Article contents

On the mechanism responsible for unconventional thermal behaviour during freezing

Published online by Cambridge University Press: 30 September 2020

Abstract

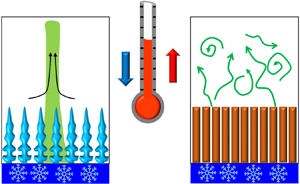

In this study, identical experiments of bottom-cooled solidification fluidic mixtures that exhibit faceted and dendritic microstructures were performed. The strength of compositional convection, created due to the rejection of a lighter solute, was correlated with the solidifying microstructure morphology via separate Rayleigh numbers in the mushy and bulk-fluid zones. While the bulk fluid in dendritic solidification experienced a monotonic decrease in the temperature, solidification of the faceted case revealed an unconventional, anomalous temperature rise in the bulk liquid after the formation of a eutectic solid. Based on the bulk-liquid temperatures, three distinct regimes of heat transfer were observed in the liquid, namely, convection-dominated, transition and conduction-dominated. The observations were analysed and verified with the help of different initial compositions and cooling conditions, as well as other mixtures that form faceted morphology upon freezing. The observed temperature rise was further ascertained by performing an energy balance in an indicative control volume ahead of the solid–liquid interface. The plausible mechanism of permeability-driven flow causing a gain in the temperature of the liquid during freezing was generalized with the help of a semi-analytical investigation of a one-dimensional system comprising solid, porous mush and liquid regions. The analytical scaling relations for fluid velocity and vorticity, for the faceted and dentritic cases, revealed contrasting vorticity values, which are much larger in low permeability (faceted case) and cause enhanced mixing in the bulk. The study sheds new insights into the role of microstructural morphology in governing the transport phenomena in the bulk liquid.

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2020. Published by Cambridge University Press

References

- 4

- Cited by