Article contents

Melting processes of phase change materials in a horizontally placed rectangular cavity

Published online by Cambridge University Press: 26 October 2022

Abstract

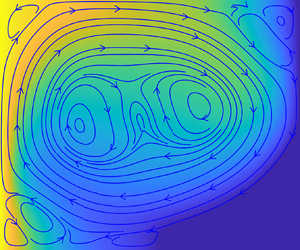

This paper revisits the melting process of phase change materials (PCMs) enclosed in a horizontally placed rectangular cavity, with isothermal and adiabatic conditions subjected to the vertical and horizontal walls, respectively. First, numerical simulations based on an improved lattice Boltzmann method are conducted to illustrate and to inform the theoretical modelling. It is shown that, compared with the traditional two-stage conduction–convection melting description, it is more reasonable to include a third stage in terms of the heat transfer behaviour. During the third stage, the remnant solid PCM is located in the corner formed by the cold and bottom walls of the cavity, and an increasing part of the input energy will be transferred directly out of the cavity without compensating for the melting latent heat, thus inducing a continuously decreasing melting rate until the end of the melting process. Then theoretical predictions are derived piecewise for the melted liquid fraction during the entire melting process, and the corresponding transitions between two successive stages are also discussed. The results are validated successfully via the available experimental and numerical data in the literature, and could guide the design and operation of latent heat storage systems.

JFM classification

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2022. Published by Cambridge University Press

References

REFERENCES

- 5

- Cited by