1. Introduction

Drop impacts are omnipresent in nature and industry (Yarin Reference Yarin2006; Josserand & Thoroddsen Reference Josserand and Thoroddsen2016; Lohse Reference Lohse2022). Yet, until the seminal experiments of Xu, Zhang & Nagel (Reference Xu, Zhang and Nagel2005) exposed the dramatic influence of ambient pressure on splashing, the influence of air on drop impact processes remained largely neglected. Indeed, predicting most macroscopic quantities associated with drop impact, such as the spreading dynamics (Riboux & Gordillo Reference Riboux and Gordillo2014; Gordillo, Riboux & Quintero Reference Gordillo, Riboux and Quintero2019) or the maximal liquid imprint (Laan et al. Reference Laan, de Bruin, Bartolo, Josserand and Bonn2014; Wildeman et al. Reference Wildeman, Visser, Sun and Lohse2016), does not require us to take into account the mediating role of air, i.e. of a surrounding medium. The interaction mechanism between the impacting drop and the solid substrate works as follows: as the drop approaches, pressure builds up in the air trapped between the liquid and the substrate, deforming the drop interface which adopts a dimple shape (Mandre, Mani & Brenner Reference Mandre, Mani and Brenner2009; Hicks & Purvis Reference Hicks and Purvis2010; Mani, Mandre & Brenner Reference Mani, Mandre and Brenner2010; Bouwhuis et al. Reference Bouwhuis, van der Veen, Tran, Keij, Winkels, Peters, van der Meer, Sun, Snoeijer and Lohse2012; van der Veen et al. Reference van der Veen, Tran, Lohse and Sun2012). The edge of this central dimple region, the so-called neck, spreads radially as it moves downwards, and becomes increasingly sharp (Mandre et al. Reference Mandre, Mani and Brenner2009; Mani et al. Reference Mani, Mandre and Brenner2010; Duchemin & Josserand Reference Duchemin and Josserand2011; Kolinski et al. Reference Kolinski, Rubinstein, Mandre, Brenner, Weitz and Mahadevan2012). In most situations, air drains and liquid–solid contact occurs at the neck, resulting in the wetting of the substrate, and in the entrapment of a central bubble (Chandra & Avedisian Reference Chandra and Avedisian1991; Thoroddsen et al. Reference Thoroddsen, Etoh, Takehara, Ootsuka and Hatsuki2005), which gives a subtle clue to the mediating role of air. Experiments and theory suggest that this scenario is the relevant one for splashing, where the influence of air manifests itself at later times, as the liquid is radially ejected along the substrate (Driscoll & Nagel Reference Driscoll and Nagel2011; Riboux & Gordillo Reference Riboux and Gordillo2014). In remarkable cases, such as low velocity impacts on smooth surfaces (Reynolds Reference Reynolds1881; Pan & Law Reference Pan and Law2007; Kolinski, Mahadevan & Rubinstein Reference Kolinski, Mahadevan and Rubinstein2014a) or in the dynamic Leidenfrost regime (Leidenfrost Reference Leidenfrost1756; Tran et al. Reference Tran, Staat, Prosperetti, Sun and Lohse2012; Quéré Reference Quéré2013), the intervening gas layer prevents contact and allows drop rebound, strikingly affecting the outcome of impacts.

Understanding the role played by the surrounding medium is crucial in applications such as inkjet printing or in immersion lithography, where air entrapment is undesirable (Switkes et al. Reference Switkes, Rothschild, Shedd, Burnett and Yeung2005; Lohse Reference Lohse2022), or cooling processes, where heat transfer is strongly reduced in the presence of a gas layer (Kim Reference Kim2007; Breitenbach, Roisman & Tropea Reference Breitenbach, Roisman and Tropea2018). In this article, we focus on non-wetting situations, and set out to exhibit the physical mechanisms that prevent the initial drainage of the gas trapped between the drop and the surface. Two effects have been theoretically and numerically shown to hinder the neck's downward motion: capillarity and nonlinear advection (Mandre & Brenner Reference Mandre and Brenner2012). However, experiments on substrates kept at ambient temperature are limited to the regime where surface tension dominates the behaviour at the neck, as liquid–solid contact occurs when the impact velocity is increased (De Ruiter et al. Reference De Ruiter, Oh, van den Ende and Mugele2012). Here, we perform impacts on superheated substrates, where vapour generation allows for contactless drop rebound for a large range of impact velocities and substrate temperatures (Tran et al. Reference Tran, Staat, Prosperetti, Sun and Lohse2012; Shirota et al. Reference Shirota, van Limbeek, Sun, Prosperetti and Lohse2016), with the goal of experimentally accessing the nonlinear advection dominated regime. We stress that our results are not relevant to determining the critical velocity for the occurrence of contact, which is driven by additional physics, such as rarefied gas effects and van der Waals interactions in idealised situations (Chubynsky et al. Reference Chubynsky, Belousov, Lockerby and Sprittles2020), substrate roughness or contamination in experiments (Kolinski et al. Reference Kolinski, Mahadevan and Rubinstein2014a) or instabilities of the vapour layer in the superheated case (Chantelot & Lohse Reference Chantelot and Lohse2021; Harvey, Harper & Burton Reference Harvey, Harper and Burton2021).

The paper is organised as follows. In § 2, we detail the experimental set-up and control parameters. We next discuss the phenomenology of an impact and report the minimum thickness of the gas film trapped under an impacting drop (§ 3). In § 4, we model the evolution of the drop interface from an initially spherical shape to a dimple shape at its closest point of approach, and derive scaling relations accounting for the thickness of the gas layer in both the capillarity and nonlinear advection dominated regimes. The paper ends with conclusions and an outlook in § 5.

2. Experimental set-up and control parameters

2.1. Set-up

In this paper, we include and complement the data presented in Chantelot & Lohse (Reference Chantelot and Lohse2021), by extending them to higher surface temperatures and impact velocities. Our experiments (sketched in figure 1) consist of impacting ethanol drops on an optically smooth heated sapphire substrate (thermal conductivity, ![]() $k_s = 35$ W K

$k_s = 35$ W K![]() $^{-1}$ m

$^{-1}$ m![]() $^{-1}$). The ethanol–sapphire combination allows us to neglect vapour cooling effects during impact, leading us to assume approximately isothermal substrate conditions (Van Limbeek et al. Reference Van Limbeek, Shirota, Sleutel, Sun, Prosperetti and Lohse2016, Reference Van Limbeek, Schaarsberg, Sobac, Rednikov, Sun, Colinet and Lohse2017). The substrate temperature

$^{-1}$). The ethanol–sapphire combination allows us to neglect vapour cooling effects during impact, leading us to assume approximately isothermal substrate conditions (Van Limbeek et al. Reference Van Limbeek, Shirota, Sleutel, Sun, Prosperetti and Lohse2016, Reference Van Limbeek, Schaarsberg, Sobac, Rednikov, Sun, Colinet and Lohse2017). The substrate temperature ![]() $T_s$ is set to a fixed value between

$T_s$ is set to a fixed value between ![]() $22$ and

$22$ and ![]() $300\,^{\circ }{\rm C}$, allowing us to determine the superheat

$300\,^{\circ }{\rm C}$, allowing us to determine the superheat ![]() $\Delta T = T_s - T_b$, where

$\Delta T = T_s - T_b$, where ![]() $T_b = 78\,^{\circ }{\rm C}$ is the boiling temperature of ethanol. Drops with radius

$T_b = 78\,^{\circ }{\rm C}$ is the boiling temperature of ethanol. Drops with radius ![]() $R = 1.1 \pm 0.1$ mm are released from a calibrated needle, whose height is adjusted to obtain impact velocities

$R = 1.1 \pm 0.1$ mm are released from a calibrated needle, whose height is adjusted to obtain impact velocities ![]() $U$ ranging from 0.3 to 1.6 m s

$U$ ranging from 0.3 to 1.6 m s![]() $^{-1}$. Table 1 gives an overview of the properties of the liquid, with subscript

$^{-1}$. Table 1 gives an overview of the properties of the liquid, with subscript ![]() $l$, and of the two components of the gas phase: air and ethanol vapour, with subscripts

$l$, and of the two components of the gas phase: air and ethanol vapour, with subscripts ![]() $a$ and

$a$ and ![]() $v$, respectively. Note that the material properties of the fluids are temperature dependent (see Appendix A) and the temperature at which they should be evaluated will be discussed throughout the manuscript.

$v$, respectively. Note that the material properties of the fluids are temperature dependent (see Appendix A) and the temperature at which they should be evaluated will be discussed throughout the manuscript.

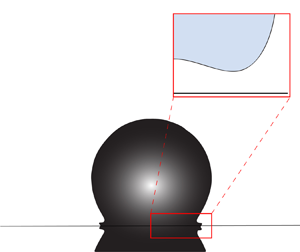

Figure 1. Ethanol drops with equilibrium radius ![]() $R$ and velocity

$R$ and velocity ![]() $U$ impact a sapphire substrate with temperature

$U$ impact a sapphire substrate with temperature ![]() $T_s$. We record side views and use total internal reflection (TIR) imaging to measure the thickness of the gas film squeezed between the liquid and the solid with two synchronised high-speed cameras. We sketch (not to scale) the typical deformation of the drop bottom interface and define the dimple height

$T_s$. We record side views and use total internal reflection (TIR) imaging to measure the thickness of the gas film squeezed between the liquid and the solid with two synchronised high-speed cameras. We sketch (not to scale) the typical deformation of the drop bottom interface and define the dimple height ![]() $h_d$, the neck height

$h_d$, the neck height ![]() $h_n$, its width

$h_n$, its width ![]() $\ell$ and its radial position

$\ell$ and its radial position ![]() $r_n$.

$r_n$.

Table 1. Physical properties of ethanol in the liquid (l) and vapour (v) phases and of air.

We study the impact dynamics using two synchronised high-speed cameras to obtain side views and interferometric measurements of the gas film (figure 1). We record side views at 20 000 frames per second (Photron Fastcam SA1.1) from which we determine the drop radius ![]() $R$ and the impact velocity

$R$ and the impact velocity ![]() $U$. We measure the gas film thickness using total internal reflection (TIR) imaging which gives quantitative absolute thickness measurements, provided the liquid–solid distance is of the order of the evanescent length scale (Kolinski et al. Reference Kolinski, Rubinstein, Mandre, Brenner, Weitz and Mahadevan2012; Shirota et al. Reference Shirota, van Limbeek, Lohse and Sun2017). Practically, TIR imaging enables us to measure film thicknesses ranging from a few tens to a few hundreds of nanometres, and to accurately monitor the occurrence of liquid–solid contact. The resulting images are recorded at a frame rate ranging from 225 000 to 480 000 frames per second (Photron Nova S12), which we checked to be sufficient to accurately monitor the gas film dynamics, using a long distance microscope with typical resolution

$U$. We measure the gas film thickness using total internal reflection (TIR) imaging which gives quantitative absolute thickness measurements, provided the liquid–solid distance is of the order of the evanescent length scale (Kolinski et al. Reference Kolinski, Rubinstein, Mandre, Brenner, Weitz and Mahadevan2012; Shirota et al. Reference Shirota, van Limbeek, Lohse and Sun2017). Practically, TIR imaging enables us to measure film thicknesses ranging from a few tens to a few hundreds of nanometres, and to accurately monitor the occurrence of liquid–solid contact. The resulting images are recorded at a frame rate ranging from 225 000 to 480 000 frames per second (Photron Nova S12), which we checked to be sufficient to accurately monitor the gas film dynamics, using a long distance microscope with typical resolution ![]() $10\,\mathrm {\mu }$m px

$10\,\mathrm {\mu }$m px![]() $^{-1}$. Details of the optical set-up, image processing and calibration of TIR measurements are given in Chantelot & Lohse (Reference Chantelot and Lohse2021).

$^{-1}$. Details of the optical set-up, image processing and calibration of TIR measurements are given in Chantelot & Lohse (Reference Chantelot and Lohse2021).

2.2. Control parameters

To identify the relevant physical effects for our choice of experimental parameters, we define and compute the values of the Weber, Reynolds, Stokes and Jakob numbers as independent variables

Note that our definition of the Stokes number, which compares inertial effects in the liquid with viscous effects in the gas (denoted by the subscript ![]() $g$), is the inverse of that of Mandre et al. (Reference Mandre, Mani and Brenner2009), but consistent with other publications on the subject.

$g$), is the inverse of that of Mandre et al. (Reference Mandre, Mani and Brenner2009), but consistent with other publications on the subject.

For millimetre sized ethanol drops, the chosen range of impact velocities corresponds to ![]() ${We} \gg 1$,

${We} \gg 1$, ![]() ${Re} \gg 1$ and

${Re} \gg 1$ and ![]() ${St} \gg 1$, indicating that inertia dominates capillary and viscous effects. The low value of the Ohnesorge number,

${St} \gg 1$, indicating that inertia dominates capillary and viscous effects. The low value of the Ohnesorge number, ![]() ${Oh} = \sqrt {{We}}/{Re} = 0.008$, further suggests that viscosity is negligible compared with capillarity. Finally, the Jakob number, which compares the sensible heat with the latent heat, takes the value

${Oh} = \sqrt {{We}}/{Re} = 0.008$, further suggests that viscosity is negligible compared with capillarity. Finally, the Jakob number, which compares the sensible heat with the latent heat, takes the value ![]() ${Ja} = 0.16$ so that we will assume the energetic cost of evaporation to be dominant compared with the cost of transiently heating the liquid to its boiling point (Shi et al. Reference Shi, Frank, Wang, Xu, Lu and Grigoropoulos2019).

${Ja} = 0.16$ so that we will assume the energetic cost of evaporation to be dominant compared with the cost of transiently heating the liquid to its boiling point (Shi et al. Reference Shi, Frank, Wang, Xu, Lu and Grigoropoulos2019).

3. Phenomenology

3.1. Sequence of events

In figure 2(a), we show side view snapshots of the impact of an ethanol drop with radius ![]() $R=1.1\,{\rm mm}$ and impact velocity

$R=1.1\,{\rm mm}$ and impact velocity ![]() $U = 1.2\,{\rm m}\,{\rm s}^{-1}$ (i.e.

$U = 1.2\,{\rm m}\,{\rm s}^{-1}$ (i.e. ![]() ${We} = 57$) on a substrate heated at

${We} = 57$) on a substrate heated at ![]() $T_s = 295\,^{\circ }{\rm C}$. We focus on the first instants of the interaction between the liquid and the substrate, that is for

$T_s = 295\,^{\circ }{\rm C}$. We focus on the first instants of the interaction between the liquid and the substrate, that is for ![]() $t \ll \tau _i$, where

$t \ll \tau _i$, where ![]() $\tau _i = R/U$ is the inertial time scale, a quantity of the order of a millisecond here.

$\tau _i = R/U$ is the inertial time scale, a quantity of the order of a millisecond here.

Figure 2. (a) Short-time side view snapshots of the impact of an ethanol drop with ![]() $R=1.1\,{\rm mm}$ and

$R=1.1\,{\rm mm}$ and ![]() $U = 1.2\,{\rm m}\,{\rm s}^{-1}$ (i.e.

$U = 1.2\,{\rm m}\,{\rm s}^{-1}$ (i.e. ![]() ${We} = 57$) on a substrate heated at

${We} = 57$) on a substrate heated at ![]() $T_s = 295\,^{\circ }{\rm C}$. Note that the side view is recorded at a small angle from the horizontal. (b) TIR snapshots for the impact pictured in (a). We show both the original grey scale frame and the reconstructed height field with a cutoff height of

$T_s = 295\,^{\circ }{\rm C}$. Note that the side view is recorded at a small angle from the horizontal. (b) TIR snapshots for the impact pictured in (a). We show both the original grey scale frame and the reconstructed height field with a cutoff height of ![]() $0.8\,\mathrm {\mu }$m. The origin of time is obtained by computing the estimated instant

$0.8\,\mathrm {\mu }$m. The origin of time is obtained by computing the estimated instant ![]() $t_0$ at which the drop centre would contact the solid in the absence of air

$t_0$ at which the drop centre would contact the solid in the absence of air ![]() $t_0 = r_{n,0}^2/(3RU)$, where

$t_0 = r_{n,0}^2/(3RU)$, where ![]() $r_{n,0}$ is the neck radius at the first instant the liquid enters within the evanescent length scale. (c) Time evolution of the azimuthally averaged neck radius

$r_{n,0}$ is the neck radius at the first instant the liquid enters within the evanescent length scale. (c) Time evolution of the azimuthally averaged neck radius ![]() $r_n(t)$ extracted from the TIR snapshots shown in (b). The solid line represents the prediction

$r_n(t)$ extracted from the TIR snapshots shown in (b). The solid line represents the prediction ![]() $r_n(t) = \sqrt {3URt}$ (Riboux & Gordillo Reference Riboux and Gordillo2014). (d) Azimuthally averaged neck height

$r_n(t) = \sqrt {3URt}$ (Riboux & Gordillo Reference Riboux and Gordillo2014). (d) Azimuthally averaged neck height ![]() $h_n(t)$. We denote by

$h_n(t)$. We denote by ![]() $h_m$ the azimuthally averaged minimum film thickness at short time. Movies (S1–S2) are in the supplementary movies available at https://doi.org/10.1017/jfm.2023.290.

$h_m$ the azimuthally averaged minimum film thickness at short time. Movies (S1–S2) are in the supplementary movies available at https://doi.org/10.1017/jfm.2023.290.

While side views only expose the radial spreading of the liquid on the inertial time scale, the bottom view TIR snapshots, that display both the original grey scale images and the calculated height fields, reveal the presence of the gas film that mediates the drop–substrate interaction (figure 2b). The drop appears as a ring, evidencing that, as it interacts with the substrate, the liquid–gas interface deforms from its initially spherical shape to that of a dimple bordered by a region of high local curvature closest to the substrate (the neck, see the inset of figure 2(d) and Mandre et al. Reference Mandre, Mani and Brenner2009; Hicks & Purvis Reference Hicks and Purvis2010; Bouwhuis et al. Reference Bouwhuis, van der Veen, Tran, Keij, Winkels, Peters, van der Meer, Sun, Snoeijer and Lohse2012). This region, the so-called neck, moves downwards and radially outwards until the minimum thickness is reached (![]() $t = 0.007\,{\rm ms}$). Contrasting with impacts on non-superheated substrates, we observe that the neck's vertical motion later reverses: it moves upwards as it spreads radially (

$t = 0.007\,{\rm ms}$). Contrasting with impacts on non-superheated substrates, we observe that the neck's vertical motion later reverses: it moves upwards as it spreads radially (![]() $t = 0.013$ and

$t = 0.013$ and ![]() $t = 0.030\,{\rm ms}$), a marker of the influence of vapour generation.

$t = 0.030\,{\rm ms}$), a marker of the influence of vapour generation.

We characterise the neck motion by tracking the azimuthally averaged neck radius ![]() $r_n(t)$ (figure 2c) and height

$r_n(t)$ (figure 2c) and height ![]() $h_n(t) = h(r_n(t),t)$ (figure 2d). As expected, the neck radius follows the prediction

$h_n(t) = h(r_n(t),t)$ (figure 2d). As expected, the neck radius follows the prediction ![]() $r_n(t) = \sqrt {3URt}$. The deviation from the prediction at long times is not systematic in our data, and here it can be attributed to the prolate shape of the drop at impact (see figure 2(a),

$r_n(t) = \sqrt {3URt}$. The deviation from the prediction at long times is not systematic in our data, and here it can be attributed to the prolate shape of the drop at impact (see figure 2(a), ![]() $t = 0.2\,{\rm ms}$). This agreement indicates the relevance of the description of impacts derived under the assumption of the absence of an intervening gas layer (Riboux & Gordillo Reference Riboux and Gordillo2014; Gordillo et al. Reference Gordillo, Riboux and Quintero2019), and the negligible influence of vapour generation on the radial dynamics (Shirota et al. Reference Shirota, van Limbeek, Sun, Prosperetti and Lohse2016; Chantelot & Lohse Reference Chantelot and Lohse2021). Note that the time origin is obtained by computing the estimated instant

$t = 0.2\,{\rm ms}$). This agreement indicates the relevance of the description of impacts derived under the assumption of the absence of an intervening gas layer (Riboux & Gordillo Reference Riboux and Gordillo2014; Gordillo et al. Reference Gordillo, Riboux and Quintero2019), and the negligible influence of vapour generation on the radial dynamics (Shirota et al. Reference Shirota, van Limbeek, Sun, Prosperetti and Lohse2016; Chantelot & Lohse Reference Chantelot and Lohse2021). Note that the time origin is obtained by computing the estimated instant ![]() $t_0$ at which the drop centre would contact the solid in the absence of air

$t_0$ at which the drop centre would contact the solid in the absence of air ![]() $t_0 = r_{n,0}^2/(3RU)$, where

$t_0 = r_{n,0}^2/(3RU)$, where ![]() $r_{n,0}$ is the neck radius at the first instant the liquid enters within the evanescent length scale. Tracking the azimuthally averaged neck height

$r_{n,0}$ is the neck radius at the first instant the liquid enters within the evanescent length scale. Tracking the azimuthally averaged neck height ![]() $h_n(t)$ allows us to determine the azimuthally averaged minimum gas film thickness

$h_n(t)$ allows us to determine the azimuthally averaged minimum gas film thickness ![]() $h_m$ (figure 2d). We now focus on identifying the effect of the impact velocity

$h_m$ (figure 2d). We now focus on identifying the effect of the impact velocity ![]() $U$ and the substrate temperature

$U$ and the substrate temperature ![]() $T_s$ on

$T_s$ on ![]() $h_m$. Indeed, in contrast to the radial dynamics, the vertical motion of the neck is strongly affected by evaporation.

$h_m$. Indeed, in contrast to the radial dynamics, the vertical motion of the neck is strongly affected by evaporation.

3.2. Minimum film thickness

In figure 3(a), we plot the minimum gas film thickness ![]() $h_m$ as a function of the impact velocity for

$h_m$ as a function of the impact velocity for ![]() $T_s$ varying from

$T_s$ varying from ![]() $105$ to

$105$ to ![]() $295\,^{\circ }{\rm C}$. The minimum distance separating the liquid from the solid is of the order of a few hundred nanometres, and we do not observe film thicknesses below 200 nm due to the occurrence of liquid–solid contact driven by isolated surface asperities or contamination (De Ruiter et al. Reference De Ruiter, Oh, van den Ende and Mugele2012; Kolinski et al. Reference Kolinski, Mahadevan and Rubinstein2014a; Chantelot & Lohse Reference Chantelot and Lohse2021).

$295\,^{\circ }{\rm C}$. The minimum distance separating the liquid from the solid is of the order of a few hundred nanometres, and we do not observe film thicknesses below 200 nm due to the occurrence of liquid–solid contact driven by isolated surface asperities or contamination (De Ruiter et al. Reference De Ruiter, Oh, van den Ende and Mugele2012; Kolinski et al. Reference Kolinski, Mahadevan and Rubinstein2014a; Chantelot & Lohse Reference Chantelot and Lohse2021).

Figure 3. (a) Minimum film thickness ![]() $h_m$ as a function of the impact velocity

$h_m$ as a function of the impact velocity ![]() $U$ for substrate temperatures

$U$ for substrate temperatures ![]() $T_s$ ranging from

$T_s$ ranging from ![]() $105$ to

$105$ to ![]() $295\,^{\circ }{\rm C}$. The dashed lines represent the prediction in the capillary regime (4.12) with prefactor

$295\,^{\circ }{\rm C}$. The dashed lines represent the prediction in the capillary regime (4.12) with prefactor ![]() $5.6 \pm 0.8$, and the solid lines stand for the prediction in the nonlinear advection regime (4.13) with prefactor

$5.6 \pm 0.8$, and the solid lines stand for the prediction in the nonlinear advection regime (4.13) with prefactor ![]() $3.4 \pm 0.3$. The error bars are empirically determined from the calibration of the TIR set-up against a concave lens of known radius of curvature (see Chantelot & Lohse Reference Chantelot and Lohse2021). (b) Plot of the minimum film thickness compensated by the prediction of (4.12),

$3.4 \pm 0.3$. The error bars are empirically determined from the calibration of the TIR set-up against a concave lens of known radius of curvature (see Chantelot & Lohse Reference Chantelot and Lohse2021). (b) Plot of the minimum film thickness compensated by the prediction of (4.12), ![]() $h_m/(R{We}^{-1}\mathcal {E}^{1/2})$, as a function of

$h_m/(R{We}^{-1}\mathcal {E}^{1/2})$, as a function of ![]() $St^{2/3}\mathcal {E}^{1/2}$, highlighting the transition from the capillary dominated regime (dashed line), to the advection dominated regime (solid line).

$St^{2/3}\mathcal {E}^{1/2}$, highlighting the transition from the capillary dominated regime (dashed line), to the advection dominated regime (solid line).

The minimum thickness is strongly affected by the substrate temperature: at fixed impact velocity, ![]() $h_m$ monotonically increases with increasing superheat. For fixed

$h_m$ monotonically increases with increasing superheat. For fixed ![]() $T_s$ and

$T_s$ and ![]() $R$, the data suggest a power-law decay of

$R$, the data suggest a power-law decay of ![]() $h_m$ with

$h_m$ with ![]() $U$,

$U$, ![]() $h_m \propto U^{-\alpha }$. The exponent associated with this power-law decay decreases as larger impact velocities are probed and the substrate temperature is increased. Indeed, while from

$h_m \propto U^{-\alpha }$. The exponent associated with this power-law decay decreases as larger impact velocities are probed and the substrate temperature is increased. Indeed, while from ![]() $T_s = 105$ to

$T_s = 105$ to ![]() $T_s = 178\,^{\circ }{\rm C}$ the observed exponent is in agreement with the value

$T_s = 178\,^{\circ }{\rm C}$ the observed exponent is in agreement with the value ![]() $\alpha = 2.0 \pm 0.2$ reported by Chantelot & Lohse (Reference Chantelot and Lohse2021), the data suggest that

$\alpha = 2.0 \pm 0.2$ reported by Chantelot & Lohse (Reference Chantelot and Lohse2021), the data suggest that ![]() $\alpha$ deviates from this value at larger superheat and impact velocities. Qualitatively, this behaviour is reminiscent of that observed by Mandre & Brenner (Reference Mandre and Brenner2012) at the transition from capillary to inertial dominance at the neck, yet it is markedly different as the strong influence of

$\alpha$ deviates from this value at larger superheat and impact velocities. Qualitatively, this behaviour is reminiscent of that observed by Mandre & Brenner (Reference Mandre and Brenner2012) at the transition from capillary to inertial dominance at the neck, yet it is markedly different as the strong influence of ![]() $T_s$ discriminates this case from impacts on non-superheated substrates.

$T_s$ discriminates this case from impacts on non-superheated substrates.

4. Modelling the minimum film thickness

We now seek to understand and predict the evolution of the minimum gas film thickness ![]() $h_m$ with the impact velocity

$h_m$ with the impact velocity ![]() $U$ and substrate temperature

$U$ and substrate temperature ![]() $T_s$. We model the initial approach of the drop, i.e. the evolution of the drop interface from a spherical to a dimple shape until

$T_s$. We model the initial approach of the drop, i.e. the evolution of the drop interface from a spherical to a dimple shape until ![]() $h_m$ is reached at the neck. We extend the model of Mandre et al. (Reference Mandre, Mani and Brenner2009), Mani et al. (Reference Mani, Mandre and Brenner2010) and Mandre & Brenner (Reference Mandre and Brenner2012), derived in the absence of evaporation, further building on our previous work on heated surfaces (Chantelot & Lohse Reference Chantelot and Lohse2021) by going beyond the capillary regime.

$h_m$ is reached at the neck. We extend the model of Mandre et al. (Reference Mandre, Mani and Brenner2009), Mani et al. (Reference Mani, Mandre and Brenner2010) and Mandre & Brenner (Reference Mandre and Brenner2012), derived in the absence of evaporation, further building on our previous work on heated surfaces (Chantelot & Lohse Reference Chantelot and Lohse2021) by going beyond the capillary regime.

4.1. Governing equations

For completeness, we recall the equations of motion for the drop liquid and the gas film in the presence of superheat. We consider a two-dimensional geometry, following Mani et al. (Reference Mani, Mandre and Brenner2010), and model the drop liquid as an incompressible fluid:

where ![]() $p_l$ is the liquid pressure, and

$p_l$ is the liquid pressure, and ![]() $\boldsymbol {u} = (u_l,v_l)$ are the velocity components in the

$\boldsymbol {u} = (u_l,v_l)$ are the velocity components in the ![]() $x$ (replacing

$x$ (replacing ![]() $r$ in this two-dimensional model) and

$r$ in this two-dimensional model) and ![]() $z$ directions, respectively. The viscous and nonlinear inertia terms, on the right-hand side of (4.1a), are initially considered to be negligible, owing to the large liquid Reynolds number and the absence of velocity gradients in the drop during free fall, respectively. We obtain an equation for the motion of the interface

$z$ directions, respectively. The viscous and nonlinear inertia terms, on the right-hand side of (4.1a), are initially considered to be negligible, owing to the large liquid Reynolds number and the absence of velocity gradients in the drop during free fall, respectively. We obtain an equation for the motion of the interface ![]() $h(x,t)$ by projecting (4.1a) in the vertical direction and evaluating it at

$h(x,t)$ by projecting (4.1a) in the vertical direction and evaluating it at ![]() $z=0$ (Mani et al. Reference Mani, Mandre and Brenner2010):

$z=0$ (Mani et al. Reference Mani, Mandre and Brenner2010):

where we used the kinematic boundary condition ![]() $\partial h/\partial t = v_l - u_l\partial h/\partial x$.

$\partial h/\partial t = v_l - u_l\partial h/\partial x$.

Next, we describe the flow in the gas layer. We do not take into account gas compressibility and non-continuum effects which set in at larger impact speeds than those probed in this study (Mandre & Brenner Reference Mandre and Brenner2012). We use the viscous lubrication approximation as the gas film is thin, ![]() $h \ll R$, and the typical value of the gas Reynolds number

$h \ll R$, and the typical value of the gas Reynolds number ![]() $Re_g = \rho _g h U / \eta _g$ is much smaller than one. It reads

$Re_g = \rho _g h U / \eta _g$ is much smaller than one. It reads

where ![]() $p_g$ is the gas pressure and we have again used the kinematic boundary condition. The influence of evaporation appears as a source term, derived under the assumptions of (i) conductive heat transfer through the gas layer, and (ii) dominant energetic cost of latent heat compared with sensible heat (i.e.

$p_g$ is the gas pressure and we have again used the kinematic boundary condition. The influence of evaporation appears as a source term, derived under the assumptions of (i) conductive heat transfer through the gas layer, and (ii) dominant energetic cost of latent heat compared with sensible heat (i.e. ![]() ${Ja} \ll 1$) (Biance, Clanet & Quéré Reference Biance, Clanet and Quéré2003; Sobac et al. Reference Sobac, Rednikov, Dorbolo and Colinet2014; Chantelot & Lohse Reference Chantelot and Lohse2021).

${Ja} \ll 1$) (Biance, Clanet & Quéré Reference Biance, Clanet and Quéré2003; Sobac et al. Reference Sobac, Rednikov, Dorbolo and Colinet2014; Chantelot & Lohse Reference Chantelot and Lohse2021).

Finally, the liquid and gas pressures are related by the Laplace pressure jump at the interface:

where ![]() $\kappa = \partial ^2 h/\partial x^2 /(1+(\partial h/\partial x)^2)^{3/2}$ is the interface curvature.

$\kappa = \partial ^2 h/\partial x^2 /(1+(\partial h/\partial x)^2)^{3/2}$ is the interface curvature.

4.2. Dominant balance

To identify the relevant contributions, it is convenient to non-dimensionalise equations (4.2)–(4.4) using the scales involved in dimple formation (Mandre et al. Reference Mandre, Mani and Brenner2009; Hicks & Purvis Reference Hicks and Purvis2010; Mani et al. Reference Mani, Mandre and Brenner2010; Bouwhuis et al. Reference Bouwhuis, van der Veen, Tran, Keij, Winkels, Peters, van der Meer, Sun, Snoeijer and Lohse2012), that have also been shown to be relevant for impacts on superheated substrates (Chantelot & Lohse Reference Chantelot and Lohse2021). Using the transformations

\begin{equation} \left.\begin{gathered} (x, z) = R {St}^{{-}1/3} (\tilde{x}, \tilde{z}),\quad h = R{St}^{{-}2/3}\tilde{h},\quad \boldsymbol{u} = U\tilde{\boldsymbol{u}}, \\ t = \frac{R {St}^{{-}2/3}}{U}\tilde{t}, \quad (p_l, p_g) = \frac{\eta_g U}{R {St}^{{-}4/3}}(\tilde{p}_l, \tilde{p}_g), \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} (x, z) = R {St}^{{-}1/3} (\tilde{x}, \tilde{z}),\quad h = R{St}^{{-}2/3}\tilde{h},\quad \boldsymbol{u} = U\tilde{\boldsymbol{u}}, \\ t = \frac{R {St}^{{-}2/3}}{U}\tilde{t}, \quad (p_l, p_g) = \frac{\eta_g U}{R {St}^{{-}4/3}}(\tilde{p}_l, \tilde{p}_g), \end{gathered}\right\} \end{equation}the governing equations become

$$\begin{gather} \frac{\partial^2 \tilde{h}}{\partial \tilde{t}^2} + \frac{\partial \tilde{p}_l}{\partial \tilde{z}} = \frac{1}{{Re}} \left( \frac{\partial^2 \tilde{v}_l}{\partial \tilde{x}^2} + \frac{\partial^2 \tilde{v}_l}{\partial \tilde{z}^2} \right) - {St}^{{-}1/3} \left( \tilde{u}_l\frac{\partial \tilde{v}_l}{\partial \tilde{x}} + \tilde{v}_l \frac{\partial \tilde{v}_l}{\partial \tilde{z}} + \frac{\partial}{\partial \tilde{t}} \left({\tilde{u}_l}\frac{\partial \tilde{h}}{\partial \tilde{x}}\right)\right), \end{gather}$$

$$\begin{gather} \frac{\partial^2 \tilde{h}}{\partial \tilde{t}^2} + \frac{\partial \tilde{p}_l}{\partial \tilde{z}} = \frac{1}{{Re}} \left( \frac{\partial^2 \tilde{v}_l}{\partial \tilde{x}^2} + \frac{\partial^2 \tilde{v}_l}{\partial \tilde{z}^2} \right) - {St}^{{-}1/3} \left( \tilde{u}_l\frac{\partial \tilde{v}_l}{\partial \tilde{x}} + \tilde{v}_l \frac{\partial \tilde{v}_l}{\partial \tilde{z}} + \frac{\partial}{\partial \tilde{t}} \left({\tilde{u}_l}\frac{\partial \tilde{h}}{\partial \tilde{x}}\right)\right), \end{gather}$$

where we introduced the evaporation number ![]() $\mathcal {E}$ (Sobac et al. Reference Sobac, Rednikov, Dorbolo and Colinet2014),

$\mathcal {E}$ (Sobac et al. Reference Sobac, Rednikov, Dorbolo and Colinet2014),

that can be understood as the ratio of the lubrication pressure originating from the evaporation source term ![]() $\eta _g k_g \Delta T/(\rho _g R^2 \mathcal {L})$ and the capillary pressure

$\eta _g k_g \Delta T/(\rho _g R^2 \mathcal {L})$ and the capillary pressure ![]() $\gamma /R$.

$\gamma /R$.

If the substrate is not superheated (i.e. ![]() $\mathcal {E} = 0$), (4.6)–(4.8) are identical to those obtained by Mandre & Brenner (Reference Mandre and Brenner2012), and the dominant balance is obtained from the left-hand side terms (see Appendix B). When

$\mathcal {E} = 0$), (4.6)–(4.8) are identical to those obtained by Mandre & Brenner (Reference Mandre and Brenner2012), and the dominant balance is obtained from the left-hand side terms (see Appendix B). When ![]() $\mathcal {E} > 0$, the left-hand sides of (4.6) and (4.8) still contain the dominant balance as

$\mathcal {E} > 0$, the left-hand sides of (4.6) and (4.8) still contain the dominant balance as ![]() ${We} \gg 1$,

${We} \gg 1$, ![]() ${Re} \gg 1$ and

${Re} \gg 1$ and ![]() ${St} \gg 1$. Yet, the evaporative source term cannot be neglected a priori in the lubrication equation (4.7). We hypothesise that in superheated conditions the gas flow is driven by the contribution of evaporation in the neck region as the substrate temperature strongly influences the minimum thickness

${St} \gg 1$. Yet, the evaporative source term cannot be neglected a priori in the lubrication equation (4.7). We hypothesise that in superheated conditions the gas flow is driven by the contribution of evaporation in the neck region as the substrate temperature strongly influences the minimum thickness ![]() $h_m$ (figure 3a), and as we estimate that the liquid–gas interface can be heated up to the liquid's boiling point on the time scale at which

$h_m$ (figure 3a), and as we estimate that the liquid–gas interface can be heated up to the liquid's boiling point on the time scale at which ![]() $h_m$ is reached (i.e. of the order of

$h_m$ is reached (i.e. of the order of ![]() $10\,\mathrm {\mu }$s, see Appendix C). Under this assumption, the dominant balance is obtained by equating the gas pressure term and the evaporative source term in (4.7).

$10\,\mathrm {\mu }$s, see Appendix C). Under this assumption, the dominant balance is obtained by equating the gas pressure term and the evaporative source term in (4.7).

4.3. Neck solution

We now look for a solution of the governing equations that describes the neck motion, that is the horizontal and vertical motions of the curved region of radial extent ![]() $\ell$ located at

$\ell$ located at ![]() $x = x_n(t)$ (

$x = x_n(t)$ (![]() $x_n$ replacing

$x_n$ replacing ![]() $r_n$ in this two-dimensional model). Using pressure continuity at the liquid–gas interface (

$r_n$ in this two-dimensional model). Using pressure continuity at the liquid–gas interface (![]() $\tilde {p} = \tilde{p}_l = \tilde {p}_g$), as the right-hand side of (4.8) is initially negligible, we construct a solution by adopting the following self-similar ansatz in the vicinity of the neck for the interface height and the pressure:

$\tilde {p} = \tilde{p}_l = \tilde {p}_g$), as the right-hand side of (4.8) is initially negligible, we construct a solution by adopting the following self-similar ansatz in the vicinity of the neck for the interface height and the pressure:

where ![]() $\varTheta (\tilde {x},\tilde {t}) = (\tilde {x} - \tilde {x}_n(\tilde {t}))/\widetilde {\ell }(\tilde {t})$ is the self-similar variable. Introducing the self-similar fields in (4.6) and (4.7), we obtain scaling relationships for the length scale and pressure at the neck from the dominant balance in superheated conditions (i.e. when

$\varTheta (\tilde {x},\tilde {t}) = (\tilde {x} - \tilde {x}_n(\tilde {t}))/\widetilde {\ell }(\tilde {t})$ is the self-similar variable. Introducing the self-similar fields in (4.6) and (4.7), we obtain scaling relationships for the length scale and pressure at the neck from the dominant balance in superheated conditions (i.e. when ![]() $\mathcal {E} > 0$):

$\mathcal {E} > 0$):

To derive (4.11a,b), we assumed: (i) that the time derivatives are dominated by their advective contribution ![]() $\partial / \partial \tilde {t} \approx \dot {\tilde {x}}_n \partial /\partial \tilde {x}$, where

$\partial / \partial \tilde {t} \approx \dot {\tilde {x}}_n \partial /\partial \tilde {x}$, where ![]() $\dot {\tilde {x}}_n$ is a constant for a fixed set of control parameters (Mani et al. Reference Mani, Mandre and Brenner2010), and (ii) that the vertical pressure gradient in the liquid scales as

$\dot {\tilde {x}}_n$ is a constant for a fixed set of control parameters (Mani et al. Reference Mani, Mandre and Brenner2010), and (ii) that the vertical pressure gradient in the liquid scales as ![]() $\tilde {p}_l/\widetilde {\ell }$. Indeed, as the nonlinear terms on the right-hand side of (4.6) are initially negligible,

$\tilde {p}_l/\widetilde {\ell }$. Indeed, as the nonlinear terms on the right-hand side of (4.6) are initially negligible, ![]() $\tilde {p}_l$ follows a Laplace equation.

$\tilde {p}_l$ follows a Laplace equation.

Equations (4.11a,b) differ in two important ways from those obtained by Mani et al. (Reference Mani, Mandre and Brenner2010) in the absence of evaporation (B1a,b). (i) They explicitly involve the superheat through the influence of the evaporation number ![]() $\mathcal {E}$. (ii) The dependency of

$\mathcal {E}$. (ii) The dependency of ![]() $\widetilde {\ell }$ and

$\widetilde {\ell }$ and ![]() $\tilde {p}_n$ on

$\tilde {p}_n$ on ![]() $\tilde {h}_n$ is modified, with the neck length scale following a power law with

$\tilde {h}_n$ is modified, with the neck length scale following a power law with ![]() $\tilde {h}_n$ with an exponent

$\tilde {h}_n$ with an exponent ![]() $2$ instead of

$2$ instead of ![]() $3/2$, and with the neck pressure following a power law with

$3/2$, and with the neck pressure following a power law with ![]() $\tilde {h}_n$ with an exponent

$\tilde {h}_n$ with an exponent ![]() $-1$ instead of

$-1$ instead of ![]() $-1/2$. Yet, with or without superheat, the horizontal extent of the neck region

$-1/2$. Yet, with or without superheat, the horizontal extent of the neck region ![]() $\widetilde {\ell }$ vanishes and the pressure

$\widetilde {\ell }$ vanishes and the pressure ![]() $\tilde {p}_n$ diverges as the neck thickness

$\tilde {p}_n$ diverges as the neck thickness ![]() $\tilde {h}_n$ decreases. Close to this divergence, it is essential to check if the self-similar solution is consistent, by assessing the importance of initially neglected physical effects. Following Mandre & Brenner (Reference Mandre and Brenner2012), we discuss the influence of capillary and nonlinear inertia effects as

$\tilde {h}_n$ decreases. Close to this divergence, it is essential to check if the self-similar solution is consistent, by assessing the importance of initially neglected physical effects. Following Mandre & Brenner (Reference Mandre and Brenner2012), we discuss the influence of capillary and nonlinear inertia effects as ![]() $\tilde {h}_n$ tends towards zero.

$\tilde {h}_n$ tends towards zero.

4.3.1. Surface tension dominated regime

The curvature of the liquid–gas interface in the neck region, ![]() $\tilde {\kappa } \sim \tilde {h}_n/\widetilde {\ell }^2$, diverges as the drop approaches the substrate. The Laplace pressure associated with this curvature, proportional to

$\tilde {\kappa } \sim \tilde {h}_n/\widetilde {\ell }^2$, diverges as the drop approaches the substrate. The Laplace pressure associated with this curvature, proportional to ![]() $\tilde {h}_n^{-3}$, diverges faster than the neck pressure, which evolves as

$\tilde {h}_n^{-3}$, diverges faster than the neck pressure, which evolves as ![]() $\tilde {h}_n^{-1}$. Capillary effects regularise the interfacial singularity as the Laplace pressure becomes of the order of the neck pressure, setting the minimum thickness of the gas film:

$\tilde {h}_n^{-1}$. Capillary effects regularise the interfacial singularity as the Laplace pressure becomes of the order of the neck pressure, setting the minimum thickness of the gas film:

as already derived in Chantelot & Lohse (Reference Chantelot and Lohse2021). For a fixed drop radius and superheat, (4.12) predicts a power-law decrease of the minimum thickness with the impact velocity, ![]() $h_m \propto U^{-2}$, that differs from that obtained for non-superheated impacts,

$h_m \propto U^{-2}$, that differs from that obtained for non-superheated impacts, ![]() $h_m \propto U^{-20/9}$ (B2). This power law is in qualitative agreement with the experimental data for

$h_m \propto U^{-20/9}$ (B2). This power law is in qualitative agreement with the experimental data for ![]() $T_s \le 178\,^{\circ }\textrm {C}$. Equation (4.12) also predicts the increase of the minimum thickness with the superheat,

$T_s \le 178\,^{\circ }\textrm {C}$. Equation (4.12) also predicts the increase of the minimum thickness with the superheat, ![]() $h_m \propto \Delta T^{1/2}$ for fixed impact parameters and material properties. Yet, the dependence of

$h_m \propto \Delta T^{1/2}$ for fixed impact parameters and material properties. Yet, the dependence of ![]() $h_m$ on

$h_m$ on ![]() $\Delta T$ is not directly given by a power law, as the material properties are temperature dependent. To quantitatively test the influence of

$\Delta T$ is not directly given by a power law, as the material properties are temperature dependent. To quantitatively test the influence of ![]() $\Delta T$, we take into account the temperature dependence of the gas properties and the reduced surface tension of the liquid–gas interface heated at its boiling point (

$\Delta T$, we take into account the temperature dependence of the gas properties and the reduced surface tension of the liquid–gas interface heated at its boiling point (![]() $\gamma = 0.017$ N m

$\gamma = 0.017$ N m![]() $^{-1}$ at

$^{-1}$ at ![]() $T_b$). We evaluate the gas viscosity

$T_b$). We evaluate the gas viscosity ![]() $\eta _g$, thermal conductivity

$\eta _g$, thermal conductivity ![]() $k_g$ and density

$k_g$ and density ![]() $\rho _g$ at

$\rho _g$ at ![]() $(T_s+T_b)/2$, as the conduction time scale

$(T_s+T_b)/2$, as the conduction time scale ![]() $h^2\rho _g C_{p,g}/k_g \approx 0.1\,\mathrm {\mu }$s suggests that steady state conductive heat transfer is applicable in the gas layer, and we further assume that, in the neck region, the gas phase is constituted of ethanol vapour. In figure 3(a), we plot the prediction of (4.12) with a prefactor

$h^2\rho _g C_{p,g}/k_g \approx 0.1\,\mathrm {\mu }$s suggests that steady state conductive heat transfer is applicable in the gas layer, and we further assume that, in the neck region, the gas phase is constituted of ethanol vapour. In figure 3(a), we plot the prediction of (4.12) with a prefactor ![]() $5.6 \pm 0.8$ obtained from a fit of the data for

$5.6 \pm 0.8$ obtained from a fit of the data for ![]() $T_s \le 178\,^{\circ }\textrm {C}$ (dashed lines). The scaling relation quantitatively captures the temperature dependence of the minimum thickness

$T_s \le 178\,^{\circ }\textrm {C}$ (dashed lines). The scaling relation quantitatively captures the temperature dependence of the minimum thickness ![]() $h_m$, as well as its decrease with increasing impact velocity for

$h_m$, as well as its decrease with increasing impact velocity for ![]() $T_s \le 178\,^{\circ }\textrm {C}$. However, the data for larger superheat deviate from the expected scaling relationship, as evidenced by plotting (4.12) for

$T_s \le 178\,^{\circ }\textrm {C}$. However, the data for larger superheat deviate from the expected scaling relationship, as evidenced by plotting (4.12) for ![]() $T_s = 230\,^{\circ }\textrm {C}$ (dashed line). We now rationalise this deviation.

$T_s = 230\,^{\circ }\textrm {C}$ (dashed line). We now rationalise this deviation.

4.3.2. Nonlinear advection dominated regime

Similarly as for the interface curvature, the nonlinear advective term diverges as the thickness at the neck vanishes. Equation (4.6) allows us to estimate the pressure associated with the nonlinear advective term which scales as ![]() ${St}^{-1/3}\tilde {h}_n^2/\widetilde {\ell }^2$, assuming that

${St}^{-1/3}\tilde {h}_n^2/\widetilde {\ell }^2$, assuming that ![]() $\tilde {v}_l \sim \partial \tilde {h}_n/\partial \tilde {t}$ and that the time derivatives are advection dominated (Mandre & Brenner Reference Mandre and Brenner2012). Using (4.11a), which relates the neck length scale

$\tilde {v}_l \sim \partial \tilde {h}_n/\partial \tilde {t}$ and that the time derivatives are advection dominated (Mandre & Brenner Reference Mandre and Brenner2012). Using (4.11a), which relates the neck length scale ![]() $\widetilde {\ell }$ to the neck height

$\widetilde {\ell }$ to the neck height ![]() $\tilde {h}_n$, we find that this pressure is proportional to

$\tilde {h}_n$, we find that this pressure is proportional to ![]() $\tilde {h}_n^{-2}$, indicating that it blows up faster than the neck pressure

$\tilde {h}_n^{-2}$, indicating that it blows up faster than the neck pressure ![]() $\tilde {p}_n \propto \tilde {h}_n^{-1}$. Nonlinear effects come into play as the pressure associated with nonlinear advection becomes of the same order as the neck pressure

$\tilde {p}_n \propto \tilde {h}_n^{-1}$. Nonlinear effects come into play as the pressure associated with nonlinear advection becomes of the same order as the neck pressure ![]() $\tilde {p}_n$ (4.11b), giving a scaling relation for the minimum thickness:

$\tilde {p}_n$ (4.11b), giving a scaling relation for the minimum thickness:

Equation (4.13) predicts a power-law decrease of the minimum thickness with the impact velocity, ![]() $h_m \propto U^{-4/3}$, for a fixed drop radius and superheat. The exponent associated with this power-law decay is lower than that identified in the capillary regime, where

$h_m \propto U^{-4/3}$, for a fixed drop radius and superheat. The exponent associated with this power-law decay is lower than that identified in the capillary regime, where ![]() $h_m \propto U^{-2}$, in qualitative agreement with our measurements, and it is equal to that reported by Mandre & Brenner (Reference Mandre and Brenner2012) in the advection dominated regime (B3). For fixed impact parameters and material properties, (4.13) also predicts the increase of

$h_m \propto U^{-2}$, in qualitative agreement with our measurements, and it is equal to that reported by Mandre & Brenner (Reference Mandre and Brenner2012) in the advection dominated regime (B3). For fixed impact parameters and material properties, (4.13) also predicts the increase of ![]() $h_m$ with

$h_m$ with ![]() $\Delta T$,

$\Delta T$, ![]() $h_m \propto \Delta T$, which is stronger than in the surface tension dominated regime (where

$h_m \propto \Delta T$, which is stronger than in the surface tension dominated regime (where ![]() $h_m \propto \Delta T^{1/2}$). Taking into account the temperature dependence of the material properties, we plot in figure 3(a) the predictions of (4.13) for

$h_m \propto \Delta T^{1/2}$). Taking into account the temperature dependence of the material properties, we plot in figure 3(a) the predictions of (4.13) for ![]() $T_s > 178\,^{\circ }\textrm {C}$ (solid lines). The data are in quantitative agreement with the proposed scaling relation, with a prefactor

$T_s > 178\,^{\circ }\textrm {C}$ (solid lines). The data are in quantitative agreement with the proposed scaling relation, with a prefactor ![]() $3.4 \pm 0.3$ which we determine from fitting the data for

$3.4 \pm 0.3$ which we determine from fitting the data for ![]() $T_s > 178\,^{\circ }\textrm {C}$.

$T_s > 178\,^{\circ }\textrm {C}$.

The transition from the dominance of capillary to nonlinear inertia effects is expected when the predictions of (4.12) and (4.13) are equal, i.e. when ![]() ${St}^{2/3} \mathcal {E}^{1/2}$ is of order one. We evidence this transition by reporting in figure 3(b) the minimum thickness

${St}^{2/3} \mathcal {E}^{1/2}$ is of order one. We evidence this transition by reporting in figure 3(b) the minimum thickness ![]() $h_m$ normalised by the capillary scaling (4.12) as a function of

$h_m$ normalised by the capillary scaling (4.12) as a function of ![]() ${St}^{2/3} \mathcal {E}^{1/2}$. This compensated plot highlights the systematic deviation from the scaling relation obtained in the capillary regime (dashed black line, (4.12)) when

${St}^{2/3} \mathcal {E}^{1/2}$. This compensated plot highlights the systematic deviation from the scaling relation obtained in the capillary regime (dashed black line, (4.12)) when ![]() ${St}^{2/3} \mathcal {E}^{1/2} \gtrsim 1$, and reiterates that this deviation is quantitatively captured by the introduction of the nonlinear inertia dominated regime (solid black line, (4.13)).

${St}^{2/3} \mathcal {E}^{1/2} \gtrsim 1$, and reiterates that this deviation is quantitatively captured by the introduction of the nonlinear inertia dominated regime (solid black line, (4.13)).

5. Conclusion and outlook

In this contribution, we experimentally evidence that nonlinear advection, similarly to capillarity, contributes to prevent liquid–solid contact during drop impact. We reveal the existence of the nonlinear inertia dominated regime, theoretically predicted by Mandre & Brenner (Reference Mandre and Brenner2012), but obscured in experiments by the occurrence of liquid–solid contact, by measuring the minimum thickness of the gas film trapped under drops impacting on superheated surfaces. We show that, for large impact velocities and substrate temperatures, the minimum thickness systematically deviates from the scaling relation predicted when assuming that capillarity dominates the behaviour in the neck region, closest to the substrate. We quantitatively capture this deviation by taking into account the influence of nonlinear advection, allowing us to derive a scaling relation for the minimum thickness in the high temperature and velocity regime. Performing impacts in the dynamical Leidenfrost regime allows us to uncover the nonlinear advection dominated regime not only by enabling us to probe contactless drop–substrate interactions for a large range of impact velocities and substrate temperatures, but also by altering the nature of the flow in the gas layer. Indeed, the presence of evaporation leads to a modified dominant balance at the neck, effectively putting the transition from the capillary to the advective regime within the experimentally accessible regime.

Future work should focus on building our physical understanding of the hydrodynamics obviating the need for gas film drainage, that is on describing the influence of capillarity and nonlinear advection beyond their ability to regularise the neck singularity. In doing so, it will be of particular interest to investigate the influence of liquid viscosity on the early dynamics of the drop impact process which displays a hitherto unexplained lift-off behaviour (Kolinski, Mahadevan & Rubinstein Reference Kolinski, Mahadevan and Rubinstein2014b; Mishra, Rubinstein & Rycroft Reference Mishra, Rubinstein and Rycroft2022).

Supplementary movies

Supplementary movies are available at https://doi.org/10.1017/jfm.2023.290.

Acknowledgements

We thank C. Datt and J.M. Gordillo for fruitful discussions.

Funding

We acknowledge funding from the ERC Advanced Grant DDD under grant no. 740479.

Declaration of interests

The authors report no conflict of interest.

Appendix A. Variation of the physical properties with temperature

In this section, we report on the determination of the temperature dependence of the physical properties used throughout the manuscript. On the one hand, we take the temperature dependent surface tension ![]() $\gamma$, liquid viscosity

$\gamma$, liquid viscosity ![]() $\eta _l$ and vapour thermal conductivity

$\eta _l$ and vapour thermal conductivity ![]() $k_v$ from tabulated values out of the Dortmund Data Bank. On the other hand, we estimate the vapour density

$k_v$ from tabulated values out of the Dortmund Data Bank. On the other hand, we estimate the vapour density ![]() $\rho _v$ by treating the vapour as an ideal gas:

$\rho _v$ by treating the vapour as an ideal gas:

where ![]() $P_0$ is the atmospheric pressure,

$P_0$ is the atmospheric pressure, ![]() $M$ the molar mass and

$M$ the molar mass and ![]() $R_g$ the universal gas constant.

$R_g$ the universal gas constant.

The temperature dependence of the vapour viscosity is given by the kinetic gas theory as

where the value ![]() $\eta _v(T_b) = 10.5\,\mathrm {\mu }$Pa s is taken from Silgardo & Storrow (Reference Silgardo and Storrow1950).

$\eta _v(T_b) = 10.5\,\mathrm {\mu }$Pa s is taken from Silgardo & Storrow (Reference Silgardo and Storrow1950).

Appendix B. Minimum thickness for impacts in the absence of evaporation

In the absence of evaporation (i.e. for ![]() $\mathcal {E}$ = 0), the dominant balance is given by the terms on the left-hand sides of (4.6), (4.7) and (4.8) as

$\mathcal {E}$ = 0), the dominant balance is given by the terms on the left-hand sides of (4.6), (4.7) and (4.8) as ![]() ${We} \gg 1$,

${We} \gg 1$, ![]() ${Re} \gg 1$ and

${Re} \gg 1$ and ![]() ${St} \gg 1$. Looking for a similarity solution at the neck gives the following scaling relations linking the pressure

${St} \gg 1$. Looking for a similarity solution at the neck gives the following scaling relations linking the pressure ![]() $\tilde {p}_n$ and the length scale

$\tilde {p}_n$ and the length scale ![]() $\widetilde {\ell }$ to the thickness

$\widetilde {\ell }$ to the thickness ![]() $\tilde {h}_n$ (Mandre et al. Reference Mandre, Mani and Brenner2009; Mani et al. Reference Mani, Mandre and Brenner2010; Mandre & Brenner Reference Mandre and Brenner2012):

$\tilde {h}_n$ (Mandre et al. Reference Mandre, Mani and Brenner2009; Mani et al. Reference Mani, Mandre and Brenner2010; Mandre & Brenner Reference Mandre and Brenner2012):

As ![]() $\tilde {h}_n$ decreases, the initially neglected capillary and nonlinear effects can regularise the singularity. Indeed, the Laplace pressure at the neck diverges as

$\tilde {h}_n$ decreases, the initially neglected capillary and nonlinear effects can regularise the singularity. Indeed, the Laplace pressure at the neck diverges as ![]() $\tilde {h}_n^{-2}$ (4.8), faster than

$\tilde {h}_n^{-2}$ (4.8), faster than ![]() $\tilde {p}_n$, indicating that the initial hypothesis neglecting surface tension is no longer valid as the drop approaches the solid, and setting the minimum thickness in the surface tension dominated regime:

$\tilde {p}_n$, indicating that the initial hypothesis neglecting surface tension is no longer valid as the drop approaches the solid, and setting the minimum thickness in the surface tension dominated regime:

Similarly, the advective contribution ![]() $\tilde {\boldsymbol {u}} \boldsymbol {\cdot }\boldsymbol {\nabla } \tilde {\boldsymbol {u}}$ diverges as

$\tilde {\boldsymbol {u}} \boldsymbol {\cdot }\boldsymbol {\nabla } \tilde {\boldsymbol {u}}$ diverges as ![]() $\tilde {h}_n^{-5/2}$, faster than the liquid pressure gradient. The breakdown of the similarity solution in the nonlinear inertia dominated regime occurs for

$\tilde {h}_n^{-5/2}$, faster than the liquid pressure gradient. The breakdown of the similarity solution in the nonlinear inertia dominated regime occurs for

and we expect to observe the transition from the surface tension dominated regime to the advection dominated regime for ![]() ${We}{St}^{-2/3} \approx 1$.

${We}{St}^{-2/3} \approx 1$.

In figure 4(a), we plot the minimum thickness for the impact of water and ethanol drops on room temperature glass substrates measured by De Ruiter et al. (Reference De Ruiter, Oh, van den Ende and Mugele2012) and for the impact of ethanol drops on room temperature mica substrates performed in the context of this study. The data for both water and ethanol drops are compatible with the predictions of (B2). Indeed, all experiments fulfil the condition ![]() ${We}{St}^{-2/3} \ll 1$, suggesting that they lie in the capillary regime (figure 4b). The occurrence of liquid–solid contact prevents us from observing the nonlinear inertia dominated regime for these impacts in the absence of evaporation.

${We}{St}^{-2/3} \ll 1$, suggesting that they lie in the capillary regime (figure 4b). The occurrence of liquid–solid contact prevents us from observing the nonlinear inertia dominated regime for these impacts in the absence of evaporation.

Figure 4. (a) Minimum film thickness ![]() $h_m$ in the absence of superheat for water and ethanol drop impacts on glass substrates extracted from the work of De Ruiter et al. (Reference De Ruiter, Oh, van den Ende and Mugele2012) (dark and light blue diamonds, respectively) and for ethanol drop impacts on freshly cleaved mica substrates (light blue circles). The solid lines represent the predictions of (B2) with prefactor 7. (b) Minimum film thickness on room temperature substrates compensated by the prediction of (B2) as a function of

$h_m$ in the absence of superheat for water and ethanol drop impacts on glass substrates extracted from the work of De Ruiter et al. (Reference De Ruiter, Oh, van den Ende and Mugele2012) (dark and light blue diamonds, respectively) and for ethanol drop impacts on freshly cleaved mica substrates (light blue circles). The solid lines represent the predictions of (B2) with prefactor 7. (b) Minimum film thickness on room temperature substrates compensated by the prediction of (B2) as a function of ![]() ${We} {St}^{-2/3}$. The data collapse onto a constant in the surface tension dominated regime, and we do not probe large enough impact velocities to reach the advection dominated region (grey shaded area).

${We} {St}^{-2/3}$. The data collapse onto a constant in the surface tension dominated regime, and we do not probe large enough impact velocities to reach the advection dominated region (grey shaded area).

Appendix C. Initial heating of the liquid–gas interface

We estimate the time needed for the drop's liquid–gas interface to reach the boiling temperature using a one-dimensional heat transfer model that we sketch in figure 5. As discussed in the main text, steady state conductive heat transfer is applicable in the gas layer, enabling us to compute the heat flux transferred from the wall to the liquid as ![]() $q_w = k_g (T_s - T_i)/h$, where

$q_w = k_g (T_s - T_i)/h$, where ![]() $T_i$ is the temperature of the interface. On the contrary, in the liquid, a thermal boundary layer with thickness

$T_i$ is the temperature of the interface. On the contrary, in the liquid, a thermal boundary layer with thickness ![]() $l_T \sim \sqrt {\kappa _l t}$ forms, allowing us to estimate the heat flux received by the liquid as

$l_T \sim \sqrt {\kappa _l t}$ forms, allowing us to estimate the heat flux received by the liquid as ![]() $q_l \sim k_l (T_i-T_a)/l_T$. When the interface temperature is below

$q_l \sim k_l (T_i-T_a)/l_T$. When the interface temperature is below ![]() $T_b$, the wall heat flux is used only to heat liquid;

$T_b$, the wall heat flux is used only to heat liquid; ![]() $q_w \sim q_l$, giving an expression for the time

$q_w \sim q_l$, giving an expression for the time ![]() $\tau$ needed for the liquid–gas interface to reach

$\tau$ needed for the liquid–gas interface to reach ![]() $T_b$:

$T_b$:

We estimate ![]() $\tau$ taking the liquid thermal diffusivity

$\tau$ taking the liquid thermal diffusivity ![]() $\kappa _l = 0.09 \times 10^6\,\textrm {m}^2\,\textrm {s}^{-1}$ and thermal conductivity

$\kappa _l = 0.09 \times 10^6\,\textrm {m}^2\,\textrm {s}^{-1}$ and thermal conductivity ![]() $k_l = 0.171 \,\textrm {W}\,\textrm {m}^{-1}\,\textrm {K}^{-1}$ at room temperature, and the air properties at

$k_l = 0.171 \,\textrm {W}\,\textrm {m}^{-1}\,\textrm {K}^{-1}$ at room temperature, and the air properties at ![]() $(T_s + T_b)/2$ (for

$(T_s + T_b)/2$ (for ![]() $T_i < T_b$, we assume little vapour is produced). For

$T_i < T_b$, we assume little vapour is produced). For ![]() $T_s = 200\,^{\circ }\textrm {C}$ and

$T_s = 200\,^{\circ }\textrm {C}$ and ![]() $h = 0.5\,\mathrm {\mu }$m, we find

$h = 0.5\,\mathrm {\mu }$m, we find ![]() $\tau \approx 15\,\mathrm {\mu }$s, a value compatible with the time at which

$\tau \approx 15\,\mathrm {\mu }$s, a value compatible with the time at which ![]() $h_m$ is reached, where we observe a strong influence of vapour generation.

$h_m$ is reached, where we observe a strong influence of vapour generation.

Figure 5. Sketch of the one-dimensional heat transfer model used to estimate the time needed for the interface temperature ![]() $T_i$ to reach the liquid boiling temperature

$T_i$ to reach the liquid boiling temperature ![]() $T_b$.

$T_b$.

Finally, we stress that this one-dimensional model oversimplifies the heat transfer problem by neglecting both the geometry of the vapour layer, and its temporal variation. We believe that the strong influence of temperature, and thus of evaporation, on the minimum neck thickness ![]() $h_m$ is the key observation that justifies assuming that the interface can be heated to

$h_m$ is the key observation that justifies assuming that the interface can be heated to ![]() $T_b$ within a time of the order of

$T_b$ within a time of the order of ![]() $10\,\mathrm {\mu }$s.

$10\,\mathrm {\mu }$s.