No CrossRef data available.

Article contents

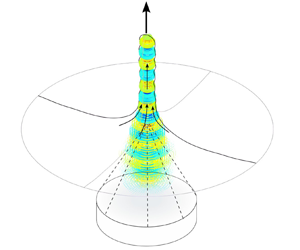

Numerical analysis of dynamic acoustic resonance with deformed liquid surfaces: the acoustic fountain

Published online by Cambridge University Press: 22 December 2023

Abstract

Applying a focused ultrasonic field on a free liquid surface results in its growth eventually leading to the so-called acoustic fountain. In this work, a numerical approach is presented to further increase the understanding of the acoustic fountain phenomenon. The developed simulation method enables the prediction of the free surface motion and the dynamic acoustic field in the moving liquid. The dynamic system is a balance between inertia, surface tension and the acoustic radiation force, and its nonlinearity is demonstrated by studying the relation between the ultrasonic excitation amplitude and corresponding liquid deformation. We show that dynamic resonance is the main mechanism causing the specific acoustic fountain shapes, and the analysis of the dynamic acoustic pressure allows us to predict Faraday-instability atomisation. We show that strong resonance peaks cause atomisation bursts and strong transient deformations corresponding to previously reported experimental observations. The quantitative prediction of the dynamic acoustic pressure enables us to assess the potential of cavitation generation in acoustic fountains. The observed local high acoustic pressures above both the cavitation and the atomisation threshold hint at the coexistence of these two phenomena in acoustic fountains.

JFM classification

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2023. Published by Cambridge University Press