Article contents

Effect of yttrium on the electrical and mechanical properties of in situ synthesized CNTs/CuCr composites

Published online by Cambridge University Press: 29 April 2019

Abstract

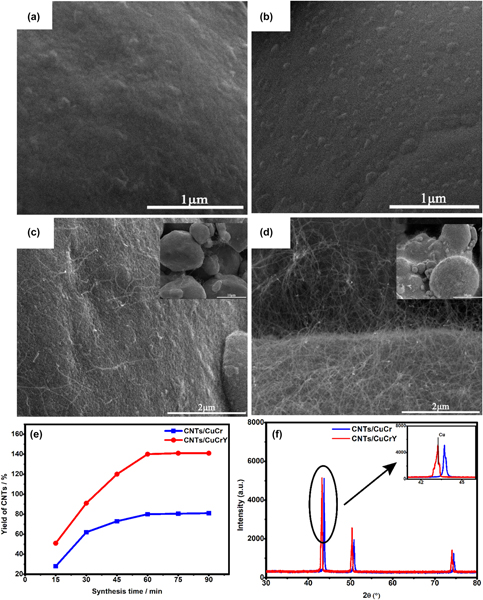

Addition of carbon nanotubes (CNTs) to copper materials significantly enhances their properties. However, the performance of CNTs/Cu composites is often not as good as expected mainly because of difficulties in controlling growth and uniform dispersion of CNTs in the matrix. Our study provides an effective way to prepare CNTs/CuCr and CNTs/CuCrY composites using chemical vapor deposition. The morphology and structure of these composites were characterized by scanning electron microscope, X-ray diffraction, X-ray photoelectron spectroscopy, and Raman spectroscopy to understand how Y incorporation affects properties of these composites. Our results showed that addition of 0.1 wt% Y enhances the catalytic properties of Cr and helps to obtain purer and pristine Cu substrate. We also studied tensile strength, electric conductivity, corrosion, and wear resistance of these composites. When Y was added, composite properties improved significantly. Tensile strength and corrosion resistance increased by 35.21 and 53.28%, respectively. Electric conductivity increased to 90.9% International Annealed Copper Standard and the coefficient of friction reduced to 0.3.

Keywords

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019

Footnotes

These authors contributed equally to this work.

References

- 5

- Cited by