rm ROI}} = 50\,\mathrm {mm}\times 50\,\mathrm {mm}\times 1\,\mathrm {mm}$ and

$V_{{\rm ROI}} = 50\,\mathrm {mm}\times 50\,\mathrm {mm}\times 1\,\mathrm {mm}$ and ![]() $V_{{\rm d}} = ({\rm \pi} /6)d^{*3}$. The values of

$V_{{\rm d}} = ({\rm \pi} /6)d^{*3}$. The values of ![]() $\phi _\mathrm {v}$ are listed in the last column of table 1 and change from approximately

$\phi _\mathrm {v}$ are listed in the last column of table 1 and change from approximately ![]() $1\times 10^{-6}$ to

$1\times 10^{-6}$ to ![]() $2\times 10^{-6}$. Following Elghobashi (Reference Elghobashi1994), the estimated liquid volume fractions are relatively small, rendering the tested sprays as dilute. In essence, compared to past studies, the non-dimensional parameters of the present study correspond to dilute sprays with small Taylor-length-scale-based Reynolds number but large Stokes numbers.

$2\times 10^{-6}$. Following Elghobashi (Reference Elghobashi1994), the estimated liquid volume fractions are relatively small, rendering the tested sprays as dilute. In essence, compared to past studies, the non-dimensional parameters of the present study correspond to dilute sprays with small Taylor-length-scale-based Reynolds number but large Stokes numbers.

For all test conditions with the co-flow, ![]() $St$,

$St$, ![]() $Re_\lambda$ and

$Re_\lambda$ and ![]() $\phi _{{\rm v}}$ vary by changing the mean bulk flow velocity and the turbulence generation mechanism. Variations of

$\phi _{{\rm v}}$ vary by changing the mean bulk flow velocity and the turbulence generation mechanism. Variations of ![]() $St$ versus

$St$ versus ![]() $U$,

$U$, ![]() $Re_\lambda$ versus

$Re_\lambda$ versus ![]() $St$ and

$St$ and ![]() $\phi _{{\rm v}}$ versus

$\phi _{{\rm v}}$ versus ![]() $St$ are presented in figure 4(a–c), respectively. As can be seen, the variations of these non-dimensional parameters are mostly influenced by the mean bulk flow velocity. That is, increasing

$St$ are presented in figure 4(a–c), respectively. As can be seen, the variations of these non-dimensional parameters are mostly influenced by the mean bulk flow velocity. That is, increasing ![]() $U$ increases

$U$ increases ![]() $St$ and

$St$ and ![]() $Re_\lambda$ but decreases

$Re_\lambda$ but decreases ![]() $\phi _{{\rm v}}$. It is important to note that, in the present study, changing the turbulence generation mechanism for a fixed value of

$\phi _{{\rm v}}$. It is important to note that, in the present study, changing the turbulence generation mechanism for a fixed value of ![]() $U$ and changing

$U$ and changing ![]() $U$ for a given turbulence generation mechanism both change the background RMS velocity fluctuations, which changes

$U$ for a given turbulence generation mechanism both change the background RMS velocity fluctuations, which changes ![]() $St$,

$St$, ![]() $Re_\lambda$ and

$Re_\lambda$ and ![]() $\phi _{{\rm v}}$.

$\phi _{{\rm v}}$.

Figure 4. Variations of (a) the Stokes number versus mean bulk flow velocity, (b) the Taylor-length-scale-based Reynolds number versus Stokes number and (c) the liquid volume fraction versus the Stokes number. The blue, green and red colours correspond to turbulence generation mechanisms with zero, one and two perforated plates, respectively.

3. Data reduction

Of prime importance to the present study are identifications of clusters and voids as well as estimating the droplets diameter. The former and the latter are obtained using the Mie scattering and the ILIDS, respectively, with details provided in the following subsections.

3.1. Clusters and voids identification

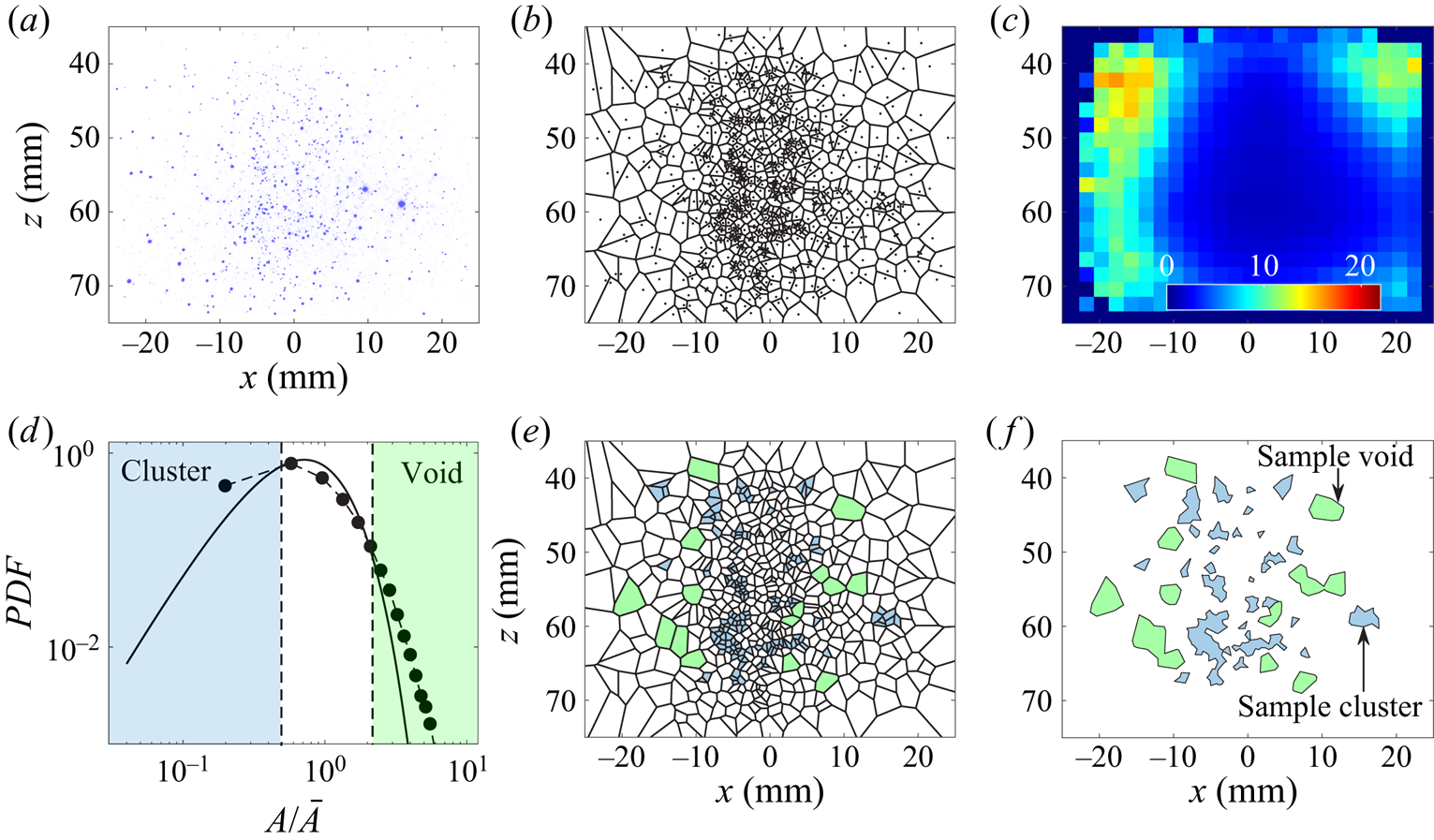

The procedures followed to identify the clusters and voids are illustrated in figure 5. A representative raw Mie scattering image corresponding to the no co-flow test condition is shown in figure 5(a). The results in figure 5(a) were binarized to identify the centres of the droplets, which are shown by the black circular data points in figure 5(b). It is important to note that the laser intensity features a nearly top-hat profile in the region of interest. Also, the Mie scattering background field (averaged over 800 images taken with the camera lens capped) is approximately 0.2 % of the maximum acquired intensity. Thus, normalizing the Mie scattering images by the spatially varying laser intensity as well as subtracting the background field from the Mie scattering images did not influence the process for identifying the droplets centres in figure 5(b). Using the centres of the droplets along with the ‘voronoi’ function in MATLAB, the Voronoï cells around each droplet were obtained and overlaid on figure 5(b) using the black lines. As can be seen in figure 5(b), the area of the Voronoï cells located at the centre of the ROI is relatively small and increases towards the periphery of this region. Such increasing trend is related to the inhomogeneous seeding of the droplets by the injector and can potentially lead to the incorrect identification of the clusters and voids which are formed because of the interaction of the droplets with the background turbulent flow. Aiming to address this issue, following Sumbekova et al. (Reference Sumbekova, Cartellier, Aliseda and Bourgoin2017), the values of the Voronoï cells area were normalized by the locally averaged value. Following this, first, the ROI was divided into several windows (widths and heights of ![]() ${\rm \Delta} x$ and

${\rm \Delta} x$ and ![]() ${\rm \Delta} z$). Then, the areas of the Voronoï cells corresponding to the droplets within each of the above windows were obtained for all frames and were averaged, with the results shown in figure 5(c). The spatially varying

${\rm \Delta} z$). Then, the areas of the Voronoï cells corresponding to the droplets within each of the above windows were obtained for all frames and were averaged, with the results shown in figure 5(c). The spatially varying ![]() $\bar {A}$, which is shown in figure 5(c), was used in the calculation of PDF

$\bar {A}$, which is shown in figure 5(c), was used in the calculation of PDF ![]() $(A/\bar {A})$. In this calculation, all Mie scattering images were used, and the resultant PDF is presented in figure 5(d) with the black circular data points.

$(A/\bar {A})$. In this calculation, all Mie scattering images were used, and the resultant PDF is presented in figure 5(d) with the black circular data points.

Figure 5. (a) Representative raw Mie scattering image corresponding to the no co-flow test condition. (b) Centres of the droplets in panel (a) and the Voronoï cells. (c) Spatial variation of the locally averaged Voronoï cells area. (d) PDF of the Voronoï cells areas normalized by their local mean. Overlaid in panel (d) is the PDF ![]() $_{\rm RPP}$ from (3.1). The dashed lines in panel (d) are

$_{\rm RPP}$ from (3.1). The dashed lines in panel (d) are ![]() $A/\bar {A} = 0.5$ and 2.2. (e) Cells with areas related to clusters (blue cells) and voids (green cells). (f) Clusters and voids corresponding to the Mie scattering image in panel (a).

$A/\bar {A} = 0.5$ and 2.2. (e) Cells with areas related to clusters (blue cells) and voids (green cells). (f) Clusters and voids corresponding to the Mie scattering image in panel (a).

Provided the droplets spatial distribution followed the RPP, the PDF of ![]() $A/\bar {A}$, referred to as PDF

$A/\bar {A}$, referred to as PDF ![]() $_\mathrm {RPP}$, could be estimated using that of Ferenc & Néda (Reference Ferenc and Néda2007) which is given by

$_\mathrm {RPP}$, could be estimated using that of Ferenc & Néda (Reference Ferenc and Néda2007) which is given by

In (3.1), ![]() $a$ and

$a$ and ![]() $b$ are fitting parameters with

$b$ are fitting parameters with ![]() $a=b=3.5$, and

$a=b=3.5$, and ![]() $\varGamma$ is the gamma function with

$\varGamma$ is the gamma function with ![]() $\varGamma (a) = 3.32$. The variation of PDF

$\varGamma (a) = 3.32$. The variation of PDF ![]() $_{\rm RPP}$ versus

$_{\rm RPP}$ versus ![]() $A/\bar {A}$ was obtained and presented by the black solid curve in figure 5(c). Additionally, using MATLAB, 800 images were synthetically generated by distributing particles inside the domain of investigation randomly, with the number of droplets identical to that shown in figure 5(a), and the PDF of

$A/\bar {A}$ was obtained and presented by the black solid curve in figure 5(c). Additionally, using MATLAB, 800 images were synthetically generated by distributing particles inside the domain of investigation randomly, with the number of droplets identical to that shown in figure 5(a), and the PDF of ![]() $A/\bar {A}$ was calculated. It was confirmed that the PDF of the Voronoï cells normalized area for randomly distributed particles closely follows the right-hand side of (3.1). Next, the intersections of PDF

$A/\bar {A}$ was calculated. It was confirmed that the PDF of the Voronoï cells normalized area for randomly distributed particles closely follows the right-hand side of (3.1). Next, the intersections of PDF ![]() $_{\rm RPP}$ and the PDF

$_{\rm RPP}$ and the PDF ![]() $(A/\bar {A})$ for the results in figure 5(d) were obtained, which are shown by the dashed lines corresponding to

$(A/\bar {A})$ for the results in figure 5(d) were obtained, which are shown by the dashed lines corresponding to ![]() $A/\bar {A} = 0.5$ and 2.2. The Voronoï cells with area smaller than

$A/\bar {A} = 0.5$ and 2.2. The Voronoï cells with area smaller than ![]() $0.5 \bar {A}$ were labelled as clusters, and Voronoï cells with area larger than

$0.5 \bar {A}$ were labelled as clusters, and Voronoï cells with area larger than ![]() $2.2\bar {A}$ were labelled as voids. The identified clusters and voids corresponding to the Mie scattering image in figure 5(a) are shown by the blue and green colour cells in figure 5(e). As can be seen, clusters or voids may feature connected boundaries forming larger clusters and voids. Following Andrade et al. (Reference Andrade, Hardalupas and Charalampous2022), in the present study, the graph theory was used to identify and group the clusters/voids cells that are interconnected. For the results presented in figure 5(e), the identified clusters and voids are shown in figure 5(f). These clusters and voids were used for further analysis in § 4. It is important to note that the identified clusters and voids are formed due to both the interaction of the droplets with the background turbulent flow as well as (potentially) the air entrainment into the spray. Isolating the effect of the latter from that of the former on the clustering is not possible and was not performed in the present study.

$2.2\bar {A}$ were labelled as voids. The identified clusters and voids corresponding to the Mie scattering image in figure 5(a) are shown by the blue and green colour cells in figure 5(e). As can be seen, clusters or voids may feature connected boundaries forming larger clusters and voids. Following Andrade et al. (Reference Andrade, Hardalupas and Charalampous2022), in the present study, the graph theory was used to identify and group the clusters/voids cells that are interconnected. For the results presented in figure 5(e), the identified clusters and voids are shown in figure 5(f). These clusters and voids were used for further analysis in § 4. It is important to note that the identified clusters and voids are formed due to both the interaction of the droplets with the background turbulent flow as well as (potentially) the air entrainment into the spray. Isolating the effect of the latter from that of the former on the clustering is not possible and was not performed in the present study.

3.2. Droplets location and diameter estimation

The ILIDS images were reduced to estimate the droplets location and diameters. A summary of the processes followed to reduce the ILIDS images is illustrated in figure 6. For clarity purposes, a cropped view of a representative raw ILIDS image is shown in figure 6(a), which corresponds to the test condition with two perforated plates and the mean bulk flow velocity of 14.0 m s![]() $^{-1}$. Following the procedure used by Bocanegra Evans et al. (Reference Bocanegra Evans, Dam, van der Voort, Bertens and van de Water2015), the image shown in figure 6(a) was convoluted with a disk-shaped mask and the resultant image is shown in figure 6(b). The convoluted image features local maxima, which correspond to the centres of the droplets. The locations of the droplets centres were obtained, with the corresponding results shown by the black circular data points in figure 6(c). The variations of the light intensity along the lines that pass through the droplets centres and are normal to the corresponding fringe pattern were considered, with a sample fringe pattern and light intensity variation for one droplet shown in figure 6(d,e), respectively. Then, the fast Fourier transform of the light intensity variation corresponding to each droplet was obtained and the number of fringes was calculated. Finally, the droplet diameter was calculated using the number of fringe patterns and (2.1). Figure 6(f) presents the centres of the droplets as well as the blue circles, with their diameter relating to the droplets’ diameter. The diameters of the blue circles scale with the diameter of the red circle shown in the figure.

$^{-1}$. Following the procedure used by Bocanegra Evans et al. (Reference Bocanegra Evans, Dam, van der Voort, Bertens and van de Water2015), the image shown in figure 6(a) was convoluted with a disk-shaped mask and the resultant image is shown in figure 6(b). The convoluted image features local maxima, which correspond to the centres of the droplets. The locations of the droplets centres were obtained, with the corresponding results shown by the black circular data points in figure 6(c). The variations of the light intensity along the lines that pass through the droplets centres and are normal to the corresponding fringe pattern were considered, with a sample fringe pattern and light intensity variation for one droplet shown in figure 6(d,e), respectively. Then, the fast Fourier transform of the light intensity variation corresponding to each droplet was obtained and the number of fringes was calculated. Finally, the droplet diameter was calculated using the number of fringe patterns and (2.1). Figure 6(f) presents the centres of the droplets as well as the blue circles, with their diameter relating to the droplets’ diameter. The diameters of the blue circles scale with the diameter of the red circle shown in the figure.

Figure 6. (a) Cropped view of a representative raw ILIDS image corresponding to the test condition with two perforated plates and mean bulk flow velocity of 14.0 m s![]() $^{-1}$. (b) Convolution of the results in panel (a) using a disk-shaped mask. (c) Identified droplets centres. (d) Inset of panel (a), highlighting a sample fringe pattern. (e) Variation of the light intensity normal to the fringe pattern in panel (d). (f) Droplets centres and their corresponding diameters.

$^{-1}$. (b) Convolution of the results in panel (a) using a disk-shaped mask. (c) Identified droplets centres. (d) Inset of panel (a), highlighting a sample fringe pattern. (e) Variation of the light intensity normal to the fringe pattern in panel (d). (f) Droplets centres and their corresponding diameters.

4. Results

The results are grouped into four subsections. In the first subsection, the characteristics of the background turbulent flow and the droplets diameter are discussed. In the second subsection, the degree of clustering is investigated. In the third subsection, the geometrical characteristics of the clusters and voids are presented. Finally, the joint characteristics of the clusters/voids and the droplets are presented in the last subsection.

4.1. Background flow and droplet diameter characteristics

The variations of the axial velocity mean (![]() $\bar {u}$) and RMS fluctuations (

$\bar {u}$) and RMS fluctuations (![]() $u^\prime$) along the

$u^\prime$) along the ![]() $x$-axis are presented in the first and second rows of figure 7, respectively. The results in the first to fourth columns correspond to the mean bulk flow velocities of 3.5, 7.0, 10.5 and 14.0 m s

$x$-axis are presented in the first and second rows of figure 7, respectively. The results in the first to fourth columns correspond to the mean bulk flow velocities of 3.5, 7.0, 10.5 and 14.0 m s![]() $^{-1}$, and are shown using circular-, square-, triangular- and diamond-shaped data symbols, respectively. The blue, green and red colours pertain to zero, one and two perforated plates, respectively. The results presented in figure 7(a–d) feature a mean velocity deficit near

$^{-1}$, and are shown using circular-, square-, triangular- and diamond-shaped data symbols, respectively. The blue, green and red colours pertain to zero, one and two perforated plates, respectively. The results presented in figure 7(a–d) feature a mean velocity deficit near ![]() $x=0$, which is due to the wake of the spray injector, similar to the results presented by Petry et al. (Reference Petry, Schäfer, Lammel and Hampp2022). Also, the mean velocity profiles are nearly symmetric for the test conditions without a perforated plate; however, these profiles are nearly asymmetric for test conditions with one and two perforated plates, which are similar to those reported by Kheirkhah & Gülder (Reference Kheirkhah and Gülder2015). Such asymmetry of the mean velocity profile is speculated to be caused by the relative positioning of the perforated plate with respect to the plane of the velocity measurements.

$x=0$, which is due to the wake of the spray injector, similar to the results presented by Petry et al. (Reference Petry, Schäfer, Lammel and Hampp2022). Also, the mean velocity profiles are nearly symmetric for the test conditions without a perforated plate; however, these profiles are nearly asymmetric for test conditions with one and two perforated plates, which are similar to those reported by Kheirkhah & Gülder (Reference Kheirkhah and Gülder2015). Such asymmetry of the mean velocity profile is speculated to be caused by the relative positioning of the perforated plate with respect to the plane of the velocity measurements.

Figure 7. (a–d) Mean streamwise velocity for the mean bulk flow velocities of 3.5, 7.0, 10.5 and 14.0 m s![]() $^{-1}$, respectively. (e–h) RMS streamwise velocity fluctuations for the mean bulk flow velocities of 3.5, 7.0, 10.5 and 14.0 m s

$^{-1}$, respectively. (e–h) RMS streamwise velocity fluctuations for the mean bulk flow velocities of 3.5, 7.0, 10.5 and 14.0 m s![]() $^{-1}$, respectively.

$^{-1}$, respectively.

The results in figure 7(e–h) shows that for all tested mean bulk flow velocities and for the majority of the horizontal locations, the RMS of the streamwise velocity for one perforated plate is smaller than that for two perforated plates, which agrees with the results of past investigations, see for example those of Kheirkhah & Gülder (Reference Kheirkhah and Gülder2015). The results in figure 7(e–h) also show that the values of ![]() $u^\prime$ for no perforated plate are larger than those of one perforated plate and close to those of two perforated plates. It is speculated that the reason for the values of

$u^\prime$ for no perforated plate are larger than those of one perforated plate and close to those of two perforated plates. It is speculated that the reason for the values of ![]() $u^\prime$ for no perforated plate being relatively large is due to the turbulence generated by the supporting bars of the tube holder shown in figure 2(a) and the wake of the spray injector. To assess this speculation, HWA experiments for a free jet (without the spray injector and without the tube holder) were performed (not presented as a test condition in table 1) and the values of

$u^\prime$ for no perforated plate being relatively large is due to the turbulence generated by the supporting bars of the tube holder shown in figure 2(a) and the wake of the spray injector. To assess this speculation, HWA experiments for a free jet (without the spray injector and without the tube holder) were performed (not presented as a test condition in table 1) and the values of ![]() $u^\prime$ were obtained. These were significantly smaller than those for the first turbulence generation mechanism. For example, for

$u^\prime$ were obtained. These were significantly smaller than those for the first turbulence generation mechanism. For example, for ![]() $U=7.0$ m s

$U=7.0$ m s![]() $^{-1}$ and at

$^{-1}$ and at ![]() $x =0$,

$x =0$, ![]() $u^\prime =0.34$ m s

$u^\prime =0.34$ m s![]() $^{-1}$ for a free jet without the spray injector and the tube holder; however, this parameter is 1.07 m s

$^{-1}$ for a free jet without the spray injector and the tube holder; however, this parameter is 1.07 m s![]() $^{-1}$ with the injector and tube holder installed (i.e. the first turbulence generation mechanism). We speculate the reason for the values of

$^{-1}$ with the injector and tube holder installed (i.e. the first turbulence generation mechanism). We speculate the reason for the values of ![]() $u^\prime$ being relatively smaller for the second turbulence generation mechanism (i.e. one perforated plate) than those for the first turbulence generation mechanism (zero perforated plate) is the break up of the eddies generated in the wake of the tube-holder bars by the perforated plate. The decrease of the RMS velocity fluctuations by the addition of the perforated plates has been reported by, for example, Wang et al. (Reference Wang, Yu, Zhang, Zhang and Huang2019).

$u^\prime$ being relatively smaller for the second turbulence generation mechanism (i.e. one perforated plate) than those for the first turbulence generation mechanism (zero perforated plate) is the break up of the eddies generated in the wake of the tube-holder bars by the perforated plate. The decrease of the RMS velocity fluctuations by the addition of the perforated plates has been reported by, for example, Wang et al. (Reference Wang, Yu, Zhang, Zhang and Huang2019).

The PDF of the droplet diameter for the first, second and third turbulence generation mechanisms are presented in figure 8(a–c), respectively. The PDFs were obtained considering all droplets within the field of view of the ILIDS measurements. For comparison purposes, the PDF of the droplet diameter for the no co-flow test condition is overlaid on figure 8(a–c) using the black circular data symbol. For the probability density function calculations, an 11.5 ![]() $\mathrm {\mu }$m droplet diameter bin size was used, since this led to the best presentation of the results. For all test conditions, the mean (

$\mathrm {\mu }$m droplet diameter bin size was used, since this led to the best presentation of the results. For all test conditions, the mean (![]() $\bar {d}$) and most probable droplet diameters were obtained and presented in figure 9(a,b), respectively. In figure 9(a,b), the error bars present twice the RMS of the droplet diameter fluctuations and the PDF bin size, respectively. The results in figure 9(b) show that the maximum change in the most probable droplet diameter as a result of changing the test condition is approximately

$\bar {d}$) and most probable droplet diameters were obtained and presented in figure 9(a,b), respectively. In figure 9(a,b), the error bars present twice the RMS of the droplet diameter fluctuations and the PDF bin size, respectively. The results in figure 9(b) show that the maximum change in the most probable droplet diameter as a result of changing the test condition is approximately ![]() $34-28=6\,\mathrm {\mu }\mathrm {m}$. This is smaller than the bin size (11.5

$34-28=6\,\mathrm {\mu }\mathrm {m}$. This is smaller than the bin size (11.5 ![]() $\mathrm {\mu }$m) used for the PDF of the droplet diameter calculation. Thus, the results in figure 9(b) suggest that the most probable diameter of the droplets does not change noticeably by increasing the mean bulk flow velocity or changing the turbulence generation mechanism. This is speculated to be due to the measurement field of view being close to the injector, which strongly impacts the droplet diameter PDF. This finding is similar to that reported by Wang, Dalla Barba & Picano (Reference Wang, Dalla Barba and Picano2021). In fact, the study of Wang et al. (Reference Wang, Dalla Barba and Picano2021) showed that at relatively small vertical distances from the injector (less than 5 diameter of the nozzle) and for bulk flow Reynolds numbers comparable to those of the present study, changing this parameter does not influence the mean droplet diameter. The lack of sensitivity of the droplet diameter PDF to the test conditions, see figure 8, may have implications for the calculation of the Stokes number discussed earlier. Although the most probable droplet diameter is used for the estimation of the Stokes number, the PDFs of the droplet diameter do not change by changing the test condition. That is, alternative definitions of the Stokes number will yield similar trends in the present study, as a representative size for the droplet diameter will not change by varying the test conditions. Although the droplets diameter PDF estimated in the entire domain of investigation is not sensitive to the tested mean bulk flow velocity and the utilized turbulence generation mechanism, it is yet to be investigated how/if these parameters influence the PDF of the droplet diameter within the clusters and voids, which are studied in the following subsections.

$\mathrm {\mu }$m) used for the PDF of the droplet diameter calculation. Thus, the results in figure 9(b) suggest that the most probable diameter of the droplets does not change noticeably by increasing the mean bulk flow velocity or changing the turbulence generation mechanism. This is speculated to be due to the measurement field of view being close to the injector, which strongly impacts the droplet diameter PDF. This finding is similar to that reported by Wang, Dalla Barba & Picano (Reference Wang, Dalla Barba and Picano2021). In fact, the study of Wang et al. (Reference Wang, Dalla Barba and Picano2021) showed that at relatively small vertical distances from the injector (less than 5 diameter of the nozzle) and for bulk flow Reynolds numbers comparable to those of the present study, changing this parameter does not influence the mean droplet diameter. The lack of sensitivity of the droplet diameter PDF to the test conditions, see figure 8, may have implications for the calculation of the Stokes number discussed earlier. Although the most probable droplet diameter is used for the estimation of the Stokes number, the PDFs of the droplet diameter do not change by changing the test condition. That is, alternative definitions of the Stokes number will yield similar trends in the present study, as a representative size for the droplet diameter will not change by varying the test conditions. Although the droplets diameter PDF estimated in the entire domain of investigation is not sensitive to the tested mean bulk flow velocity and the utilized turbulence generation mechanism, it is yet to be investigated how/if these parameters influence the PDF of the droplet diameter within the clusters and voids, which are studied in the following subsections.

Figure 8. (a–c) PDFs of the droplet diameter for no perforated plate, one perforated plate and two perforated plates, respectively. The black circular data points are the PDF of the no co-flow test condition, which is repeated in panels (a–c) for comparison purposes.

Figure 9. (a,b) Variations of the mean and most probable droplet diameter versus the mean bulk flow velocity for all test conditions.

4.2. The droplets degree of clustering

The Voronoï cells were used to study the droplets degree of clustering, following the procedure discussed in § 3. For all test conditions, the PDFs of the Voronoï cells area (![]() $A$) are calculated and presented in figure 10(a). Also, the PDFs of the Voronoï cells area normalized by the locally averaged area (

$A$) are calculated and presented in figure 10(a). Also, the PDFs of the Voronoï cells area normalized by the locally averaged area (![]() $A/\bar {A}$) are shown in figure 10(b) for all test conditions. As can be seen, the PDFs of

$A/\bar {A}$) are shown in figure 10(b) for all test conditions. As can be seen, the PDFs of ![]() $A/\bar {A}$ collapse for all test conditions, which is similar to the results presented by Obligado et al. (Reference Obligado, Teitelbaum, Cartellier, Mininni and Bourgoin2014) and Monchaux et al. (Reference Monchaux, Bourgoin and Cartellier2010). Overlaid on figure 10 is the PDF of the normalized area of the Voronoï cells provided these cells are spatially distributed following the RPP, with the formulation of PDF

$A/\bar {A}$ collapse for all test conditions, which is similar to the results presented by Obligado et al. (Reference Obligado, Teitelbaum, Cartellier, Mininni and Bourgoin2014) and Monchaux et al. (Reference Monchaux, Bourgoin and Cartellier2010). Overlaid on figure 10 is the PDF of the normalized area of the Voronoï cells provided these cells are spatially distributed following the RPP, with the formulation of PDF ![]() $_{\rm RPP}$ presented in (3.1). The results in figure 10 show that, for all test conditions, the PDFs of

$_{\rm RPP}$ presented in (3.1). The results in figure 10 show that, for all test conditions, the PDFs of ![]() $A/\bar {A}$ intersect with PDF

$A/\bar {A}$ intersect with PDF ![]() $_{\rm RPP}$ at

$_{\rm RPP}$ at ![]() $A/\bar {A} = 0.5$ and 2.2, which are shown by the vertical dashed lines in figure 10(b) and are similar to those shown in figure 5(c). Using the above normalized areas and following the procedure presented in § 3.1, the clusters and voids were identified, and the degree of clustering is studied below.

$A/\bar {A} = 0.5$ and 2.2, which are shown by the vertical dashed lines in figure 10(b) and are similar to those shown in figure 5(c). Using the above normalized areas and following the procedure presented in § 3.1, the clusters and voids were identified, and the degree of clustering is studied below.

Figure 10. (a) PDFs of the Voronoï cells area, PDF ![]() $(A)$, for all test conditions. (b) PDF of the Voronoï cells area normalized by the locally averaged area. The solid black curve in panel (b) is the PDF of the normalized Voronoï cells area provided they were distributed following an RPP, with the formulation given in (3.1). The dashed lines in panel (b) correspond to

$(A)$, for all test conditions. (b) PDF of the Voronoï cells area normalized by the locally averaged area. The solid black curve in panel (b) is the PDF of the normalized Voronoï cells area provided they were distributed following an RPP, with the formulation given in (3.1). The dashed lines in panel (b) correspond to ![]() $A/\bar {A} = 0.5$ and 2.2.

$A/\bar {A} = 0.5$ and 2.2.