1. Introduction

In response to fluid flows, elastic structures observed in nature adjust their shapes to control the fluid loadings exerted on them. For example, leaves streamline, tree branches bend and grasses lump to reduce their frontal areas and mitigate the drag forces (Vogel Reference Vogel1984, Reference Vogel1989). Such adaptive deformation for the purpose of altering the fluid force, referred to as reconfiguration, has received considerable attention in the field of fluid–structure interactions. Since the pioneering investigations of Vogel (Reference Vogel1984, Reference Vogel1989), who elucidated the effectiveness of reconfiguration, the aerodynamic and hydrodynamic mechanisms responsible for the change in drag force induced by elastic deformation have been widely investigated. For instance, the effects of reconfiguration on the drag imposed on plants were examined experimentally using diverse species, and it has been revealed that the flow-induced deformation of vegetation reduces the drag force significantly in aquatic and land plants (Harder et al. Reference Harder, Speck, Hurd and Speck2004; de Langre, Gutierrez & Cossé Reference de Langre, Gutierrez and Cossé2012; Nepf Reference Nepf2012; Whittaker et al. Reference Whittaker, Wilson, Aberle, Rauch and Xavier2013). Moreover, by adopting simplified models such as flexible fibres and thin elastic plates, theoretical relationships between drag reduction and the deformation of elastic structures have been modelled for various flow conditions, including uniform flow (Alben, Shelley & Zhang Reference Alben, Shelley and Zhang2002; Gosselin, de Langre & Machado-Almeida Reference Gosselin, de Langre and Machado-Almeida2010; Luhar & Nepf Reference Luhar and Nepf2011; Hassani, Mureithi & Gosselin Reference Hassani, Mureithi and Gosselin2016) and unsteady flow (Leclercq & de Langre Reference Leclercq and de Langre2016; Luhar & Nepf Reference Luhar and Nepf2016; Leclercq & de Langre Reference Leclercq and de Langre2018; Zhang & Nepf Reference Zhang and Nepf2021).

Elastic leaves and branches form a porous tree and bend collectively in the wind (de Langre Reference de Langre2008; Gosselin Reference Gosselin2019). Like trees and grass canopies, poroelastic structures passively adapt their configurations when subjected to external flow, thereby changing the fluid forces. The reconfigured state and change in drag force of poroelastic structures were investigated experimentally over wide ranges of the porosity and Reynolds number for perforated strips (Guttag et al. Reference Guttag, Karimi, Falcón and Reis2018; Jin et al. Reference Jin, Kim, Cheng, Barry and Chamorro2020; Pezzulla et al. Reference Pezzulla, Strong, Gallaire and Reis2020) and for a three-dimensional poroelastic model in which a number of flexible filaments are radially attached to a rigid sphere (Gosselin & de Langre Reference Gosselin and de Langre2011). Poroelastic structures generally streamline and reduce the drag. However, the drag can increase under particular circumstances. For example, Gosselin & de Langre (Reference Gosselin and de Langre2011) showed that the drag of a poroelastic model increases when the Cauchy number (the ratio between the fluid force on the undeformed shape of the structure and the structure rigidity) is not sufficiently high to fully streamline the model. In addition, Jin et al. (Reference Jin, Kim, Cheng, Barry and Chamorro2020) reported that an elastic strip perforated with many holes could increase the drag force, despite its streamlined shape, when the porosity of the strip was sufficiently high. Because the flows penetrating the holes produce small recirculating regions immediately behind the bent strip, the region of maximum velocity deficit is located closer to the porous strip than to a non-porous strip, generating a larger drag.

Based on previous studies on the reconfiguration of poroelastic structures, this study investigates a poroelastic cluster, which is a single porous system composed of numerous elastic individuals with distinct spacing. The overall behaviour of this poroelastic cluster is determined by the individual actions of its constituents and the fluid-dynamic interaction between them. This collective behaviour is different from the behaviour of a perforated structure or a poroelastic medium, which is basically a continuum containing voids or pores. In nature, poroelastic clusters often exhibit extraordinary flight performances, and underlying aerodynamic mechanisms have been investigated with regard to their porous structure. For instance, by virtue of porosity in a low-Reynolds-number regime, bristled wings of several tiny insects could generate the aerodynamic forces comparable to those of common non-porous wings, even with almost one-tenth the mass (Sunada et al. Reference Sunada, Takashima, Hattori, Yasuda and Kawachi2002; Davidi & Weihs Reference Davidi and Weihs2012). Plumed seeds, another example of aerodynamic poroelastic clusters in nature, can fly a distance of several kilometres with centimetre sizes (Greene & Johnson Reference Greene and Johnson1990; Nathan et al. Reference Nathan, Katul, Horn, Thomas, Oren, Avissar, Pacala and Levin2002; Tackenberg, Poschlod & Kahmen Reference Tackenberg, Poschlod and Kahmen2003; Greene Reference Greene2005). Recently, Cummins et al. (Reference Cummins, Seale, Macente, Certini, Mastropaolo, Viola and Nakayama2018) revealed that the porous structure of the seeds enables a steady flight by generating a stable separated vortex ring. Furthermore, by means of high porosity, a three-dimensional poroelastic structure effectively traces unsteady flows better than spherical objects of the same size (Galler & Rival Reference Galler and Rival2021).

Despite many studies on the effects of porosity, the effects of deformation on the aerodynamic performance of poroelastic clusters remain unexplored. Because the drag force contributes enhancing the flight performance of freely flying poroelastic clusters in terms of long-distance flight (Tackenberg et al. Reference Tackenberg, Poschlod and Kahmen2003), it could be hypothesised that the free poroelastic cluster would deform to augment the drag force, in contrast to fixed elastic structures that reconfigure to mitigate fluid loadings. As a preliminary study, we numerically investigate the rearrangement of poroelastic clusters by adopting simplified two-dimensional models that contain the notable features of general poroelastic clusters. The term rearrangement is used throughout this study to emphasise the collective movement of individual elastic constituents that produces the overall deformation of the poroelastic cluster. The changes in constituent distribution and drag force are examined by varying porosity and elasticity in the quasi-steady state, which is more closely related to long-distance flight than the initial transient state. In § 2, our simplified model for the poroelastic cluster and numerical method are described. In § 3.1, we discuss a characteristic flow phenomenon around the cluster, which dominates its rearrangement process. The effects of the flow phenomenon on the changes in cylinder arrangement and drag with respect to porosity and elasticity are explained by examining the force components of the cluster in § 3.2. A new variable that incorporates the effects of elasticity and porosity is introduced to characterise the rearrangement in § 3.3. Finally, concluding remarks are presented in § 4.

2. Problem description

2.1. Model and parameters

For the investigation of porous structures composed of multiple entities, two-dimensional simplification has often been adopted. For instance, a dandelion seed was modelled as a permeable disc (Casseau et al. Reference Casseau, de Croon, Izzo and Pandolfi2015; Ledda et al. Reference Ledda, Siconolfi, Viola, Camarri and Gallaire2019), and a three-dimensional bristled wing was represented by a linear array of two-dimensional circular cylinders with gaps (Jones et al. Reference Jones, Yun, Hedrick, Griffith and Miller2016; Lee & Kim Reference Lee and Kim2020, Reference Lee and Kim2021; Wu, Liu & Sun Reference Wu, Liu and Sun2021). Despite simplicity in the configurations, the underlying fluid-dynamic mechanisms were elucidated effectively in terms of identifying the flow behaviour around the porous structure or the fluid-dynamic interaction between multiple constituents. Similarly, as a simplified two-dimensional poroelastic cluster, we introduce a collection of circularly aligned cylinders where each cylinder is elastically mounted at its own centre (figure 1a). Our simplified model captures the salient features of general poroelastic clusters, where elastic individuals with distinct spacings congregate to form a single porous system.

Figure 1. (a) Simplified two-dimensional poroelastic cluster model with seven elastically mounted cylinders, (b) computational domain and (c) five poroelastic clusters (A7, A20, A39, A64 and A95).

Each cylinder has a diameter of ![]() $d$ and a mass of

$d$ and a mass of ![]() $m$, and the cluster is subjected to a uniform fluid flow of velocity

$m$, and the cluster is subjected to a uniform fluid flow of velocity ![]() $U$ and density

$U$ and density ![]() $\rho _f$. To realise diverse porosities within the cluster, the number of constituent cylinders,

$\rho _f$. To realise diverse porosities within the cluster, the number of constituent cylinders, ![]() $N_C$, is varied while the outermost diameter of the cluster

$N_C$, is varied while the outermost diameter of the cluster ![]() $D$ is restricted to

$D$ is restricted to ![]() $21d$ (figure 1a). The clusters with

$21d$ (figure 1a). The clusters with ![]() $N_C = 7$, 20, 39, 64 and 95 are denoted as A7, A20, A39, A64 and A95, respectively (figure 1c). For each model, the cylinders are arranged in layers of concentric circles, with one cylinder at the centre. The positions of the cylinders are determined such that they are located as evenly as possible, following the approach of Nicolle & Eames (Reference Nicolle and Eames2011). The porosity of the model is represented by the solid fraction

$N_C = 7$, 20, 39, 64 and 95 are denoted as A7, A20, A39, A64 and A95, respectively (figure 1c). For each model, the cylinders are arranged in layers of concentric circles, with one cylinder at the centre. The positions of the cylinders are determined such that they are located as evenly as possible, following the approach of Nicolle & Eames (Reference Nicolle and Eames2011). The porosity of the model is represented by the solid fraction ![]() $\phi = N_Cd^2/D^2$, which indicates the portion of the area occupied by the cylinders within the circular boundary of the cluster (Nicolle & Eames Reference Nicolle and Eames2011; Chang & Constantinescu Reference Chang and Constantinescu2015; Taddei, Manes & Ganapathisubramani Reference Taddei, Manes and Ganapathisubramani2016; Kingora & Sadat Reference Kingora and Sadat2022). By definition,

$\phi = N_Cd^2/D^2$, which indicates the portion of the area occupied by the cylinders within the circular boundary of the cluster (Nicolle & Eames Reference Nicolle and Eames2011; Chang & Constantinescu Reference Chang and Constantinescu2015; Taddei, Manes & Ganapathisubramani Reference Taddei, Manes and Ganapathisubramani2016; Kingora & Sadat Reference Kingora and Sadat2022). By definition, ![]() $\phi$ increases with

$\phi$ increases with ![]() $N_C$, and

$N_C$, and ![]() $\phi = 1$ corresponds to an impervious cylinder of diameter

$\phi = 1$ corresponds to an impervious cylinder of diameter ![]() $D$. The values of

$D$. The values of ![]() $\phi$ for our clusters are presented in table 1.

$\phi$ for our clusters are presented in table 1.

Table 1. Number of cylinders ![]() $N_C$ and solid fraction

$N_C$ and solid fraction ![]() $\phi ({=}N_Cd^2/D^2)$ for five poroelastic clusters (A7, A20, A39, A64 and A95).

$\phi ({=}N_Cd^2/D^2)$ for five poroelastic clusters (A7, A20, A39, A64 and A95).

To numerically simulate the flow-induced motion of cylinders, a mass–spring–damper system is separately adopted for each cylinder, and each cylinder is elastically mounted at its own initial centre. In the two-dimensional domain, only the ![]() $x$- and

$x$- and ![]() $y$-directional translations of the cylinder are considered because actual long and thin hairs in three-dimensional space mostly bend under the flow, but rarely twist. For each cylinder, the springs for the

$y$-directional translations of the cylinder are considered because actual long and thin hairs in three-dimensional space mostly bend under the flow, but rarely twist. For each cylinder, the springs for the ![]() $x$- and

$x$- and ![]() $y$-directional translations are decoupled (figure 1a). All springs are assumed to have an identical stiffness of

$y$-directional translations are decoupled (figure 1a). All springs are assumed to have an identical stiffness of ![]() $k$. The motion of each cylinder is then governed by the dimensionless equation

$k$. The motion of each cylinder is then governed by the dimensionless equation

where ![]() $m^* = m/(\rho _f d^2)$,

$m^* = m/(\rho _f d^2)$, ![]() $c^* = c/(\rho _f U d)$ and

$c^* = c/(\rho _f U d)$ and ![]() $k^* = k/(\rho _f U^2)$ are dimensionless parameters for the mass, damping coefficient and spring stiffness of a cylinder, respectively. Here

$k^* = k/(\rho _f U^2)$ are dimensionless parameters for the mass, damping coefficient and spring stiffness of a cylinder, respectively. Here ![]() $Q^*_i$ is the

$Q^*_i$ is the ![]() $i$-coordinate of the dimensionless position for the cylinder centre with respect to its own initial location, and is normalised by the cylinder diameter

$i$-coordinate of the dimensionless position for the cylinder centre with respect to its own initial location, and is normalised by the cylinder diameter ![]() $d$, where

$d$, where ![]() $i$ denotes the

$i$ denotes the ![]() $x$- or

$x$- or ![]() $y$-component;

$y$-component; ![]() $\ddot {Q^*_i}$ and

$\ddot {Q^*_i}$ and ![]() $\dot {Q^*_i}$ correspond to the dimensionless acceleration and velocity of the cylinder, respectively;

$\dot {Q^*_i}$ correspond to the dimensionless acceleration and velocity of the cylinder, respectively; ![]() $f^*_i$, which is normalised by

$f^*_i$, which is normalised by ![]() $\rho _f U^2 d$, is the

$\rho _f U^2 d$, is the ![]() $i$-component of the dimensionless fluid force vector exerted on the cylinder. Because the current study is primarily aimed at understanding the effects of elasticity (spring stiffness

$i$-component of the dimensionless fluid force vector exerted on the cylinder. Because the current study is primarily aimed at understanding the effects of elasticity (spring stiffness ![]() $k^*$) on the rearrangement and drag force of the poroelastic cluster,

$k^*$) on the rearrangement and drag force of the poroelastic cluster, ![]() $m^*$ is fixed to unity (

$m^*$ is fixed to unity (![]() $m^* = 1$). In addition, damping is not considered (

$m^* = 1$). In addition, damping is not considered (![]() $c^* = 0$) because our interest is behaviours in the quasi-steady state after the initial transient state passes; the damping does not affect the steady solution of a mass–spring–damper system. Although our poroelastic cluster models are composed of multiple cylinders, we confirmed that the results of the quasi-steady state remained consistent, regardless of the

$c^* = 0$) because our interest is behaviours in the quasi-steady state after the initial transient state passes; the damping does not affect the steady solution of a mass–spring–damper system. Although our poroelastic cluster models are composed of multiple cylinders, we confirmed that the results of the quasi-steady state remained consistent, regardless of the ![]() $c^*$ value.

$c^*$ value.

The spring stiffness ![]() $k^*$ of the individual cylinders ranges between 0.3 and 1.0 (

$k^*$ of the individual cylinders ranges between 0.3 and 1.0 (![]() $k^* = 0.3$, 0.5, 0.7 and 1.0). Because a similar trend is observed as

$k^* = 0.3$, 0.5, 0.7 and 1.0). Because a similar trend is observed as ![]() $k^*$ increases beyond 1.0, the maximum value is limited to 1.0. As

$k^*$ increases beyond 1.0, the maximum value is limited to 1.0. As ![]() $k^*$ becomes greater, the cylinders behave more stiffly. For example, an extreme case of

$k^*$ becomes greater, the cylinders behave more stiffly. For example, an extreme case of ![]() $k^* = 10$ shows aerodynamic behaviours very similar to the rigid counterpart with

$k^* = 10$ shows aerodynamic behaviours very similar to the rigid counterpart with ![]() $k^* = \infty$. The minimum value of

$k^* = \infty$. The minimum value of ![]() $k^*$ is limited to 0.3 because most poroelastic models produce unrealistic motions for smaller values of

$k^*$ is limited to 0.3 because most poroelastic models produce unrealistic motions for smaller values of ![]() $k^*$; a few cylinders revolve around adjacent cylinders, which is unlikely to occur in poroelastic clusters in nature. Moreover, when

$k^*$; a few cylinders revolve around adjacent cylinders, which is unlikely to occur in poroelastic clusters in nature. Moreover, when ![]() $k^* < 0.3$, the shape of the cluster becomes excessively irregular, and collisions occur between the cylinders with large

$k^* < 0.3$, the shape of the cluster becomes excessively irregular, and collisions occur between the cylinders with large ![]() $\phi$. As we aim to reveal the general effects of the rearrangement, extreme circumstances with irregular rearrangement are not addressed in the present study. The chosen range of

$\phi$. As we aim to reveal the general effects of the rearrangement, extreme circumstances with irregular rearrangement are not addressed in the present study. The chosen range of ![]() $k^*$ is sufficient to comprehensively understand the effects of

$k^*$ is sufficient to comprehensively understand the effects of ![]() $k^*$. In addition, a rigid cluster with

$k^*$. In addition, a rigid cluster with ![]() $k^*=\infty$, in which the cylinders are stationary, is also considered for comparison. Here

$k^*=\infty$, in which the cylinders are stationary, is also considered for comparison. Here ![]() $k^*$ represents the ratio between the elastic restoring force and the fluid loading, similar to the reciprocal of the Cauchy number

$k^*$ represents the ratio between the elastic restoring force and the fluid loading, similar to the reciprocal of the Cauchy number ![]() $C_Y$ that is generally used to characterise the reconfiguration of elastic or poroelastic structures (de Langre Reference de Langre2008; Gosselin et al. Reference Gosselin, de Langre and Machado-Almeida2010; Gosselin & de Langre Reference Gosselin and de Langre2011; Luhar & Nepf Reference Luhar and Nepf2016; Guttag et al. Reference Guttag, Karimi, Falcón and Reis2018; Pezzulla et al. Reference Pezzulla, Strong, Gallaire and Reis2020). Because the spring stiffness

$C_Y$ that is generally used to characterise the reconfiguration of elastic or poroelastic structures (de Langre Reference de Langre2008; Gosselin et al. Reference Gosselin, de Langre and Machado-Almeida2010; Gosselin & de Langre Reference Gosselin and de Langre2011; Luhar & Nepf Reference Luhar and Nepf2016; Guttag et al. Reference Guttag, Karimi, Falcón and Reis2018; Pezzulla et al. Reference Pezzulla, Strong, Gallaire and Reis2020). Because the spring stiffness ![]() $k$ is varied in this study, we employ

$k$ is varied in this study, we employ ![]() $k^*$ instead of

$k^*$ instead of ![]() $C_Y$ (

$C_Y$ (![]() ${=}1.0\unicode{x2013}3.3$) to represent the force ratio in a straightforward manner.

${=}1.0\unicode{x2013}3.3$) to represent the force ratio in a straightforward manner.

The poroelastic cluster is subjected to a free stream of constant velocity ![]() $U$. The rearrangement of the poroelastic cluster in the quasi-steady state remains unaffected even if the free stream is unsteady in the initial transient phase, prior to attaining the constant velocity. This consistency justifies the use of the constant velocity

$U$. The rearrangement of the poroelastic cluster in the quasi-steady state remains unaffected even if the free stream is unsteady in the initial transient phase, prior to attaining the constant velocity. This consistency justifies the use of the constant velocity ![]() $U$ for the velocity profile to examine the quasi-steady state. In nature, poroelastic clusters usually reside in the low-Reynolds-number regime of

$U$ for the velocity profile to examine the quasi-steady state. In nature, poroelastic clusters usually reside in the low-Reynolds-number regime of ![]() $Re = O(10)$ or less, where

$Re = O(10)$ or less, where ![]() $Re$ is based on the diameter of entities comprising the cluster (Greene & Johnson Reference Greene and Johnson1990; Santhanakrishnan et al. Reference Santhanakrishnan, Robinson, Jones, Low, Gadi, Hedrick and Miller2014). In this

$Re$ is based on the diameter of entities comprising the cluster (Greene & Johnson Reference Greene and Johnson1990; Santhanakrishnan et al. Reference Santhanakrishnan, Robinson, Jones, Low, Gadi, Hedrick and Miller2014). In this ![]() $Re$ regime, hydrodynamic interaction between multiple bodies within the cluster is so strong that the flow hardly passes through spacings between the bodies (Nawroth et al. Reference Nawroth, Feitl, Colin, Costello and Dabiri2010; Lee & Kim Reference Lee and Kim2017; Lee, Lee & Kim Reference Lee, Lee and Kim2020). Through preliminary tests, we determined the Reynolds number that sufficiently realised such flow phenomenon. The Reynolds number

$Re$ regime, hydrodynamic interaction between multiple bodies within the cluster is so strong that the flow hardly passes through spacings between the bodies (Nawroth et al. Reference Nawroth, Feitl, Colin, Costello and Dabiri2010; Lee & Kim Reference Lee and Kim2017; Lee, Lee & Kim Reference Lee, Lee and Kim2020). Through preliminary tests, we determined the Reynolds number that sufficiently realised such flow phenomenon. The Reynolds number ![]() $Re_d$ for a single cylinder in our model is fixed to be 10:

$Re_d$ for a single cylinder in our model is fixed to be 10: ![]() $Re_d = U d/\nu = 10$. Accordingly, the Reynolds number

$Re_d = U d/\nu = 10$. Accordingly, the Reynolds number ![]() $Re_D\ ({=}UD/\nu )$ for the whole cluster is 210.

$Re_D\ ({=}UD/\nu )$ for the whole cluster is 210.

2.2. Numerical method

To compute the interaction between the flow and the multiple cylinders, an in-house code is constructed by building a new OpenFOAM library that implements the direct-forcing immersed boundary method (IBM) (Mahravan, Lahooti & Kim Reference Mahravan, Lahooti and Kim2023). Our in-house code numerically solves the governing equations for a two-dimensional incompressible laminar flow, which are given as

where ![]() $\boldsymbol {u}$ is the flow velocity vector,

$\boldsymbol {u}$ is the flow velocity vector, ![]() $p$ is the pressure and

$p$ is the pressure and ![]() $\nu$ is the kinematic viscosity of the fluid. The force

$\nu$ is the kinematic viscosity of the fluid. The force ![]() $\boldsymbol{f}_{\!\!IB}$ per unit mass in (2.2b) refers to a source term satisfying the continuity condition across the immersed boundaries (Uhlmann Reference Uhlmann2005). Here

$\boldsymbol{f}_{\!\!IB}$ per unit mass in (2.2b) refers to a source term satisfying the continuity condition across the immersed boundaries (Uhlmann Reference Uhlmann2005). Here ![]() $\boldsymbol{f}_{\!\!IB}$ is formulated by transferring variables between the Eulerian coordinate of the fluid domain

$\boldsymbol{f}_{\!\!IB}$ is formulated by transferring variables between the Eulerian coordinate of the fluid domain ![]() $\varOmega$ and the Lagrangian coordinate

$\varOmega$ and the Lagrangian coordinate ![]() $\varPi$ that formulates the immersed boundary composed of Lagrangian markers.

$\varPi$ that formulates the immersed boundary composed of Lagrangian markers.

At the beginning of each time step, the momentum equation (2.2b) is first solved without ![]() $\boldsymbol{f}_{\!\!IB}$ to compute an intermediate Eulerian velocity

$\boldsymbol{f}_{\!\!IB}$ to compute an intermediate Eulerian velocity ![]() $\tilde {\boldsymbol {u}}$. Interpolating

$\tilde {\boldsymbol {u}}$. Interpolating ![]() $\tilde {\boldsymbol {u}}$ through the discrete Dirac delta function

$\tilde {\boldsymbol {u}}$ through the discrete Dirac delta function ![]() $\delta$ (Roma, Peskin & Berger Reference Roma, Peskin and Berger1999), the preliminary velocity at the Lagrangian markers is obtained:

$\delta$ (Roma, Peskin & Berger Reference Roma, Peskin and Berger1999), the preliminary velocity at the Lagrangian markers is obtained: ![]() $\tilde {\boldsymbol {U}}(\boldsymbol {X}) = \int _{\varOmega } \tilde {\boldsymbol {u}}(\boldsymbol {x}) \delta (\boldsymbol {x} - \boldsymbol {X}) \,\textrm {d}V$. The Lagrangian force

$\tilde {\boldsymbol {U}}(\boldsymbol {X}) = \int _{\varOmega } \tilde {\boldsymbol {u}}(\boldsymbol {x}) \delta (\boldsymbol {x} - \boldsymbol {X}) \,\textrm {d}V$. The Lagrangian force ![]() $\boldsymbol {F}_{IB}$ is then determined using the Lagrangian velocity

$\boldsymbol {F}_{IB}$ is then determined using the Lagrangian velocity ![]() $\boldsymbol {U}$ from the previous time step as

$\boldsymbol {U}$ from the previous time step as ![]() $\boldsymbol {F}_{IB} = \textrm {d}(\boldsymbol {U}-\tilde {\boldsymbol {U}})/\textrm {d}t$. Finally, the Eulerian force

$\boldsymbol {F}_{IB} = \textrm {d}(\boldsymbol {U}-\tilde {\boldsymbol {U}})/\textrm {d}t$. Finally, the Eulerian force ![]() $\boldsymbol{f}_{\!\!IB}$ in (2.2b) is calculated by transferring

$\boldsymbol{f}_{\!\!IB}$ in (2.2b) is calculated by transferring ![]() $\boldsymbol {F}_{IB}$ from the surrounding Lagrangian markers to the Eulerian nodes:

$\boldsymbol {F}_{IB}$ from the surrounding Lagrangian markers to the Eulerian nodes:

With ![]() $\boldsymbol{f}_{\!\!IB}$ included, the governing equations (2.2a) and (2.2b) are solved using the PISO algorithm modified by Constant et al. (Reference Constant, Favier, Meldi, Meliga and Serre2017). This modified algorithm allows stable and accurate calculations when implemented with the IBM embedded in OpenFOAM. The time is discretised using the first-order implicit Euler scheme. For spatial discretisation, the second-order Gauss scheme is used for all terms except the convection term, for which the second-order linear upwind scheme is applied.

$\boldsymbol{f}_{\!\!IB}$ included, the governing equations (2.2a) and (2.2b) are solved using the PISO algorithm modified by Constant et al. (Reference Constant, Favier, Meldi, Meliga and Serre2017). This modified algorithm allows stable and accurate calculations when implemented with the IBM embedded in OpenFOAM. The time is discretised using the first-order implicit Euler scheme. For spatial discretisation, the second-order Gauss scheme is used for all terms except the convection term, for which the second-order linear upwind scheme is applied.

After solving the flow field, the fluid forces exerted on Lagrangian markers are calculated again at the same time step. The fluid forces are then summed for the markers comprising the surface of a cylinder, yielding the total fluid force ![]() $\boldsymbol {f}$ exerted on the cylinder. Therefore, the dimensionless force term

$\boldsymbol {f}$ exerted on the cylinder. Therefore, the dimensionless force term ![]() $f^*_i$ on the right-hand side of (2.1) corresponds to the dimensionless form of

$f^*_i$ on the right-hand side of (2.1) corresponds to the dimensionless form of ![]() $\boldsymbol {f}$:

$\boldsymbol {f}$: ![]() $f^*_i = f_i / \rho _f U^2 d$, where

$f^*_i = f_i / \rho _f U^2 d$, where ![]() $i=x$ or

$i=x$ or ![]() $y$. At the end of the time step, the velocity of the cylinder is updated by discretising and solving (2.1) with regard to the velocity, and the position of the cylinder is updated from the obtained velocity.

$y$. At the end of the time step, the velocity of the cylinder is updated by discretising and solving (2.1) with regard to the velocity, and the position of the cylinder is updated from the obtained velocity.

The rectangular fluid domain spans ![]() $[-16D, 32D] \times [-16D, 16D]$, and the origin of the coordinate system coincides with the initial centre of the cylinder cluster (figure 1b). The free stream enters the left boundary of the domain, and the pressure outlet condition of

$[-16D, 32D] \times [-16D, 16D]$, and the origin of the coordinate system coincides with the initial centre of the cylinder cluster (figure 1b). The free stream enters the left boundary of the domain, and the pressure outlet condition of ![]() $p = 0$ and a zero normal gradient of velocity is imposed at the right boundary downstream. The top and bottom boundaries are set to have zero normal gradients for the pressure and slip conditions for the velocity, i.e. slip-wall boundary conditions.

$p = 0$ and a zero normal gradient of velocity is imposed at the right boundary downstream. The top and bottom boundaries are set to have zero normal gradients for the pressure and slip conditions for the velocity, i.e. slip-wall boundary conditions.

Figure 2 illustrates the grid sizes and layouts, in which the immersed boundaries of the cylinders are marked with black and white circles in panels (b-ii) and (b-iii), respectively. As shown in figure 2(a), the entire fluid domain is divided into nine regions having different grid sizes ![]() $\Delta x$. Each region consists of uniform square grids, and the grid size doubles in the neighbouring outer region, following the approach of Constant et al. (Reference Constant, Favier, Meldi, Meliga and Serre2017); see figure 2(b-i) for the overall layout of the constructed grids. In our numerical algorithm, all immersed boundaries move inside the fluid region with uniform grids of the same size. However, enlarging the finest region to enclose the movements of all cylinders increases the computational cost significantly. To resolve this issue, adaptive mesh refinement (AMR) is applied to generate the finest grids of

$\Delta x$. Each region consists of uniform square grids, and the grid size doubles in the neighbouring outer region, following the approach of Constant et al. (Reference Constant, Favier, Meldi, Meliga and Serre2017); see figure 2(b-i) for the overall layout of the constructed grids. In our numerical algorithm, all immersed boundaries move inside the fluid region with uniform grids of the same size. However, enlarging the finest region to enclose the movements of all cylinders increases the computational cost significantly. To resolve this issue, adaptive mesh refinement (AMR) is applied to generate the finest grids of ![]() $\Delta x_f = 0.02d$ near the poroelastic clusters by refining the surrounding grids of

$\Delta x_f = 0.02d$ near the poroelastic clusters by refining the surrounding grids of ![]() $\Delta x = 0.04d$. The refinement is performed only when any cylinder inside the finest region approaches an interface with the outer region of

$\Delta x = 0.04d$. The refinement is performed only when any cylinder inside the finest region approaches an interface with the outer region of ![]() $\Delta x = 0.04d$; that is, only when any cylinder is about to escape the region of

$\Delta x = 0.04d$; that is, only when any cylinder is about to escape the region of ![]() $\Delta x_f = 0.02d$. The finest region, which is indicated by the blue circle in figure 2(b-iii), is large enough to fully encompass the cluster. The finest grids around two cylinders are presented in figure 2(b-ii) to visualise that the size of the finest grid is much smaller than the diameter of a single cylinder. The size of the discretised Lagrangian markers for the immersed boundaries is identical to that of the finest grid in the fluid domain,

$\Delta x_f = 0.02d$. The finest region, which is indicated by the blue circle in figure 2(b-iii), is large enough to fully encompass the cluster. The finest grids around two cylinders are presented in figure 2(b-ii) to visualise that the size of the finest grid is much smaller than the diameter of a single cylinder. The size of the discretised Lagrangian markers for the immersed boundaries is identical to that of the finest grid in the fluid domain, ![]() $\Delta s = 0.02d$.

$\Delta s = 0.02d$.

Figure 2. (a) Grid size of nine fluid subdomains and (b) computational grid layouts. Panel (b-i) demonstrates the overall layout of constructed grids, whereas panels (b-ii) and (b-iii) depict the grid layouts around two cylinders and the whole cluster, respectively. The black circle in panel (a) corresponds to the blue circle in panel (b-iii).

A series of tests are conducted to confirm the feasibility and accuracy of our numerical set-up. As a first step to validate that our in-house code solves the flow-induced motion of cylinders accurately, the vortex-induced vibration of two tandem circular cylinders under a uniform flow is considered. To match the conditions with those of Bao et al. (Reference Bao, Huang, Zhou, Tu and Han2012), the centre of the downstream cylinder is located 5![]() $d$ downstream from the centre of the upstream cylinder. Both cylinders have the same diameter

$d$ downstream from the centre of the upstream cylinder. Both cylinders have the same diameter ![]() $d$ and undergo two-degree-of-freedom motion in which the cylinder oscillates on the

$d$ and undergo two-degree-of-freedom motion in which the cylinder oscillates on the ![]() $xy$-plane. The Reynolds number

$xy$-plane. The Reynolds number ![]() $Re_d = 150$ and mass coefficient

$Re_d = 150$ and mass coefficient ![]() $m^* = 2$ match those of Bao et al. (Reference Bao, Huang, Zhou, Tu and Han2012) as well. Over a broad range of reduced velocity

$m^* = 2$ match those of Bao et al. (Reference Bao, Huang, Zhou, Tu and Han2012) as well. Over a broad range of reduced velocity ![]() $U_r = U/(f_N d)$, where natural frequency

$U_r = U/(f_N d)$, where natural frequency ![]() $f_N = {1}/{2{\rm \pi} }(k/m)^{1/2}$, the maximum amplitudes in the

$f_N = {1}/{2{\rm \pi} }(k/m)^{1/2}$, the maximum amplitudes in the ![]() $x$-direction (

$x$-direction (![]() $X_{max}/d$) and

$X_{max}/d$) and ![]() $y$-direction (

$y$-direction (![]() $Y_{max}/d$) are compared in figures 3(a) and 3(b), respectively. For both cylinders, our results are in good agreement with the previous results, ensuring that the flow-induced motion of cylinders can be accurately simulated by our numerical set-up.

$Y_{max}/d$) are compared in figures 3(a) and 3(b), respectively. For both cylinders, our results are in good agreement with the previous results, ensuring that the flow-induced motion of cylinders can be accurately simulated by our numerical set-up.

Figure 3. Comparison of maximum amplitudes (a) ![]() $X_{max}/d$ and (b)

$X_{max}/d$ and (b) ![]() $Y_{max}/d$ with respect to reduced velocity

$Y_{max}/d$ with respect to reduced velocity ![]() $U_r$ for two tandem cylinders (

$U_r$ for two tandem cylinders (![]() $m^* = 2, Re_d = 150$) undergoing vortex-induced vibration. (c) Comparison of time-averaged drag coefficient

$m^* = 2, Re_d = 150$) undergoing vortex-induced vibration. (c) Comparison of time-averaged drag coefficient ![]() $\bar {C}_D$ with respect to solid fraction

$\bar {C}_D$ with respect to solid fraction ![]() $\phi$ for a stationary cluster at

$\phi$ for a stationary cluster at ![]() $Re_d = 100$.

$Re_d = 100$.

Moreover, the accuracy in solving the interaction between multiple bodies and a free stream is evaluated. The drag forces exerted on the circular array of stationary cylinders are compared with those reported by Nicolle & Eames (Reference Nicolle and Eames2011). Along with identical cluster configurations, the Reynolds number based on the diameter of a cylinder matches as ![]() $Re_d = 100$. The total drag force

$Re_d = 100$. The total drag force ![]() $F_x$ acting on the cylinder array is represented as a sum of

$F_x$ acting on the cylinder array is represented as a sum of ![]() $x$-directional forces exerted on all cylinders:

$x$-directional forces exerted on all cylinders: ![]() $F_x(t) = \sum _{j = 1}^{N_C} f_{x,j}(t)$. Because

$F_x(t) = \sum _{j = 1}^{N_C} f_{x,j}(t)$. Because ![]() $F_x(t)$ fluctuates periodically at this

$F_x(t)$ fluctuates periodically at this ![]() $Re_d$, the time-averaged drag coefficient of the cluster is defined as

$Re_d$, the time-averaged drag coefficient of the cluster is defined as

\begin{equation} \bar{C}_D = \frac{1}{T} \int^{t_0+T}_{t_0} \frac{F_x (t)}{\dfrac{1}{2}\rho_f U^2 D} \textrm{d}t, \end{equation}

\begin{equation} \bar{C}_D = \frac{1}{T} \int^{t_0+T}_{t_0} \frac{F_x (t)}{\dfrac{1}{2}\rho_f U^2 D} \textrm{d}t, \end{equation}

where ![]() $T$ is the period of

$T$ is the period of ![]() $F_x(t)$ and

$F_x(t)$ and ![]() $t_0$ is a reference time. Figure 3(c) shows that our results match those of Nicolle & Eames (Reference Nicolle and Eames2011) with averaged difference less than 2 %, and our numerical set-up reliably computes multi-body problems.

$t_0$ is a reference time. Figure 3(c) shows that our results match those of Nicolle & Eames (Reference Nicolle and Eames2011) with averaged difference less than 2 %, and our numerical set-up reliably computes multi-body problems.

Convergence tests are also performed to ensure that our solutions are independent of grid and time step sizes. The convergence is evaluated with the time history of ![]() $F^*_x$, which is the sum of the dimensionless forces exerted on every cylinder in the

$F^*_x$, which is the sum of the dimensionless forces exerted on every cylinder in the ![]() $x$-direction (

$x$-direction (![]() $F^*_x = \sum _{j = 1}^{N_C} f^*_{x,j}$), for the A39 model with

$F^*_x = \sum _{j = 1}^{N_C} f^*_{x,j}$), for the A39 model with ![]() $k^* =$ 0.5. For grid convergence test, four cases with different finest grid sizes of

$k^* =$ 0.5. For grid convergence test, four cases with different finest grid sizes of ![]() $\Delta x_f = 0.01d$, 0.02

$\Delta x_f = 0.01d$, 0.02![]() $d$, 0.04

$d$, 0.04![]() $d$ and 0.08

$d$ and 0.08![]() $d$ are compared. Figure 4(a) indicates that the solution clearly converges for the case of

$d$ are compared. Figure 4(a) indicates that the solution clearly converges for the case of ![]() $\Delta x_f = 0.02d$, and thus the finest grid size is chosen to be

$\Delta x_f = 0.02d$, and thus the finest grid size is chosen to be ![]() $\Delta x_f = 0.02d$ for all simulations. In addition, the time step size is varied for the same cluster model:

$\Delta x_f = 0.02d$ for all simulations. In addition, the time step size is varied for the same cluster model: ![]() $\Delta t = 0.001d/U$, 0.002

$\Delta t = 0.001d/U$, 0.002![]() $d/U$, 0.004

$d/U$, 0.004![]() $d/U$ and 0.008

$d/U$ and 0.008![]() $d/U$ (figure 4b). The time histories of

$d/U$ (figure 4b). The time histories of ![]() $F^*_x$ show that the solution is hardly affected when

$F^*_x$ show that the solution is hardly affected when ![]() $\Delta t \leqq 0.004d/U$. Accordingly,

$\Delta t \leqq 0.004d/U$. Accordingly, ![]() $\Delta t = 0.004d/U$ is chosen for all simulations.

$\Delta t = 0.004d/U$ is chosen for all simulations.

Figure 4. Comparison of total ![]() $x$-directional force

$x$-directional force ![]() $F^*_x$ of the A39 model (

$F^*_x$ of the A39 model (![]() $k^* = 0.5$) for (a) four different finest grid sizes of

$k^* = 0.5$) for (a) four different finest grid sizes of ![]() $\Delta x_f = 0.01d$, 0.02

$\Delta x_f = 0.01d$, 0.02![]() $d$, 0.04

$d$, 0.04![]() $d$ and 0.08

$d$ and 0.08![]() $d$ and (b) four different time step sizes of

$d$ and (b) four different time step sizes of ![]() $\Delta t = 0.001d/U$, 0.002

$\Delta t = 0.001d/U$, 0.002![]() $d/U$, 0.004

$d/U$, 0.004![]() $d/U$ and 0.008

$d/U$ and 0.008![]() $d/U$. The inset in panel (b) presents

$d/U$. The inset in panel (b) presents ![]() $F^*_x$ for a short period of

$F^*_x$ for a short period of ![]() $tU/d = 14\unicode{x2013}18$ to clearly demonstrate the convergence with respect to

$tU/d = 14\unicode{x2013}18$ to clearly demonstrate the convergence with respect to ![]() $\Delta t$.

$\Delta t$.

3. Results and discussion

3.1. Rearrangement and hydrodynamic blockage

When the cylinders comprising the poroelastic cluster are continuously exposed to a uniform free stream of constant velocity, they reach the quasi-steady state with negligible motion after undergoing notable movements in the initial transient state. In the quasi-steady state, the cylinders rearrange in such a way that the overall shape of the cluster expands in the direction normal to the incoming flow. In other words, the rearrangement of the poroelastic cluster enlarges its frontal area, causing the generation of a larger overall drag force, compared with the rigid cluster of ![]() $k^*=\infty$ in which the frontal area remains unchanged. Figure 5 depicts this phenomenon in a simplified manner. Note that the degree of rearrangement and the magnitude of the drag force in figure 5(b) are exaggerated to some extent to more distinctly contrast the rigid and poroelastic clusters. In this section, we examine the characteristic flow phenomenon that is mainly responsible for this unique and counter-intuitive behaviour of the poroelastic cluster, where the frontal area expanded under the flow augments the drag.

$k^*=\infty$ in which the frontal area remains unchanged. Figure 5 depicts this phenomenon in a simplified manner. Note that the degree of rearrangement and the magnitude of the drag force in figure 5(b) are exaggerated to some extent to more distinctly contrast the rigid and poroelastic clusters. In this section, we examine the characteristic flow phenomenon that is mainly responsible for this unique and counter-intuitive behaviour of the poroelastic cluster, where the frontal area expanded under the flow augments the drag.

Figure 5. Schematics of the overall configurations and flow patterns for (a) a rigid cluster and (b) a poroelastic cluster in the quasi-steady state. The black and grey arrows indicate the drag force ![]() $F_x$ imposed on the clusters and streamlines, respectively. The red dashed line represents the boundary of the cluster.

$F_x$ imposed on the clusters and streamlines, respectively. The red dashed line represents the boundary of the cluster.

To quantify the amount of rearrangement in terms of the frontal area normal to the flow, the frontal area is defined as a ![]() $y$-directional length

$y$-directional length ![]() $L_y$ of the boundary encompassing the poroelastic cluster. Because the cylinders are not circularly positioned in the quasi-steady state due to the rearrangement, the boundary is fitted to an ellipse (red dashed line in figure 6a). The ellipse is first fitted using the centres of the outermost cylinders via direct least-squares fitting (Fitzgibbon, Pilu & Fisher Reference Fitzgibbon, Pilu and Fisher1999), and then the two major ellipse axes are expanded by

$L_y$ of the boundary encompassing the poroelastic cluster. Because the cylinders are not circularly positioned in the quasi-steady state due to the rearrangement, the boundary is fitted to an ellipse (red dashed line in figure 6a). The ellipse is first fitted using the centres of the outermost cylinders via direct least-squares fitting (Fitzgibbon, Pilu & Fisher Reference Fitzgibbon, Pilu and Fisher1999), and then the two major ellipse axes are expanded by ![]() $d/2$ with respect to the ellipse centre;

$d/2$ with respect to the ellipse centre; ![]() $d/2$ is the radius of each cylinder. The fitted ellipse accurately depicts the outer boundary of the rearranged cluster. The frontal area

$d/2$ is the radius of each cylinder. The fitted ellipse accurately depicts the outer boundary of the rearranged cluster. The frontal area ![]() $L_y$, which is the distance between the uppermost and lowermost points of the ellipse, is made dimensionless using the initial cluster diameter

$L_y$, which is the distance between the uppermost and lowermost points of the ellipse, is made dimensionless using the initial cluster diameter ![]() $D$ in figure 1(a) (

$D$ in figure 1(a) (![]() $L^*_y = L_y / D$); thus,

$L^*_y = L_y / D$); thus, ![]() $L^*_y = 1$ corresponds to the frontal area of a rigid cluster. The drag force of a cluster is defined as the total sum of the

$L^*_y = 1$ corresponds to the frontal area of a rigid cluster. The drag force of a cluster is defined as the total sum of the ![]() $x$-directional fluid forces exerted on all cylinders; the cluster drag

$x$-directional fluid forces exerted on all cylinders; the cluster drag ![]() $F^*_x = \sum _{j = 1}^{N_C} f^*_{x,j}$, where

$F^*_x = \sum _{j = 1}^{N_C} f^*_{x,j}$, where ![]() $f^*_x$ is the

$f^*_x$ is the ![]() $x$-component of the dimensionless force imposed on a single cylinder (

$x$-component of the dimensionless force imposed on a single cylinder (![]() $f^*_x = f_x/\rho _f U^2 d$). The quasi-steady state is defined as the state in which the values of

$f^*_x = f_x/\rho _f U^2 d$). The quasi-steady state is defined as the state in which the values of ![]() $L^*_y$ and

$L^*_y$ and ![]() $F^*_x$ change less than 0.5 % over a dimensionless time period of

$F^*_x$ change less than 0.5 % over a dimensionless time period of ![]() $tU/d = 10$. In all cases considered herein, the quasi-steady state satisfied such a condition at

$tU/d = 10$. In all cases considered herein, the quasi-steady state satisfied such a condition at ![]() $tU/d =$ 200. Thus, the following results presented for

$tU/d =$ 200. Thus, the following results presented for ![]() $L^*_y$ and

$L^*_y$ and ![]() $F^*_x$ correspond to this instant.

$F^*_x$ correspond to this instant.

Figure 6. (a) Rearranged poroelastic clusters in the quasi-steady state for five models with ![]() $k^* = 0.3$. The ellipse (red dashed line) is fitted to represent the boundary of the cluster. (b) Frontal area

$k^* = 0.3$. The ellipse (red dashed line) is fitted to represent the boundary of the cluster. (b) Frontal area ![]() $L^*_y$ and (c) drag

$L^*_y$ and (c) drag ![]() $F^*_x$ of the cluster in the quasi-steady state with respect to the solid fraction

$F^*_x$ of the cluster in the quasi-steady state with respect to the solid fraction ![]() $\phi$. (d) Ratio of the poroelastic cluster drag over the rigid cluster drag,

$\phi$. (d) Ratio of the poroelastic cluster drag over the rigid cluster drag, ![]() $F^*_x/F^*_{x,{rigid}}$, with respect to

$F^*_x/F^*_{x,{rigid}}$, with respect to ![]() $L^*_y$.

$L^*_y$.

Regarding the A7 model, which has the smallest solid fraction of ![]() $\phi = 0.02$ (table 1), the frontal area

$\phi = 0.02$ (table 1), the frontal area ![]() $L^*_y \approx$ 1 for

$L^*_y \approx$ 1 for ![]() $k^* = 0.3$–1.0 (figure 6b), and the cluster drag

$k^* = 0.3$–1.0 (figure 6b), and the cluster drag ![]() $F^*_x$ is very similar to that of the rigid counterpart (figure 6c). However, for

$F^*_x$ is very similar to that of the rigid counterpart (figure 6c). However, for ![]() $\phi >$ 0.02,

$\phi >$ 0.02, ![]() $L^*_y$ and

$L^*_y$ and ![]() $F^*_x$ are distinctly greater than those of the rigid counterparts, regardless of

$F^*_x$ are distinctly greater than those of the rigid counterparts, regardless of ![]() $k^*$. The frontal area and the cluster drag exhibit the same trend. As

$k^*$. The frontal area and the cluster drag exhibit the same trend. As ![]() $\phi$ increases, both

$\phi$ increases, both ![]() $L^*_y$ and

$L^*_y$ and ![]() $F^*_x$ increase and then decrease, having a peak at some intermediate value of

$F^*_x$ increase and then decrease, having a peak at some intermediate value of ![]() $\phi$, and are consistently greater for smaller

$\phi$, and are consistently greater for smaller ![]() $k^*$. The maxima of both

$k^*$. The maxima of both ![]() $L^*_y$ and

$L^*_y$ and ![]() $F^*_x$ for the poroelastic clusters occur at

$F^*_x$ for the poroelastic clusters occur at ![]() $\phi = 0.09$ and

$\phi = 0.09$ and ![]() $k^* = 0.3$. In this condition,

$k^* = 0.3$. In this condition, ![]() $L^*_y$ and

$L^*_y$ and ![]() $F^*_x$ are 8.6 % and 19.2 % greater than their values in the rigid counterpart, respectively. On the other hand, when the drag coefficient

$F^*_x$ are 8.6 % and 19.2 % greater than their values in the rigid counterpart, respectively. On the other hand, when the drag coefficient ![]() $C_D$ is calculated using the frontal area

$C_D$ is calculated using the frontal area ![]() $L_y$ as a characteristic length scale (

$L_y$ as a characteristic length scale (![]() $C_D = 2F_x/\rho _fU^2L_y$),

$C_D = 2F_x/\rho _fU^2L_y$), ![]() $F^*_x$ and

$F^*_x$ and ![]() $C_D$ exhibit identical trends with respect to

$C_D$ exhibit identical trends with respect to ![]() $\phi$ and

$\phi$ and ![]() $k^*$. Although the drag force experienced by the cluster can be expressed by either

$k^*$. Although the drag force experienced by the cluster can be expressed by either ![]() $F^*_x$ or

$F^*_x$ or ![]() $C_D$,

$C_D$, ![]() $F^*_x$ is used in our analysis. In contrast to

$F^*_x$ is used in our analysis. In contrast to ![]() $F^*_x$,

$F^*_x$, ![]() $C_D$ includes

$C_D$ includes ![]() $L_y$ in its denominator, and thus the effect of the frontal area change induced by the rearrangement on the drag, which is one of the main interests in this study, cannot be captured directly by

$L_y$ in its denominator, and thus the effect of the frontal area change induced by the rearrangement on the drag, which is one of the main interests in this study, cannot be captured directly by ![]() $C_D$.

$C_D$.

To clarify the relation between the frontal area and the drag augmentation, we define the extent of drag increment as the ratio of the drag force experienced by a poroelastic cluster to that of a rigid cluster, ![]() $F^*_x/F^*_{x,{rigid}}$. According to figure 6(d),

$F^*_x/F^*_{x,{rigid}}$. According to figure 6(d), ![]() $F^*_x/F^*_{x,{rigid}}$ tends to increase linearly with

$F^*_x/F^*_{x,{rigid}}$ tends to increase linearly with ![]() $L^*_y$, implying that the drag of the poroelastic cluster is strongly affected by the frontal area; other poroelastic clusters with different sizes also follow this linear relation as reported in figure 14(a) of the Appendix. The linear relation between the drag force and the frontal area is general for non-porous structures isolated alone. In this sense, the results in figure 6(d) suggest that the fluid-dynamic phenomenon, which is responsible for enlarging the frontal area and, thus, augmenting the drag, makes multiple cylinders function as a collective group in which entities interact cohesively, rather than as independent entities.

$L^*_y$, implying that the drag of the poroelastic cluster is strongly affected by the frontal area; other poroelastic clusters with different sizes also follow this linear relation as reported in figure 14(a) of the Appendix. The linear relation between the drag force and the frontal area is general for non-porous structures isolated alone. In this sense, the results in figure 6(d) suggest that the fluid-dynamic phenomenon, which is responsible for enlarging the frontal area and, thus, augmenting the drag, makes multiple cylinders function as a collective group in which entities interact cohesively, rather than as independent entities.

In the low-Reynolds-number regime of ![]() $O$(10) or less, strong viscous diffusion forms shear layers around the separated bodies which are thick enough to create virtual fluid barriers inside the gaps between the separated bodies. These barriers consequently interrupt the flow penetrating the gaps (Nawroth et al. Reference Nawroth, Feitl, Colin, Costello and Dabiri2010; Lee & Kim Reference Lee and Kim2017; Lee, Lahooti & Kim Reference Lee, Lahooti and Kim2018). This phenomenon, namely hydrodynamic blockage, is more effective when

$O$(10) or less, strong viscous diffusion forms shear layers around the separated bodies which are thick enough to create virtual fluid barriers inside the gaps between the separated bodies. These barriers consequently interrupt the flow penetrating the gaps (Nawroth et al. Reference Nawroth, Feitl, Colin, Costello and Dabiri2010; Lee & Kim Reference Lee and Kim2017; Lee, Lahooti & Kim Reference Lee, Lahooti and Kim2018). This phenomenon, namely hydrodynamic blockage, is more effective when ![]() $Re$ is smaller or the bodies are located closer together (Davidi & Weihs Reference Davidi and Weihs2012; Lee & Kim Reference Lee and Kim2020; Lee et al. Reference Lee, Lee and Kim2020). Similarly, for our clusters of

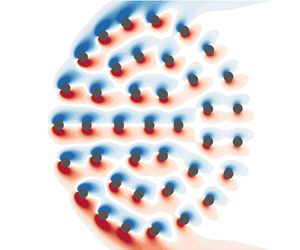

$Re$ is smaller or the bodies are located closer together (Davidi & Weihs Reference Davidi and Weihs2012; Lee & Kim Reference Lee and Kim2020; Lee et al. Reference Lee, Lee and Kim2020). Similarly, for our clusters of ![]() $Re_d = 10$, the streamwise velocity inside the cluster indicates the emergence of hydrodynamic blockage, and the effect of the blockage strengthens as the solid fraction increases (figure 7). For the smallest

$Re_d = 10$, the streamwise velocity inside the cluster indicates the emergence of hydrodynamic blockage, and the effect of the blockage strengthens as the solid fraction increases (figure 7). For the smallest ![]() $\phi = 0.02$ with the largest spacing between the cylinders, most of the incoming flow penetrates the gaps within the cluster at almost the same speed. At intermediate values of

$\phi = 0.02$ with the largest spacing between the cylinders, most of the incoming flow penetrates the gaps within the cluster at almost the same speed. At intermediate values of ![]() $\phi = 0.05$ and 0.09, the internal flow within the cluster diminishes gradually, as indicated by the reduced streamwise velocity and the smaller number of streamlines, and the incoming flow starts to detour around the cluster. Finally, at high solid fractions of

$\phi = 0.05$ and 0.09, the internal flow within the cluster diminishes gradually, as indicated by the reduced streamwise velocity and the smaller number of streamlines, and the incoming flow starts to detour around the cluster. Finally, at high solid fractions of ![]() $\phi = 0.15$ and 0.22, the hydrodynamic interaction between the cylinders is so dominant that the penetrating flow almost disappears; the velocity is almost zero inside the cluster. Thus, the incoming flow mostly curves around the outer edge of the cluster.

$\phi = 0.15$ and 0.22, the hydrodynamic interaction between the cylinders is so dominant that the penetrating flow almost disappears; the velocity is almost zero inside the cluster. Thus, the incoming flow mostly curves around the outer edge of the cluster.

Figure 7. Contours of streamwise velocity in the quasi-steady state for five cluster models with different solid fractions ![]() $\phi$ (

$\phi$ (![]() $k^* = 0.3$). Streamwise velocity is normalised as

$k^* = 0.3$). Streamwise velocity is normalised as ![]() $u_x/U$. In each panel, streamlines of the incoming flow are illustrated on velocity contours.

$u_x/U$. In each panel, streamlines of the incoming flow are illustrated on velocity contours.

To elaborate the effects of hydrodynamic blockage on the fluid forces imposed on the cylinders and the resultant rearrangement, a representative distribution of the fluid forces is visualised in figure 8 for the poroelastic clusters with ![]() $k^* = 0.3$. When most of the incoming flow passes through the gaps between the cylinders (

$k^* = 0.3$. When most of the incoming flow passes through the gaps between the cylinders (![]() $\phi = 0.02$), all cylinders are subjected to similar magnitudes of the fluid force (figure 8a). However, even with the weakest hydrodynamic blockage, the drag force

$\phi = 0.02$), all cylinders are subjected to similar magnitudes of the fluid force (figure 8a). However, even with the weakest hydrodynamic blockage, the drag force ![]() $f^*_x$ of a cylinder in the cluster is notably smaller than that of a single isolated cylinder,

$f^*_x$ of a cylinder in the cluster is notably smaller than that of a single isolated cylinder, ![]() $f^*_{x,{single}}$. For example, at

$f^*_{x,{single}}$. For example, at ![]() $k^* = 0.3$,

$k^* = 0.3$, ![]() $f^*_x$ averaged over all the cylinders is equal to 0.71

$f^*_x$ averaged over all the cylinders is equal to 0.71![]() $f^*_{x,{single}}$. In contrast, for the clusters with larger

$f^*_{x,{single}}$. In contrast, for the clusters with larger ![]() $\phi$, for which the flow is diverted by the development of virtual fluid barriers, the cylinders experience different fluid forces depending on their positions, and clear spatial variations in the fluid forces appear (figure 8b–e). At intermediate solid fractions (

$\phi$, for which the flow is diverted by the development of virtual fluid barriers, the cylinders experience different fluid forces depending on their positions, and clear spatial variations in the fluid forces appear (figure 8b–e). At intermediate solid fractions (![]() $\phi = 0.05, 0.09$), the fluid forces exerted on the cylinders at the rear of the cluster become smaller than for those at the front compared with

$\phi = 0.05, 0.09$), the fluid forces exerted on the cylinders at the rear of the cluster become smaller than for those at the front compared with ![]() $\phi = 0.02$. Accordingly, by the development of hydrodynamic blockage, cylinders experience significantly reduced drag forces compared with

$\phi = 0.02$. Accordingly, by the development of hydrodynamic blockage, cylinders experience significantly reduced drag forces compared with ![]() $f^*_{x,{single}}$. For clusters with

$f^*_{x,{single}}$. For clusters with ![]() $k^* = 0.3$,

$k^* = 0.3$, ![]() $f^*_x$ averaged over all the cylinders is half of

$f^*_x$ averaged over all the cylinders is half of ![]() $f^*_{x,{single}}$ at

$f^*_{x,{single}}$ at ![]() $\phi = 0.05$ and further decreases to

$\phi = 0.05$ and further decreases to ![]() $0.30f^*_{x,{single}}$ at

$0.30f^*_{x,{single}}$ at ![]() $\phi = 0.09$. Moreover, for high solid fractions (

$\phi = 0.09$. Moreover, for high solid fractions (![]() $\phi = 0.15, 0.22$), the rear cylinders rarely experience any fluid force, whereas the front cylinders are still subjected to noticeable fluid forces. In common, when the hydrodynamic blockage is in effect, the outer cylinders that are directly exposed to the detouring flow encounter stronger fluid forces than the inner cylinders.

$\phi = 0.15, 0.22$), the rear cylinders rarely experience any fluid force, whereas the front cylinders are still subjected to noticeable fluid forces. In common, when the hydrodynamic blockage is in effect, the outer cylinders that are directly exposed to the detouring flow encounter stronger fluid forces than the inner cylinders.

Figure 8. Magnitude and direction of fluid force ![]() $\boldsymbol {f}^*$ exerted on each cylinder for five cluster models with different solid fractions

$\boldsymbol {f}^*$ exerted on each cylinder for five cluster models with different solid fractions ![]() $\phi$ (

$\phi$ (![]() $k^* = 0.3$). The red solid line denotes the force vector of each cylinder, and the horizontal red solid line at the bottom right of the figure indicates the magnitude of

$k^* = 0.3$). The red solid line denotes the force vector of each cylinder, and the horizontal red solid line at the bottom right of the figure indicates the magnitude of ![]() $|\boldsymbol {f}^*| = 1$.

$|\boldsymbol {f}^*| = 1$.

Furthermore, whereas the flow passing through the cluster exerts a fluid force along almost the entire ![]() $x$-direction for the sparsely distributed cluster (figure 8a), the flow that detours under the hydrodynamic blockage effect induces remarkable

$x$-direction for the sparsely distributed cluster (figure 8a), the flow that detours under the hydrodynamic blockage effect induces remarkable ![]() $y$-directional fluid forces for the more densely distributed clusters (figure 8b–e). The cylinders are rearranged to be symmetric with respect to the

$y$-directional fluid forces for the more densely distributed clusters (figure 8b–e). The cylinders are rearranged to be symmetric with respect to the ![]() $x$-axis because of the flow symmetry through and around the cluster, as shown in figure 7. Thus, for a pair of cylinders symmetrically located between the upper and lower sides of the cluster, the magnitudes of the force vectors are equal, but their orientations are opposite in the

$x$-axis because of the flow symmetry through and around the cluster, as shown in figure 7. Thus, for a pair of cylinders symmetrically located between the upper and lower sides of the cluster, the magnitudes of the force vectors are equal, but their orientations are opposite in the ![]() $y$-direction. Although the distributions of the rearranged cylinders and the fluid forces are not perfectly symmetric with respect to the

$y$-direction. Although the distributions of the rearranged cylinders and the fluid forces are not perfectly symmetric with respect to the ![]() $x$-axis, the degree of asymmetry with respect to the

$x$-axis, the degree of asymmetry with respect to the ![]() $x$-axis is extremely small, and the distributions can be regarded symmetric. Moreover, the angle between the force vector and the

$x$-axis is extremely small, and the distributions can be regarded symmetric. Moreover, the angle between the force vector and the ![]() $x$-axis is greater for the outer cylinders than for the inner cylinders on the front side. Accordingly, the cylinders experience

$x$-axis is greater for the outer cylinders than for the inner cylinders on the front side. Accordingly, the cylinders experience ![]() $y$-directional motions during the rearrangement process, with greater movements of the outer cylinders. By virtue of the hydrodynamic blockage of which the degree is determined by the solid fraction, the frontal area of the rearranged poroelastic cluster becomes greater than that of the rigid cluster, eventually leading to an increase in cluster drag, as reported in figure 6(b–d).

$y$-directional motions during the rearrangement process, with greater movements of the outer cylinders. By virtue of the hydrodynamic blockage of which the degree is determined by the solid fraction, the frontal area of the rearranged poroelastic cluster becomes greater than that of the rigid cluster, eventually leading to an increase in cluster drag, as reported in figure 6(b–d).

The rearrangement of the poroelastic cluster is noteworthy in that the drag force is augmented through the enlargement of the frontal area under the flow. Although the drag increment has been reported for the reconfigured poroelastic strip (Jin et al. Reference Jin, Kim, Cheng, Barry and Chamorro2020) and poroelastic system composed of elastic filaments radially attached to a centre sphere in spherical form (Gosselin & de Langre Reference Gosselin and de Langre2011), the underlying mechanisms differ from our model. Although the drag of the poroelastic strip increases under certain conditions (Jin et al. Reference Jin, Kim, Cheng, Barry and Chamorro2020), the drag increment is because of a specific flow pattern behind the strip rather than the enlargement of the frontal area; the strip streamlines under a flow and its frontal area decreases. The streamlined reconfiguration of the poroelastic system of Gosselin & de Langre (Reference Gosselin and de Langre2011), which generally contributes to drag reduction, could increase the drag when all the elastic filaments are not fully streamlined at a low Cauchy number. However, the poroelastic system reconfigures primarily by the bending of independent filaments, and the effects of porosity on drag augmentation appear to be rather minor. In contrast, the rearrangement of our poroelastic clusters is achieved by the hydrodynamic blockage between constituents, and they exhibit different behaviours with respect to the solid fraction, yielding an optimal solid fraction for the cluster drag.

As a drag-based flier, the flight performance of a poroelastic cluster is mainly evaluated with the flight distance that is crucially affected by aerodynamic drag. The horizontal wind mainly induces a dispersion, and the updraft, which exerts the aerodynamic force against the gravity, sustains the dispersion in the air (Tackenberg et al. Reference Tackenberg, Poschlod and Kahmen2003). Because the poroelastic cluster can generate greater drag by enlarging its frontal area, it is expected to prolong flight duration compared with the rigid cluster, thereby enabling to fly longer distances. In addition, we suppose that the flight stability of the poroelastic cluster would not significantly differ from that of the rigid cluster. In the high-Reynolds-number (high-![]() $Re$) regime, vortex shedding may occur behind the cluster, and the surrounding flow responds more sensitively to structural modifications or flow disturbances than in the low-

$Re$) regime, vortex shedding may occur behind the cluster, and the surrounding flow responds more sensitively to structural modifications or flow disturbances than in the low-![]() $Re$ regime. In such conditions, the expansion of the frontal area would further intensify the flow instability, leading to unstable flight. However, in the low-

$Re$ regime. In such conditions, the expansion of the frontal area would further intensify the flow instability, leading to unstable flight. However, in the low-![]() $Re$ regime where the poroelastic cluster can take advantage of hydrodynamic blockage in enlarging the frontal area, the flow around the cluster remains stable as shown in figure 7, and the enlargement of the frontal area would not significantly affect the flight stability in comparison with the rigid cluster.

$Re$ regime where the poroelastic cluster can take advantage of hydrodynamic blockage in enlarging the frontal area, the flow around the cluster remains stable as shown in figure 7, and the enlargement of the frontal area would not significantly affect the flight stability in comparison with the rigid cluster.

3.2. Force components of the poroelastic cluster

In § 3.1, a characteristic flow behaviour that causes the rearrangement of the poroelastic cluster was identified, namely hydrodynamic blockage. Here, we discuss how hydrodynamic blockage affects the frontal area ![]() $L^*_y$ and cluster drag

$L^*_y$ and cluster drag ![]() $F^*_x$ with respect to porosity (solid fraction

$F^*_x$ with respect to porosity (solid fraction ![]() $\phi$) and elasticity (spring stiffness

$\phi$) and elasticity (spring stiffness ![]() $k^*$), using the force components acting on the cylinders. First, as

$k^*$), using the force components acting on the cylinders. First, as ![]() $\phi$ increases, the drag force of the rigid and poroelastic clusters increases and then decreases for all

$\phi$ increases, the drag force of the rigid and poroelastic clusters increases and then decreases for all ![]() $k^*$, exhibiting the maximum

$k^*$, exhibiting the maximum ![]() $F^*_x$ at certain values of

$F^*_x$ at certain values of ![]() $\phi$ (figure 6c). The rigid cluster presents a peak

$\phi$ (figure 6c). The rigid cluster presents a peak ![]() $F^*_x$ of 12.01 at

$F^*_x$ of 12.01 at ![]() $\phi = 0.05$, and

$\phi = 0.05$, and ![]() $F^*_x$ attains a maximum for all poroelastic clusters at

$F^*_x$ attains a maximum for all poroelastic clusters at ![]() $\phi = 0.09$, where

$\phi = 0.09$, where ![]() $F^*_x = 13.98$, 13.36, 13.12 and 12.86 for

$F^*_x = 13.98$, 13.36, 13.12 and 12.86 for ![]() $k^* = 0.3$, 0.5, 0.7 and 1.0, respectively.

$k^* = 0.3$, 0.5, 0.7 and 1.0, respectively.

The increase and subsequent decrease in the cluster drag with respect to the solid fraction has been generally observed for arrays of static cylinders over a wide range of the Reynolds number (Chang & Constantinescu Reference Chang and Constantinescu2015; Taddei et al. Reference Taddei, Manes and Ganapathisubramani2016; Tang et al. Reference Tang, Yu, Shan, Chen and Su2019, Reference Tang, Yu, Shan, Li and Yu2020; Kingora & Sadat Reference Kingora and Sadat2022). However, less is known about the fluid-dynamic mechanism responsible for the presence of an optimal porosity that maximises the cluster drag. For example, Chang & Constantinescu (Reference Chang and Constantinescu2015) and Tang et al. (Reference Tang, Yu, Shan, Li and Yu2020) reported that the peak drag appeared between two solid-fraction regimes characterised by weak interaction between cylinders (low ![]() $\phi$) and strong interaction that induces global vortex shedding behind the cylinder array (high

$\phi$) and strong interaction that induces global vortex shedding behind the cylinder array (high ![]() $\phi$), respectively. However, as illustrated in figure 7, the periodic vortex shedding does not occur behind our poroelastic clusters at low

$\phi$), respectively. However, as illustrated in figure 7, the periodic vortex shedding does not occur behind our poroelastic clusters at low ![]() $Re$. In addition, Kingora & Sadat (Reference Kingora and Sadat2022) employed a physical concept known as sheltering effect, which is similar to the effect of hydrodynamic blockage in our study, in order to analyse the spatial variation of fluid forces depending on the cylinder locations. However, the sheltering effect indicates a decrease in mean flow within the cylinder array, without specifically addressing the hydrodynamic interaction between multiple bodies by strong viscous diffusion, and it was not adopted to explain the drag experienced by the entire cylinder array. In this study, the mechanism that accounts for the appearance of an optimal

$Re$. In addition, Kingora & Sadat (Reference Kingora and Sadat2022) employed a physical concept known as sheltering effect, which is similar to the effect of hydrodynamic blockage in our study, in order to analyse the spatial variation of fluid forces depending on the cylinder locations. However, the sheltering effect indicates a decrease in mean flow within the cylinder array, without specifically addressing the hydrodynamic interaction between multiple bodies by strong viscous diffusion, and it was not adopted to explain the drag experienced by the entire cylinder array. In this study, the mechanism that accounts for the appearance of an optimal ![]() $\phi$ is inferred by analysing the effects of hydrodynamic blockage on the cluster drag.

$\phi$ is inferred by analysing the effects of hydrodynamic blockage on the cluster drag.

Whereas the degree of hydrodynamic blockage strengthens monotonically with an increase in the solid fraction ![]() $\phi$, the cluster drag

$\phi$, the cluster drag ![]() $F^*_x$ does not exhibit a monotonic change over

$F^*_x$ does not exhibit a monotonic change over ![]() $\phi$ due to the hydrodynamic blockage effect. If the hydrodynamic blockage is absent, the increase in

$\phi$ due to the hydrodynamic blockage effect. If the hydrodynamic blockage is absent, the increase in ![]() $\phi$ produces an effect that is hydrodynamically equivalent to that of simply increasing

$\phi$ produces an effect that is hydrodynamically equivalent to that of simply increasing ![]() $N_C$, which causes the cluster drag to increase. However, once the virtual fluid barrier interrupts the penetration of the incoming flow, the rear cylinders encounter little incoming flow, and thus increasing

$N_C$, which causes the cluster drag to increase. However, once the virtual fluid barrier interrupts the penetration of the incoming flow, the rear cylinders encounter little incoming flow, and thus increasing ![]() $\phi$ does not function equivalently as increasing

$\phi$ does not function equivalently as increasing ![]() $N_C$. As

$N_C$. As ![]() $F^*_x$ decreases with increasing

$F^*_x$ decreases with increasing ![]() $\phi$ for

$\phi$ for ![]() $\phi \geqq 0.09$, where the flow behaviour is predominated by the hydrodynamic blockage, it could be conjectured that the blockage yields an effect equivalent to that of decreasing

$\phi \geqq 0.09$, where the flow behaviour is predominated by the hydrodynamic blockage, it could be conjectured that the blockage yields an effect equivalent to that of decreasing ![]() $N_C$. To comprehensively understand how the hydrodynamic blockage affects the cluster drag, drag components are analysed in terms of the flow fields around the cluster.

$N_C$. To comprehensively understand how the hydrodynamic blockage affects the cluster drag, drag components are analysed in terms of the flow fields around the cluster.

We decompose the drag ![]() $f_x$ of a single cylinder into the drag

$f_x$ of a single cylinder into the drag ![]() $f_{x,v}$ due to viscous stress

$f_{x,v}$ due to viscous stress ![]() $\boldsymbol {\tau }$ and the drag

$\boldsymbol {\tau }$ and the drag ![]() $f_{x,p}$ due to pressure

$f_{x,p}$ due to pressure ![]() $p$ as

$p$ as

where ![]() $S$ is the surface of a cylinder and

$S$ is the surface of a cylinder and ![]() $\boldsymbol {n}$ is the unit normal vector out of

$\boldsymbol {n}$ is the unit normal vector out of ![]() $S$. Both components of the cylinder drag are made dimensionless using

$S$. Both components of the cylinder drag are made dimensionless using ![]() $\rho _f$,

$\rho _f$, ![]() $U$ and

$U$ and ![]() $d$ as

$d$ as ![]() $f^*_{x,v} = f_{x,v} / \rho _f U^2 d$ and

$f^*_{x,v} = f_{x,v} / \rho _f U^2 d$ and ![]() $f^*_{x,p} = f_{x,p} / \rho _f U^2 d$. The viscous and pressure drag forces on a cluster are defined in the same manner as the cluster drag

$f^*_{x,p} = f_{x,p} / \rho _f U^2 d$. The viscous and pressure drag forces on a cluster are defined in the same manner as the cluster drag ![]() $F^*_x$; thus,

$F^*_x$; thus, ![]() $F^*_{x,v} = \sum _{j=1}^{N_C} (f^*_{x,v})_j$ and

$F^*_{x,v} = \sum _{j=1}^{N_C} (f^*_{x,v})_j$ and ![]() $F^*_{x,p} = \sum _{j=1}^{N_C} (f^*_{x,p})_j$, respectively, where

$F^*_{x,p} = \sum _{j=1}^{N_C} (f^*_{x,p})_j$, respectively, where ![]() $F^*_{x,v} + F^*_{x,p} = F^*_x$. Similar to

$F^*_{x,v} + F^*_{x,p} = F^*_x$. Similar to ![]() $F^*_x$,

$F^*_x$, ![]() $F^*_{x,v}$ and

$F^*_{x,v}$ and ![]() $F^*_{x,p}$ increase and then decrease with respect to

$F^*_{x,p}$ increase and then decrease with respect to ![]() $\phi$, reaching a maximum at the same value of

$\phi$, reaching a maximum at the same value of ![]() $\phi = 0.09$ (figure 9). The changes in

$\phi = 0.09$ (figure 9). The changes in ![]() $F^*_{x,v}$ and

$F^*_{x,v}$ and ![]() $F^*_{x,p}$ are analysed using vorticity fields (figure 10a,b) and pressure fields (figure 10c,d), respectively, near to the clusters of

$F^*_{x,p}$ are analysed using vorticity fields (figure 10a,b) and pressure fields (figure 10c,d), respectively, near to the clusters of ![]() $\phi = 0.02$ (minimum), 0.09 (optimum) and 0.22 (maximum) with

$\phi = 0.02$ (minimum), 0.09 (optimum) and 0.22 (maximum) with ![]() $k^* = 0.3$ as representative cases. The vorticity field is considered for

$k^* = 0.3$ as representative cases. The vorticity field is considered for ![]() $F^*_{x,v}$ because the viscous stress tensor

$F^*_{x,v}$ because the viscous stress tensor ![]() $\boldsymbol {\tau }$ is linearly related to the vorticity

$\boldsymbol {\tau }$ is linearly related to the vorticity ![]() $\boldsymbol {\omega }$ on the cylinder surface

$\boldsymbol {\omega }$ on the cylinder surface ![]() $S$ according to

$S$ according to ![]() $\boldsymbol {n} \boldsymbol{\cdot} \boldsymbol {\tau } = -\mu \boldsymbol {n} \times \boldsymbol {\omega }$.

$\boldsymbol {n} \boldsymbol{\cdot} \boldsymbol {\tau } = -\mu \boldsymbol {n} \times \boldsymbol {\omega }$.

Figure 9. Cluster drag ![]() $F^*_x$ (solid lines) and drag components due to pressure

$F^*_x$ (solid lines) and drag components due to pressure ![]() $F^*_{x,p}$ (dashed lines) and viscous stress

$F^*_{x,p}$ (dashed lines) and viscous stress ![]() $F^*_{x,v}$ (dotted-dashed lines) of clusters.

$F^*_{x,v}$ (dotted-dashed lines) of clusters.

Figure 10. (a,b) Vorticity and (c,d) pressure fields for clusters with solid fractions of (i) ![]() $\phi =0.02$, (ii)

$\phi =0.02$, (ii) ![]() $\phi =0.09$ and (iii)

$\phi =0.09$ and (iii) ![]() $\phi =0.22$ with

$\phi =0.22$ with ![]() $k^* = 0.3$. Vorticity contours in panel (a) and pressure contours in panel (c) correspond to magnified views of panels (b,d), respectively. Vorticity and pressure are normalised as

$k^* = 0.3$. Vorticity contours in panel (a) and pressure contours in panel (c) correspond to magnified views of panels (b,d), respectively. Vorticity and pressure are normalised as ![]() $\omega _zd/U$ and

$\omega _zd/U$ and ![]() $p/\rho _f U^2$, respectively.

$p/\rho _f U^2$, respectively.

For the A7 model with the lowest ![]() $\phi = 0.02$, flow structures around all cylinders appear to behave individually because the effects of hydrodynamic blockage on the flow are minor. The incoming flow passing through the cluster generates strong shear layers around every cylinder, including the most rearward cylinder, and the shear layers do not interact with each other (figure 10a-i,b-i). For each cylinder, two counter-rotating vortices are clearly identified. Moreover, a local pressure field is generated around each cylinder; high- and low-pressure regions form at the windward and leeward sides of each cylinder, respectively (figure 10c-i). However, although each cylinder is subjected to strong