1. Introduction

Numerous previous studies (e.g. Carty Reference Carty1957; Jan & Shen Reference Jan and Shen1995) and dedicated reviews (Thompson, Leweke & Hourigan Reference Thompson, Leweke and Hourigan2021) have focused on the simple process of a sphere rolling down an inclined plane. Rolling sphere experiments date back to the time of Galileo Galilei (Galilei Reference Galilei1638), which have recently been corrected to include the effects of aerodynamic drag and rolling resistance (Breiland Reference Breiland2022). This process has practical applications, such as the re-suspension and transport of particles deposited on a surface, including dust on the ground or sediment in rivers. Despite the practical importance and apparent simplicity of this process, it is surprising that the mechanisms that allow sphere motion, while in contact with the plane, are not yet fully understood.

Lubrication theory (Goldman, Cox & Brenner Reference Goldman, Cox and Brenner1967; O'Neill & Stewartson Reference O'Neill and Stewartson1967; Cooley & O'Neill Reference Cooley and O'Neill1968) predicts an infinite drag coefficient (![]() $C_{D}$) for an ideally smooth sphere rolling in contact with a smooth surface, and in an incompressible fluid. Therefore, a sphere in contact with the panel will neither move nor roll due to infinite pressure peaks at the point of contact. However, spheres are observed to move in experiments (Carty Reference Carty1957; Jan & Shen Reference Jan and Shen1995), forming the basis of the rolling paradox (Prokunin Reference Prokunin2003; Thompson et al. Reference Thompson, Leweke and Hourigan2021).

$C_{D}$) for an ideally smooth sphere rolling in contact with a smooth surface, and in an incompressible fluid. Therefore, a sphere in contact with the panel will neither move nor roll due to infinite pressure peaks at the point of contact. However, spheres are observed to move in experiments (Carty Reference Carty1957; Jan & Shen Reference Jan and Shen1995), forming the basis of the rolling paradox (Prokunin Reference Prokunin2003; Thompson et al. Reference Thompson, Leweke and Hourigan2021).

For a sphere in a Newtonian incompressible fluid to move, a gap must exist between the sphere and the plane, which may occur via cavitation (Prokunin Reference Prokunin2003; Ashmore, Del Pino & Mullin Reference Ashmore, Del Pino and Mullin2005; Seddon & Mullin Reference Seddon and Mullin2006), compressibility (Terrington, Thompson & Hourigan Reference Terrington, Thompson and Hourigan2022) or surface roughness (Smart, Beimfohr & Leighton Reference Smart, Beimfohr and Leighton1993; Galvin, Zhao & Davis Reference Galvin, Zhao and Davis2001; Houdroge et al. Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) depending on the flow regime. This study considers the flow regime where the sphere maintains contact with the surface, in which the effective gap is determined by the roughness of both the sphere and the plane.

Prior to the extensive investigation by Carty (Reference Carty1957) (see figure 1), very little research had been conducted on the variation of the mean drag coefficient (![]() $\bar {C}_{D}$) with mean Reynolds number (

$\bar {C}_{D}$) with mean Reynolds number (![]() $\overline {Re}=\bar {U}D/\nu$, where

$\overline {Re}=\bar {U}D/\nu$, where ![]() $\bar {U}$ is the mean sphere velocity,

$\bar {U}$ is the mean sphere velocity, ![]() $D$ the sphere diameter and

$D$ the sphere diameter and ![]() $\nu$ the fluid kinematic viscosity) for a sphere freely rolling down an inclined plane. Following the work by Carty (Reference Carty1957), many other researchers performed similar experiments and obtained consistent results, with some degree of scatter in the data (Garde & Sethuraman Reference Garde and Sethuraman1969; Jan & Shen Reference Jan and Shen1995; Jan & Chen Reference Jan and Chen1997; Chhabra & Ferreira Reference Chhabra and Ferreira1999; Verekar & Arakeri Reference Verekar and Arakeri2010; Wardhaugh & Williams Reference Wardhaugh and Williams2014; Tee Reference Tee2018). For comparison, the results of Garde & Sethuraman (Reference Garde and Sethuraman1969) are also plotted in figure 1, which indicates the degree of scatter present in existing experimental studies. More recent work by Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) produced

$\nu$ the fluid kinematic viscosity) for a sphere freely rolling down an inclined plane. Following the work by Carty (Reference Carty1957), many other researchers performed similar experiments and obtained consistent results, with some degree of scatter in the data (Garde & Sethuraman Reference Garde and Sethuraman1969; Jan & Shen Reference Jan and Shen1995; Jan & Chen Reference Jan and Chen1997; Chhabra & Ferreira Reference Chhabra and Ferreira1999; Verekar & Arakeri Reference Verekar and Arakeri2010; Wardhaugh & Williams Reference Wardhaugh and Williams2014; Tee Reference Tee2018). For comparison, the results of Garde & Sethuraman (Reference Garde and Sethuraman1969) are also plotted in figure 1, which indicates the degree of scatter present in existing experimental studies. More recent work by Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) produced ![]() $\bar {C}_{D}$ vs

$\bar {C}_{D}$ vs ![]() $\overline {Re}$ results that are in agreement with those of Carty (Reference Carty1957), with minimal scatter in the data. The findings of the present study are also consistent with these two investigations.

$\overline {Re}$ results that are in agreement with those of Carty (Reference Carty1957), with minimal scatter in the data. The findings of the present study are also consistent with these two investigations.

Figure 1. The ![]() $\bar {C}_{D}$ vs

$\bar {C}_{D}$ vs ![]() $\overline {Re}$ comparison of previous experimental, analytical and computational studies. As seen in the figure, analytical predictions are generally well below both experimental and numerical predictions. Goldman et al. (Reference Goldman, Cox and Brenner1967) and Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) (see (2.4)) predictions have been plotted with a

$\overline {Re}$ comparison of previous experimental, analytical and computational studies. As seen in the figure, analytical predictions are generally well below both experimental and numerical predictions. Goldman et al. (Reference Goldman, Cox and Brenner1967) and Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) (see (2.4)) predictions have been plotted with a ![]() $G/D$ value of

$G/D$ value of ![]() $1\times 10^{-4}$, which is an average value based on experimental data of the present study (see figure 12 for equivalent experimental

$1\times 10^{-4}$, which is an average value based on experimental data of the present study (see figure 12 for equivalent experimental ![]() $\xi =G/D$ values).

$\xi =G/D$ values).

Analytical solutions of the Stokes equations (i.e. ![]() $Re = 0$) for a sphere translating and rotating parallel to a plane wall were obtained by Dean & O'Neill (Reference Dean and O'Neill1963) and O'Neill (Reference O'Neill1964, Reference O'Neill1967), using a bi-spherical coordinate transformation. However, their series solution suffers from poor numerical convergence for small gap ratios. An asymptotic solution, valid for small gap ratios, was obtained by Goldman et al. (Reference Goldman, Cox and Brenner1967), and independently by O'Neill & Stewartson (Reference O'Neill and Stewartson1967) and Cooley & O'Neill (Reference Cooley and O'Neill1968), using a combined Stokes-flow/lubrication approach. These studies find that the drag varies logarithmically with the gap height, and diverges towards infinity as the gap height approaches zero. A similar logarithmic divergence of the drag with gap height was reported by Bhattacharya, Mishra & Bhattacharya (Reference Bhattacharya, Mishra and Bhattacharya2010) for spherical particles translating and rotating in a cylindrical conduit.

$Re = 0$) for a sphere translating and rotating parallel to a plane wall were obtained by Dean & O'Neill (Reference Dean and O'Neill1963) and O'Neill (Reference O'Neill1964, Reference O'Neill1967), using a bi-spherical coordinate transformation. However, their series solution suffers from poor numerical convergence for small gap ratios. An asymptotic solution, valid for small gap ratios, was obtained by Goldman et al. (Reference Goldman, Cox and Brenner1967), and independently by O'Neill & Stewartson (Reference O'Neill and Stewartson1967) and Cooley & O'Neill (Reference Cooley and O'Neill1968), using a combined Stokes-flow/lubrication approach. These studies find that the drag varies logarithmically with the gap height, and diverges towards infinity as the gap height approaches zero. A similar logarithmic divergence of the drag with gap height was reported by Bhattacharya, Mishra & Bhattacharya (Reference Bhattacharya, Mishra and Bhattacharya2010) for spherical particles translating and rotating in a cylindrical conduit.

Figure 1 presents the solutions provided by Goldman et al. (Reference Goldman, Cox and Brenner1967) for a fixed gap/diameter ratio (![]() $G/D$) of

$G/D$) of ![]() $10^{-4}$. Goldman et al. (Reference Goldman, Cox and Brenner1967) assumed that the sphere and the plane were not in contact, and separated by a small gap, where the flow could be described using classical lubrication theory. However, the idealised model provided by Goldman et al. (Reference Goldman, Cox and Brenner1967) underestimated

$10^{-4}$. Goldman et al. (Reference Goldman, Cox and Brenner1967) assumed that the sphere and the plane were not in contact, and separated by a small gap, where the flow could be described using classical lubrication theory. However, the idealised model provided by Goldman et al. (Reference Goldman, Cox and Brenner1967) underestimated ![]() $C_{D}$ in comparison with the experimental results of Carty (Reference Carty1957), and required

$C_{D}$ in comparison with the experimental results of Carty (Reference Carty1957), and required ![]() $G/D$ of the order of

$G/D$ of the order of ![]() $10^{-8}$ for agreement with the Carty (Reference Carty1957) results, well beyond the limits of applicability of the model. Goldman et al. (Reference Goldman, Cox and Brenner1967) suggested six possible explanations for the observed divergence, including surface roughness, compressibility or cavitation linked to the large pressure magnitudes in the interstice, breakdown of the continuum assumption, inertial effects, non-Newtonian effects and deformation of the sphere. Goldman et al. (Reference Goldman, Cox and Brenner1967) provided cavitation as the most likely explanation for the observed divergence, due to the lack of supporting evidence for the other mechanisms. In particular, surface roughness was ruled out since the Carty (Reference Carty1957) results indicated a single

$10^{-8}$ for agreement with the Carty (Reference Carty1957) results, well beyond the limits of applicability of the model. Goldman et al. (Reference Goldman, Cox and Brenner1967) suggested six possible explanations for the observed divergence, including surface roughness, compressibility or cavitation linked to the large pressure magnitudes in the interstice, breakdown of the continuum assumption, inertial effects, non-Newtonian effects and deformation of the sphere. Goldman et al. (Reference Goldman, Cox and Brenner1967) provided cavitation as the most likely explanation for the observed divergence, due to the lack of supporting evidence for the other mechanisms. In particular, surface roughness was ruled out since the Carty (Reference Carty1957) results indicated a single ![]() $\overline {Re}$ vs

$\overline {Re}$ vs ![]() $\bar {C}_{D}$ curve for

$\bar {C}_{D}$ curve for ![]() $\overline {Re}<60$, despite the various degrees of roughness present in the experiments. However, more recent experiments by Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) have indicated that, when additional data points are obtained, multiple curves corresponding to various

$\overline {Re}<60$, despite the various degrees of roughness present in the experiments. However, more recent experiments by Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) have indicated that, when additional data points are obtained, multiple curves corresponding to various ![]() $G/D$ values are observed. While Goldman et al. (Reference Goldman, Cox and Brenner1967) dismissed the effects of surface roughness as a plausible explanation for the deviation of his predictions from experimental data, the results of Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) have shown that variations in surface roughness can lead to variations in

$G/D$ values are observed. While Goldman et al. (Reference Goldman, Cox and Brenner1967) dismissed the effects of surface roughness as a plausible explanation for the deviation of his predictions from experimental data, the results of Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) have shown that variations in surface roughness can lead to variations in ![]() $\bar {C}_{D}$ in inertial flow, which will be investigated in more detail in the present study.

$\bar {C}_{D}$ in inertial flow, which will be investigated in more detail in the present study.

The analytical work of Goldman et al. (Reference Goldman, Cox and Brenner1967) was further extended by Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) to describe the value of ![]() $C_{D}$ of a sphere in contact with a plane, rolling without slipping and at finite

$C_{D}$ of a sphere in contact with a plane, rolling without slipping and at finite ![]() $\overline {Re}$. Contact forces between the sphere and the wall increase the predicted

$\overline {Re}$. Contact forces between the sphere and the wall increase the predicted ![]() $C_{D}$ compared with the model of Goldman et al. (Reference Goldman, Cox and Brenner1967). In addition, the inclusion of inertial effects at non-zero

$C_{D}$ compared with the model of Goldman et al. (Reference Goldman, Cox and Brenner1967). In addition, the inclusion of inertial effects at non-zero ![]() $\overline {Re}$ results in an additional contribution to the drag coefficient, known as the wake drag coefficient (

$\overline {Re}$ results in an additional contribution to the drag coefficient, known as the wake drag coefficient (![]() $C_{D,{wake}}$) (see § 2.1). Figure 1 shows the combined analytical and numerical predictions of Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) for a fixed

$C_{D,{wake}}$) (see § 2.1). Figure 1 shows the combined analytical and numerical predictions of Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) for a fixed ![]() $G/D=10^{-4}$, which marginally underpredict

$G/D=10^{-4}$, which marginally underpredict ![]() $C_{D}$ compared with the measurements of Carty (Reference Carty1957) for

$C_{D}$ compared with the measurements of Carty (Reference Carty1957) for ![]() $\overline {Re}<200$. We note that the surface roughness was not measured in the Carty (Reference Carty1957) experiments. The value of

$\overline {Re}<200$. We note that the surface roughness was not measured in the Carty (Reference Carty1957) experiments. The value of ![]() $G/D=10^{-5}$ provides much better agreement between the Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) predictions and the Carty (Reference Carty1957) results. Given that Carty (Reference Carty1957) used spheres with diameters ranging from

$G/D=10^{-5}$ provides much better agreement between the Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) predictions and the Carty (Reference Carty1957) results. Given that Carty (Reference Carty1957) used spheres with diameters ranging from ![]() $2$ to

$2$ to ![]() $30$ mm made from different materials (Lucite, glass, steel and acetate), to obtain

$30$ mm made from different materials (Lucite, glass, steel and acetate), to obtain ![]() $G/D \approx 10^{-5}$,

$G/D \approx 10^{-5}$, ![]() $G$ should be approximately

$G$ should be approximately ![]() $0.02$ to

$0.02$ to ![]() $0.3\,\mathrm {\mu }$m, which is of the same order of magnitude as the surface roughness measurements obtained in this study.

$0.3\,\mathrm {\mu }$m, which is of the same order of magnitude as the surface roughness measurements obtained in this study.

Numerical simulations have shown that, while the wake dynamics of a rolling body is independent of the gap size, when the gap is small, the observed forces are highly sensitive to it (Rao et al. Reference Rao, Passaggia, Bolnot, Thompson, Leweke and Hourigan2012). Zhang et al. (Reference Zhang, Soga, Kumar, Sun and Jin2017) investigated the value of ![]() $C_{D}$ for a particle moving parallel to a wall for

$C_{D}$ for a particle moving parallel to a wall for ![]() $G/D=0$ that should produce infinite drag at the point of contact, but which has not been captured in the lattice-Boltzmann method they have used. However, their findings were consistent with the results of Carty (Reference Carty1957) for higher

$G/D=0$ that should produce infinite drag at the point of contact, but which has not been captured in the lattice-Boltzmann method they have used. However, their findings were consistent with the results of Carty (Reference Carty1957) for higher ![]() $\overline {Re}$

$\overline {Re}$ ![]() $(>100)$, but there was a noticeable deviation at lower

$(>100)$, but there was a noticeable deviation at lower ![]() $\overline {Re}$ (refer to figure 1). This indicates that the numerical schemes are effective in capturing the effects of wake drag on

$\overline {Re}$ (refer to figure 1). This indicates that the numerical schemes are effective in capturing the effects of wake drag on ![]() $C_{D}$ that dominate at higher

$C_{D}$ that dominate at higher ![]() $\overline {Re}$, but diverge as the gap-dependent drag (

$\overline {Re}$, but diverge as the gap-dependent drag (![]() $C_{D,{gap}}$, primarily arising from high pressure gradients and viscous forces within the gap region) dominates at lower

$C_{D,{gap}}$, primarily arising from high pressure gradients and viscous forces within the gap region) dominates at lower ![]() $\overline {Re}$. This divergence can be attributed to limitations in a gap height introduced at the point of contact (or zero gap in the case of Zhang et al. Reference Zhang, Soga, Kumar, Sun and Jin2017) between the sphere and plane to avoid mesh singularities. Simulation by Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) demonstrated this sensitivity of

$\overline {Re}$. This divergence can be attributed to limitations in a gap height introduced at the point of contact (or zero gap in the case of Zhang et al. Reference Zhang, Soga, Kumar, Sun and Jin2017) between the sphere and plane to avoid mesh singularities. Simulation by Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) demonstrated this sensitivity of ![]() $C_{D}$ to

$C_{D}$ to ![]() $G/D$, where the predicted

$G/D$, where the predicted ![]() $C_{D}$ increased by

$C_{D}$ increased by ![]() $40\,\%$ at

$40\,\%$ at ![]() $\overline {Re}=50$, when the gap height is reduced from

$\overline {Re}=50$, when the gap height is reduced from ![]() $0.01$ to

$0.01$ to ![]() $0.0002$ (see also figure 12). To effectively capture a value of

$0.0002$ (see also figure 12). To effectively capture a value of ![]() $C_{D,{gap}}$ comparable to experimental results, gap heights in the range of

$C_{D,{gap}}$ comparable to experimental results, gap heights in the range of ![]() $10^{-5}$–

$10^{-5}$–![]() $10^{-8}$ are required, which are not computationally feasible to carry out over a large range of

$10^{-8}$ are required, which are not computationally feasible to carry out over a large range of ![]() $\overline {Re}$. To address these numerical difficulties, Terrington, Thompson & Hourigan (Reference Terrington, Thompson and Hourigan2023) proposed a combined analytic and numerical approach for a two-dimensional cylinder translating and rotating adjacent to a plane wall. Similar to the method used by Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023), the newly proposed method decomposes the total flow into the inner flow, which is represented using analytical expressions using lubrication theory, and outer flow, described using numerical simulations.

$\overline {Re}$. To address these numerical difficulties, Terrington, Thompson & Hourigan (Reference Terrington, Thompson and Hourigan2023) proposed a combined analytic and numerical approach for a two-dimensional cylinder translating and rotating adjacent to a plane wall. Similar to the method used by Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023), the newly proposed method decomposes the total flow into the inner flow, which is represented using analytical expressions using lubrication theory, and outer flow, described using numerical simulations.

While surface roughness has often been neglected in studies performed in the inertial regime, many previous studies have considered the effects of surface roughness on the dynamics of a rolling sphere in the Stokes regime (Smart & Leighton Reference Smart and Leighton1989; King & Leighton Reference King and Leighton1997; Galvin et al. Reference Galvin, Zhao and Davis2001; Zhao, Galvin & Davis Reference Zhao, Galvin and Davis2002; Prokunin Reference Prokunin2003). Smart & Leighton (Reference Smart and Leighton1989) developed a technique for measuring the effective hydrodynamic gap, based on the time taken for the sphere to fall away from the wall under the influence of gravity. For a stationary sphere, they show that the effective hydrodynamic gap is determined by the height of the largest scale of surface asperity with sufficient coverage to support the sphere. Smart et al. (Reference Smart, Beimfohr and Leighton1993) used the effective hydrodynamic roughness to predict the rotational and translational velocities of a rolling sphere in the Stokes regime, finding good agreement between their predictions and experimental measurements.

King & Leighton (Reference King and Leighton1997), Galvin et al. (Reference Galvin, Zhao and Davis2001) and Zhao et al. (Reference Zhao, Galvin and Davis2002) extended this analysis to include multiple scales of roughness, rather than the single scale of roughness considered by Smart & Leighton (Reference Smart and Leighton1989) and Smart et al. (Reference Smart, Beimfohr and Leighton1993). Galvin et al. (Reference Galvin, Zhao and Davis2001) and Zhao et al. (Reference Zhao, Galvin and Davis2002) propose a model featuring two scales of roughness: a dense coverage of small asperities, and a sparse coverage of large asperities. The small asperities support the sphere at rest and low speeds (![]() $U$), while the sphere only contacts the large asperities at higher

$U$), while the sphere only contacts the large asperities at higher ![]() $U$. This hypothesis explained the discrepancy between the model of Smart et al. (Reference Smart, Beimfohr and Leighton1993) and experimental measurements at higher

$U$. This hypothesis explained the discrepancy between the model of Smart et al. (Reference Smart, Beimfohr and Leighton1993) and experimental measurements at higher ![]() $U$.

$U$.

These studies have clearly demonstrated that surface roughness plays a key role in the dynamics of a rolling sphere in the Stokes-flow regime. However, determining the effects of surface roughness on the motion of a sphere in the inertial flow regime (![]() $Re>1$) requires further investigations. The present study aims to demonstrate the effects of surface roughness on the motion of a rolling sphere in the inertial flow regime.

$Re>1$) requires further investigations. The present study aims to demonstrate the effects of surface roughness on the motion of a rolling sphere in the inertial flow regime.

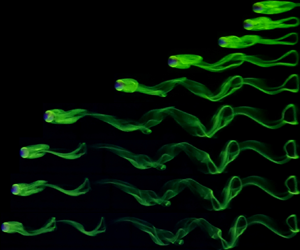

In addition to the investigation of the effects of surface roughness on ![]() $C_{D}$, we will also be presenting experimental flow visualisations, path tracking and vortex-induced vibration (VIV) analysis on freely rolling spheres. The value of

$C_{D}$, we will also be presenting experimental flow visualisations, path tracking and vortex-induced vibration (VIV) analysis on freely rolling spheres. The value of ![]() $C_{D}$ of a freely rolling sphere is dependent on its velocity, and the sphere wake dynamics has a direct influence on the down-slope and cross-slope velocities. As such, it is crucial to obtain a better understanding of the wake of a freely rolling sphere, which will be achieved using flow visualisations. In addition, wake shedding has been observed to induce oscillations (also called VIV) on a freely rolling sphere (Houdroge Reference Houdroge2017). We will also investigate this relationship between the sphere wake dynamics and VIV, while also examining the effects of surface roughness on the VIV response of a sphere.

$C_{D}$ of a freely rolling sphere is dependent on its velocity, and the sphere wake dynamics has a direct influence on the down-slope and cross-slope velocities. As such, it is crucial to obtain a better understanding of the wake of a freely rolling sphere, which will be achieved using flow visualisations. In addition, wake shedding has been observed to induce oscillations (also called VIV) on a freely rolling sphere (Houdroge Reference Houdroge2017). We will also investigate this relationship between the sphere wake dynamics and VIV, while also examining the effects of surface roughness on the VIV response of a sphere.

Many previous studies have investigated wake formation behind bluff bodies and some previous research has been undertaken on rolling spheres (Taneda Reference Taneda1965; Stewart et al. Reference Stewart, Leweke, Hourigan and Thompson2008, Reference Stewart, Thompson, Leweke and Hourigan2010a,Reference Stewart, Thompson, Leweke and Houriganb; Rao et al. Reference Rao, Stewart, Thompson, Leweke and Hourigan2011; Verekar & Arakeri Reference Verekar and Arakeri2019). Experimental flow visualisations by Leweke et al. (Reference Leweke, Provansal, Ormiéres and Lebescond1999) captured the wake of an isolated sphere in great detail, showing the division of the re-circulation region into two parallel threads with opposite vorticity, which later combine to form a hairpin-like structure with centre-line mirror symmetry. The photographs also capture the connection between the head of one hairpin vortex to the tail of the previous hairpin vortex, demonstrating the complexity of the wake of an isolated sphere. Houdroge (Reference Houdroge2017) also experimentally visualised the wake of a freely rolling sphere and obtained results in good agreement with numerical predictions. Although these studies have presented flow visualisations at a few distinct ![]() $\overline {Re}$, the present literature lacks a detailed experimental investigation of the wake of a freely rolling sphere, visualising the transitions with increase in

$\overline {Re}$, the present literature lacks a detailed experimental investigation of the wake of a freely rolling sphere, visualising the transitions with increase in ![]() $\overline {Re}$. As such, in the present study, we will be presenting detailed visualisations of the wake of a freely rolling sphere, and comparing our results with existing experimental and numerical predictions.

$\overline {Re}$. As such, in the present study, we will be presenting detailed visualisations of the wake of a freely rolling sphere, and comparing our results with existing experimental and numerical predictions.

At low ![]() $\overline {Re}$, the flow behind a rolling sphere is steady, remains attached and a fluid re-circulation zone has been observed (Stewart et al. Reference Stewart, Thompson, Leweke and Hourigan2010b). This is analogous to an isolated sphere, where a double threaded wake comprised a counter-rotating vortex pair, as described by Thompson et al. (Reference Thompson, Leweke and Hourigan2021). As

$\overline {Re}$, the flow behind a rolling sphere is steady, remains attached and a fluid re-circulation zone has been observed (Stewart et al. Reference Stewart, Thompson, Leweke and Hourigan2010b). This is analogous to an isolated sphere, where a double threaded wake comprised a counter-rotating vortex pair, as described by Thompson et al. (Reference Thompson, Leweke and Hourigan2021). As ![]() $\overline {Re}$ increases, this re-circulation zone grows in size, and the flow becomes increasingly unsteady. Numerical simulations conducted by Stewart et al. (Reference Stewart, Thompson, Leweke and Hourigan2010b) identified that the flow undergoes a transition to unsteady, periodic flow in the range

$\overline {Re}$ increases, this re-circulation zone grows in size, and the flow becomes increasingly unsteady. Numerical simulations conducted by Stewart et al. (Reference Stewart, Thompson, Leweke and Hourigan2010b) identified that the flow undergoes a transition to unsteady, periodic flow in the range ![]() $125 < Re < 150$ for a forward rolling sphere. Rao et al. (Reference Rao, Passaggia, Bolnot, Thompson, Leweke and Hourigan2012) found that this transition occurs at

$125 < Re < 150$ for a forward rolling sphere. Rao et al. (Reference Rao, Passaggia, Bolnot, Thompson, Leweke and Hourigan2012) found that this transition occurs at ![]() $Re=139$ (

$Re=139$ (![]() $Re_{c1}$) and further identified a second transition at

$Re_{c1}$) and further identified a second transition at ![]() $Re=192$ (

$Re=192$ (![]() $Re_{c2}$) where mirror symmetry was broken. Interestingly, Houdroge (Reference Houdroge2017) also found that the first critical transition is strongly dependent on the mass ratio,

$Re_{c2}$) where mirror symmetry was broken. Interestingly, Houdroge (Reference Houdroge2017) also found that the first critical transition is strongly dependent on the mass ratio, ![]() $\beta =\rho _{s}/\rho _{f}$ (where

$\beta =\rho _{s}/\rho _{f}$ (where ![]() $\rho _{s}$ and

$\rho _{s}$ and ![]() $\rho _{f}$ are the densities of the sphere and fluid, respectively), which acts to delay the onset of unsteadiness in the flow. As

$\rho _{f}$ are the densities of the sphere and fluid, respectively), which acts to delay the onset of unsteadiness in the flow. As ![]() $\overline {Re}$ increases further, hairpin vortices are shed into the wake, and in the second transition, centre-plane symmetry of the wake is broken. In simulations by Houdroge (Reference Houdroge2017), significant lateral movement was observed, and vortices were shed at varying orientations. Similar lateral oscillations were observed experimentally by Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023), who attributed these oscillations at lower

$\overline {Re}$ increases further, hairpin vortices are shed into the wake, and in the second transition, centre-plane symmetry of the wake is broken. In simulations by Houdroge (Reference Houdroge2017), significant lateral movement was observed, and vortices were shed at varying orientations. Similar lateral oscillations were observed experimentally by Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023), who attributed these oscillations at lower ![]() $\overline {Re}$ to imperfections and dust on the rolling surface. This unsteadiness in the wake leads to VIVs which produce Strouhal numbers (

$\overline {Re}$ to imperfections and dust on the rolling surface. This unsteadiness in the wake leads to VIVs which produce Strouhal numbers (![]() $St$) ranging between

$St$) ranging between ![]() $0.10$ and

$0.10$ and ![]() $0.15$ in line, and

$0.15$ in line, and ![]() $0.05$ cross-slope, for

$0.05$ cross-slope, for ![]() $\overline {Re}<300$ (Houdroge et al. Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023). We will investigate these phenomena further in the present paper.

$\overline {Re}<300$ (Houdroge et al. Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023). We will investigate these phenomena further in the present paper.

In this study, we will experimentally investigate the effects of surface roughness on the drag coefficient of spheres, freely rolling without slipping down an inclined plane. We aim to provide experimental evidence that ![]() $\bar {C}_{D}$ is dependent on both the sphere and panel surface roughness, and the effective gap (

$\bar {C}_{D}$ is dependent on both the sphere and panel surface roughness, and the effective gap (![]() $G$) between the panel and sphere can be estimated by assuming an effective gap determined by the surface roughness parameters. However, it should be noted that, due to the logarithmic dependence of

$G$) between the panel and sphere can be estimated by assuming an effective gap determined by the surface roughness parameters. However, it should be noted that, due to the logarithmic dependence of ![]() $C_{D}$ on gap height (see (2.2)), an order of magnitude change in

$C_{D}$ on gap height (see (2.2)), an order of magnitude change in ![]() $G/D$ or surface roughness will only produce relatively small changes in

$G/D$ or surface roughness will only produce relatively small changes in ![]() $\bar {C}_{D}$, posing a challenge in establishing the effects of surface roughness on

$\bar {C}_{D}$, posing a challenge in establishing the effects of surface roughness on ![]() $\bar {C}_{D}$. Nevertheless, we will demonstrate that variations in surface roughness (

$\bar {C}_{D}$. Nevertheless, we will demonstrate that variations in surface roughness (![]() $25$-fold change) leads to a change in observed

$25$-fold change) leads to a change in observed ![]() $\bar {C}_{D}$ (

$\bar {C}_{D}$ (![]() $\approx 10\,\%$), which is well beyond the experimental uncertainty (typically

$\approx 10\,\%$), which is well beyond the experimental uncertainty (typically ![]() $1\,\%\unicode{x2013}2\,\%$) of the measurements.

$1\,\%\unicode{x2013}2\,\%$) of the measurements.

Moreover, we demonstrate that the measured drag coefficients are in agreement with the predicted drag coefficient for a smooth sphere and smooth wall, with a gap approximately equal to the root-mean-square (r.m.s.) surface roughness. Our primary focus will be on the inertial flow regime (![]() $30<\overline {Re}<800$), where the present literature lacks experimental evidence of the dependence of

$30<\overline {Re}<800$), where the present literature lacks experimental evidence of the dependence of ![]() $C_{D}$ on surface roughness. A limited set of experiments of freely rolling foam spheres in air will be conducted for comparison against the results with spheres in water. These results will be used to demonstrate that cavitation (or compressibility) is not a necessary requirement to allow sphere motion. Additional flow visualisations and VIV analysis will also be used to indicate the complexity of the rolling sphere wake and to provide experimental validation of the relative significance of surface roughness and wake formation for the unsteady motion of the sphere. Experimental flow visualisation will be used to validate critical flow transitions that have been observed in previous numerical studies (Rao et al. Reference Rao, Passaggia, Bolnot, Thompson, Leweke and Hourigan2012; Houdroge Reference Houdroge2017). We will demonstrate that the VIV response of a freely rolling sphere is independent of surface roughness, and that results are also in relative agreement with numerical predictions which have been produced assuming a gap between the sphere and plane. This paper is organised as follows. Section 2 describes the problem and the existing analytical solutions and § 3 presents the experimental method. Section 4 presents detailed experimental results of the investigation including flow visualisations and path tracking information together with discussion of observations. Section 5 presents concluding remarks.

$C_{D}$ on surface roughness. A limited set of experiments of freely rolling foam spheres in air will be conducted for comparison against the results with spheres in water. These results will be used to demonstrate that cavitation (or compressibility) is not a necessary requirement to allow sphere motion. Additional flow visualisations and VIV analysis will also be used to indicate the complexity of the rolling sphere wake and to provide experimental validation of the relative significance of surface roughness and wake formation for the unsteady motion of the sphere. Experimental flow visualisation will be used to validate critical flow transitions that have been observed in previous numerical studies (Rao et al. Reference Rao, Passaggia, Bolnot, Thompson, Leweke and Hourigan2012; Houdroge Reference Houdroge2017). We will demonstrate that the VIV response of a freely rolling sphere is independent of surface roughness, and that results are also in relative agreement with numerical predictions which have been produced assuming a gap between the sphere and plane. This paper is organised as follows. Section 2 describes the problem and the existing analytical solutions and § 3 presents the experimental method. Section 4 presents detailed experimental results of the investigation including flow visualisations and path tracking information together with discussion of observations. Section 5 presents concluding remarks.

2. Problem description

The general case of a sphere of diameter ![]() $D$ rolling down a plane sloped at an angle

$D$ rolling down a plane sloped at an angle ![]() $\theta$ to the horizontal, considered in this study, is shown in figure 2. The sphere density is denoted by

$\theta$ to the horizontal, considered in this study, is shown in figure 2. The sphere density is denoted by ![]() $\rho _{s}$ and the fluid density

$\rho _{s}$ and the fluid density ![]() $\rho _{f}$; typically

$\rho _{f}$; typically ![]() $\rho _{s}>\rho _{f}$ (negatively buoyant). The coordinate system is attached to the centre of the body and the fluid is stationary with respect to the plane. Once the body reaches a quasi-steady state, it will travel at the time-mean terminal velocity

$\rho _{s}>\rho _{f}$ (negatively buoyant). The coordinate system is attached to the centre of the body and the fluid is stationary with respect to the plane. Once the body reaches a quasi-steady state, it will travel at the time-mean terminal velocity ![]() $\bar {U}$ in the

$\bar {U}$ in the ![]() $x$ direction and mean angular velocity

$x$ direction and mean angular velocity ![]() $\omega$ about the

$\omega$ about the ![]() $y$ direction, as indicated in the figure. The

$y$ direction, as indicated in the figure. The ![]() $x$ direction is also referred to as the down-slope direction, and the

$x$ direction is also referred to as the down-slope direction, and the ![]() $y$ direction is referred to as the cross-slope direction;

$y$ direction is referred to as the cross-slope direction; ![]() $W_{B}$ is the buoyant weight of the body (

$W_{B}$ is the buoyant weight of the body (![]() $W_{B}={\rm \pi} D^{3} (\rho _{s}-\rho _{f})/6$), and

$W_{B}={\rm \pi} D^{3} (\rho _{s}-\rho _{f})/6$), and ![]() $N$ is the normal reaction at the point of contact between the body and the plane;

$N$ is the normal reaction at the point of contact between the body and the plane; ![]() $\xi$ is the non-dimensional effective gap between the body and the plane imposed by surface roughness, given by

$\xi$ is the non-dimensional effective gap between the body and the plane imposed by surface roughness, given by ![]() $\xi = G/D$. The parameter

$\xi = G/D$. The parameter ![]() $\xi$ will be discussed in detail in § 2.2. The parameter

$\xi$ will be discussed in detail in § 2.2. The parameter ![]() $F_{L}$ is the lift force acting on the body, while

$F_{L}$ is the lift force acting on the body, while ![]() $T_{y}$ is the total torque about the

$T_{y}$ is the total torque about the ![]() $y$ axis and

$y$ axis and ![]() $F_{D}$ indicates the total drag force acting on the body.

$F_{D}$ indicates the total drag force acting on the body.

Figure 2. The schematic free body diagram of the forces acting on a sphere rolling down an inclined plane under the influence of gravity, in a stationary fluid.

Considering the force balance parallel to the plane, the mean drag coefficient of a freely rolling sphere is given by (2.1). Note that the experimentally measured drag coefficient includes both a hydrodynamic component (drag and torque) and contact forces

2.1. Analytical predictions

Goldman et al. (Reference Goldman, Cox and Brenner1967) provided analytical expressions for the non-dimensional drag force on a sphere, both translating and rotating near a plane wall in Stokes flow, as a function of ![]() $G/D$. Assuming no contact forces between the sphere and the wall, they concluded that a sphere rolling down the plane must slip. Smart et al. (Reference Smart, Beimfohr and Leighton1993) and Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) assume that static friction forces due to physical contact between surface asperities on both the sphere and the wall cause the sphere to roll without slipping. They present the following expression for the total effective drag coefficient for the Stokes-flow case, which includes both hydrodynamic and contact forces:

$G/D$. Assuming no contact forces between the sphere and the wall, they concluded that a sphere rolling down the plane must slip. Smart et al. (Reference Smart, Beimfohr and Leighton1993) and Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) assume that static friction forces due to physical contact between surface asperities on both the sphere and the wall cause the sphere to roll without slipping. They present the following expression for the total effective drag coefficient for the Stokes-flow case, which includes both hydrodynamic and contact forces:

It should also be noted that, in the derivation of (2.2), a frictional force was required at the contact point to maintain the no-slip boundary condition. Without this force, as stated by Goldman et al. (Reference Goldman, Cox and Brenner1967), the sphere will slip. Therefore, a frictional force at the point of contact is essential for the sphere to roll without slip. Note that the static contact force included in (2.2) does no work on the sphere, and therefore does not reduce the sphere's total kinetic energy. Instead, it transfers the sphere's total kinetic energy between translation and rotation to maintain no slip.

The above equation expresses the contributions of the lubrication flow in the narrow gap between the sphere and the plane to the total drag coefficient, which is referred to as gap-dependent drag (![]() $C_{D,{gap}}$). The lubrication approach assumes that the gap is much smaller than the sphere diameter (

$C_{D,{gap}}$). The lubrication approach assumes that the gap is much smaller than the sphere diameter (![]() $G \ll D$), which holds for the spheres considered in the present work.

$G \ll D$), which holds for the spheres considered in the present work.

For non-zero ![]() $\overline {Re}$, there is an additional contribution to the drag coefficient known as wake drag (

$\overline {Re}$, there is an additional contribution to the drag coefficient known as wake drag (![]() $C_{D,{wake}}$), which is approximately independent of

$C_{D,{wake}}$), which is approximately independent of ![]() $G/D$ (Houdroge et al. Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023; Terrington et al. Reference Terrington, Thompson and Hourigan2023). Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) provide the following empirical expression for the wake drag coefficient, valid for

$G/D$ (Houdroge et al. Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023; Terrington et al. Reference Terrington, Thompson and Hourigan2023). Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) provide the following empirical expression for the wake drag coefficient, valid for ![]() $5<\overline {Re}<300$, based on numerical simulations performed at

$5<\overline {Re}<300$, based on numerical simulations performed at ![]() $G/D = 0.005$:

$G/D = 0.005$:

The total drag coefficient is then obtained as the sum of the gap-dependent drag and wake drag

Equation (2.4) is plotted in figure 1 for a fixed ![]() $G/D=10^{-4}$ and shows the same general trend as observed by Carty (Reference Carty1957) for

$G/D=10^{-4}$ and shows the same general trend as observed by Carty (Reference Carty1957) for ![]() $\overline {Re}<100$. Slight differences between the predictions and experiments are attributed to the influence of gap size, which is not known for Carty's experiments. The experimental results of the present investigation will be compared against the predictions from (2.4), in § 4.4.

$\overline {Re}<100$. Slight differences between the predictions and experiments are attributed to the influence of gap size, which is not known for Carty's experiments. The experimental results of the present investigation will be compared against the predictions from (2.4), in § 4.4.

2.2. Relationship between gap and surface roughness

A primary aim of the present investigation is to establish the relationship between the effective gap (![]() $G$) to be used in (2.2)–(2.4), and the surface roughness parameters. Many parameters may be used to describe surface roughness, that vary depending on the application. British Standard Geometric Product Specifications (GPS) – Surface texture: Profile method – Terms, definitions and surface texture parameters, BS ISO 4287:1997 describes these parameters in detail. The most common parameters are mean absolute deviation, r.m.s. and peak roughness (

$G$) to be used in (2.2)–(2.4), and the surface roughness parameters. Many parameters may be used to describe surface roughness, that vary depending on the application. British Standard Geometric Product Specifications (GPS) – Surface texture: Profile method – Terms, definitions and surface texture parameters, BS ISO 4287:1997 describes these parameters in detail. The most common parameters are mean absolute deviation, r.m.s. and peak roughness (![]() $R_{a}$,

$R_{a}$, ![]() $R_{q}$ and

$R_{q}$ and ![]() $R_{p}$, respectively).

$R_{p}$, respectively).

Based on these roughness parameters, a new non-dimensional relative roughness ![]() $\xi$ will be defined as follows:

$\xi$ will be defined as follows:

where ![]() $\xi$ is the non-dimensional roughness coefficient or relative roughness,

$\xi$ is the non-dimensional roughness coefficient or relative roughness, ![]() $R_{panel}$ and

$R_{panel}$ and ![]() $R_{sphere}$ are the relevant roughness lengths corresponding to the panel and sphere. It is currently unclear what statistical measure of surface roughness best describes the effective gap. In this study, we consider the parameters

$R_{sphere}$ are the relevant roughness lengths corresponding to the panel and sphere. It is currently unclear what statistical measure of surface roughness best describes the effective gap. In this study, we consider the parameters ![]() $\xi _{q}$,

$\xi _{q}$, ![]() $\xi _{a}$ and

$\xi _{a}$ and ![]() $\xi _{p}$, based on the r.m.s. roughness (

$\xi _{p}$, based on the r.m.s. roughness (![]() $R_{q,{panel}}$ and

$R_{q,{panel}}$ and ![]() $R_{q,{sphere}}$), mean absolute deviation (

$R_{q,{sphere}}$), mean absolute deviation (![]() $R_{a,{panel}}$ and

$R_{a,{panel}}$ and ![]() $R_{a,{sphere}}$) and peak roughness (

$R_{a,{sphere}}$) and peak roughness (![]() $R_{p,{panel}}$ and

$R_{p,{panel}}$ and ![]() $R_{p,{sphere}}$), respectively.

$R_{p,{sphere}}$), respectively.

Equation (2.5) assumes that the effective gap (![]() $G_{effective}$) at the point of contact is the linear summation of the individual roughness values. This is a simplistic approach in approximating the effective roughness, where we have assumed that the sphere and the panel roughness contribute equally to the effective gap between them. This assumption will be discussed in detail in § 4.1.

$G_{effective}$) at the point of contact is the linear summation of the individual roughness values. This is a simplistic approach in approximating the effective roughness, where we have assumed that the sphere and the panel roughness contribute equally to the effective gap between them. This assumption will be discussed in detail in § 4.1.

It is expected that the surface roughness of both sphere and panel will contain multiple scales of roughness, with varying heights and spatial distributions (Galvin et al. Reference Galvin, Zhao and Davis2001; Zhao et al. Reference Zhao, Galvin and Davis2002). The different scales of roughness likely do not contribute equally to determining the effective gap between the sphere and plane. For example, the largest asperities may be too sparsely distributed to provide a significant contribution to the effective gap, while the smallest asperities may be too short to physically contact the opposing wall. Therefore, simple statistical measures of the average roughness properties may be insufficient to fully characterise the effective gap. This is discussed further in § 4.4.

3. Experimental methodology and roughness characterisation

3.1. Experimental set-up

The present experiments were conducted within the Fluids Laboratory for Aeronautical and Industrial Research (FLAIR) at Monash University, Clayton, Australia. Figure 3 shows a schematic diagram of the experimental set-up (not to scale) in the FLAIR laboratory. The water tank used for the experiments measured ![]() $1000\times 500\times 600 \,{\rm mm}^{3}$ (

$1000\times 500\times 600 \,{\rm mm}^{3}$ (![]() $L\times W\times H$), with a glass plate of dimensions

$L\times W\times H$), with a glass plate of dimensions ![]() $800\times 480\times 10 \,{\rm mm}^{3}$ mounted on an adjustable stainless steel frame. The frame was mounted on a base frame, with one end hinged, to allow for the angle of inclination of the top panel and frame to be adjusted using a threaded rod at the other end. The inclination angle varied from

$800\times 480\times 10 \,{\rm mm}^{3}$ mounted on an adjustable stainless steel frame. The frame was mounted on a base frame, with one end hinged, to allow for the angle of inclination of the top panel and frame to be adjusted using a threaded rod at the other end. The inclination angle varied from ![]() $4 ^{\circ }$ to

$4 ^{\circ }$ to ![]() $20 ^{\circ }$. It was observed that, at angles of inclination smaller than

$20 ^{\circ }$. It was observed that, at angles of inclination smaller than ![]() $4 ^{\circ }$, the uncertainty of measurements escalated. Other panels made of glass, ceramic and acrylic with varied surface roughness, typically

$4 ^{\circ }$, the uncertainty of measurements escalated. Other panels made of glass, ceramic and acrylic with varied surface roughness, typically ![]() $700\times 300\times 10 \,{\rm mm}^{3}$ in size, were also used for the experiments. These panels were placed atop the existing glass panel and clamped down to limit relative movement. The properties of the panels and spheres used during the experimental process are described in tables 1 and 2.

$700\times 300\times 10 \,{\rm mm}^{3}$ in size, were also used for the experiments. These panels were placed atop the existing glass panel and clamped down to limit relative movement. The properties of the panels and spheres used during the experimental process are described in tables 1 and 2.

Figure 3. Experimental set-up of the water tank at the FLAIR Laboratory, Monash University.

Table 1. Panel types used as inclined planes are detailed here. Max. deviation is the maximum absolute deviation of surface height measurements from the mean plane. Max. gradient is the maximum cross-slope gradient over a minimum cross-slope measurement distance of 50 mm.

Table 2. Specifications of spheres used for experimental evaluation are given in the table above. Each diameter corresponds to a set of eight individual spheres, and three measurements of each sphere were obtained to calculate the values presented above. The mean values of diameter including the error for each set are shown above. Refer to Appendix A for details of the uncertainty analysis.

The flatness of the panels used was estimated by measuring the surface height variation based on 48 equally spaced grid points on the surface of the panels. Panels were placed on a cast iron surface plate (manufactured by Wing Industries, Australia; Grade D), machined and installed to be horizontally levelled, which was used as a reference surface. A metric dial indicator (manufactured by Mitutoyo, Japan; accuracy = ![]() $0.01$ mm) and an arm were used to measure the height of the rolling surface of the panel, from which a mean plane was obtained. Two parameters have been used in table 1 to describe the flatness of the plates. Max. deviation (mm) describes the maximum absolute deviation of surface height measurements from the mean plane. Max. gradient is the maximum cross-slope gradient over a measurement distance of

$0.01$ mm) and an arm were used to measure the height of the rolling surface of the panel, from which a mean plane was obtained. Two parameters have been used in table 1 to describe the flatness of the plates. Max. deviation (mm) describes the maximum absolute deviation of surface height measurements from the mean plane. Max. gradient is the maximum cross-slope gradient over a measurement distance of ![]() $50$ mm. The smallest angle of inclination used for experiments was

$50$ mm. The smallest angle of inclination used for experiments was ![]() $4 ^{\circ }$, which yields a maximum gradient of

$4 ^{\circ }$, which yields a maximum gradient of ![]() ${\approx }7\,\%$ down the slope. Comparing this with the maximum cross-slope gradient of

${\approx }7\,\%$ down the slope. Comparing this with the maximum cross-slope gradient of ![]() $0.3\,\%$ for the acrylic panel, we can conclude that the non-flatness of the panel is negligible compared with the down-slope angle of inclination of the panels.

$0.3\,\%$ for the acrylic panel, we can conclude that the non-flatness of the panel is negligible compared with the down-slope angle of inclination of the panels.

A waterproof digital inclinometer (model: DWL 280, Digi-Pas US, accuracy = ![]() $0.05^{\circ }$) was used to measure the angle of the panel with respect to the horizontal axis. Water temperature was initially measured using a water-resistant digital thermometer (Mextek, accuracy =

$0.05^{\circ }$) was used to measure the angle of the panel with respect to the horizontal axis. Water temperature was initially measured using a water-resistant digital thermometer (Mextek, accuracy = ![]() $0.1\,^{\circ }$C). During the second stage of testing, a residual temperature device configured for the temperature range of 10–40

$0.1\,^{\circ }$C). During the second stage of testing, a residual temperature device configured for the temperature range of 10–40 ![]() $^{\circ }$C, for an output voltage range of 0–10 V, was used (ECEFast RTD PT100, Accuracy = 0.001 V). These measurements allowed for the calculation of water viscosity and density in accordance with the International Association for the Properties of Water and Steam (IAPWS) Formulation 2008 for the Viscosity of Ordinary Water Substance (reference IAPWS 2008).

$^{\circ }$C, for an output voltage range of 0–10 V, was used (ECEFast RTD PT100, Accuracy = 0.001 V). These measurements allowed for the calculation of water viscosity and density in accordance with the International Association for the Properties of Water and Steam (IAPWS) Formulation 2008 for the Viscosity of Ordinary Water Substance (reference IAPWS 2008).

The spheres were pre-soaked under the water level, and air bubbles were manually removed using vibration and stirring. Then the spheres were placed atop the inclined plane, at a collection port and released, carefully ensuring minimum disturbance to the water surface. Following any perturbation of the water, a minimum of 2 min was allowed to ensure that the water was reset to rest prior to any further measurements. The water tank was also cleaned regularly to ensure that any dust or fibres were not deposited on the surface of the panels. It was noted that the presence of small air bubbles, fibres or dust deposited on the panel surface significantly affected measurements. As such, all attempts were made to ensure that the presented results were void of these errors.

The rolling sphere velocities were calculated by measuring the time taken to travel a fixed distance. The spheres were allowed to roll a minimum of ![]() $20 D$ prior to starting the measurements. Initially, a stopwatch was used to measure the time taken to travel

$20 D$ prior to starting the measurements. Initially, a stopwatch was used to measure the time taken to travel ![]() $200$ mm distance atop the removable panel (

$200$ mm distance atop the removable panel (![]() $70\,\%$ of data). In the second half of the project, a new system incorporating three laser-based object detectors was developed to improve the accuracy and efficiency of these measurements (see figure 4,

$70\,\%$ of data). In the second half of the project, a new system incorporating three laser-based object detectors was developed to improve the accuracy and efficiency of these measurements (see figure 4, ![]() $30\,\%$ of data). The uncertainty analysis presented in Appendix A considers errors from both types of measurements. The results presented in this paper include both sets of data. Each measurement presented in § 4.1 represents the mean values of eight individual runs recorded using a set of spheres with same density and diameter. In addition, spot checks were done at random locations to ensure the data were repeatable, even under different fluid temperatures.

$30\,\%$ of data). The uncertainty analysis presented in Appendix A considers errors from both types of measurements. The results presented in this paper include both sets of data. Each measurement presented in § 4.1 represents the mean values of eight individual runs recorded using a set of spheres with same density and diameter. In addition, spot checks were done at random locations to ensure the data were repeatable, even under different fluid temperatures.

Figure 4. Laser set-up used to measure sphere velocity.

Table 2 presents the uncertainty of the sphere diameter in each set of spheres, which was typically less than ![]() $1\,\%$. The uncertainty in sphere diameter was used to estimate deviations in sphericity. Given that the uncertainties in the diameter of acrylic and cellulose acetate (CA) spheres were generally below

$1\,\%$. The uncertainty in sphere diameter was used to estimate deviations in sphericity. Given that the uncertainties in the diameter of acrylic and cellulose acetate (CA) spheres were generally below ![]() $1\,\%$, it was assumed that deviations in the sphericity of spheres could be neglected.

$1\,\%$, it was assumed that deviations in the sphericity of spheres could be neglected.

To minimise any distortion of spheres and panels due to water absorption (mainly acrylic, which is known to absorb water), they were removed from the water tank outside of measurement windows and dried regularly.

A set of preliminary tests at angles of inclination in the range ![]() $4^{\circ }\unicode{x2013}20^{\circ }$ using a subset of the spheres, covering a range of

$4^{\circ }\unicode{x2013}20^{\circ }$ using a subset of the spheres, covering a range of ![]() $\overline {Re} (40\unicode{x2013}900)$ were carried out to test whether the sphere slips in our experiments. A marker was placed on the sphere surface and the sphere was recorded with a digital camera. The estimated rotational velocity was compared against the measured translational velocity and no significant deviation between translational and rotational velocities (

$\overline {Re} (40\unicode{x2013}900)$ were carried out to test whether the sphere slips in our experiments. A marker was placed on the sphere surface and the sphere was recorded with a digital camera. The estimated rotational velocity was compared against the measured translational velocity and no significant deviation between translational and rotational velocities (![]() ${<}1\,\%$) was observed. Therefore, any slip between the sphere and the wall, if present, is negligible. In addition, detailed experiments conducted by Wardhaugh & Williams (Reference Wardhaugh and Williams2014) and Tee (Reference Tee2018) observed no slip below

${<}1\,\%$) was observed. Therefore, any slip between the sphere and the wall, if present, is negligible. In addition, detailed experiments conducted by Wardhaugh & Williams (Reference Wardhaugh and Williams2014) and Tee (Reference Tee2018) observed no slip below ![]() ${\approx }25 ^{\circ }$ for spheres rolling on a glass plate in water. This evidence, coupled with our own preliminary measurements, was sufficient to conclude that the no-slip condition is met under the present experimental conditions.

${\approx }25 ^{\circ }$ for spheres rolling on a glass plate in water. This evidence, coupled with our own preliminary measurements, was sufficient to conclude that the no-slip condition is met under the present experimental conditions.

3.2. Surface roughness measurements

An optical profilometer (Bruker Contour GT-I) located at the Melbourne Centre for Nanofabrication in the Victorian Node of the Australian National Fabrication Facility was used to obtain non-contact surface roughness measurements of all the spheres and panels. Roughness measurements were obtained under 50 times magnification using the vertical scanning interferrometry method. Vertical scanning interferrometry utilises a broad band light source and is accurate when measuring typically rough surfaces. Tables 3 and 4 present the measured values.

Table 3. Measured surface roughness values of panels. Values presented are the arithmetic mean of five individual measurements. The measurement area of each presented measurement is ![]() $0.25\times 0.25\,{\rm mm}^{2}$ (12 measurements under

$0.25\times 0.25\,{\rm mm}^{2}$ (12 measurements under ![]() $50 \times 1$ magnification joined together).

$50 \times 1$ magnification joined together).

Table 4. Measured surface roughness values of spheres. Values presented are arithmetic mean of five individual measurements of five separate spheres, of the same diameter. The measurement area of each presented measurement is ![]() $0.3\times 0.3$ mm

$0.3\times 0.3$ mm![]() $^{2}$ for all diameters (12 measurements under

$^{2}$ for all diameters (12 measurements under ![]() $50\times 1$ magnification joined together), leading to percentage measurement areas ranging from

$50\times 1$ magnification joined together), leading to percentage measurement areas ranging from ![]() $0.23\,\%$ for

$0.23\,\%$ for ![]() $D=3.44$ mm to

$D=3.44$ mm to ![]() $0.02\,\%$ for

$0.02\,\%$ for ![]() $D=11.49$ mm. All measurements were corrected for sphere curvature prior to obtaining roughness statistics.

$D=11.49$ mm. All measurements were corrected for sphere curvature prior to obtaining roughness statistics.

Figure 5 depicts the surface roughness measurements of two panels and two spheres used for experiments. The surface roughness profiles of the glass panel in figure 5(a) range from ![]() $40$ to

$40$ to ![]() $60$ nm while frosted glass in figure 5(b) has significantly taller asperities reaching as high as

$60$ nm while frosted glass in figure 5(b) has significantly taller asperities reaching as high as ![]() $5\,\mathrm {\mu }$m. Similarly, the asperities on both spheres indicated in figure 5(c,d) also contain a sparse distribution of asperities taller than

$5\,\mathrm {\mu }$m. Similarly, the asperities on both spheres indicated in figure 5(c,d) also contain a sparse distribution of asperities taller than ![]() $1\,\mathrm {\mu }$m, with the majority of asperities being around the

$1\,\mathrm {\mu }$m, with the majority of asperities being around the ![]() $0.5\,\mathrm {\mu }$m range. A clear observation from these images is the sparse distribution of very tall asperities. Captions of tables 3 and 4 contain additional information regarding the measurement techniques used.

$0.5\,\mathrm {\mu }$m range. A clear observation from these images is the sparse distribution of very tall asperities. Captions of tables 3 and 4 contain additional information regarding the measurement techniques used.

Figure 5. Surface roughness profiles obtained using the optical profilometer, under ![]() $50{\times }$ magnification. (a)Glass panel, (b) frosted glass panel, (c) 3.95 mm diameter acrylic sphere, (d) 6.35 mm diameter CA sphere.

$50{\times }$ magnification. (a)Glass panel, (b) frosted glass panel, (c) 3.95 mm diameter acrylic sphere, (d) 6.35 mm diameter CA sphere.

4. Results and discussion

4.1. Measured Reynolds number vs drag coefficient data in water

Based on the experimental set-up and methodology noted in § 3.1, measurements of ![]() $\bar {C}_{D}$ and

$\bar {C}_{D}$ and ![]() $\overline {Re}$ were obtained for

$\overline {Re}$ were obtained for ![]() $30<\overline {Re}<800$, corresponding to 13 different diameter spheres rolling on four separate panels. Figure 6(a) shows all of the data gathered, with the figure legend indicating the marker shapes corresponding to sphere diameters. Figure 6(b) presents the same data on a log–log scale, with the legend showing the marker colours corresponding to panel types. The data indicate a similar trend to those of previous studies (i.e.

$30<\overline {Re}<800$, corresponding to 13 different diameter spheres rolling on four separate panels. Figure 6(a) shows all of the data gathered, with the figure legend indicating the marker shapes corresponding to sphere diameters. Figure 6(b) presents the same data on a log–log scale, with the legend showing the marker colours corresponding to panel types. The data indicate a similar trend to those of previous studies (i.e. ![]() $1/Re$ trend, as observed by Carty Reference Carty1957; Garde & Sethuraman Reference Garde and Sethuraman1969; Jan & Chen Reference Jan and Chen1997). Results of Carty (Reference Carty1957) are plotted in figure 6 for comparison. There is a notable variation of

$1/Re$ trend, as observed by Carty Reference Carty1957; Garde & Sethuraman Reference Garde and Sethuraman1969; Jan & Chen Reference Jan and Chen1997). Results of Carty (Reference Carty1957) are plotted in figure 6 for comparison. There is a notable variation of ![]() $\bar {C}_{D}$ with panel type and sphere diameter at a given

$\bar {C}_{D}$ with panel type and sphere diameter at a given ![]() $\overline {Re}$ for

$\overline {Re}$ for ![]() $\overline {Re}<200$; at

$\overline {Re}<200$; at ![]() $\overline {Re}=100$ this observed deviation is of the order of

$\overline {Re}=100$ this observed deviation is of the order of ![]() $10\,\%$.

$10\,\%$.

Figure 6. Variation of ![]() $\bar {C}_{D}$ with

$\bar {C}_{D}$ with ![]() $\overline {Re}$ for a sphere rolling down an inclined plane. Markers corresponding to individual sphere diameters are as indicated in the legend of figure 6(a) and the marker colours correspond to the panel as indicated in figure 6(b). (a) All data points,

$\overline {Re}$ for a sphere rolling down an inclined plane. Markers corresponding to individual sphere diameters are as indicated in the legend of figure 6(a) and the marker colours correspond to the panel as indicated in figure 6(b). (a) All data points, ![]() $\overline {Re} = 30\unicode{x2013}800$ range; (b)

$\overline {Re} = 30\unicode{x2013}800$ range; (b) ![]() $\overline {Re} = 30\unicode{x2013}1000$ range in log–log scale.

$\overline {Re} = 30\unicode{x2013}1000$ range in log–log scale.

A distinctly higher ![]() $\bar {C}_{D}$ for the three larger CA spheres (

$\bar {C}_{D}$ for the three larger CA spheres (![]() $D=6.89$ mm,

$D=6.89$ mm, ![]() $9.74$ mm and

$9.74$ mm and ![]() $11.49$ mm) is seen in figure 6. Generally, these spheres follow a separate

$11.49$ mm) is seen in figure 6. Generally, these spheres follow a separate ![]() $\bar {C}_{D}$ vs

$\bar {C}_{D}$ vs ![]() $\overline {Re}$ trend compared with the other spheres investigated. Additionally, in figure 9, we observe a distinct increase in

$\overline {Re}$ trend compared with the other spheres investigated. Additionally, in figure 9, we observe a distinct increase in ![]() $\bar {C}_{D}$ for the

$\bar {C}_{D}$ for the ![]() $D=6.89$ mm CA sphere, for all four panels considered. At this stage, we cannot quantitatively explain this jump in

$D=6.89$ mm CA sphere, for all four panels considered. At this stage, we cannot quantitatively explain this jump in ![]() $\bar {C}_{D}$ for the larger CA spheres. However, the surface finish of these larger spheres (matte finish) was distinct from the smaller spheres (shiny finish). The matte finish spheres contained a higher density of larger peaks and valleys. Despite the distinct surface finishes, the roughness statistics of both types of spheres are nominally similar (table 4,

$\bar {C}_{D}$ for the larger CA spheres. However, the surface finish of these larger spheres (matte finish) was distinct from the smaller spheres (shiny finish). The matte finish spheres contained a higher density of larger peaks and valleys. Despite the distinct surface finishes, the roughness statistics of both types of spheres are nominally similar (table 4, ![]() $R_q \approx 0.5\, \mathrm {\mu } {\rm m}$). A plausible explanation, to be investigated in more detail in the future, is that the higher

$R_q \approx 0.5\, \mathrm {\mu } {\rm m}$). A plausible explanation, to be investigated in more detail in the future, is that the higher ![]() $\bar {C}_{D}$ is due to an increased rolling resistance induced by the higher density of the taller peaks. Mechanisms concerning rolling resistance are discussed further in § 4.4.3.

$\bar {C}_{D}$ is due to an increased rolling resistance induced by the higher density of the taller peaks. Mechanisms concerning rolling resistance are discussed further in § 4.4.3.

The results of foam spheres are not included in figure 6, and are presented in § 4.2.

Upon closer examination of the data for ![]() $\overline {Re}<300$, multiple trend lines are observed as the panel surface roughness and sphere diameter are varied, as was observed by Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023). This variation of

$\overline {Re}<300$, multiple trend lines are observed as the panel surface roughness and sphere diameter are varied, as was observed by Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023). This variation of ![]() $\bar {C}_{D}$ with panel type is clearly observed in figure 6(b). Figure 7 presents the variation of

$\bar {C}_{D}$ with panel type is clearly observed in figure 6(b). Figure 7 presents the variation of ![]() $\bar {C}_{D}$ with

$\bar {C}_{D}$ with ![]() $\overline {Re}$ ranging from

$\overline {Re}$ ranging from ![]() $50<\overline {Re}<120$, in which two least-squares lines of the form

$50<\overline {Re}<120$, in which two least-squares lines of the form ![]() $a+b/Re$ have been fitted through the data points corresponding to the two panels used. The

$a+b/Re$ have been fitted through the data points corresponding to the two panels used. The ![]() $r^{2}$ values, indicating goodness of fit of the curves, are approximately

$r^{2}$ values, indicating goodness of fit of the curves, are approximately ![]() $0.9$, indicating a good fit. The deviation of

$0.9$, indicating a good fit. The deviation of ![]() $\bar {C}_{D}$ with the change in panel roughness is highlighted in this figure. There is an approximately

$\bar {C}_{D}$ with the change in panel roughness is highlighted in this figure. There is an approximately ![]() $10\,\%$ increase in

$10\,\%$ increase in ![]() $\bar {C}_{D}$ at

$\bar {C}_{D}$ at ![]() $\overline {Re}=100$ between the frosted glass panel and the glass panel (which corresponds to an 80 times decrease in panel

$\overline {Re}=100$ between the frosted glass panel and the glass panel (which corresponds to an 80 times decrease in panel ![]() $R_{a}$ roughness). The increase in

$R_{a}$ roughness). The increase in ![]() $\bar {C}_{D}$ with a decrease in roughness (or

$\bar {C}_{D}$ with a decrease in roughness (or ![]() $\xi =G/D$) can be attributed to the increase in the gap drag component with a decrease in gap height, as was predicted in (2.4).

$\xi =G/D$) can be attributed to the increase in the gap drag component with a decrease in gap height, as was predicted in (2.4).

Figure 7. Variation of ![]() $\bar {C}_{D}$ with

$\bar {C}_{D}$ with ![]() $\overline {Re}$ for the two individual panels, with least-squares lines fitted through each panel. Marker shapes correspond to sphere diameter, as indicated in the legend of figure 6(a). The

$\overline {Re}$ for the two individual panels, with least-squares lines fitted through each panel. Marker shapes correspond to sphere diameter, as indicated in the legend of figure 6(a). The ![]() $R_{q}$ roughness of the two panels are as follows: frosted glass panel;

$R_{q}$ roughness of the two panels are as follows: frosted glass panel; ![]() $2.33\,\mathrm {\mu }$m, glass panel;

$2.33\,\mathrm {\mu }$m, glass panel; ![]() $0.029\,\mathrm {\mu }$m. Error bars indicate combined bias error and random error. Refer to Appendix A for details on error analysis.

$0.029\,\mathrm {\mu }$m. Error bars indicate combined bias error and random error. Refer to Appendix A for details on error analysis.

This increase in ![]() $\bar {C}_{D}$ with a decrease in panel surface roughness is further highlighted in figure 8, where the sphere diameter was fixed (

$\bar {C}_{D}$ with a decrease in panel surface roughness is further highlighted in figure 8, where the sphere diameter was fixed (![]() $D=5.86$ mm) while the panel roughness was varied. The individual variations of

$D=5.86$ mm) while the panel roughness was varied. The individual variations of ![]() $\overline {Re}$ vs

$\overline {Re}$ vs ![]() $\bar {C}_{D}$ are clearly observed in this figure.

$\bar {C}_{D}$ are clearly observed in this figure.

Figure 8. Variation of ![]() $\bar {C}_{D}$ with

$\bar {C}_{D}$ with ![]() $\overline {Re}$ for a fixed diameter,

$\overline {Re}$ for a fixed diameter, ![]() $D=5.86$ mm. Data for three individual panels, with least-squares lines fitted through each panel are shown. Error bars indicate bias error only.

$D=5.86$ mm. Data for three individual panels, with least-squares lines fitted through each panel are shown. Error bars indicate bias error only.

Upon even further examination of figure 7, what initially appears to be scatter around curves fitted for a panel, more trend lines indicating variation in ![]() $\bar {C}_{D}$ vs

$\bar {C}_{D}$ vs ![]() $\overline {Re}$ for specific diameters are observed. Figure 9 presents the data separated by panel roughness, with least-squares lines of the form

$\overline {Re}$ for specific diameters are observed. Figure 9 presents the data separated by panel roughness, with least-squares lines of the form ![]() $a+b/Re$ fitted through the data corresponding to individual diameters. A subset of the data is presented in this figure to highlight the variation of

$a+b/Re$ fitted through the data corresponding to individual diameters. A subset of the data is presented in this figure to highlight the variation of ![]() $\bar {C}_{D}$ with sphere diameter. It is observed that variations in

$\bar {C}_{D}$ with sphere diameter. It is observed that variations in ![]() $D$ with a fixed panel surface roughness lead to variations in measured

$D$ with a fixed panel surface roughness lead to variations in measured ![]() $\bar {C}_{D}$. As indicated in figures 9 and 10, an increase in sphere

$\bar {C}_{D}$. As indicated in figures 9 and 10, an increase in sphere ![]() $D$ leads to an increase in

$D$ leads to an increase in ![]() $\bar {C}_{D}$. This observed increase is greater at lower

$\bar {C}_{D}$. This observed increase is greater at lower ![]() $\overline {Re}$ than at higher values; however, the observed variations still maintain the overall

$\overline {Re}$ than at higher values; however, the observed variations still maintain the overall ![]() $1/Re$ behaviour. A similar observation was made by Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) on the variation of

$1/Re$ behaviour. A similar observation was made by Houdroge et al. (Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) on the variation of ![]() $C_{D}$ with the sphere diameter. These observations provide further evidence that the relative roughness (

$C_{D}$ with the sphere diameter. These observations provide further evidence that the relative roughness (![]() $\xi$) is dependent on the panel roughness, the sphere roughness and also the sphere diameter, as we have assumed in (2.5). For each

$\xi$) is dependent on the panel roughness, the sphere roughness and also the sphere diameter, as we have assumed in (2.5). For each ![]() $\xi$, we observe a separate

$\xi$, we observe a separate ![]() $\bar {C}_{D}$ vs

$\bar {C}_{D}$ vs ![]() $\overline {Re}$ relationship.

$\overline {Re}$ relationship.

Figure 9. Variation of ![]() $\bar {C}_{D}$ with

$\bar {C}_{D}$ with ![]() $\overline {Re}$ for the four panels used for experimentation in the range