Introduction

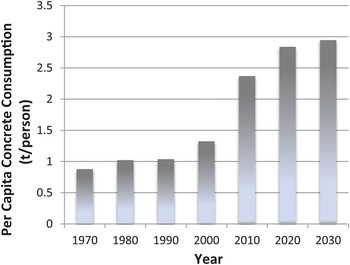

Global per capita consumption of concrete has increased since 1970 from less than 1 tonne per person per year to nearly 2.5 tonnes per person per year today. By 2030, it is projected to increase to more than 3 tonnes per person per year ( Figure 1 ). 1,2 At the same time, the world population has increased from 3.7 billion to more than 7 billion people, meaning that 20 Gt of concrete is placed in service each year. To meet infrastructure needs in regions where population growth is highest, cement production has increased steeply, more than doubling in Africa and in the former Soviet Union and more than tripling in Asia during 2001–2014 alone. 1 In developed regions with more stable or even decreasing populations, infrastructure maintenance, including reconstruction to maintain serviceability and moderate expansion to facilitate economic growth, is apparent through more modest increases of 25–50% in cement production during this period. With worldwide production in excess of 4 billion tonnes annually, Europe is the only region where cement production has remained relatively consistent since the turn of the 21st century. 2

Because of the vast quantity of cement-based materials produced each year, there is much to be gained through improvements in the manufacturing of cement and the production of concrete in terms of meeting societal demand in an increasingly sustainable manner. Even those who are engaged in sustainable development on a global scale and at the forefront of technological innovation recognize the important role key advances in commodity materials such as concrete can play in sustainability. For example, Bill Gates supports the idea—originally proposed by Vaclav Smil’s Making the Modern World: Materials and Dematerialization—that concrete is the most important human-made material. Gates cites the economic and health (or sanitation-related) benefits of concrete construction, while also recognizing that technological advances are needed to reduce the environmental impacts of the material’s vast use. Reference Gates3

Although “concrete” and “cement” are used interchangeably colloquially, cement is one component of concrete, along with water and fine and coarse aggregate (i.e., sand and crushed rock or gravel, respectively). The cement and water combine chemically over time to form heterogeneous hydrated phases that bind the mineral aggregates together, forming a water-resistant composite material. In modern concrete production, a portion of the cement might be replaced or augmented with finely divided siliceous or aluminosiliceous minerals (often industrial by-products), called supplementary cementitious materials (SCMs). Chemical admixtures and fibers might also be included in the mix, and reinforcing bars or strands—commonly carbon steel—can also be used as continuous reinforcement in concrete members.

With kiln temperatures exceeding 1400°C, modern manufacturing of cement clinker (i.e., the cement components formed within the kiln) is a highly energy-intensive process and one that is associated with 2–3% of global energy use, as well as 5–7% of anthropogenic CO2 emissions. When fossil fuels are used to generate this heat, 40% of the embodied CO2 emissions associated with cement manufacture are attributable to the energy source, whereas 60% of emissions derive directly from the calcination of limestone, the predominant raw material used in portland cement manufacture. Reference Damtoft, Lukasik, Herfort, Sorrentino and Gartner4 Technology enabling continuous carbon capture at the main cement-kiln exhaust stack is a compelling, but highly challenging, need in the industry. Postcombustion capture is the most appropriate approach because it can be applied to both new and existing kilns without extensive changes in the manufacturing process. Reference Hoenig, Hoppe and Emberger5 Additional environmental concerns include emissions of particulate matter, nitrogen and sulfur oxides, and mercury, which are controlled and monitored to ensure compliance with current regulations. 6

Anticipating ever-increasing environmental regulations and ever-expanding performance criteria, innovations in the cement industry have allowed tremendous progress to be made in increasing energy efficiency and reducing emissions. For example, since transitioning from wet-process manufacturing during the first global energy crisis in the 1970s to more efficient dry-process production, including preheating with recycled kiln gases introduced in the 1990s, the energy consumed in modern cement manufacture has decreased substantially. Reference Schneider, Romer, Tschudin and Bolio7 In addition, alternative fuel sources—including waste materials such as tires that are difficult to dispose of—are routinely used, with efforts centered on increasing substitution rates while also addressing potential changes in cement composition upon introduction of ashes from these alternative fuel sources. Reference Wirthwein and Emberger8 At the same time, portland cement compositions have been increasingly optimized, shifting to larger proportions of the more rapidly reacting tricalcium silicate (3CaO·SiO2) phase and relatively less of the slower-reacting dicalcium silicate (2CaO·SiO2), leading to higher rates of compressive strength development in concrete. These innovations in cement manufacture are deployed worldwide.

The manufacture of widely utilized portland cement has been largely optimized to meet or exceed both environmental and certain performance targets, and incremental improvements in this relatively mature technology can further contribute to improvements on those metrics. However, larger gains toward sustainably meeting future infrastructure demands can be made through increasingly innovative science-based approaches to the production of concrete. Specifically, because the embodied energy and greenhouse gas (GHG) (especially CO2) emissions in concrete are largely associated with the cement (or more broadly the “binder”) fraction and because the characteristics of this phase are important to the development of strength and to impermeability, innovations in the production and composition of binders in concrete will play a major role in the development of “green” concretes.

This article reviews recent developments in three areas that have the potential to transform ways in which infrastructure is specified, designed, and constructed:

-

1. expanding the use of SCMs and identification of alternative supplementary cementitious materials (ASCMs);

-

2. growing the use of alternative cements and binder technologies; and

-

3. developing alternative reinforcement options.

Finally, remarks are made on strategies to facilitate the transfer of these emerging and next-generation materials and technologies from the research arena into real structures.

Supplementary cementitious materials and alternatives

Historically, blends of portland cement and finely divided, largely amorphous silicates and aluminosilicates (“pozzolans,” a type of SCM) have produced high-quality concrete; this practice contributes to sustainability not only by reducing the cement clinker fraction (and proportionate embodied energy and GHGs) but also by potentially improving durability through increases in impermeability and decreases in leachable and reactive phases, such as hydrated lime. Materials scientists today employ techniques such as thermal analysis, synchrotron and x-ray microdiffraction, tomography, electron microscopy, and nuclear magnetic resonance spectroscopy to characterize fundamental reactions between ancient pozzolanic volcanic ash, natural zeolites, and lime, Reference Silva, Wenk and Monteiro9 as well as their interactions with their environment. Reference Jackson, Moon, Gotti, Taylor, Chae, Kunz, Emwas, Meral, Guttman, Levits, Wenk and Monteiro10,Reference Jackson, Chae, Mulcahy, Meral, Taylor, Li, Emwas, Moon, Yoon, Vola, Wenk and Monteiro11 Such fundamental studies provide new insights into the persistence of these ancient cementitious materials over millennia and also form the foundation for the modern production of low-energy binder systems, based on naturally occurring and industrial-by-product siliceous and aluminosiliceous sources in combination with portland cement or other calcium-rich and alkaline materials.

Today, combining cement with pozzolans or SCMs, relatively inexpensively sourced as industrial by-products such as fly ash from coal-burning power plants and slag from blast-furnace steel production, is common practice. India and China consume 65% of the cement produced worldwide each year, and both rely heavily on coal as a power source. Their domestic fly-ash utilization rates have increased steadily over the past two decades to ∼50–60%, comparable to fly-ash utilization rates in the United States but lower than those in the European Union (EU) and Japan. Reference Tang, Ma, Ding, Wang, Zheng and Zhai12–Reference Feuerborn15

Yet many believe that these by-product materials remain underutilized in concrete construction. The inherent variability in the composition of by-product materials complicates their routine use, particularly in a commodity-scale product where small variations in performance can compromise material quality. This problem can be reduced through innovations in characterizing the structure, composition, and nanoscale reactivity of individual fly-ash particles, such as by using synchrotron-based three-dimensional chemical segmentation or quantification of phase compositions through laboratory-based x-ray and image analysis. Reference Chancey, Stutzman, Juenger and Fowler16 The resulting library of information can ultimately be used to model and predict service performance for a myriad of fly-ash sources and firing conditions and, ultimately, a broader range of SCMs and ASCMs. Reference Ley and Tabb17,Reference Williamson, Juenger and Sant18

In the United States and Europe, declining reliance in recent years on coal as an energy source has resulted in variability in the availability and characteristics (e.g., mineralogy, particle size distribution, and morphology) of fly ash. 19,20 Moreover, increasing regulation has altered the practice of coal burning, resulting in lower combustion temperatures, carbon and mineral injection, and increases in the practice of biomass co-firing, affecting both the consistency and availability of fly ash. 21 At the same time, blast-furnace steel manufacturing is declining in these regions, and the cost differential between slag and cement is narrowing. 22 In China, the problem of fly-ash underutilization is complicated by geology, geography, and logistics: Much of the population growth is occurring in the eastern coastal regions in the Bohai Rim, Yangtze River Delta, and Pearl River Delta where fly-ash utilization is 90%, but most of the country’s coal deposits are in the far less populated northern and western regions, resulting in over 3 billion tonnes of “stored” fly ash. Reference Tang, Ma, Ding, Wang, Zheng and Zhai12

To address the declining availability of the most widely used SCMs in the United States and Europe and the geographic challenges impeding greater use in China and other parts of the world, ASCMs need to be identified and technologies developed to facilitate their practical use. In particular, such alternatives are critically important for the future production of high-performance concrete with low permeability and mass concrete where heat of hydration must be controlled. ASCMs also contribute to sustainability through a reduction in the cement clinker fraction in concrete. Such materials should enhance the properties of concrete and ideally should be readily and widely available, consistent in quality, and lower or comparable in cost to cement—a tall order, indeed!

As candidate ASCMs, researchers are examining by-product materials, including crushed recycled glass Reference Jiang, Chen, Rajabipour and Hendrickson23 and lower-quality combustion residuals (e.g., biomass, co-fired ashes, and previously impounded fly ash), as well as natural materials including zeolites and kaolin of varying quality. Reference Shearer and Kurtis24–Reference Tyra, Groppo, Robl and Minster31 Beyond using these materials in their existing states, various low-cost, low-environmental-impact processing methods, such as heat treatment, alkali activation, and acid treatment, can enhance their reactivity with cement. Reference Burris and Juenger32–Reference Uzal, Turanli, Yucel, Goncuoglu and Culfaz35 In many cases, such finely divided materials, when used at the same rates as more conventional SCMs (e.g., replacing 20% or more of the cement by mass), result in substantially decreased workability. Appropriate water-reducing admixtures can maintain workability in ASCM-containing concrete, with good flowability and setting characteristics at up to 30–40% cement replacement. Reference Zaribaf, Uzal, Kurtis, Scrivener and Favier36 To further address sustainability, new “green” water-reducing admixtures are being developed through controlled radical polymerization to graft hydrophilic groups onto inexpensive and abundant bio-based polymers from waste streams, enhancing their plasticizing efficiency in cement-based materials. Reference Gupta, Sverdlove and Washburn37

Alternative cements and binder technologies

Whereas portland cement (often in combination with traditional SCMs) is used in the vast majority of concrete construction today, potential improvements in concrete sustainability have spurred recent renewed interest in blended cements and alternative cement or binder compositions.

One trend is the increasing combination of portland cement clinker with uncalcined limestone. Specifications in standards ASTM C59538 and AASHTO M24039 allow the substitution of limestone for cement clinker at up to 15% by mass for certain US cements, with Canadian and European specifications allowing up to 35% mass substitution by limestone for certain blended cement types. Hydration behavior, microstructure, and performance are related to potential densification due to particle packing and surface nucleation effects, as well as minor reaction of the limestone resulting in the formation of carboaluminate phases; Reference Tennis, Thomas and Weiss40 these properties can be tailored to achieve desired performance. Energy and GHG reductions are proportional to the fraction of clinker replaced by limestone, according to lifecycle assessment. Reference Zaribaf, Uzal, Kurtis, Scrivener and Favier36

In addition, interest is growing in the large-scale use of alternative cement chemistries. Reference Shi, Jimenez and Palomo41–Reference Hicks, Caldarone and Besher46 Some of these, such as calcium aluminate, calcium sulfoaluminate, and magnesium phosphate cements, have been used for decades in specialty applications, such as for rapid repair, shrinkage compensation, and high-temperature resistance. Other materials systems, such as calcium sulfoaluminate belite (CSA) cement, chemically activated binders including geopolymers, and carbonate-based binders, are more recent innovations motivated in a significant way by sustainability interests. Alternative cements and other binder technologies have the potential to reduce the CO2 emissions associated with concrete production by approximately 40–60% compared to traditional cement formulations, depending on source materials, chemistry, and processing (as shown in Table I ), with additional innovations potentially leading to even greater contributions.

Table I. Relative CO2 emissions for alternative cements and other binder technologies on a gram-per-gram of material basis compared to ordinary portland cement. Reference Burris, Kurtis, Moser, Ley, Berke, Meininger and Morton58

Based on life-cycle assessments reported in References Reference Zaribaf, Uzal, Kurtis, Scrivener and Favier36 and Reference Gartner and Macphee43 using information provided in the references listed for each material system as indicated in the table.

* Emissions result from chemical activator manufacture and transportation only.

Such industrial-scale and commercially viable “green” cements have been developed, but in at least a few cases, their anticipated launch essentially coincided with the prior decade’s global economic downturn, which affected the construction sector quite heavily. Reference Gartner54 With recent reinvestments in construction and infrastructure, the introduction of new binder technologies is again anticipated. Reference Blackstock55–57 However, transitioning these materials from the laboratory to use in structural concrete requires investments in both research and new technology. Reference Burris, Alpati, Moser, Ley, Berke and Kurtis45 For example, extending the time to set for alternative materials traditionally used in repair is necessary to enable large-scale cast-in-place construction, and this will require both the study of hydration kinetics and the identification and perhaps development of new chemical admixtures. Reference Burris, Kurtis, Moser, Ley, Berke, Meininger and Morton58 A fundamental understanding of shrinkage and creep phenomena and characterization of long-term durability, through accelerated testing correlated with field performance studies, will be necessary to develop and validate service-life models. Reference Burris, Alpati, Moser, Ley, Berke and Kurtis45,Reference Burris, Kurtis, Moser, Ley, Berke, Meininger and Morton58

Alternative reinforcement strategies

Cement-based materials, although strong in compression, are inherently brittle, weak in tension, and prone to cracking. In structural applications, internal reinforcement with deformed reinforcing bars, twisted wire tendons, and randomly dispersed fibers enhances tensile capacity. In addition to the innovations in concrete formulations outlined in the preceding sections, innovations in reinforcement—including the use of bio-derived and corrosion-resistant reinforcement—further address the sustainability of concrete construction by contributing to the enhanced longevity of reinforced-concrete structures by limiting cracking and increasing tensile-load-carrying capacity.

Like pozzolans, bio-derived fibers have been used as reinforcement in cementitious composites since ancient times, but their development and use in construction applications has grown since their initial substitution for hazardous asbestos in cement siding. Reference Campbell and Coutts59 Because natural fibers are more renewable, economical, and abundant than other commonly used fibers in concrete, they are increasingly found in many cementitious products such as extruded nonpressure pipes and nonstructural building materials such as siding, cladding, and soffit panels. 60 Although their relatively low strength means that they cannot replace metallic reinforcements, emerging applications include the use of functionalized natural fibers for the control of cracking due to plastic shrinkage and as internal curing agents. Reference Kawashima and Shah61–Reference Westland and O’Callaghan63 Rapidly renewable species, such as eucalyptus, offer additional sustainability benefits while maintaining crack mitigation, even though their fibers are shorter than those of softwood. Reference Jongvisuttisun and Kurtis64,Reference Tonoli, Savastano, Fuente, Negro, Blanco and Lahr65

For continuous reinforcement (long bars or strands), corrosion-resistant options for infrastructure applications have grown in recent years and now include austenitic and duplex austenitic–ferritic stainless steels, duplex martensitic–ferritic steels, stainless-steel-clad mild steel, and glass fibers. Reference Azizinamini, Power, Myers and Ozyildirim66–Reference Clemena, Kukreja and Napier68 The primary motivation for the use of such materials is extending service life in marine and other corrosive environments (e.g., salt-laden bridge decks). For alternative binder systems that cannot adequately passivate steel from corrosion or for cases in which sufficiently high concentrations of chloride or other aggressive species are provided by ASCMs or SCMs blended with cement, reinforcement with such corrosion-resistant materials might be necessary for the production of durable concrete. The higher materials costs of austenitic or duplex stainless steel have been shown to be compensated by reductions in maintenance over a 75-year service life. Reference Azizinamini, Power, Myers and Ozyildirim66 Whereas stainless steels have more-than-adequate strength and corrosion resistance for infrastructure applications, Reference Moser, Singh, Kahn and Kurtis69 improvements in ductility are sought; investigations into twinning-induced plasticity can improve ductility while retaining strength, Reference Bouaziz, Allain, Scott, Cugy and Barbier70 but gains in stress-corrosion-cracking resistance and weldability are also desirable.

Role of standardization and specification in upscaling new materials technology

Significant challenges remain in “upscaling” emerging sustainable technologies from the laboratory scale to practical application in construction. The construction industry is relatively risk adverse, and since the 2008 economic crisis, there is perhaps even greater reluctance to accept additional risk associated with the adoption of new materials or technologies. Therefore, three strategies are critical in speeding practical acceptance of emerging and next-generation technologies: (1) standardization in materials evaluation; (2) site-production and field-exposure studies; and (3) modernization of industry-accepted design guidelines, specifications, and codes.

Consistent methods for assessing and comparing materials performance that can accommodate novel materials compositions and combinations in concretes are needed. ASTM International’s Standard Guide for Evaluation of Alternative Supplementary Cementitious Materials (ASCM) for Use in Concrete, adopted in 2011, is one step toward the guidance needed to ease acceptance of new materials technologies. 71 This document provides a step-by-step evaluation program that can be used in the initial evaluation of the use of a potential ASCM in combination with cement in concrete. Required performance levels on the metrics in the guide must, however, be defined by the user. Similar guides are needed for alternative cements and binders.

It is also vital that the durability of emerging technologies be understood in a range of environmental conditions, in the interest of sustainability as well as safety. Current standard test methods, which typically use conditions that accelerate degradation, must be evaluated for their suitability for nonconventional materials. Likewise, test procedures will need to be re-evaluated to account for fundamental differences in the materials themselves (e.g., variations in specific gravity affect porosity in cast samples), as well as their physical properties (e.g., prior assumptions relating the water-to-cementitious materials ratio to permeability might not be valid) and mechanical properties (e.g., strength development rates will vary). “Functional equivalence,” based on relevant criteria for specific accelerated test methods, will need to be established and practiced in a uniform and consistent manner such that the performance characteristics of different materials can be compared.

Some lessons can be learned only through field production and placement; controlled and documented large-scale field studies with these emerging technologies are needed. For example, whereas the fast reaction kinetics of some alternative binder systems are less problematic at the bench scale, rapid setting could occur in conventional concrete mixing trucks. Field experience has shown that mobile volumetric mixers might be required for large-scale placements with certain alternative binders, requiring a significant investment in equipment. Reference Ramseyer and Perez72 In addition, the behavior and results from accelerated durability tests must be assessed for consistency with field performance. Sites for studying long-term natural weathering of concrete and reinforced concrete materials, such as the one managed by the US Army Corps of Engineers since 1936 at Treat Island, Maine, will play an important role in understanding the durability of novel binders, ASCMs, and reinforcing materials (see Figure 2 ). Such data are needed to develop appropriate service-life models.

Figure 2. Because of tidal conditions and cold weather exposure, the natural weathering station maintained by the US Army Corps of Engineers at Treat Island, Maine, is useful for assessing the long-term durability of emerging concrete technologies, including alternative binders and blends of portland cement and supplementary and alternative supplementary cementitious materials.

Finally, design guidelines, codes, and specifications must be updated to accommodate emerging and next-generation materials and technologies. The shift over the prior decade from prescriptive to performance-based specifications facilitates this effort to some extent, as new materials can be considered as long-established performance criteria are met. However, as noted previously, performance requirements must be defined. In recent decades, the construction industry has begun evolving in that regard, expanding performance metrics beyond measurements of material workability (conventionally measured by the subsidence or “slump” of consolidated concrete after the removal of the conical form) and compressive strength (most conventionally measured after 28 days of moist curing) to include, for example, permeability, durability, and shrinkage criteria.

In some cases, the incorporation of novel materials into conventional infrastructure can contribute to sustainability through materials savings or improved performance. For example, considering the design of a concrete column, doubling the concrete compressive strength while requiring more cement per cubic meter of concrete results in a net cement savings of about one-fifth, because a smaller volume of concrete is required to carry the same load. Reference Schokker73 Such savings will come from broader recognition of the availability and benefits of new materials technologies and from the gains attainable by identifying appropriate performance metrics for a particular job.

Overall, a body of knowledge surrounding not only construction but also initial design and long-term performance of emerging technologies must be developed. Avoiding the “valley of death” (see the article in this issue by Philip Ball) in the translation of these technologies from the benchtop to the job site will require investments in research and field trials alike, as well as close interactions among researchers, educators, design and construction professionals, and professional organizations.

Acknowledgments

The author gratefully acknowledges the research support provided by the US Department of Transportation/Federal Highway Association, Georgia Department of Transportation, Southern Company, and Burgess Pigment.