1. Introduction

Heavy oil reserves occupy approximately 70 % of whole oil reserves (Dusseault Reference Dusseault2001), but one of the major challenges with the use of heavy oil is its transport within a pipe because of its high viscosity. Among various drag reduction technologies investigated, water-lubricated transport has been known as an effective tool (Ghosh et al. Reference Ghosh, Mandal, Das and Das2009). This arrangement is called a core–annular flow because high viscosity oil is encapsulated in the pipe core region by less viscous water in the annulus. In experiments, core–annular flows in horizontal and vertical pipes have been considered, and drag reductions by water in the annulus have been observed in wide ranges of oil properties and flow conditions (Charles, Govier & Hodgson Reference Charles, Govier and Hodgson1961; Bai, Chen & Joseph Reference Bai, Chen and Joseph1992; Prada & Bannwart Reference Prada and Bannwart2001; Sotgia, Tartarini & Stalio Reference Sotgia, Tartarini and Stalio2008) and also validated in real-scale experiments with several-hundred-metre pipes (Arney et al. Reference Arney, Ribeiro, Guevara, Bai and Joseph1996; Rodriguez, Bannwart & de Carvalho Reference Rodriguez, Bannwart and de Carvalho2009). The differences in the flow characteristics between the vertical and horizontal pipes are attributed to different gravitational directions.

For a horizontal pipe, the directions of the main flow and gravity are perpendicular to each other and heavy oil rises by the buoyancy because the density of heavy oil is usually lower than that of water (Joseph et al. Reference Joseph, Bai, Chen and Renardy1997). The buoyancy force is balanced by the hydrodynamic (negative) lift force, which prevents the core from touching the wall and forms an eccentric core in the pipe. This lift force is caused by the pressure force from water lubrication at low Reynolds number (Ooms et al. Reference Ooms, Segal, van der Wees, Meerhoff and Oliemans1983) but is dominated by the inertial effect with increasing Reynolds number (Oliemans et al. Reference Oliemans, Ooms, Wu and Duijvestijn1987; Feng, Huang & Joseph Reference Feng, Huang and Joseph1995; Ooms, Pourquie & Poesio Reference Ooms, Pourquie and Poesio2012).

Many experimental studies have measured the variations of the pressure drop and oil holdup (![]() $\epsilon _o = V_o/V$, where

$\epsilon _o = V_o/V$, where ![]() $V_o$ and

$V_o$ and ![]() $V$ are the oil and whole pipe volumes, respectively) with the superficial velocities of oil and water for core–annular flows in horizontal pipes, and shown that the core–annular flow is effective in reducing the drag on the pipe wall (Charles et al. Reference Charles, Govier and Hodgson1961; Oliemans et al. Reference Oliemans, Ooms, Wu and Duijvestijn1987; Arney et al. Reference Arney, Bai, Guevara, Joseph and Liu1993; Sotgia et al. Reference Sotgia, Tartarini and Stalio2008; Vuong Reference Vuong2009; Shi, Gourma & Yeung Reference Shi, Gourma and Yeung2017; Tripathi et al. Reference Tripathi, Tabor, Singh and Bhattacharya2017). Vuong (Reference Vuong2009;

$V$ are the oil and whole pipe volumes, respectively) with the superficial velocities of oil and water for core–annular flows in horizontal pipes, and shown that the core–annular flow is effective in reducing the drag on the pipe wall (Charles et al. Reference Charles, Govier and Hodgson1961; Oliemans et al. Reference Oliemans, Ooms, Wu and Duijvestijn1987; Arney et al. Reference Arney, Bai, Guevara, Joseph and Liu1993; Sotgia et al. Reference Sotgia, Tartarini and Stalio2008; Vuong Reference Vuong2009; Shi, Gourma & Yeung Reference Shi, Gourma and Yeung2017; Tripathi et al. Reference Tripathi, Tabor, Singh and Bhattacharya2017). Vuong (Reference Vuong2009; ![]() $\mu _o = 0.23\unicode{x2013}1.07$ Pa s) and Shi (Reference Shi2015;

$\mu _o = 0.23\unicode{x2013}1.07$ Pa s) and Shi (Reference Shi2015; ![]() $\mu _o = 3.3\unicode{x2013}7.1$ Pa s) showed that, when the oil viscosity (

$\mu _o = 3.3\unicode{x2013}7.1$ Pa s) showed that, when the oil viscosity (![]() $\mu _o$) is high enough, the pressure drop and flow pattern are not significantly changed by

$\mu _o$) is high enough, the pressure drop and flow pattern are not significantly changed by ![]() $\mu _o$ at high Reynolds numbers. Arney et al. (Reference Arney, Bai, Guevara, Joseph and Liu1993) observed that a core–annular flow with a non-Newtonian Bingham plastic oil (waxy crude oil/water emulsion:

$\mu _o$ at high Reynolds numbers. Arney et al. (Reference Arney, Bai, Guevara, Joseph and Liu1993) observed that a core–annular flow with a non-Newtonian Bingham plastic oil (waxy crude oil/water emulsion: ![]() $\mu _o = 200\unicode{x2013}900$ Pa s) produces drag reduction but larger fluctuations in the pressure drop than that of the Newtonian oil (No. 6 fuel oil:

$\mu _o = 200\unicode{x2013}900$ Pa s) produces drag reduction but larger fluctuations in the pressure drop than that of the Newtonian oil (No. 6 fuel oil: ![]() $\mu _o = 2.7$ Pa s). Based on their own and other experimental data, Arney et al. (Reference Arney, Bai, Guevara, Joseph and Liu1993) suggested a pressure drop model based on the friction factor of single-phase pipe flow and an empirical holdup model, which was later modified by considering the eccentricity and oil fouling effects (Shi et al. Reference Shi, Gourma and Yeung2017). Other pressure drop and oil holdup models have been suggested from several studies (Oliemans, Pots & Trompe Reference Oliemans, Pots and Trompe1986; Brauner Reference Brauner1991; Bai et al. Reference Bai, Chen and Joseph1992; Bannwart Reference Bannwart2001; Kim & Choi Reference Kim and Choi2018).

$\mu _o = 2.7$ Pa s). Based on their own and other experimental data, Arney et al. (Reference Arney, Bai, Guevara, Joseph and Liu1993) suggested a pressure drop model based on the friction factor of single-phase pipe flow and an empirical holdup model, which was later modified by considering the eccentricity and oil fouling effects (Shi et al. Reference Shi, Gourma and Yeung2017). Other pressure drop and oil holdup models have been suggested from several studies (Oliemans, Pots & Trompe Reference Oliemans, Pots and Trompe1986; Brauner Reference Brauner1991; Bai et al. Reference Bai, Chen and Joseph1992; Bannwart Reference Bannwart2001; Kim & Choi Reference Kim and Choi2018).

Only a few studies have investigated the characteristics of turbulent core–annular flow in a horizontal pipe by experiments owing to the difficulty in flow measurements. Oliemans et al. (Reference Oliemans, Ooms, Wu and Duijvestijn1987) showed that turbulence effects are restricted near the lower surface of the pipe, and Tripathi et al. (Reference Tripathi, Tabor, Singh and Bhattacharya2017) observed a broad-banded spectrum of the phase interface wave. They demonstrated that large-wavelength interfacial modes dominate at low Reynolds numbers, while small-wavelength interfacial modes dominate at high Reynolds numbers. However, the dynamics of the phase interface, and the lift and drag forces on the core have been rarely investigated for the turbulent core–annular flow in a horizontal pipe. Thus, the detailed characteristics of turbulent flow and phase interface have been studied mostly by numerical simulations using interface tracking methods. For laminar flow, a few numerical simulations have been conducted to find the pressure distribution across the phase interface between oil and water. For example, Bai, Kelkar & Joseph (Reference Bai, Kelkar and Joseph1996) observed for axisymmetric laminar core–annular flows that the pressure difference across the phase interface between heavy oil and water increases as the gap size between the interface and pipe wall decreases, and thus suggested that an eccentric core–annular flow can be stably maintained because the gap size below the upper pipe wall is smaller (so, high pressure there) than that above the lower pipe wall (low pressure). This was confirmed by Ooms et al. (Reference Ooms, Pourquie and Poesio2012) for a laminar core–annular flow in a horizontal pipe using numerical simulation. They observed that, for a given wavy phase interface shape, the difference in the water pressures on the upper and lower interfaces increases with increasing eccentricity of the core and balances the buoyancy except at a very low Reynolds number where the direction of the lift force is the opposite to the gravitational direction.

For turbulent flow, studies have been limited to numerical simulations with turbulence models. For example, Shi et al. (Reference Shi, Gourma and Yeung2017) showed that the flow statistics change with turbulence models adopted, and a shear stress transport ![]() $k-\omega$ turbulence model with turbulence damping at the phase interface works better than others. Their numerical results show a 30 % difference in the pressure drop and a 14 % difference in the holdup from those by experiments. Housz et al. (Reference Housz, Ooms, Henkes, Pourquie, Kidess and Radhakrishnan2017) showed using Launder–Sharma

$k-\omega$ turbulence model with turbulence damping at the phase interface works better than others. Their numerical results show a 30 % difference in the pressure drop and a 14 % difference in the holdup from those by experiments. Housz et al. (Reference Housz, Ooms, Henkes, Pourquie, Kidess and Radhakrishnan2017) showed using Launder–Sharma ![]() $k-\omega$ turbulence model that the difference in the pressure drops from experiment and numerical simulation is within 15 %, and their instantaneous amplitude and wavelength of the phase interface wave reasonably agree with those observed in experiments. So far, to the best of our knowledge, the only numerical simulation without using a turbulence model (i.e. direct numerical simulation) for turbulent core–annular flow is that by Kim & Choi (Reference Kim and Choi2018) in which the flow in a vertical pipe was considered. Li et al. (Reference Li, Pourquie, Ooms and Henkes2023) conducted Reynolds-Averaged Navier–Stokes simulation using the Launder–Sharma low-Reynolds number

$k-\omega$ turbulence model that the difference in the pressure drops from experiment and numerical simulation is within 15 %, and their instantaneous amplitude and wavelength of the phase interface wave reasonably agree with those observed in experiments. So far, to the best of our knowledge, the only numerical simulation without using a turbulence model (i.e. direct numerical simulation) for turbulent core–annular flow is that by Kim & Choi (Reference Kim and Choi2018) in which the flow in a vertical pipe was considered. Li et al. (Reference Li, Pourquie, Ooms and Henkes2023) conducted Reynolds-Averaged Navier–Stokes simulation using the Launder–Sharma low-Reynolds number ![]() $k$-

$k$-![]() $\epsilon$ model at the same condition considered by Kim & Choi (Reference Kim and Choi2018). Their simulation observed travelling interfacial waves like those of Kim & Choi (Reference Kim and Choi2018), but provided an 18 % lower friction factor and slightly higher holdup ratio.

$\epsilon$ model at the same condition considered by Kim & Choi (Reference Kim and Choi2018). Their simulation observed travelling interfacial waves like those of Kim & Choi (Reference Kim and Choi2018), but provided an 18 % lower friction factor and slightly higher holdup ratio.

As summarized above, the understanding of the flow characteristics in turbulent core–annular flow with water-lubricated high viscosity oil in a horizontal pipe is still very limited. Therefore, in the present study, we perform direct numerical simulation of this flow to investigate the asymmetric flow features inside the pipe and the pressure variation across the interface between oil and water. The spatiotemporal deformation of the phase interface is tracked with a level-set method. The details of numerical methods and flow conditions are given in § 2. In § 3, the axial pressure drop is compared with that of the experiment (Sotgia et al. Reference Sotgia, Tartarini and Stalio2008), and the characteristics of water flow in the annulus and high viscosity oil flow in the core are discussed, respectively. The spectral characteristics and dynamics of the phase interface are examined in §§ 4.1 and 4.2, respectively, followed by the investigation of near-wall flow dynamics in § 4.3. Finally, a summary is given in § 5.

2. Computational details

The numerical method to track the phase interface between two immiscible fluids, high viscosity oil and water, is essentially the same as that in our previous study on turbulent core–annular flow in a vertical pipe (Kim & Choi Reference Kim and Choi2018). We use a level-set method to track the interface (Herrmann Reference Herrmann2008; Kim & Moin Reference Kim and Moin2011),

where ![]() $x_j$ are the cylindrical coordinates,

$x_j$ are the cylindrical coordinates, ![]() $u_j$ are the corresponding velocity components and

$u_j$ are the corresponding velocity components and ![]() $\phi$ is the level-set function which is a signed-distance function from the phase interface having positive values in water, negative ones in oil and zero at the phase interface. Equation (2.1) is solved at grids near the phase interface using a third-order total variation diminishing Runge–Kutta method in time (Gottlieb & Shu Reference Gottlieb and Shu1998) and a fifth-order weighted essentially non-oscillatory scheme in space in conjunction with a local Lax–Friedrichs entropy correction (Jiang & Peng Reference Jiang and Peng2000). A partial-differential-equation-based reinitialization method (Sussman, Smereka & Osher Reference Sussman, Smereka and Osher1994; Peng et al. Reference Peng, Merriman, Osher, Zhao and Kang1999) and a global mass conservation method (Son Reference Son2001; Zhang, Zou & Greaves Reference Zhang, Zou and Greaves2010) are used to preserve the signed-distance property,

$\phi$ is the level-set function which is a signed-distance function from the phase interface having positive values in water, negative ones in oil and zero at the phase interface. Equation (2.1) is solved at grids near the phase interface using a third-order total variation diminishing Runge–Kutta method in time (Gottlieb & Shu Reference Gottlieb and Shu1998) and a fifth-order weighted essentially non-oscillatory scheme in space in conjunction with a local Lax–Friedrichs entropy correction (Jiang & Peng Reference Jiang and Peng2000). A partial-differential-equation-based reinitialization method (Sussman, Smereka & Osher Reference Sussman, Smereka and Osher1994; Peng et al. Reference Peng, Merriman, Osher, Zhao and Kang1999) and a global mass conservation method (Son Reference Son2001; Zhang, Zou & Greaves Reference Zhang, Zou and Greaves2010) are used to preserve the signed-distance property, ![]() $|\boldsymbol {\nabla } \phi |= 1$, and compensate the volume loss, respectively. The periodic boundary condition is applied in the axial and azimuthal directions, and the Neumann boundary condition,

$|\boldsymbol {\nabla } \phi |= 1$, and compensate the volume loss, respectively. The periodic boundary condition is applied in the axial and azimuthal directions, and the Neumann boundary condition, ![]() $\partial \phi / \partial r = 0$, is used at the pipe wall.

$\partial \phi / \partial r = 0$, is used at the pipe wall.

The governing equations for unsteady incompressible two-phase flow are

where ![]() $-{\rm d}P/{{\rm d}\kern0.7pt x}$ is the mean pressure gradient to drive a constant mass flow rate in a pipe,

$-{\rm d}P/{{\rm d}\kern0.7pt x}$ is the mean pressure gradient to drive a constant mass flow rate in a pipe, ![]() $p$ is the pressure fluctuation,

$p$ is the pressure fluctuation, ![]() $g$ is the gravitational acceleration,

$g$ is the gravitational acceleration, ![]() $\sigma$ is the surface tension coefficient,

$\sigma$ is the surface tension coefficient, ![]() $\kappa$ is the curvature,

$\kappa$ is the curvature, ![]() $n_i$ is the surface-normal vector on the phase interface,

$n_i$ is the surface-normal vector on the phase interface, ![]() $\delta _{ij}$ is the Kronecker delta,

$\delta _{ij}$ is the Kronecker delta, ![]() $i = 1$ and 3 for the streamwise (or axial) and vertical (the opposite direction to that of the gravity) directions, respectively, and

$i = 1$ and 3 for the streamwise (or axial) and vertical (the opposite direction to that of the gravity) directions, respectively, and ![]() $\delta$ is the delta function (non-zero value at the phase interface and zero otherwise). The density and viscosity are constants for each fluid, but change continuously near the phase interface like

$\delta$ is the delta function (non-zero value at the phase interface and zero otherwise). The density and viscosity are constants for each fluid, but change continuously near the phase interface like

where the subscripts ![]() $w$ and

$w$ and ![]() $o$ denote water and oil, respectively. Here,

$o$ denote water and oil, respectively. Here, ![]() $\psi$ is the water volume fraction in a control volume calculated from the linearization of the level-set function (van der Pijl et al. Reference van der Pijl, Segal, Vuik and Wesseling2005; Herrmann Reference Herrmann2008). Thus,

$\psi$ is the water volume fraction in a control volume calculated from the linearization of the level-set function (van der Pijl et al. Reference van der Pijl, Segal, Vuik and Wesseling2005; Herrmann Reference Herrmann2008). Thus, ![]() $\psi = 0$ or 1 for the cells containing oil or water only, respectively, and

$\psi = 0$ or 1 for the cells containing oil or water only, respectively, and ![]() $0 < \psi < 1$ for the cells containing the phase interface. The density and viscosity of oil used for present simulations are

$0 < \psi < 1$ for the cells containing the phase interface. The density and viscosity of oil used for present simulations are ![]() $\rho _o = 889\ {\rm kg}\ {\rm m}^{-3}$ and

$\rho _o = 889\ {\rm kg}\ {\rm m}^{-3}$ and ![]() $\mu _o = 0.919$ Pa s, and those of water are

$\mu _o = 0.919$ Pa s, and those of water are ![]() $\rho _w = 998\ {\rm kg}\ {\rm m}^{-3}$ and

$\rho _w = 998\ {\rm kg}\ {\rm m}^{-3}$ and ![]() $\mu _w = 0.001$ Pa s, respectively, and the surface tension coefficient is

$\mu _w = 0.001$ Pa s, respectively, and the surface tension coefficient is ![]() $\sigma = 0.02\ {\rm N}\ {\rm m}^{-1}$ (Sotgia et al. Reference Sotgia, Tartarini and Stalio2008). We also confirmed that oil used in the experiment was Newtonian (G. Sotgia, private communication).

$\sigma = 0.02\ {\rm N}\ {\rm m}^{-1}$ (Sotgia et al. Reference Sotgia, Tartarini and Stalio2008). We also confirmed that oil used in the experiment was Newtonian (G. Sotgia, private communication).

Equations (2.2) and (2.3) are solved using a four-step fractional step method (Choi & Moin Reference Choi and Moin1994),

$$\begin{gather} \frac{\hat{\rho} \hat u_i - \rho^n u_i^n}{\Delta t} + \frac{1}{2} \frac{\partial}{\partial x_j} \left(\hat{\rho} \hat u_i \hat u_j + \rho^n u_i^n u_j^n \right) =- \frac{{\rm d}P^n}{{\rm d}\kern0.7pt x} \delta_{i1} - \frac{\partial p^n}{\partial x_i}\nonumber\\ + \frac{1}{2}\frac{\partial}{\partial x_j} \left\{ \hat{\mu} \left(\frac{\partial \hat u_i}{\partial x_j} + \frac{\partial \hat u_j}{\partial x_i} \right) + \mu^n \left(\frac{\partial u^n_i}{\partial x_j} + \frac{\partial u^n_j}{\partial x_i} \right)\right\} -\frac{1}{2} \left( \hat{\rho} + \rho^n \right) g \delta_{i3} + \sigma \kappa^n \delta^n n_i^n, \end{gather}$$

$$\begin{gather} \frac{\hat{\rho} \hat u_i - \rho^n u_i^n}{\Delta t} + \frac{1}{2} \frac{\partial}{\partial x_j} \left(\hat{\rho} \hat u_i \hat u_j + \rho^n u_i^n u_j^n \right) =- \frac{{\rm d}P^n}{{\rm d}\kern0.7pt x} \delta_{i1} - \frac{\partial p^n}{\partial x_i}\nonumber\\ + \frac{1}{2}\frac{\partial}{\partial x_j} \left\{ \hat{\mu} \left(\frac{\partial \hat u_i}{\partial x_j} + \frac{\partial \hat u_j}{\partial x_i} \right) + \mu^n \left(\frac{\partial u^n_i}{\partial x_j} + \frac{\partial u^n_j}{\partial x_i} \right)\right\} -\frac{1}{2} \left( \hat{\rho} + \rho^n \right) g \delta_{i3} + \sigma \kappa^n \delta^n n_i^n, \end{gather}$$

where ![]() $\hat {\rho }$ and

$\hat {\rho }$ and ![]() $\hat {\mu }$ are the provisional density and viscosity obtained from (2.4), (2.5) and the continuity equation,

$\hat {\mu }$ are the provisional density and viscosity obtained from (2.4), (2.5) and the continuity equation, ![]() ${\partial \rho }/{\partial t} + {\partial \rho u_j}/{\partial x_j} = 0$ (see Kim & Choi (Reference Kim and Choi2018) for the detail),

${\partial \rho }/{\partial t} + {\partial \rho u_j}/{\partial x_j} = 0$ (see Kim & Choi (Reference Kim and Choi2018) for the detail), ![]() $\Delta t$ is the computational time step size, and the superscript

$\Delta t$ is the computational time step size, and the superscript ![]() $n$ is the time step index. The second-order central difference scheme is used for all the spatial derivative terms except the convection term near the phase interface where an upwind-type mass-flux scheme is applied (Kim & Moin Reference Kim and Moin2011; Raessi & Pitsch Reference Raessi and Pitsch2012). The Crank–Nicolson method is applied to the convection and diffusion terms to avoid severe time step restriction. To solve the resulting system matrix, a Newton iterative method with an approximate factorization (Choi, Moin & Kim Reference Choi, Moin and Kim1993) and an Aitken-type accelerator (Irons & Tuck Reference Irons and Tuck1969) are adopted. The surface tension term is explicitly treated with a continuum surface force approach (Brackbill, Kothe & Zemach Reference Brackbill, Kothe and Zemach1992). An iterative constant-coefficient Poisson solver (Kim & Moin Reference Kim and Moin2011) using a fast Fourier transform is applied to solve the variable-coefficient pressure Poisson equation (2.8). The details of numerical methods are available in Kim & Choi (Reference Kim and Choi2018).

$n$ is the time step index. The second-order central difference scheme is used for all the spatial derivative terms except the convection term near the phase interface where an upwind-type mass-flux scheme is applied (Kim & Moin Reference Kim and Moin2011; Raessi & Pitsch Reference Raessi and Pitsch2012). The Crank–Nicolson method is applied to the convection and diffusion terms to avoid severe time step restriction. To solve the resulting system matrix, a Newton iterative method with an approximate factorization (Choi, Moin & Kim Reference Choi, Moin and Kim1993) and an Aitken-type accelerator (Irons & Tuck Reference Irons and Tuck1969) are adopted. The surface tension term is explicitly treated with a continuum surface force approach (Brackbill, Kothe & Zemach Reference Brackbill, Kothe and Zemach1992). An iterative constant-coefficient Poisson solver (Kim & Moin Reference Kim and Moin2011) using a fast Fourier transform is applied to solve the variable-coefficient pressure Poisson equation (2.8). The details of numerical methods are available in Kim & Choi (Reference Kim and Choi2018).

Figure 1 shows the schematic diagram of a core–annular flow in a horizontal pipe. The gravity direction is perpendicular to the mean flow direction, and thus the oil core naturally rises by the buoyancy due to its lower density than that of water. The cylindrical coordinates ![]() $(x, r, \theta )$ and the corresponding velocity components

$(x, r, \theta )$ and the corresponding velocity components ![]() $(u, v, w)$ are used for simulation, and the

$(u, v, w)$ are used for simulation, and the ![]() $y$ and

$y$ and ![]() $z$ coordinates are used for convenience to represent the lateral and vertical directions at the pipe cross-section, respectively. We fix the superficial velocity of oil,

$z$ coordinates are used for convenience to represent the lateral and vertical directions at the pipe cross-section, respectively. We fix the superficial velocity of oil, ![]() $j_o = q_o/{\rm \pi} R^2 = 0.88\ {\rm m}\ {\rm s}^{-1}$, and vary the superficial velocity of water as

$j_o = q_o/{\rm \pi} R^2 = 0.88\ {\rm m}\ {\rm s}^{-1}$, and vary the superficial velocity of water as ![]() $j_w = q_w/{\rm \pi} R^2 = 0.05, 0.075, 0.1, 0.15, 0.22$ and

$j_w = q_w/{\rm \pi} R^2 = 0.05, 0.075, 0.1, 0.15, 0.22$ and ![]() $0.36\ {\rm m}\ {\rm s}^{-1}$, where

$0.36\ {\rm m}\ {\rm s}^{-1}$, where ![]() ${R (= 0.013\,{\rm m})}$ is the pipe radius, and

${R (= 0.013\,{\rm m})}$ is the pipe radius, and ![]() $q_o$ and

$q_o$ and ![]() $q_w$ are the volume flow rates of oil and water, respectively. This is one of the experimental conditions in Sotgia et al. (Reference Sotgia, Tartarini and Stalio2008), where a core–annular flow is maintained in the pipe. Note that Sotgia et al. (Reference Sotgia, Tartarini and Stalio2008) varied the oil and water superficial velocities together with the pipe radius and showed various flow regimes including core–annular and dispersed flows. The numerical method of maintaining constant superficial velocities of both fluids is given in Appendix A.

$q_w$ are the volume flow rates of oil and water, respectively. This is one of the experimental conditions in Sotgia et al. (Reference Sotgia, Tartarini and Stalio2008), where a core–annular flow is maintained in the pipe. Note that Sotgia et al. (Reference Sotgia, Tartarini and Stalio2008) varied the oil and water superficial velocities together with the pipe radius and showed various flow regimes including core–annular and dispersed flows. The numerical method of maintaining constant superficial velocities of both fluids is given in Appendix A.

Figure 1. Schematic diagram of the core–annular flow in a horizontal pipe.

Table 1 shows the bulk Reynolds number, ![]() $Re_b = u_b(2R)/\nu _w = (j_w+j_o)(2R)/\nu _w$, number of grid points, computed friction Reynolds number,

$Re_b = u_b(2R)/\nu _w = (j_w+j_o)(2R)/\nu _w$, number of grid points, computed friction Reynolds number, ![]() $Re_\tau = u_\tau R/\nu _w$, and oil holdup,

$Re_\tau = u_\tau R/\nu _w$, and oil holdup, ![]() $\epsilon _o = V_o / V$, for six superficial velocity ratios,

$\epsilon _o = V_o / V$, for six superficial velocity ratios, ![]() $j_w/j_o$. Here,

$j_w/j_o$. Here, ![]() $V$ is the total computational volume,

$V$ is the total computational volume, ![]() $V_o$ is the volume occupied by oil,

$V_o$ is the volume occupied by oil, ![]() $u_\tau = \sqrt {\bar {\tau }_w / \rho _w}$ is the friction velocity,

$u_\tau = \sqrt {\bar {\tau }_w / \rho _w}$ is the friction velocity, ![]() $\bar {\tau }_w$ is the mean wall shear stress and

$\bar {\tau }_w$ is the mean wall shear stress and ![]() $\nu _w$ is the kinematic viscosity of water. For comparison, we also conduct a numerical simulation of water flow at a similar Reynolds number (

$\nu _w$ is the kinematic viscosity of water. For comparison, we also conduct a numerical simulation of water flow at a similar Reynolds number (![]() $Re_b = 24\,580$), whose results agree well with those of Wu & Moin (Reference Wu and Moin2008). The streamwise domain size (

$Re_b = 24\,580$), whose results agree well with those of Wu & Moin (Reference Wu and Moin2008). The streamwise domain size (![]() $L_x$) is

$L_x$) is ![]() $2 {\rm \pi}R$ except that of single-phase flow simulation (

$2 {\rm \pi}R$ except that of single-phase flow simulation (![]() $10R$), and periodic boundary conditions are applied in the streamwise (

$10R$), and periodic boundary conditions are applied in the streamwise (![]() $x$) and azimuthal (

$x$) and azimuthal (![]() $\theta$) directions where uniform grids are used. As shown in § 3, large-scale structures in the core–annular flow are confined by the wavelength of the phase interface, and thus the streamwise domain size of

$\theta$) directions where uniform grids are used. As shown in § 3, large-scale structures in the core–annular flow are confined by the wavelength of the phase interface, and thus the streamwise domain size of ![]() $L_x = 2{\rm \pi} R$ is large enough to contain those structures for the cases considered. The no-slip boundary condition is used at the wall, and in the radial (

$L_x = 2{\rm \pi} R$ is large enough to contain those structures for the cases considered. The no-slip boundary condition is used at the wall, and in the radial (![]() $r$) direction dense grids are allocated near the wall and interface, but coarse grids are used in the core region where flow is laminar due to the high viscosity of oil. Grid resolutions in wall units are

$r$) direction dense grids are allocated near the wall and interface, but coarse grids are used in the core region where flow is laminar due to the high viscosity of oil. Grid resolutions in wall units are ![]() $\Delta x^+ = \Delta x u_\tau / \nu _w \approx 6\unicode{x2013}7, \Delta r^+_{min} \approx 0.6\unicode{x2013}0.7$ and

$\Delta x^+ = \Delta x u_\tau / \nu _w \approx 6\unicode{x2013}7, \Delta r^+_{min} \approx 0.6\unicode{x2013}0.7$ and ![]() $(R \Delta \theta )^+ \approx 6\unicode{x2013}7$. The number of grid points used for the level-set equation is twice that for the Navier–Stokes equation in each direction. We simulated flow with one and half times the grid points for the streamwise and azimuthal directions for the case of

$(R \Delta \theta )^+ \approx 6\unicode{x2013}7$. The number of grid points used for the level-set equation is twice that for the Navier–Stokes equation in each direction. We simulated flow with one and half times the grid points for the streamwise and azimuthal directions for the case of ![]() $j_w/j_o = 0.17$, and the result showed the changes in the pressure drop and oil holdup less than 4 % and 1 %, respectively. All the computations are carried out for the non-dimensional time of approximately

$j_w/j_o = 0.17$, and the result showed the changes in the pressure drop and oil holdup less than 4 % and 1 %, respectively. All the computations are carried out for the non-dimensional time of approximately ![]() $250 R/j_o$, and averaging is conducted over

$250 R/j_o$, and averaging is conducted over ![]() $150 R/j_o$ to obtain mean values.

$150 R/j_o$ to obtain mean values.

Table 1. Superficial velocity ratio, bulk Reynolds number, number of grid points, computed friction Reynolds number and oil holdup.

3. Characteristics of the core and annular flows

Figure 2 shows the variation of the mean pressure gradient with the superficial velocity ratio for a fixed superficial oil velocity (![]() $\,j_o = q_o/{\rm \pi} R^2 = 0.88\ {\rm m}\ {\rm s}^{-1}$), together with the experimental result by Sotgia et al. (Reference Sotgia, Tartarini and Stalio2008). An excellent agreement between the present and experimental data is observed for

$\,j_o = q_o/{\rm \pi} R^2 = 0.88\ {\rm m}\ {\rm s}^{-1}$), together with the experimental result by Sotgia et al. (Reference Sotgia, Tartarini and Stalio2008). An excellent agreement between the present and experimental data is observed for ![]() $j_w/j_o \ge 0.17$, but the agreement becomes poorer at lower

$j_w/j_o \ge 0.17$, but the agreement becomes poorer at lower ![]() $j_w/j_o$. This relative disagreement at low

$j_w/j_o$. This relative disagreement at low ![]() $j_w/j_o$ may be attributed to the fact that oil frequently sticks to the wall due to a narrow water region (Bai et al. Reference Bai, Chen and Joseph1992; Arney et al. Reference Arney, Bai, Guevara, Joseph and Liu1993), which may change the relative location of the phase interface and thus the mean pressure drop (note that the present numerical method does not prevent the formation of oil drops or oil sticking to the wall, but such phenomena do not occur during the present simulations). A similar discrepancy at low

$j_w/j_o$ may be attributed to the fact that oil frequently sticks to the wall due to a narrow water region (Bai et al. Reference Bai, Chen and Joseph1992; Arney et al. Reference Arney, Bai, Guevara, Joseph and Liu1993), which may change the relative location of the phase interface and thus the mean pressure drop (note that the present numerical method does not prevent the formation of oil drops or oil sticking to the wall, but such phenomena do not occur during the present simulations). A similar discrepancy at low ![]() $j_w/j_o$ was also observed for turbulent core–annular flow in a vertical pipe (Kim & Choi Reference Kim and Choi2018). With increasing

$j_w/j_o$ was also observed for turbulent core–annular flow in a vertical pipe (Kim & Choi Reference Kim and Choi2018). With increasing ![]() $j_w/j_o$, the mean pressure gradient first decreases, reaches a minimum and then increases, providing an optimal superficial velocity of water (

$j_w/j_o$, the mean pressure gradient first decreases, reaches a minimum and then increases, providing an optimal superficial velocity of water (![]() $\,j_w \vert _{opt}$) for the lowest mean pressure gradient to transport a given oil flow rate (

$\,j_w \vert _{opt}$) for the lowest mean pressure gradient to transport a given oil flow rate (![]() $q_o$ or

$q_o$ or ![]() $j_o$) in a pipe. This has also been observed in other experiments of core–annular flows in vertical and horizontal pipes (Bai et al. Reference Bai, Chen and Joseph1992; Prada & Bannwart Reference Prada and Bannwart2001; Sotgia et al. Reference Sotgia, Tartarini and Stalio2008; Vuong Reference Vuong2009; Housz et al. Reference Housz, Ooms, Henkes, Pourquie, Kidess and Radhakrishnan2017). The optimal superficial velocity ratios obtained from present numerical simulation and experiment by Sotgia et al. (Reference Sotgia, Tartarini and Stalio2008) are slightly different (

$j_o$) in a pipe. This has also been observed in other experiments of core–annular flows in vertical and horizontal pipes (Bai et al. Reference Bai, Chen and Joseph1992; Prada & Bannwart Reference Prada and Bannwart2001; Sotgia et al. Reference Sotgia, Tartarini and Stalio2008; Vuong Reference Vuong2009; Housz et al. Reference Housz, Ooms, Henkes, Pourquie, Kidess and Radhakrishnan2017). The optimal superficial velocity ratios obtained from present numerical simulation and experiment by Sotgia et al. (Reference Sotgia, Tartarini and Stalio2008) are slightly different (![]() $\,j_w/j_o \vert _{opt} = 0.11$ and 0.085, respectively), because flow conditions are not exactly same due to non-hydrodynamic effects such as chemical adhesion (Arney et al. Reference Arney, Ribeiro, Guevara, Bai and Joseph1996) as described before. When

$\,j_w/j_o \vert _{opt} = 0.11$ and 0.085, respectively), because flow conditions are not exactly same due to non-hydrodynamic effects such as chemical adhesion (Arney et al. Reference Arney, Ribeiro, Guevara, Bai and Joseph1996) as described before. When ![]() $j_w/j_o$ is smaller than the optimal one, the mean pressure gradient increases because of high wall shear stress from the narrow gap between the phase interface and upper wall (for

$j_w/j_o$ is smaller than the optimal one, the mean pressure gradient increases because of high wall shear stress from the narrow gap between the phase interface and upper wall (for ![]() $j_w/j_o=0.057$, the minimum gap size is

$j_w/j_o=0.057$, the minimum gap size is ![]() $8$ wall units, where 9 and 18 grid points for the Navier–Stokes and level-set equations are located). On the other hand, when

$8$ wall units, where 9 and 18 grid points for the Navier–Stokes and level-set equations are located). On the other hand, when ![]() $j_w/j_o$ is larger than the optimal one, the pressure gradient increases again because of the increase in the bulk Reynolds number,

$j_w/j_o$ is larger than the optimal one, the pressure gradient increases again because of the increase in the bulk Reynolds number, ![]() $Re_b = (j_w+j_o)(2R)/\nu _w$. For large superficial velocity ratios, the corresponding water flows are similar to single-phase flows (see later in figure 6c), and thus the mean pressure gradient follows the Blasius friction factor formula,

$Re_b = (j_w+j_o)(2R)/\nu _w$. For large superficial velocity ratios, the corresponding water flows are similar to single-phase flows (see later in figure 6c), and thus the mean pressure gradient follows the Blasius friction factor formula, ![]() $ (-{{\rm d}P}/{{\rm d}\kern0.7pt x}) ({R}/{\rho _w u_b^2}) \sim Re_b^{-1/4}$, where

$ (-{{\rm d}P}/{{\rm d}\kern0.7pt x}) ({R}/{\rho _w u_b^2}) \sim Re_b^{-1/4}$, where ![]() $u_b = j_w + j_o$. Since

$u_b = j_w + j_o$. Since ![]() $Re_b^{-1/4}$ little changes in the range of the Reynolds numbers considered (see table 1), the mean pressure gradient normalized by

$Re_b^{-1/4}$ little changes in the range of the Reynolds numbers considered (see table 1), the mean pressure gradient normalized by ![]() $j_o^2$ increases with increasing

$j_o^2$ increases with increasing ![]() $j_w/j_o$ for

$j_w/j_o$ for ![]() $j_w/j_o \ge 0.17$ (figure 2), i.e.

$j_w/j_o \ge 0.17$ (figure 2), i.e.

\begin{equation} - \frac{{\rm d}P}{{\rm d}\kern0.7pt x} \frac{R}{\rho_w j_o^2} =-\frac{{\rm d}P}{{\rm d}\kern0.7pt x} \frac{R}{\rho_w u_b^2} \left(1 + \frac{j_w}{j_o}\right)^2 \sim \left(1 + \frac{j_w}{j_o}\right)^2. \end{equation}

\begin{equation} - \frac{{\rm d}P}{{\rm d}\kern0.7pt x} \frac{R}{\rho_w j_o^2} =-\frac{{\rm d}P}{{\rm d}\kern0.7pt x} \frac{R}{\rho_w u_b^2} \left(1 + \frac{j_w}{j_o}\right)^2 \sim \left(1 + \frac{j_w}{j_o}\right)^2. \end{equation}

The mean pressure gradient of the core–annular flow normalized by ![]() $\rho _w$ and

$\rho _w$ and ![]() $u_b (= j_o+j_w)$ is

$u_b (= j_o+j_w)$ is ![]() $(-{\rm d}P/{{\rm d}\kern0.06em x}) (R / \rho _w u_b^2) = 8 Re_\tau ^2 / Re_b^2$ (from momentum analysis)

$(-{\rm d}P/{{\rm d}\kern0.06em x}) (R / \rho _w u_b^2) = 8 Re_\tau ^2 / Re_b^2$ (from momentum analysis) ![]() $\approx 0.0067$ at

$\approx 0.0067$ at ![]() $j_w/j_o = 0.085\ (Re_b = 24\,780)$, which is similar to 0.0064 obtained for the single-phase water flow at

$j_w/j_o = 0.085\ (Re_b = 24\,780)$, which is similar to 0.0064 obtained for the single-phase water flow at ![]() $Re_b = 24\,580$, and is much lower than

$Re_b = 24\,580$, and is much lower than ![]() $(-{\rm d}P/{{\rm d}\kern0.7pt x}) (R / \rho _w u_b^2) = (16 / Re_b) (\rho _o/\rho _w) \approx 0.64$ for single-phase high-viscosity laminar oil flow (

$(-{\rm d}P/{{\rm d}\kern0.7pt x}) (R / \rho _w u_b^2) = (16 / Re_b) (\rho _o/\rho _w) \approx 0.64$ for single-phase high-viscosity laminar oil flow (![]() $u_b = j_o = 0.88\ {\rm m}\ {\rm s}^{-1}$;

$u_b = j_o = 0.88\ {\rm m}\ {\rm s}^{-1}$; ![]() $Re_b = 22.13$; normalized by

$Re_b = 22.13$; normalized by ![]() $\rho _w$ for comparison). This clearly indicates that the core–annular flow significantly reduces the drag for the heavy-oil delivery.

$\rho _w$ for comparison). This clearly indicates that the core–annular flow significantly reduces the drag for the heavy-oil delivery.

Figure 2. Variation of the mean pressure gradient with the superficial velocity ratio: ![]() $\bullet$, present simulation;

$\bullet$, present simulation; ![]() $\circ$, experiment by Sotgia et al. (Reference Sotgia, Tartarini and Stalio2008).

$\circ$, experiment by Sotgia et al. (Reference Sotgia, Tartarini and Stalio2008).

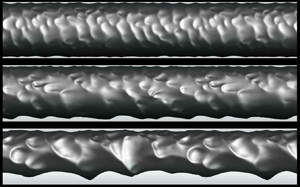

Figure 3 shows the shapes of the instantaneous phase interface for different superficial velocity ratios, together with snapshots of the phase interface from experiment by Sotgia et al. (Reference Sotgia, Tartarini and Stalio2008). Also shown in figure 3(a–f) are the contours of the instantaneous relative velocity to the core velocity in water flow, where ![]() $u_{core} = \int u\,{\rm d}V_o / V_o =\int u \,{\rm d}V_o/V {\times } (V/V_o) = j_o / \epsilon _o$ and

$u_{core} = \int u\,{\rm d}V_o / V_o =\int u \,{\rm d}V_o/V {\times } (V/V_o) = j_o / \epsilon _o$ and ![]() $V_o$ is the volume occupied by oil. The shapes of the phase interface qualitatively agree well with the experimental ones considering the differences in the experimental and simulation set-ups as mentioned above. Due to the buoyancy, the flow characteristics vary in the azimuthal direction. The lower gap between the phase interface and pipe wall rapidly increases with increasing superficial velocity ratio, whereas the upper gap slowly increases (see below). The phase interfaces consist of different streamwise and azimuthal wavenumber components, and the wavelength and wave amplitude increase with increasing superficial velocity ratio (or increasing gap size). When the gap is narrow, the crest of the phase interface almost touches the wall, and no small-scale vortices are observed there (see later in figure 5a). With increasing

$V_o$ is the volume occupied by oil. The shapes of the phase interface qualitatively agree well with the experimental ones considering the differences in the experimental and simulation set-ups as mentioned above. Due to the buoyancy, the flow characteristics vary in the azimuthal direction. The lower gap between the phase interface and pipe wall rapidly increases with increasing superficial velocity ratio, whereas the upper gap slowly increases (see below). The phase interfaces consist of different streamwise and azimuthal wavenumber components, and the wavelength and wave amplitude increase with increasing superficial velocity ratio (or increasing gap size). When the gap is narrow, the crest of the phase interface almost touches the wall, and no small-scale vortices are observed there (see later in figure 5a). With increasing ![]() $j_w/j_o$, the flow in the gap changes from laminar to turbulent, especially near the lower pipe wall.

$j_w/j_o$, the flow in the gap changes from laminar to turbulent, especially near the lower pipe wall.

Figure 3. Shapes of the instantaneous phase interface and contours of the instantaneous relative velocity to the core velocity for different superficial velocity ratios: (a) ![]() $j_w/j_o = 0.057$; (b) 0.085; (c) 0.11; (d) 0.17; (e) 0.25; (f) 0.41; (g) 0.057; (h) 0.41. Here, (a–f) are from the present numerical simulation and (g,h) are from the experiment by Sotgia et al. (Reference Sotgia, Tartarini and Stalio2008).

$j_w/j_o = 0.057$; (b) 0.085; (c) 0.11; (d) 0.17; (e) 0.25; (f) 0.41; (g) 0.057; (h) 0.41. Here, (a–f) are from the present numerical simulation and (g,h) are from the experiment by Sotgia et al. (Reference Sotgia, Tartarini and Stalio2008).

Figure 4(a) shows the mean radial locations of the phase interface in the azimuthal direction for different superficial velocity ratios,

where ![]() $h$ is the instantaneous radial location of the phase interface, the superscript

$h$ is the instantaneous radial location of the phase interface, the superscript ![]() $\tilde {.}$ denotes the averaging over the streamwise direction and in time, and

$\tilde {.}$ denotes the averaging over the streamwise direction and in time, and ![]() $T$ is the integration time. The averaged value of

$T$ is the integration time. The averaged value of ![]() $\tilde {h}(\theta )$ over the azimuthal direction is

$\tilde {h}(\theta )$ over the azimuthal direction is ![]() $h_{avg} / R = \sqrt {V_o / V} = \sqrt {\epsilon _o}$, and they are

$h_{avg} / R = \sqrt {V_o / V} = \sqrt {\epsilon _o}$, and they are ![]() $h_{avg} / R = 0.96, 0.94, 0.93, 0.90, 0.87$ and 0.81 for

$h_{avg} / R = 0.96, 0.94, 0.93, 0.90, 0.87$ and 0.81 for ![]() $j_w/j_o = 0.057, 0.085, 0.11, 0.17, 0.25$ and 0.41, respectively. For

$j_w/j_o = 0.057, 0.085, 0.11, 0.17, 0.25$ and 0.41, respectively. For ![]() $j_w/j_o = 0.057$,

$j_w/j_o = 0.057$, ![]() $\tilde {h} (\theta )$ is nearly constant in the azimuthal direction due to the small amount of water flow, but, for higher

$\tilde {h} (\theta )$ is nearly constant in the azimuthal direction due to the small amount of water flow, but, for higher ![]() $j_w/j_o$, it has a plateau near the top wall (

$j_w/j_o$, it has a plateau near the top wall (![]() $\theta \approx 0^{\circ }$) but rapidly decreases near the bottom wall (

$\theta \approx 0^{\circ }$) but rapidly decreases near the bottom wall (![]() $\theta \approx 180^{\circ }$) because the core rises upward by the buoyancy. The gap size between the phase interface and wall,

$\theta \approx 180^{\circ }$) because the core rises upward by the buoyancy. The gap size between the phase interface and wall, ![]() $R - \tilde {h}(\theta )$, increases with

$R - \tilde {h}(\theta )$, increases with ![]() $j_w/j_o$ for all azimuthal locations (figure 4b). At large superficial velocity ratios, the gap size increases almost linearly with the superficial velocity ratio. This linear growth in the gap size starts to occur at lower superficial velocity ratio for larger

$j_w/j_o$ for all azimuthal locations (figure 4b). At large superficial velocity ratios, the gap size increases almost linearly with the superficial velocity ratio. This linear growth in the gap size starts to occur at lower superficial velocity ratio for larger ![]() $\theta$.

$\theta$.

Figure 4. Mean radial locations of the phase interface and mean gap sizes along the azimuthal direction for different superficial velocity ratios: (a) mean radial location, ![]() $\tilde {h} (\theta )$; (b) mean gap size,

$\tilde {h} (\theta )$; (b) mean gap size, ![]() $R - \tilde {h} (\theta )$. Here,

$R - \tilde {h} (\theta )$. Here, ![]() $\theta = 0^{\circ }$ and

$\theta = 0^{\circ }$ and ![]() $180^{\circ }$ denote the top and bottom locations of the pipe, respectively.

$180^{\circ }$ denote the top and bottom locations of the pipe, respectively.

Figure 5 shows the contours of the instantaneous modified pressure fluctuations, ![]() $p^\ast (=p + \rho _w gz - \bar {p}^\ast _{wall})$, and the instantaneous velocity vectors relative to the core velocity for

$p^\ast (=p + \rho _w gz - \bar {p}^\ast _{wall})$, and the instantaneous velocity vectors relative to the core velocity for ![]() $j_w/j_o = 0.057$ and 0.41, where

$j_w/j_o = 0.057$ and 0.41, where ![]() $\bar {p}_{wall}^\ast = \int (p+\rho _w g z) \,{\rm d}A_{wall} / A_{wall}$ and

$\bar {p}_{wall}^\ast = \int (p+\rho _w g z) \,{\rm d}A_{wall} / A_{wall}$ and ![]() $A_{wall}$ is the area of the pipe wall. Here, we add

$A_{wall}$ is the area of the pipe wall. Here, we add ![]() $\rho _w g z$ in the modified pressure to remove the hydrostatic effect in the pressure. For the narrow gap of

$\rho _w g z$ in the modified pressure to remove the hydrostatic effect in the pressure. For the narrow gap of ![]() $j_w/j_o = 0.057$, there is a recirculating flow in the wave valley, and high- and low-pressure fluctuations are observed ahead of and behind the crest, which is similar to those observed from core–annular flows in vertical pipes (Bai et al. Reference Bai, Kelkar and Joseph1996; Li & Renardy Reference Li and Renardy1999; Kim & Choi Reference Kim and Choi2018). However, for

$j_w/j_o = 0.057$, there is a recirculating flow in the wave valley, and high- and low-pressure fluctuations are observed ahead of and behind the crest, which is similar to those observed from core–annular flows in vertical pipes (Bai et al. Reference Bai, Kelkar and Joseph1996; Li & Renardy Reference Li and Renardy1999; Kim & Choi Reference Kim and Choi2018). However, for ![]() $j_w/j_o = 0.41$, the gap between the interface and lower pipe wall is sufficiently wide and turbulent flow is observed within an oil-free region near the lower wall. Near the crest,

$j_w/j_o = 0.41$, the gap between the interface and lower pipe wall is sufficiently wide and turbulent flow is observed within an oil-free region near the lower wall. Near the crest, ![]() $p^\ast$ is high and low ahead of and behind the crest, respectively. This indicates that the oil flow in the core drags the water flow. Also,

$p^\ast$ is high and low ahead of and behind the crest, respectively. This indicates that the oil flow in the core drags the water flow. Also, ![]() $p^\ast$ is overall high and low near the upper and lower surfaces of the pipe, respectively, and this difference is in balance with the buoyancy (Feng et al. Reference Feng, Huang and Joseph1995; Ooms et al. Reference Ooms, Pourquie and Poesio2012), which is discussed later in § 4.2.

$p^\ast$ is overall high and low near the upper and lower surfaces of the pipe, respectively, and this difference is in balance with the buoyancy (Feng et al. Reference Feng, Huang and Joseph1995; Ooms et al. Reference Ooms, Pourquie and Poesio2012), which is discussed later in § 4.2.

Figure 5. Contours of the instantaneous modified pressure fluctuations and relative velocity vectors: (a) ![]() $j_w/j_o = 0.057$; (b) 0.41. The velocity vectors relative to the core velocity are drawn at every eighth grid points in the streamwise and radial directions, except for the zoomed view in (a) where they are drawn at every other grid point.

$j_w/j_o = 0.057$; (b) 0.41. The velocity vectors relative to the core velocity are drawn at every eighth grid points in the streamwise and radial directions, except for the zoomed view in (a) where they are drawn at every other grid point.

Figure 6 shows the mean streamwise velocity profiles of water (![]() $\tilde {u}_w$) and oil (

$\tilde {u}_w$) and oil (![]() $\tilde {u}_o$) normalized by the core velocity

$\tilde {u}_o$) normalized by the core velocity ![]() $u_{core}$ and local friction velocity

$u_{core}$ and local friction velocity ![]() $\tilde {u}_\tau (\theta )$, respectively, for

$\tilde {u}_\tau (\theta )$, respectively, for ![]() $j_w/j_o = 0.057, 0.17$ and 0.41, where

$j_w/j_o = 0.057, 0.17$ and 0.41, where ![]() $\tilde {u}_w, \tilde {u}_o$ and

$\tilde {u}_w, \tilde {u}_o$ and ![]() $\tilde {u}_\tau$ are obtained as

$\tilde {u}_\tau$ are obtained as

\begin{gather} \tilde{u}_w (r, \theta) = \frac{\displaystyle\int^T_0 \int^{L_x}_0 u(x, r, \theta, t) \psi(x, r, \theta, t) \,{{\rm d}\kern0.7pt x}\, {\rm d}t}{\displaystyle\int^T_0 \int^{L_x}_0 \psi(x, r, \theta, t) \,{\rm d}\kern0.06em x\,{\rm d}t}, \end{gather}

\begin{gather} \tilde{u}_w (r, \theta) = \frac{\displaystyle\int^T_0 \int^{L_x}_0 u(x, r, \theta, t) \psi(x, r, \theta, t) \,{{\rm d}\kern0.7pt x}\, {\rm d}t}{\displaystyle\int^T_0 \int^{L_x}_0 \psi(x, r, \theta, t) \,{\rm d}\kern0.06em x\,{\rm d}t}, \end{gather} \begin{gather} \tilde{u}_0 (r, \theta) = \frac{\displaystyle\int^T_0 \int^{L_x}_0 u(x, r, \theta, t) (1 - \psi(x, r, \theta, t)) \,{{\rm d}\kern0.7pt x}\, {\rm d}t}{\displaystyle\int^T_0 \int^{L_x}_0 (1 - \psi(x, r, \theta, t)) \,{\rm d}\kern0.06em x\,{\rm d}t}, \end{gather}

\begin{gather} \tilde{u}_0 (r, \theta) = \frac{\displaystyle\int^T_0 \int^{L_x}_0 u(x, r, \theta, t) (1 - \psi(x, r, \theta, t)) \,{{\rm d}\kern0.7pt x}\, {\rm d}t}{\displaystyle\int^T_0 \int^{L_x}_0 (1 - \psi(x, r, \theta, t)) \,{\rm d}\kern0.06em x\,{\rm d}t}, \end{gather} \begin{gather} \tilde{u}_\tau (\theta) = \sqrt{\nu_w \int^T_0 \int^{L_x}_0 \left( -\partial u / \partial r \vert_{wall} \right) \,{\rm d}\kern0.06em x\,{\rm d}t / (L_x T)}. \end{gather}

\begin{gather} \tilde{u}_\tau (\theta) = \sqrt{\nu_w \int^T_0 \int^{L_x}_0 \left( -\partial u / \partial r \vert_{wall} \right) \,{\rm d}\kern0.06em x\,{\rm d}t / (L_x T)}. \end{gather}

Since the core flow is almost a plug flow, ![]() $\tilde {u}_o/u_{core} \approx 1$ but slightly decreases with increasing

$\tilde {u}_o/u_{core} \approx 1$ but slightly decreases with increasing ![]() $r$. The annular flow may be considered as a Poiseuille–Couette-type flow driven by both the mean pressure gradient and the core. For

$r$. The annular flow may be considered as a Poiseuille–Couette-type flow driven by both the mean pressure gradient and the core. For ![]() $j_w/j_o = 0.057$ (figure 6a), the gap between the interface and wall is narrow and little varies along the azimuthal direction (see figure 4). Thus,

$j_w/j_o = 0.057$ (figure 6a), the gap between the interface and wall is narrow and little varies along the azimuthal direction (see figure 4). Thus, ![]() $\tilde {u}_w$ at different azimuthal locations are quite similar among themselves and have linear profiles except near the interface, indicating that the flow in water at this low superficial velocity ratio is more like Couette flow driven by the core. With increasing

$\tilde {u}_w$ at different azimuthal locations are quite similar among themselves and have linear profiles except near the interface, indicating that the flow in water at this low superficial velocity ratio is more like Couette flow driven by the core. With increasing ![]() $j_w/j_o$, the gap size increases and the water velocity profile approaches the log-law of the single-phase flow (see the velocity profiles at

$j_w/j_o$, the gap size increases and the water velocity profile approaches the log-law of the single-phase flow (see the velocity profiles at ![]() $\theta = 180^{\circ }$ for

$\theta = 180^{\circ }$ for ![]() $j_w/j_o = 0.17$ and at

$j_w/j_o = 0.17$ and at ![]() $\theta = 90^{\circ }$ and

$\theta = 90^{\circ }$ and ![]() $180^{\circ }$ for

$180^{\circ }$ for ![]() $j_w/j_o = 0.41$ in figures 6b and 6c, respectively). Note that the oil-free region at

$j_w/j_o = 0.41$ in figures 6b and 6c, respectively). Note that the oil-free region at ![]() $\theta =180^\circ$ becomes wider with increasing

$\theta =180^\circ$ becomes wider with increasing ![]() $j_w / j_o$ and the mean velocity profiles there follow the law of the wall of the single-phase flow.

$j_w / j_o$ and the mean velocity profiles there follow the law of the wall of the single-phase flow.

Figure 6. Profiles of the mean streamwise velocity of water (![]() $\tilde {u}_w$) and oil (

$\tilde {u}_w$) and oil (![]() $\tilde {u}_o$) normalized by (a i,b i,c i)

$\tilde {u}_o$) normalized by (a i,b i,c i) ![]() $u_{core}$ and (aii, bii, cii) local friction velocity

$u_{core}$ and (aii, bii, cii) local friction velocity ![]() $\tilde {u}_\tau (\theta )$ , respectively: (a)

$\tilde {u}_\tau (\theta )$ , respectively: (a) ![]() $j_w/j_o = 0.057$; (b) 0.17; (c) 0.41.

$j_w/j_o = 0.057$; (b) 0.17; (c) 0.41.

Figure 7(a) shows the variations of the mean core-flow characteristics including the holdup ratio (![]() $s = (q_o/q_w)/(V_o/V_w)$), oil holdup (

$s = (q_o/q_w)/(V_o/V_w)$), oil holdup (![]() $\epsilon _o = V_o/(V_w+V_o)$) and core (

$\epsilon _o = V_o/(V_w+V_o)$) and core (![]() $u_{core}$) and annular (

$u_{core}$) and annular (![]() $u_{annular}$) velocities with

$u_{annular}$) velocities with ![]() $j_w/j_o$. The holdup ratio is the ratio of the bulk velocity of oil (core) to that of water (annular) and is greater than 1, because the annular water flow is heavily influenced by the viscous effect. With increasing

$j_w/j_o$. The holdup ratio is the ratio of the bulk velocity of oil (core) to that of water (annular) and is greater than 1, because the annular water flow is heavily influenced by the viscous effect. With increasing ![]() $j_w/j_o$, the holdup ratio decreases from 1.50 to 1.29, indicating that the amount of increase in

$j_w/j_o$, the holdup ratio decreases from 1.50 to 1.29, indicating that the amount of increase in ![]() $V_w/V_o$ is smaller than that in

$V_w/V_o$ is smaller than that in ![]() $j_w/j_o (= q_w/q_o)$. With increasing

$j_w/j_o (= q_w/q_o)$. With increasing ![]() $j_w/j_o$, the oil holdup

$j_w/j_o$, the oil holdup ![]() $\epsilon _o$ decreases, and the core and annular velocities normalized by

$\epsilon _o$ decreases, and the core and annular velocities normalized by ![]() $j_o (u_{core}/j_o = 1/\epsilon _o)$ increase.

$j_o (u_{core}/j_o = 1/\epsilon _o)$ increase.

Figure 7. Mean characteristics of the core flow: (a) holdup ratio (![]() $s$), oil holdup (

$s$), oil holdup (![]() $\epsilon _o$), core velocity (

$\epsilon _o$), core velocity (![]() $u_{core}/j_o$) and annular velocity (

$u_{core}/j_o$) and annular velocity (![]() $u_{annular}/j_o$); (b) contours of the mean water volume fraction

$u_{annular}/j_o$); (b) contours of the mean water volume fraction ![]() $\tilde {\psi }$ (black solid line) and the mean location of the phase interface

$\tilde {\psi }$ (black solid line) and the mean location of the phase interface ![]() $\tilde {h} (\theta )$ (red solid line) for

$\tilde {h} (\theta )$ (red solid line) for ![]() $j_w/j_o = 0.41$; (c) eccentricity (

$j_w/j_o = 0.41$; (c) eccentricity (![]() $e$) and roundness (

$e$) and roundness (![]() $\chi$). Contour levels of

$\chi$). Contour levels of ![]() $\tilde {\psi }$ are from 0.05 to 0.95 by increments of 0.1.

$\tilde {\psi }$ are from 0.05 to 0.95 by increments of 0.1.

Figure 7(b) shows the contours of the mean water volume fraction ![]() $\tilde {\psi } (r, \theta )$ and the mean location of the phase interface

$\tilde {\psi } (r, \theta )$ and the mean location of the phase interface ![]() $\tilde {h}(\theta )$ for

$\tilde {h}(\theta )$ for ![]() $j_w/j_o = 0.41$, where

$j_w/j_o = 0.41$, where ![]() $\tilde {\psi }(r,\theta ) = \int ^T_0 \int ^{L_x}_0 \psi (x,r,\theta,t)\,{\rm d}\kern0.06em x\,{\rm d}t / (L_x T)$. The region of

$\tilde {\psi }(r,\theta ) = \int ^T_0 \int ^{L_x}_0 \psi (x,r,\theta,t)\,{\rm d}\kern0.06em x\,{\rm d}t / (L_x T)$. The region of ![]() $0 < \tilde {\psi } < 1$ is wider near the lower pipe wall than that near the upper one, which indicates that the amplitude of the phase interface wave is large and small near the lower and upper pipe walls, respectively. As shown with

$0 < \tilde {\psi } < 1$ is wider near the lower pipe wall than that near the upper one, which indicates that the amplitude of the phase interface wave is large and small near the lower and upper pipe walls, respectively. As shown with ![]() $\tilde {h}(\theta )$, the core is deformed due to the buoyancy and is eccentric to the pipe centre. Figure 7(c) shows the roundness

$\tilde {h}(\theta )$, the core is deformed due to the buoyancy and is eccentric to the pipe centre. Figure 7(c) shows the roundness ![]() $\chi$ and eccentricity

$\chi$ and eccentricity ![]() $e$ of the phase interface. The roundness

$e$ of the phase interface. The roundness ![]() $\chi$ is defined as (the ratio of the volume of the core to that of a circular cylinder having the same surface area of the core)

$\chi$ is defined as (the ratio of the volume of the core to that of a circular cylinder having the same surface area of the core)

\begin{equation} \chi = 4 {\rm \pi}\frac{\displaystyle\int^T_0 \int^{L_x}_0 \int^{2{\rm \pi}}_0 \dfrac{1}{2} h^2 \,{\rm d}\theta \,{\rm d}\kern0.06em x\,{\rm d}t / (L_x T)}{\left\{\displaystyle\int^T_0 \int^{L_x}_0 \int^{2{\rm \pi}}_0 h \,{\rm d}\theta \,{\rm d}\kern0.06em x\,{\rm d}t / (L_x T)\right\}^2}, \end{equation}

\begin{equation} \chi = 4 {\rm \pi}\frac{\displaystyle\int^T_0 \int^{L_x}_0 \int^{2{\rm \pi}}_0 \dfrac{1}{2} h^2 \,{\rm d}\theta \,{\rm d}\kern0.06em x\,{\rm d}t / (L_x T)}{\left\{\displaystyle\int^T_0 \int^{L_x}_0 \int^{2{\rm \pi}}_0 h \,{\rm d}\theta \,{\rm d}\kern0.06em x\,{\rm d}t / (L_x T)\right\}^2}, \end{equation}

and the eccentricity is ![]() $e = z_{cm} / (R - h_{avg})$, where

$e = z_{cm} / (R - h_{avg})$, where ![]() $z_{cm} (= \int ^T_0 \int ^V_0 z (1 - \psi ) \,{\rm d}V\,{\rm d}t / \int ^T_0 \int ^V_0 (1-\psi ) \,{\rm d}V\,{\rm d}t)$ is the vertical distance from the pipe centre to the centre of mass of the core, and

$z_{cm} (= \int ^T_0 \int ^V_0 z (1 - \psi ) \,{\rm d}V\,{\rm d}t / \int ^T_0 \int ^V_0 (1-\psi ) \,{\rm d}V\,{\rm d}t)$ is the vertical distance from the pipe centre to the centre of mass of the core, and ![]() $h_{avg} = \int ^{2{\rm \pi} }_0 \tilde {h} (\theta ) \,{\rm d}\theta / 2 {\rm \pi}$ is the overall mean radius of the phase interface. To calculate the perimeter

$h_{avg} = \int ^{2{\rm \pi} }_0 \tilde {h} (\theta ) \,{\rm d}\theta / 2 {\rm \pi}$ is the overall mean radius of the phase interface. To calculate the perimeter ![]() $\int h \,{\rm d}\theta$, the trapezoidal rule is used. The roundness of the circle is 1, but that of the core is less than 1 and decreases with increasing

$\int h \,{\rm d}\theta$, the trapezoidal rule is used. The roundness of the circle is 1, but that of the core is less than 1 and decreases with increasing ![]() $j_w/j_o$. For

$j_w/j_o$. For ![]() $j_w/j_o = 0.41$, the interface is most deformed among the cases considered and the roundness is approximately 0.94, which is similar to that of the ellipse whose major and minor axes are 1.5 and 1, respectively. Instantaneous interface shapes are much more non-circular than the mean shape shown in figure 7(b). The eccentricity is very small for

$j_w/j_o = 0.41$, the interface is most deformed among the cases considered and the roundness is approximately 0.94, which is similar to that of the ellipse whose major and minor axes are 1.5 and 1, respectively. Instantaneous interface shapes are much more non-circular than the mean shape shown in figure 7(b). The eccentricity is very small for ![]() $j_w/j_o = 0.057$, indicating that the phase interface is nearly circular because oil occupies almost the whole circular pipe. The eccentricity rapidly increases from

$j_w/j_o = 0.057$, indicating that the phase interface is nearly circular because oil occupies almost the whole circular pipe. The eccentricity rapidly increases from ![]() $j_w/j_o = 0.057$ to 0.085, is nearly constant for

$j_w/j_o = 0.057$ to 0.085, is nearly constant for ![]() $0.085 < j_w/j_o < 0.25$ and then slowly increases with increasing

$0.085 < j_w/j_o < 0.25$ and then slowly increases with increasing ![]() $j_w/j_o$, because the core rises upward.

$j_w/j_o$, because the core rises upward.

4. Phase interface and near-wall dynamics

4.1. Wave characteristics of the phase interface

The wave characteristics of the phase interface are investigated by computing the streamwise wavenumber (![]() $k_x$) and frequency (

$k_x$) and frequency (![]() $\omega$) power spectra of the phase interface amplitude,

$\omega$) power spectra of the phase interface amplitude, ![]() $\zeta (\theta ) (= h - \tilde {h}(\theta ))$. The range of the streamwise wavenumber is

$\zeta (\theta ) (= h - \tilde {h}(\theta ))$. The range of the streamwise wavenumber is ![]() $0 \le k_x \le 383/R$

$0 \le k_x \le 383/R$ ![]() $(\Delta k_x = 1/R)$, and the sampling interval is

$(\Delta k_x = 1/R)$, and the sampling interval is ![]() $\Delta t_s = 0.02 R/j_o$ during

$\Delta t_s = 0.02 R/j_o$ during ![]() $T = 81.92 R/j_o$ which is divided into 15 overlapping segments with 50 % overlap (

$T = 81.92 R/j_o$ which is divided into 15 overlapping segments with 50 % overlap (![]() $0 \le \omega \le 157 j_o/R$ with

$0 \le \omega \le 157 j_o/R$ with ![]() $\Delta \omega = 0.6136 j_o/R$; for more details, see Choi & Moin (Reference Choi and Moin1990)). The one-dimensional wavenumber spectrum

$\Delta \omega = 0.6136 j_o/R$; for more details, see Choi & Moin (Reference Choi and Moin1990)). The one-dimensional wavenumber spectrum ![]() $\varphi (k_x,\theta )$ and frequency spectrum

$\varphi (k_x,\theta )$ and frequency spectrum ![]() $\varphi (\omega,\theta )$ of the phase interface amplitude

$\varphi (\omega,\theta )$ of the phase interface amplitude ![]() $\zeta$ satisfy the following condition:

$\zeta$ satisfy the following condition:

where ![]() $\zeta _{rms}(\theta )$ is the root-mean-square fluctuations of the phase interface amplitude.

$\zeta _{rms}(\theta )$ is the root-mean-square fluctuations of the phase interface amplitude.

Figure 8 shows the streamwise wavenumber and frequency spectra of the phase interface amplitude at ![]() $\theta = 0^\circ$ and

$\theta = 0^\circ$ and ![]() $180^\circ$ for

$180^\circ$ for ![]() $j_w/j_o = 0.057, 0.17$ and 0.41. The spectra are broad-banded, indicating that the motion of the phase interface amplitude has a turbulent nature. For

$j_w/j_o = 0.057, 0.17$ and 0.41. The spectra are broad-banded, indicating that the motion of the phase interface amplitude has a turbulent nature. For ![]() $j_w/j_o = 0.057$, the streamwise wavenumber spectrum is more or less homogeneous in the azimuthal direction, and high powers appear in low wavenumbers,

$j_w/j_o = 0.057$, the streamwise wavenumber spectrum is more or less homogeneous in the azimuthal direction, and high powers appear in low wavenumbers, ![]() $k_x R \le 12$

$k_x R \le 12$ ![]() $(\lambda \ge {\rm \pi}R/6)$, where

$(\lambda \ge {\rm \pi}R/6)$, where ![]() $\lambda$ is the corresponding wavelength. With increasing

$\lambda$ is the corresponding wavelength. With increasing ![]() $j_w/j_o$, the power peak moves to lower wavenumbers on the bottom interface (

$j_w/j_o$, the power peak moves to lower wavenumbers on the bottom interface (![]() $\theta = 180^{\circ }$), whereas the power on the top interface is relatively insensitive to

$\theta = 180^{\circ }$), whereas the power on the top interface is relatively insensitive to ![]() $j_w/j_o$. This is consistent with the variation of large-scale wavy structures on the bottom interface with

$j_w/j_o$. This is consistent with the variation of large-scale wavy structures on the bottom interface with ![]() $j_w/j_o$ in figure 3: the power peak occurs at

$j_w/j_o$ in figure 3: the power peak occurs at ![]() $k_x R = 12, 5$ and 3 for

$k_x R = 12, 5$ and 3 for ![]() $j_w/j_o = 0.057, 0.17$ and 0.41, respectively, corresponding to the dominant wavelengths of

$j_w/j_o = 0.057, 0.17$ and 0.41, respectively, corresponding to the dominant wavelengths of ![]() $\lambda /R = 0.52, 1.26$ and

$\lambda /R = 0.52, 1.26$ and ![]() $2.09$. Note also that the power at low wavenumbers and frequencies is much larger at

$2.09$. Note also that the power at low wavenumbers and frequencies is much larger at ![]() $\theta = 180^{\circ }$ than at

$\theta = 180^{\circ }$ than at ![]() $\theta = 0^{\circ }$ for

$\theta = 0^{\circ }$ for ![]() $j_w/j_o = 0.17$ and 0.41. The frequency spectra are very similar to the streamwise wavenumber spectra, showing the convective nature of the phase interface.

$j_w/j_o = 0.17$ and 0.41. The frequency spectra are very similar to the streamwise wavenumber spectra, showing the convective nature of the phase interface.

Figure 8. Streamwise wavenumber and frequency spectra of the phase interface amplitude at ![]() $\theta =0^{\circ }$ and

$\theta =0^{\circ }$ and ![]() $180^{\circ }$: (a)

$180^{\circ }$: (a) ![]() $j_w/j_o = 0.057$; (b) 0.17; (c) 0.41.

$j_w/j_o = 0.057$; (b) 0.17; (c) 0.41.

Figure 9(a) shows the contours of the streamwise wavenumber–frequency power spectrum of the phase interface amplitude, ![]() $\varPhi (k_x,\omega ) = \int ^{2{\rm \pi} }_0 \tilde {\varPhi }(k_x,\omega,\theta ) \,{\rm d}\theta / 2{\rm \pi}$, for

$\varPhi (k_x,\omega ) = \int ^{2{\rm \pi} }_0 \tilde {\varPhi }(k_x,\omega,\theta ) \,{\rm d}\theta / 2{\rm \pi}$, for ![]() $j_w/j_o = 0.17$, where

$j_w/j_o = 0.17$, where ![]() $\tilde {\varPhi }(k_x,\omega,\theta )$ is the two-dimensional power spectrum as a function of the azimuthal angle. As shown, the streamwise wavenumber–frequency power spectrum shows a strong convective nature. The convection velocity of the phase interface can be obtained as (Wills Reference Wills1971; Choi & Moin Reference Choi and Moin1990)

$\tilde {\varPhi }(k_x,\omega,\theta )$ is the two-dimensional power spectrum as a function of the azimuthal angle. As shown, the streamwise wavenumber–frequency power spectrum shows a strong convective nature. The convection velocity of the phase interface can be obtained as (Wills Reference Wills1971; Choi & Moin Reference Choi and Moin1990)

where ![]() $\omega (k_x,\theta )$ is obtained from

$\omega (k_x,\theta )$ is obtained from

\begin{equation} \left.\frac{\partial \tilde{\varPhi}(k_x,\omega,\theta)}{\partial \omega} \right\vert_{\omega = \omega(k_x,\theta)} = 0. \end{equation}

\begin{equation} \left.\frac{\partial \tilde{\varPhi}(k_x,\omega,\theta)}{\partial \omega} \right\vert_{\omega = \omega(k_x,\theta)} = 0. \end{equation}

A quadratic polynomial is used to find ![]() $\omega (k_x,\theta )$ in (4.3) (Kang, Moin & Iaccarino Reference Kang, Moin and Iaccarino2008). Figure 9(b) shows the convection velocity normalized by the core velocity as a function of the streamwise wavenumbers at three different azimuthal angles. The scatters of the data shown in this figure are due to the limited statistical sample available for locating the maxima of the spectrum within a set of discrete frequencies and wavenumbers, and the convection velocities at low wavenumbers are also contaminated by a specific window function (Hanning window) or the sampling period used (see also Choi & Moin (Reference Choi and Moin1990) and Kim & Choi (Reference Kim and Choi2018)). The convection velocity is smaller than the core velocity, indicating that the core drags the phase interface. At low wavenumbers where the spectrum has a peak (

$\omega (k_x,\theta )$ in (4.3) (Kang, Moin & Iaccarino Reference Kang, Moin and Iaccarino2008). Figure 9(b) shows the convection velocity normalized by the core velocity as a function of the streamwise wavenumbers at three different azimuthal angles. The scatters of the data shown in this figure are due to the limited statistical sample available for locating the maxima of the spectrum within a set of discrete frequencies and wavenumbers, and the convection velocities at low wavenumbers are also contaminated by a specific window function (Hanning window) or the sampling period used (see also Choi & Moin (Reference Choi and Moin1990) and Kim & Choi (Reference Kim and Choi2018)). The convection velocity is smaller than the core velocity, indicating that the core drags the phase interface. At low wavenumbers where the spectrum has a peak (![]() $k_x R = 1\unicode{x2013}10$), the convection velocities are lower than those at higher wavenumbers (

$k_x R = 1\unicode{x2013}10$), the convection velocities are lower than those at higher wavenumbers (![]() $\tilde {U}_{conv} (k_x,\theta ) / u_{core} \approx 0.94\unicode{x2013}0.98$), suggesting that the energy-containing large-scale structures of the phase interface more strongly interact with the water flow and resist the core flow more than the small-scale structures do. This characteristic is similar to that of the core–annular flow in a vertical pipe (Kim & Choi Reference Kim and Choi2018). Note also that the convection velocity at

$\tilde {U}_{conv} (k_x,\theta ) / u_{core} \approx 0.94\unicode{x2013}0.98$), suggesting that the energy-containing large-scale structures of the phase interface more strongly interact with the water flow and resist the core flow more than the small-scale structures do. This characteristic is similar to that of the core–annular flow in a vertical pipe (Kim & Choi Reference Kim and Choi2018). Note also that the convection velocity at ![]() $\theta =0^{\circ }$ is lower than those at

$\theta =0^{\circ }$ is lower than those at ![]() $\theta =90^{\circ }$ and

$\theta =90^{\circ }$ and ![]() $180^{\circ }$ due to the viscous effect at the narrow gap, although the difference is not so large. The overall convection velocity

$180^{\circ }$ due to the viscous effect at the narrow gap, although the difference is not so large. The overall convection velocity ![]() $U_{conv}$ of the most energetic wave is obtained from

$U_{conv}$ of the most energetic wave is obtained from

where

The overall convection velocity increases with increasing ![]() $j_w/j_o$; i.e.

$j_w/j_o$; i.e. ![]() $U_{conv}/u_{core} \approx 0.94, 0.95$ and 0.96 for

$U_{conv}/u_{core} \approx 0.94, 0.95$ and 0.96 for ![]() $j_w/j_o = 0.057, 0.17$ and 0.41, respectively. This indicates that most energetic motions move downstream at a speed slightly lower than the core velocity.

$j_w/j_o = 0.057, 0.17$ and 0.41, respectively. This indicates that most energetic motions move downstream at a speed slightly lower than the core velocity.

Figure 9. Two-dimensional spectrum and convection velocity of the phase interface (![]() $\,j_w/j_o = 0.17$): (a) contours of

$\,j_w/j_o = 0.17$): (a) contours of ![]() $\varPhi (k_x,\omega )$; (b) convection velocity at three different azimuthal locations as a function of the streamwise wavenumber. In (a), contour levels are logarithmically equally spaced.

$\varPhi (k_x,\omega )$; (b) convection velocity at three different azimuthal locations as a function of the streamwise wavenumber. In (a), contour levels are logarithmically equally spaced.

4.2. Dynamics of oil core

The stress on the phase interface is obtained as

where the subscripts ![]() $i = 1, 2$ and 3 indicate the axial (

$i = 1, 2$ and 3 indicate the axial (![]() $x$), lateral (

$x$), lateral (![]() $y$) and vertical (

$y$) and vertical (![]() $z$) coordinates, respectively (figure 1). The pressure and velocity gradient on the interface are obtained by a linear interpolation from grid points at the nearest oil region to those at the phase interface. From the stress boundary condition at the phase interface ( jump condition), the stress at the phase interface from the core region is the sum of the stress at the phase interface from the annular region and the surface tension (Brackbill et al. Reference Brackbill, Kothe and Zemach1992).

$z$) coordinates, respectively (figure 1). The pressure and velocity gradient on the interface are obtained by a linear interpolation from grid points at the nearest oil region to those at the phase interface. From the stress boundary condition at the phase interface ( jump condition), the stress at the phase interface from the core region is the sum of the stress at the phase interface from the annular region and the surface tension (Brackbill et al. Reference Brackbill, Kothe and Zemach1992).

Figure 10 shows the contours of the instantaneous stresses on the interface, ![]() $\sigma _{zj} n_j / (\rho _w - \rho _o)gR$ and

$\sigma _{zj} n_j / (\rho _w - \rho _o)gR$ and ![]() $\sigma _{xj} n_j / \rho _w u_\tau ^2$, and their components for

$\sigma _{xj} n_j / \rho _w u_\tau ^2$, and their components for ![]() $j_w/j_o = 0.41$. Here, the viscous normal stress is included in the pressure. Note that the stresses

$j_w/j_o = 0.41$. Here, the viscous normal stress is included in the pressure. Note that the stresses ![]() $\sigma _{zj}$ and

$\sigma _{zj}$ and ![]() $\sigma _{xj}$ are normalized by the hydrostatic pressure difference and wall shear stress, respectively, to explain

$\sigma _{xj}$ are normalized by the hydrostatic pressure difference and wall shear stress, respectively, to explain ![]() $\sigma _{zj}$ and

$\sigma _{zj}$ and ![]() $\sigma _{xj}$ in terms of the lift and drag forces, respectively. The stagnation pressure ahead of the crest generates the wall-repulsive (

$\sigma _{xj}$ in terms of the lift and drag forces, respectively. The stagnation pressure ahead of the crest generates the wall-repulsive (![]() $-r$ direction) and drag (

$-r$ direction) and drag (![]() $-x$ direction) forces (in this figure,

$-x$ direction) forces (in this figure, ![]() $\delta _{xj} n_j$ are positive and negative on the forward and leeward sides, respectively). The pressure on the upper interface is higher than that of the lower one (

$\delta _{xj} n_j$ are positive and negative on the forward and leeward sides, respectively). The pressure on the upper interface is higher than that of the lower one (![]() $\delta _{zj} n_j$ are positive and negative on the upper and lower interfaces, respectively), providing a negative lift (

$\delta _{zj} n_j$ are positive and negative on the upper and lower interfaces, respectively), providing a negative lift (![]() $-z$ direction) force on the core which balances its buoyancy force, whereas the contribution of the viscous shear stress to the lift force is very small (figure 10a). For the drag force (figure 10b), both the pressure and viscous shear stress are highly positive and negative on the forward side of the crest, respectively, and thus push the crest in the upstream direction, whereas low pressure and positive viscous shear stress are generated on the leeward side of the crest, indicating that the flow separates across the crest.

$-z$ direction) force on the core which balances its buoyancy force, whereas the contribution of the viscous shear stress to the lift force is very small (figure 10a). For the drag force (figure 10b), both the pressure and viscous shear stress are highly positive and negative on the forward side of the crest, respectively, and thus push the crest in the upstream direction, whereas low pressure and positive viscous shear stress are generated on the leeward side of the crest, indicating that the flow separates across the crest.

Figure 10. Contours of the instantaneous stresses acting on the phase interface (![]() $\,j_w/j_o = 0.41$): (a)

$\,j_w/j_o = 0.41$): (a) ![]() $\sigma _{zj} n_j / (\rho _w - \rho _o)gR$; (b)

$\sigma _{zj} n_j / (\rho _w - \rho _o)gR$; (b) ![]() $\sigma _{xj} n_j / \rho _w u_\tau ^2$.

$\sigma _{xj} n_j / \rho _w u_\tau ^2$.

Figure 11 shows the variations of the mean lift (![]() $C_L = - \bar {F}_z / (\rho _w-\rho _o)gV_o$) and drag (

$C_L = - \bar {F}_z / (\rho _w-\rho _o)gV_o$) and drag (![]() $C_D = - \bar {F}_x / \rho _w u_\tau ^2 A_{core}$) coefficients on the oil core with

$C_D = - \bar {F}_x / \rho _w u_\tau ^2 A_{core}$) coefficients on the oil core with ![]() $j_w/j_o$, together with the analytic solutions of the mean lift and drag coefficients (

$j_w/j_o$, together with the analytic solutions of the mean lift and drag coefficients (![]() $C_L = 1$ and

$C_L = 1$ and ![]() $C_D = \sqrt {\epsilon _0 \chi }$), where the instantaneous forces are obtained by integrating the stresses over the phase interface,

$C_D = \sqrt {\epsilon _0 \chi }$), where the instantaneous forces are obtained by integrating the stresses over the phase interface,

and ![]() $A_{core}$ is the surface area of the phase interface at the same oil holdup. The analytical mean drag coefficient of

$A_{core}$ is the surface area of the phase interface at the same oil holdup. The analytical mean drag coefficient of ![]() $C_D=\sqrt {\epsilon _o \chi }$ is obtained by combining the momentum balances on the whole domain and oil core, respectively, and introducing