Article contents

Influence of liquid miscibility and wettability on the structures produced by drop–jet collisions

Published online by Cambridge University Press: 27 December 2019

Abstract

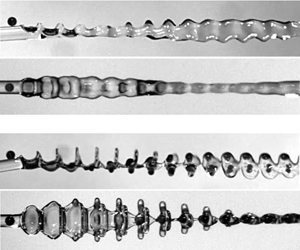

Collisions between a stream of drops and a continuous jet of a different liquid are experimentally investigated. In contrast to previous studies, our work focuses on the effects of liquid miscibility and wettability on the collision outcomes. Thus, miscible and immiscible liquids providing total and partial wetting are used. We show that, as long as the jet surface tension is smaller than the drop surface tension, the drops can be encapsulated by the jet, providing the so-called drops-in-jet structure. The transitions between the different regimes remain similar in nature with a capillary fragmentation responsible for the jet break-up and an inertial fragmentation causing the drops (and then possibly the jet) to break up. The dimensionless numbers proposed in the literature to model the inertial fragmentation thresholds do not bring the results obtained with different liquids at the same critical value. We explain the reason via a detailed analysis of the collisions, accounting for the drop and jet extensions and their kinetics. The drop fragmentation is found to occur during the recoil phase, leading us to propose a new dimensionless parameter that successfully reproduced all our experimental data obtained with immiscible liquids. Finally, we demonstrate that the most dramatic change of the collision outcomes is produced by using drops that totally wet the jet. In this case, the encapsulation of the drops cannot be achieved, constituting a true limit to some applications based on the solidification of the drops-in-jet structure.

JFM classification

- Type

- JFM Papers

- Information

- Copyright

- © 2019 Cambridge University Press

References

Baumgartner et al. supplementary movie 1

Hexadecane (colored) spreading on an aqueous liquid bath showing partial wetting.

Baumgartner et al. supplementary movie 2

Silicon oil (colored) spreading o an aqueous liquid bath showing total wetting.

Baumgartner et al. supplementary movie 3

This movie corresponds to a jet of silicon oil M5 and drops of G5 exhibiting fragmented drops in jet. It illustrates how the drops typically extend and fragment. The jet diameter is 287 µm, the drop diameter is 212 µm, the relative velocity is U=6.79 m/s and the drop frequency is 15500 Hz.

Baumgartner et al. supplementary movie 4

This movie corresponds to a jet of silicon oil M5 and drops of G5 exhibiting fragmented drops in jet. It illustrates how the drops typically extend and fragment. The jet diameter is 277 µm, the drop diameter is 208 µm, the relative velocity is U=7.15 m/s and the drop frequency is 15200 Hz.

Baumgartner et al. supplementary movie 5

This movie corresponds to a jet n-hexadecane and drops of G5 exhibiting fragmented drops in jet. As for the movies recorded with a jet of silicon oil, the drop extension and fragmentation can be very well followed. The jet diameter is 274 µm, the drop diameter is 193 µm, the relative velocity is U=8.84 m/s and the drop frequency is 25200 Hz.

Baumgartner et al. supplementary movie 6

This movie corresponds to a jet n-hexadecane and drops of G5 exhibiting mixed fragmentation with jet diameter 283 µm, drop diameter 219 µm, relative velocity U= 6.11 m/s and drop frequencies 10900 Hz. Here again, the drop extension and fragmentation can be very well followed.

Baumgartner et al. supplementary movie 7

This movie corresponds to a jet of perfluorodecalin and drops of G5 exhibiting fragmented drops in jet. As for the jet of silicon oil or n-hexadecane, it is possible to track the drop-jet interface and identify the drop fragmentation. The jet diameter is 282 µm, the drop diameter is 220 µm, the relative velocity is U= 5.96 m/s and the drop frequency is 10850 Hz.

Baumgartner et al. supplementary movie 8

This movie corresponds to a jet of perfluorodecalin and drops of G5 exhibiting fragmented drops in jet. The drop-jet interface can be weel tracked and the drop fragmentation well identified. The jet diameter is 278 µm, the drop diameter is 218 µm, the relative velocity is U=5.25 m/s and the drop frequency is 10600 Hz.

Baumgartner et al. supplementary movie 9

This movie corresponds to a jet of G5 and drops of silicon oil M5 exhibiting a coated jet. In contrast to the movies showing aqueous drops, the drop phase is not engulfed by the jet but quickly spreads around it forming a continuous cylindrical shell. The jet diameter is 282 µm, the drop diameter is 187 µm, the relative velocities is U=4.25 m/s and the drop frequency 18000 Hz.

Baumgartner et al. supplementary movie 10

This movie corresponds to a jet of EtOH and drops of G5 exhibiting drops in jet. Despite the miscibility of both liquids, we observe well localized darker spheres in the jet. This observation demonstrates the possibility to create via drop-jet collisions of miscible liquids a regular composition pattern within a continous jet. This jet could then be solidified to produce advanced fibers. The jet diameter is 278 µm, the drop diameter is 199 µm, the relative velocity is U=3.72 m/s and the drop frequency is 15400 Hz.

- 9

- Cited by