1 Introduction

Interfaces between fluids appear throughout science, technology, industry and nature. Bubbles are generated by crashing waves in the ocean, by agitation in washing machines, during froth flotation in the mining and energy industries and when super-saturated, dissolved gasses nucleate and grow bubbles in sodas, geysers, canned whipped cream and during fermentations. Droplets of one liquid may be emulsified in a second immiscible liquid – as found in foods, consumer products, pharmaceuticals, oil production and processing. Sea surfaces may be smooth and glassy, or riddled with capillary waves.

Almost without exception, ‘surface-active’ molecules and/or particles – collectively called ‘surfactants’ – control the initiation, dynamics and behaviour of these and other processes. The fluid mechanics community knows quite well that surfactants reduce the interfacial tension of liquid surfaces, thus lowering the energetic cost of blowing bubbles or inflating lungs. By extension, surfactant gradients are well known to exert ‘Marangoni’ stresses on fluid interfaces, often driving or influencing the flow of the fluids that form them.

Surfactants also impact a variety of scientific and industrial processes through a number of processes and mechanisms that are not so clear. A simple example highlights the difficulties that arise: the buoyant rise of a small bubble through a Newtonian liquid (figure 1). A bubble of radius

![]() $R$

with a perfectly clean surface rises according to the classic Stokes drag calculation, imposing a no-shear stress boundary condition, to give

$R$

with a perfectly clean surface rises according to the classic Stokes drag calculation, imposing a no-shear stress boundary condition, to give

where

![]() $F$

is the drag and

$F$

is the drag and

![]() $\unicode[STIX]{x1D702}$

is the shear viscosity of the fluid. In many cases, however, bubbles rise with velocities much closer to

$\unicode[STIX]{x1D702}$

is the shear viscosity of the fluid. In many cases, however, bubbles rise with velocities much closer to

as one would expect for a rigid particle. What is the reason?

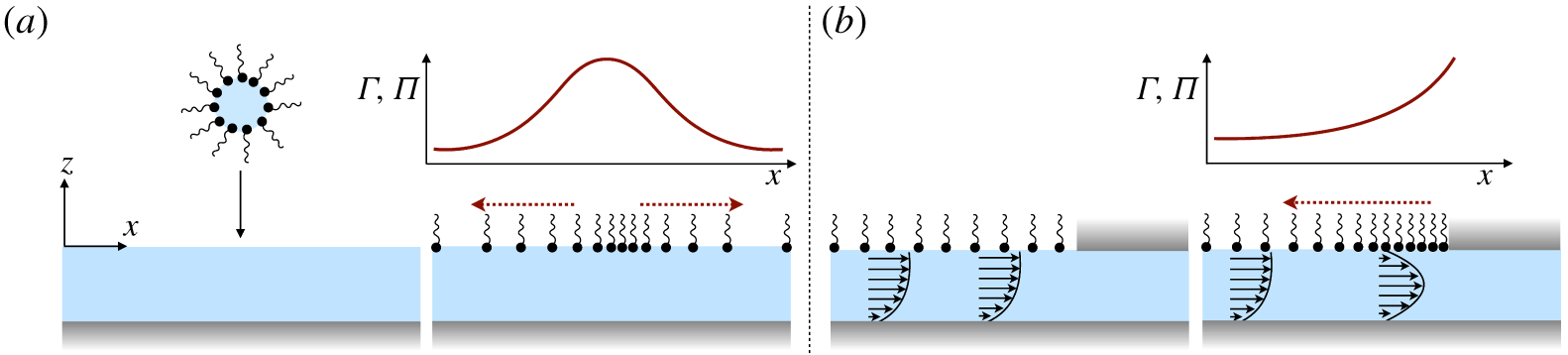

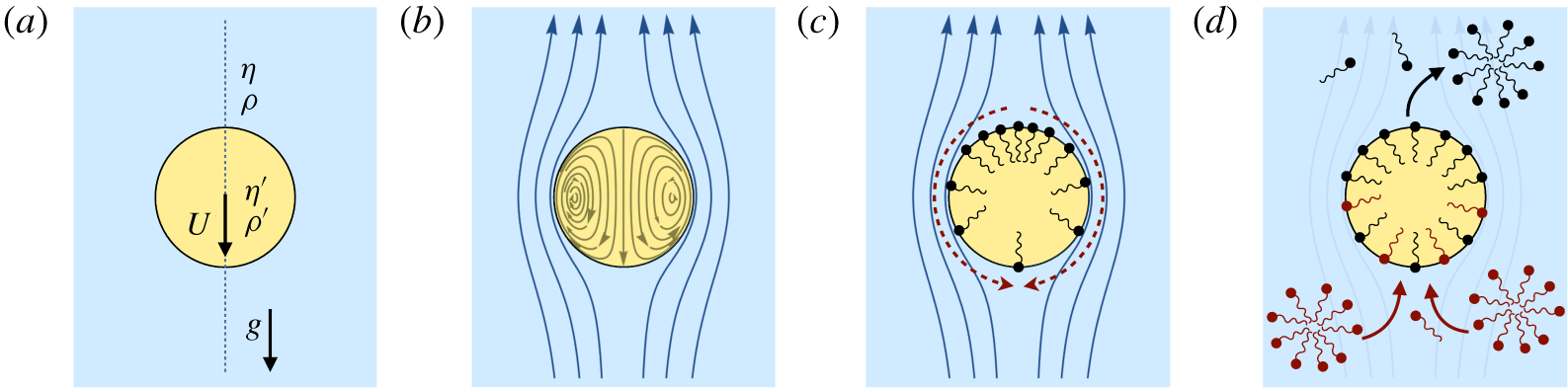

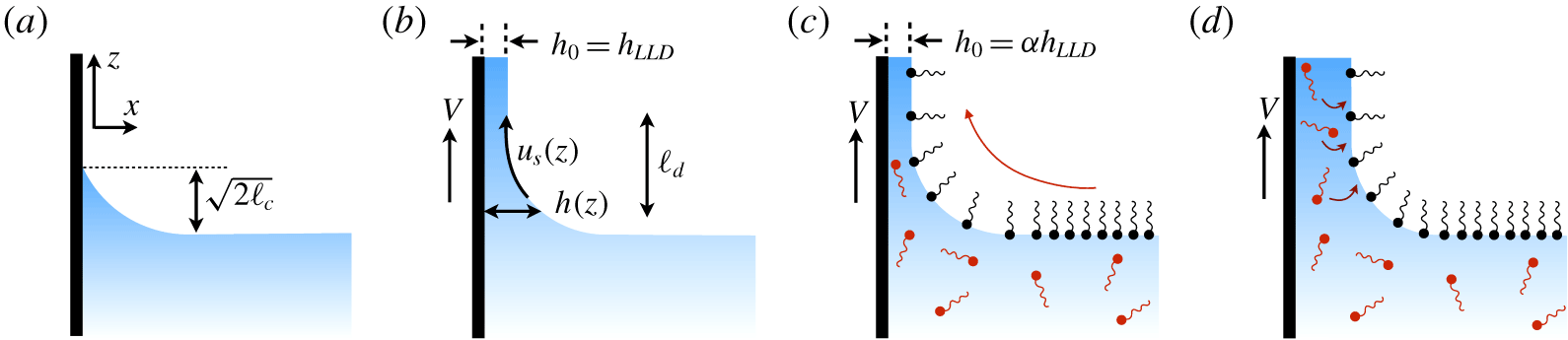

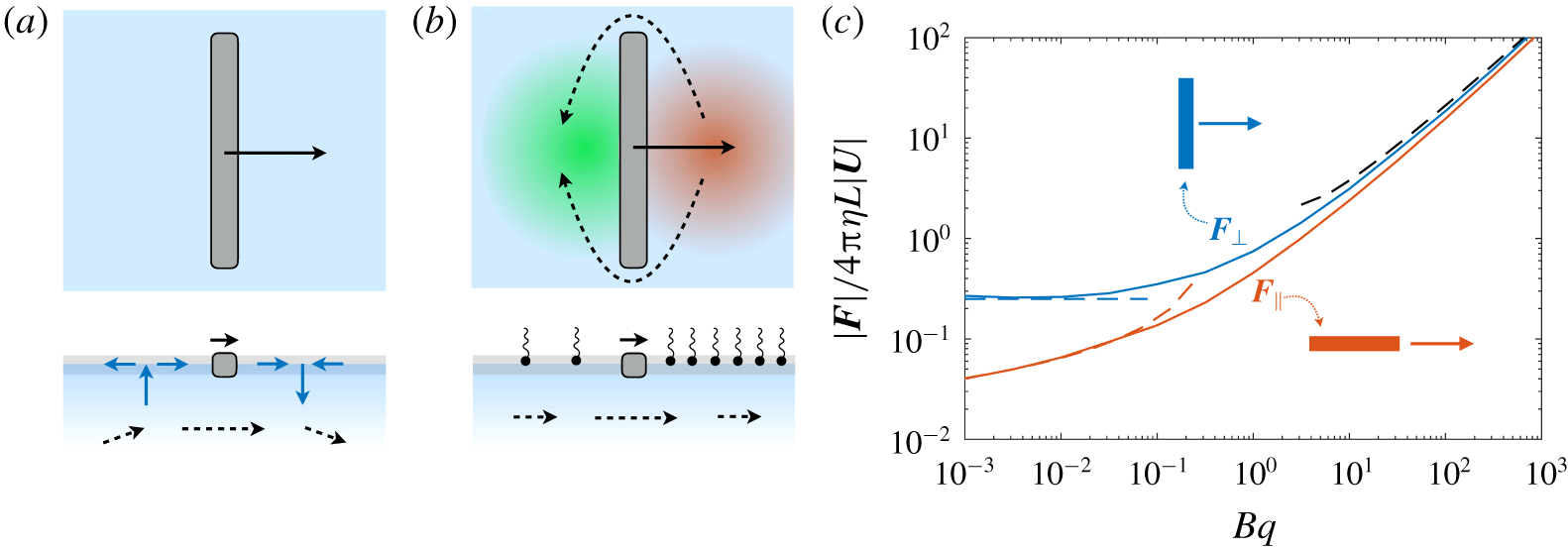

A vague acknowledgment that surfactants exist does not help much. In fact, a number of phenomena may be responsible for the slower rise. Boussinesq (Reference Boussinesq1913) originally surmised that the fluid/gas interface might itself have some surface-excess viscosity, dissipating energy as it deforms (figure 1 b). A more modern understanding holds that such surface viscosities are established by the surfactants adsorbed to the interface. Even without surface rheology, bulk viscous stresses advect surfactant to the rear of the bubble as it rises (figure 1 e), establishing a concentration gradient that drives a counter-acting Marangoni stress (figure 1 f). The strength of this gradient depends on how the surfactant responds (Levich Reference Levich1962) to being driven out of equilibrium. Insoluble surfactants diffusively fight to equalize their surface concentration (figure 1 g). Soluble surfactants adsorb and desorb from the interface to maintain an equilibrium (figure 1 h). If this equilibration process occurs slowly, gradients (and Marangoni stresses) are strong; conversely, rapid equilibration causes only weak gradients.

Figure 1. (a) ‘Hidden’ surfactant variables modify the interfacial flow of a rising bubble such that it might behave like a clean drop, a rigid particle or somewhere in between. The associated surfactant transport processes are not often easy to differentiate, and systems may exhibit one or a non-trivial combination of several processes. (b–d) For instance, an interfacial or surface excess viscosity can resist the surface flow. The solid lines depict surface flow, and dashed red arrows indicate tangential (viscous) stresses resisting deformation. (e–g) Alternatively, surfactants swept to the rear of the bubble build a concentration gradient and generate a counter-acting Marangoni stress (dashed red arrows) that resists surface convection (blue arrows). These Marangoni forces may be weakened by surface diffusion against the gradient. (h–j) If the surfactant is soluble, adsorption/desorption from the bulk can drive the surface concentration back to equilibrium over a finite time. This process might be controlled by (i) diffusive transport in the bulk across bulk concentration gradients over a time scale

![]() $\unicode[STIX]{x1D70F}_{d}$

, or by (j) the finite-rate kinetics over a finite time scale

$\unicode[STIX]{x1D70F}_{d}$

, or by (j) the finite-rate kinetics over a finite time scale

![]() $\unicode[STIX]{x1D70F}_{k}$

.

$\unicode[STIX]{x1D70F}_{k}$

.

It is hard to imagine a simpler experiment than this – measuring the rise velocity of a nearly spherical bubble in a liquid, say as a function of bubble radius. If the measured velocity matches

![]() $U^{c}$

from (1.1), one can conclude that the drop is clean. If, on the other hand, the measured velocity is slower than

$U^{c}$

from (1.1), one can conclude that the drop is clean. If, on the other hand, the measured velocity is slower than

![]() $U^{c}$

, the discrepancy might be caused by (a) inherent surface viscosity; (b) surface viscosity due to a surfactant; (c) flow-induced Marangoni stresses from an insoluble surfactant; (d) flow-induced Marangoni stresses from a soluble surfactant, the magnitude of which might be determined by (i) adsorption/desorption rate kinetics; or (ii) surfactant diffusion across the bubble; (iii) convection–diffusion transport of surfactant across the bubble. However sensible figure 1(a) may seem, the

$U^{c}$

, the discrepancy might be caused by (a) inherent surface viscosity; (b) surface viscosity due to a surfactant; (c) flow-induced Marangoni stresses from an insoluble surfactant; (d) flow-induced Marangoni stresses from a soluble surfactant, the magnitude of which might be determined by (i) adsorption/desorption rate kinetics; or (ii) surfactant diffusion across the bubble; (iii) convection–diffusion transport of surfactant across the bubble. However sensible figure 1(a) may seem, the

![]() $x$

-axis is often difficult to unambiguously determine.

$x$

-axis is often difficult to unambiguously determine.

This difficulty – of identifying mechanisms by which surfactants act – arises much more broadly, in systems and processes that are much more complicated. Surfactants influence film thicknesses in coating flows (Quéré Reference Quéré1999; Shen et al. Reference Shen, Gleason, McKinley and Stone2002; Scheid et al. Reference Scheid, Delacotte, Dollet, Rio, Restagno, van Nierop, Cantat, Langevin and Stone2010), the dispersion of surface waves (Levich Reference Levich1962; Lucassen & Hansen Reference Lucassen and Hansen1966), the dynamics and thicknesses of spreading films (Troian, Herbolzheimer & Safran Reference Troian, Herbolzheimer and Safran1990; Darhuber & Troian Reference Darhuber and Troian2005) and the lifetime of foams and emulsions (Langevin Reference Langevin2000; Cohen-Addad, Höhler & Pitois Reference Cohen-Addad, Höhler and Pitois2013). Mechanisms by which these effects arise can be complicated and varied. For example, surfactants may provide additional energetic barriers to droplet and bubble coalescence: surfactants on either side of a liquid film may repel each other sterically or electrostatically, and thus retard or arrest the thinning of the film (Bibette et al. Reference Bibette, Morse, Witten and Weitz1992; Stancik, Kouhkan & Fuller Reference Stancik, Kouhkan and Fuller2004). Alternatively, or additionally, dynamic mechanisms may also act: surfactants advected by thinning films establish gradients, and thus Marangoni stresses, that oppose the film drainage (Leal Reference Leal2004). Monolayers of surfactant may introduce an excess surface viscosity, elasticity or visco-elasticity that retards or alters film thinning (Langevin Reference Langevin2000). Even more subtle, surfactant exchange between the bulk and the interface can mimic surface-excess (dilatational) viscosity, masking the physical origin of the dissipation (Levich Reference Levich1962; Lucassen & van den Tempel Reference Lucassen and van den Tempel1972).

Despite the controlling influence that surfactants exert over many fluid systems, the surfactants themselves are effectively invisible in most experiments, and to most techniques. Interpreting such experiments becomes challenging at best, given that physically distinct surfactant processes impact measurements in identical ways. In many ways, surfactants behave like ‘hidden variables’ that cannot be measured directly, yet influence fluid flows so profoundly that they must be determined in order to understand even gross, qualitative fluid phenomena. Surfactant distributions are thus typically inferred from observable fluid phenomena – e.g. measured fluid velocity fields, free surface dynamics or Laplace pressure measurements. Connecting measurements and observations with the underlying surfactant fields, however, requires some model for the dynamics and mechanics of surfactant transport.

The fact that physically distinct surfactant processes can impact measurable properties in the same way – while the surfactants themselves elude detection – has caused significant confusion. For example, the origin and even existence of surface rheology has long been controversial (Scriven & Sternling Reference Scriven and Sternling1960), with justifiable reason: if Marangoni stresses can explain an experimental observation, what is the need to invoke surface rheology? Why should a rightly sceptical scientist invoke some nebulous phenomenon, when established processes can explain measurements? At the same time, plausible mechanisms should not be dismissed out of hand: after all, however familiar a process may be, it might actually not be the one responsible for an observation.

Understanding these surfactant systems – and ultimately predicting and designing them – requires that these mechanisms and processes be differentiated unambiguously. This might be accomplished by specifically designing experiments to excite one process but not others: forcing a surfactant-laden interface to deform in a purely shear fashion – i.e. with zero compression or dilation – should not trigger Marangoni stresses, but would be sensitive to surface shear rheology. In systems with compression, it may not be easy or even possible to separate stresses cause by surface dilatational viscosity – an intrinsic material property – from an effective surface viscoelasticity due to surfactant adsorption and desorption, surface and bulk diffusion, aggregation or phase transitions, Marangoni flows, or some combination of these processes. Knowing how these processes scale with e.g. system geometry, fluid velocity, surfactant concentrations and properties, however, might suggest complementary experiments to tease apart these influences.

The objective of this Perspective, then, is to enumerate and elucidate the multitude of transport processes involved in the formation, flow and rheological response of surfactant-laden interfaces, and therefore to better understand, interpret, predict and design surfactant/fluid flows and materials. By presenting these diverse phenomena in one comprehensive piece, described using the same language and within the same context, we hope to to empower the fluid mechanics and soft condensed matter physics communities to discern and differentiate between the various dynamics surfactants might cause. We also hope to connect the fluid mechanics community to the physical chemistry literature on surfactants, which is more steeped in equilibrium thermodynamics than typical fluid mechanicians have at their fingertips. To this end, this perspective highlights paradigmatic examples chosen for their paedagogic value in weaving a coherent and compelling picture of surfactant dynamics, rather than a comprehensive treatment of this vast literature.

In what follows, we treat surfactants from the physical–chemical standpoint, hopefully giving the fluid mechanician enough basis to connect with the surfactant literature. We will start with equilibrium arguments about surface tension and surface pressure, including the equilibrium properties of soluble and insoluble surfactants (§ 2). We then move on to dynamic processes – which tend to be more familiar to the fluid mechanician – and discuss the various ways in which surfactant is transported (§ 3). We will touch on surface rheology, which is relatively unfamiliar to both communities. Then, in § 4, we show how even these most basic treatments give rise to remarkable richness in a series of paradigmatic problems: (§ 4.1) the buoyant translation of bubbles and drops; (§ 4.2) the oscillatory compression of soluble monolayers; (§ 4.3) surface wave dynamics; (§ 4.4) coating flows; (§ 4.5) foam drainage; and (§ 4.6) particle motion within surfactant-laden interfaces. These problems are chosen both for their ubiquity and importance, as well as the non-trivial and rich phenomena that appear even for the simplest assumptions for the processes described in § 3. Finally, in § 5, we present a variety of complexities that arise even in common surfactant systems – beyond the ‘simplest’ treatments in §§ 2–4 – with the goal of highlighting areas where standard assumptions may not capture experimental observations, and to encourage new directions for research and innovation.

2 Interfaces at equilibrium

2.1 Surface tension and its origins

Surface tension originates from the imbalance in mutually attractive forces felt by molecules near an interface. A liquid molecule in the bulk of a fluid is surrounded by neighbours of the same kind, all exerting attractive intermolecular forces. Molecules that are surrounded experience no net force, due to the symmetric distribution of their neighbours. A force is required to pull one molecule out of the bulk liquid, however, one must supply enough free energy to break the

![]() $N$

‘bonds’, each of strength

$N$

‘bonds’, each of strength

![]() $\unicode[STIX]{x0394}U$

.

$\unicode[STIX]{x0394}U$

.

A molecule near an immiscible fluid–fluid interface, however, feels a net force towards the fluid phase with higher intermolecular attractions. These interfacial molecules are in an energetically unfavourable state, and creation of additional interfacial area is expensive. A fluid system, therefore, minimizes interfacial area. The surface tension

![]() $\unicode[STIX]{x1D6FE}$

of a fluid–fluid interface is then the energy associated with creating excess area, which depends on the strength of intermolecular forces in both bulk phases. For example, a clean air–water interface has

$\unicode[STIX]{x1D6FE}$

of a fluid–fluid interface is then the energy associated with creating excess area, which depends on the strength of intermolecular forces in both bulk phases. For example, a clean air–water interface has

![]() $\unicode[STIX]{x1D6FE}\approx 0.072~\text{J}~\text{m}^{-2}$

, or equivalently,

$\unicode[STIX]{x1D6FE}\approx 0.072~\text{J}~\text{m}^{-2}$

, or equivalently,

![]() $72~\text{mN}~\text{m}^{-1}$

.

$72~\text{mN}~\text{m}^{-1}$

.

The surface tension of a liquid can be estimated with the simple thought experiment depicted in figure 2. Each molecule in the bulk liquid has attractive interactions with

![]() $N$

neighbours. Cleaving the bulk into two, and therefore creating two interfaces, requires

$N$

neighbours. Cleaving the bulk into two, and therefore creating two interfaces, requires

![]() $N/2$

bonds, each of energy

$N/2$

bonds, each of energy

![]() $\unicode[STIX]{x0394}U$

, to be supplied for every interfacial molecule. Given

$\unicode[STIX]{x0394}U$

, to be supplied for every interfacial molecule. Given

![]() $\unicode[STIX]{x1D6E4}_{s}$

molecules per unit area, cleaving these bonds requires an energy per unit area,

$\unicode[STIX]{x1D6E4}_{s}$

molecules per unit area, cleaving these bonds requires an energy per unit area,

![]() $\unicode[STIX]{x1D6FE}$

, given by

$\unicode[STIX]{x1D6FE}$

, given by

Of course, molecules at the interface might relax and re-arrange, changing the energetics of interfacial molecules, but we neglect these small changes. The interaction energy

![]() $N\unicode[STIX]{x0394}U$

must be

$N\unicode[STIX]{x0394}U$

must be

![]() $O(k_{B}T)$

in order for the bulk to be a liquid: if the interaction energy were much stronger than thermal energy (

$O(k_{B}T)$

in order for the bulk to be a liquid: if the interaction energy were much stronger than thermal energy (

![]() $N\unicode[STIX]{x0394}U\gg k_{B}T$

), molecules would lock in place as a solid or glass, whereas if it were much weaker (

$N\unicode[STIX]{x0394}U\gg k_{B}T$

), molecules would lock in place as a solid or glass, whereas if it were much weaker (

![]() $N\unicode[STIX]{x0394}U\ll k_{B}T$

), the molecules would fly apart to form a gas. Ignoring numerical prefactors, this suggests a surface tension

$N\unicode[STIX]{x0394}U\ll k_{B}T$

), the molecules would fly apart to form a gas. Ignoring numerical prefactors, this suggests a surface tension

However crude, this approximation gives reasonable estimates: assuming water molecules to have an approximate radius

![]() $r_{w}\sim 0.2~\text{nm}$

(based on the bulk density and molecular mass of water) suggests water molecules occupy the interface with density

$r_{w}\sim 0.2~\text{nm}$

(based on the bulk density and molecular mass of water) suggests water molecules occupy the interface with density

![]() $\unicode[STIX]{x1D6E4}_{s}\sim 9~\text{nm}^{-2}$

. Using

$\unicode[STIX]{x1D6E4}_{s}\sim 9~\text{nm}^{-2}$

. Using

![]() $k_{B}T\sim 4~\text{pN}~\text{nm}$

at room temperature gives

$k_{B}T\sim 4~\text{pN}~\text{nm}$

at room temperature gives

![]() $\unicode[STIX]{x1D6FE}\sim 40~\text{mN}~\text{m}^{-1}$

, which is within a factor of two of the measured value

$\unicode[STIX]{x1D6FE}\sim 40~\text{mN}~\text{m}^{-1}$

, which is within a factor of two of the measured value

![]() $72~\text{mN}~\text{m}^{-1}$

. More generally, most liquids with approximately Angstrom radii thus have surface tensions in the tens of

$72~\text{mN}~\text{m}^{-1}$

. More generally, most liquids with approximately Angstrom radii thus have surface tensions in the tens of

![]() $\text{mN}~\text{m}^{-1}$

.

$\text{mN}~\text{m}^{-1}$

.

Figure 2. A liquid molecule in the bulk of a fluid experiences no net force due to a (time-averaged) symmetric distribution of neighbours. Creating an interface, however, requires breaking intermolecular ‘bonds’ on the interface and is energetically expensive.

Surface tension can be alternatively interpreted in terms of the mechanical work done in stretching an interface. If the application of a force

![]() $F$

within the plane of the interface changes its area by

$F$

within the plane of the interface changes its area by

![]() $\text{d}A$

, the net change in energy is a sum of mechanical work done and the surface energy associated with surface tension

$\text{d}A$

, the net change in energy is a sum of mechanical work done and the surface energy associated with surface tension

At mechanical equilibrium,

![]() $\text{d}U=0$

, and writing

$\text{d}U=0$

, and writing

![]() $\text{d}A=\ell \,\text{d}x$

where

$\text{d}A=\ell \,\text{d}x$

where

![]() $\ell$

is the width of the interfacial layer, we find

$\ell$

is the width of the interfacial layer, we find

![]() $\unicode[STIX]{x1D6FE}=F/\ell$

. In other words, surface tension gives the force per unit length to create interfacial area.

$\unicode[STIX]{x1D6FE}=F/\ell$

. In other words, surface tension gives the force per unit length to create interfacial area.

Finally,

![]() $\unicode[STIX]{x1D6FE}$

can be thought of as a surface stress, pulling isotropically within the plane of the interface, and is therefore analogous to a negative three-dimensional (3-D) pressure. We will soon extend this analogy with 3-D pressure, as surfactants exert a ‘surface pressure’,

$\unicode[STIX]{x1D6FE}$

can be thought of as a surface stress, pulling isotropically within the plane of the interface, and is therefore analogous to a negative three-dimensional (3-D) pressure. We will soon extend this analogy with 3-D pressure, as surfactants exert a ‘surface pressure’,

![]() $\unicode[STIX]{x1D6F1}$

, against the surface tension

$\unicode[STIX]{x1D6F1}$

, against the surface tension

![]() $\unicode[STIX]{x1D6FE}$

of the clean interface.

$\unicode[STIX]{x1D6FE}$

of the clean interface.

Unlike bulk 3-D fluids, however, surfaces are two-dimensional and can be curved, which modifies the static stress required to create additional area. For example, increasing the volume of a bubble of gas

![]() $A$

suspended at equilibrium in liquid

$A$

suspended at equilibrium in liquid

![]() $B$

increases the surface area of the bubble, and therefore its interfacial energy. If the bubble radius increases from

$B$

increases the surface area of the bubble, and therefore its interfacial energy. If the bubble radius increases from

![]() $R$

to

$R$

to

![]() $R+\text{d}R$

, the net free energy change is

$R+\text{d}R$

, the net free energy change is

where

![]() $\unicode[STIX]{x1D6FE}_{AB}$

is the surface tension of the

$\unicode[STIX]{x1D6FE}_{AB}$

is the surface tension of the

![]() $A$

–

$A$

–

![]() $B$

interface,

$B$

interface,

![]() $p_{A}$

and

$p_{A}$

and

![]() $p_{B}$

are the pressures inside and outside the bubble, respectively,

$p_{B}$

are the pressures inside and outside the bubble, respectively,

![]() $\text{d}V_{A}=-\text{d}V_{B}=4\unicode[STIX]{x03C0}R^{2}\,\text{d}R$

and

$\text{d}V_{A}=-\text{d}V_{B}=4\unicode[STIX]{x03C0}R^{2}\,\text{d}R$

and

![]() $\text{d}A=8\unicode[STIX]{x03C0}R\,\text{d}R$

. Imposing

$\text{d}A=8\unicode[STIX]{x03C0}R\,\text{d}R$

. Imposing

![]() $\text{d}U=0$

to satisfy mechanical equilibrium reveals the well-known Laplace pressure jump across the bubble surface:

$\text{d}U=0$

to satisfy mechanical equilibrium reveals the well-known Laplace pressure jump across the bubble surface:

The larger the interfacial curvature or surface tension, the greater is the bulk fluid pressure required to maintain the system in equilibrium: smaller bubbles have a higher internal pressure. More generally, the Laplace pressure is given by the Young–Laplace equation (Leal Reference Leal2007)

where

![]() $\boldsymbol{n}$

is the normal to the interface, pointing away from the fluid

$\boldsymbol{n}$

is the normal to the interface, pointing away from the fluid

![]() $A$

,

$A$

,

![]() $\unicode[STIX]{x1D735}_{s}=(\unicode[STIX]{x1D644}-\boldsymbol{n}\boldsymbol{n})\boldsymbol{\cdot }\unicode[STIX]{x1D735}$

is the surface gradient operator, and

$\unicode[STIX]{x1D735}_{s}=(\unicode[STIX]{x1D644}-\boldsymbol{n}\boldsymbol{n})\boldsymbol{\cdot }\unicode[STIX]{x1D735}$

is the surface gradient operator, and

![]() $\unicode[STIX]{x1D735}_{s}\boldsymbol{\cdot }\boldsymbol{n}$

is the mean curvature of the surface.

$\unicode[STIX]{x1D735}_{s}\boldsymbol{\cdot }\boldsymbol{n}$

is the mean curvature of the surface.

2.2 ‘Dirty’ interfaces: surfactants of different classes

Many surfactants are ‘amphiphilic’ – having both hydrophilic and hydrophobic parts – and adsorb to surfaces to minimize energetically unfavourable interactions. For instance, amphiphilic molecules adsorb to a water–air interface with their hydrophobic tails directed out of the water phase (figure 3). Adsorption to a surface comes at a cost, however: the bulk fluid offers a wider range of translational and rotational micro-states and therefore, a larger entropy per surfactant molecule. At equilibrium, the balance between adsorbed surfactants, with surface concentration

![]() $\unicode[STIX]{x1D6E4}$

, and dissolved surfactants, with bulk concentration

$\unicode[STIX]{x1D6E4}$

, and dissolved surfactants, with bulk concentration

![]() $C$

, reflects a balance between the (favourable) enthalpy change and the (unfavourable) entropy loss that occurs during adsorption. With increasing bulk concentration, the balance between the energetic expense of hydrophobic groups remaining within the bulk and the entropic loss of moving to the interface tilts in favour of adsorption (figure 3

b,c) and a monolayer of increasing surface concentration

$C$

, reflects a balance between the (favourable) enthalpy change and the (unfavourable) entropy loss that occurs during adsorption. With increasing bulk concentration, the balance between the energetic expense of hydrophobic groups remaining within the bulk and the entropic loss of moving to the interface tilts in favour of adsorption (figure 3

b,c) and a monolayer of increasing surface concentration

![]() $\unicode[STIX]{x1D6E4}$

forms at the interface.

$\unicode[STIX]{x1D6E4}$

forms at the interface.

Figure 3. (a) Schematic representation of an amphiphilic molecule. (b,c) Surfactant molecules adsorb to the interface to an extent determined by the competition between (loss of) entropy and energetically favourable interactions during adsorption. Also shown in (c) are the concentration profiles of surfactant (solid line) and water (dashed line) molecules. The ‘excess’ surface concentration is in grey, which represents the amount of surfactant in excess of a hypothetical state where the concentration of dissolved surfactant is constant up until the surface.

The affinity of surfactant molecules towards interfaces creates a surface ‘excess’ concentration,

![]() $\unicode[STIX]{x1D6E4}$

. In other words,

$\unicode[STIX]{x1D6E4}$

. In other words,

![]() $\unicode[STIX]{x1D6E4}$

is the number of molecules per unit interfacial area in excess of a hypothetical reference state, in which the adjoining bulk phases maintain their constant concentrations (figure 3

c) up until the surface. The position of the surface itself is arbitrary, and is typically chosen such that the surface-excess concentration of the solvent is zero.

$\unicode[STIX]{x1D6E4}$

is the number of molecules per unit interfacial area in excess of a hypothetical reference state, in which the adjoining bulk phases maintain their constant concentrations (figure 3

c) up until the surface. The position of the surface itself is arbitrary, and is typically chosen such that the surface-excess concentration of the solvent is zero.

It is conceptually simple to appreciate the surface-active nature of molecules with physically distinct hydrophilic and hydrophobic portions, as depicted in figure 3(a). Such clearly differentiated portions, however, are not necessary for surface activity. The basic surfactant argument holds just as well for chemically homogeneous molecules or particles that possess an intermediate wettability with respect to the fluids on either side of the interface (Binks Reference Binks2002).

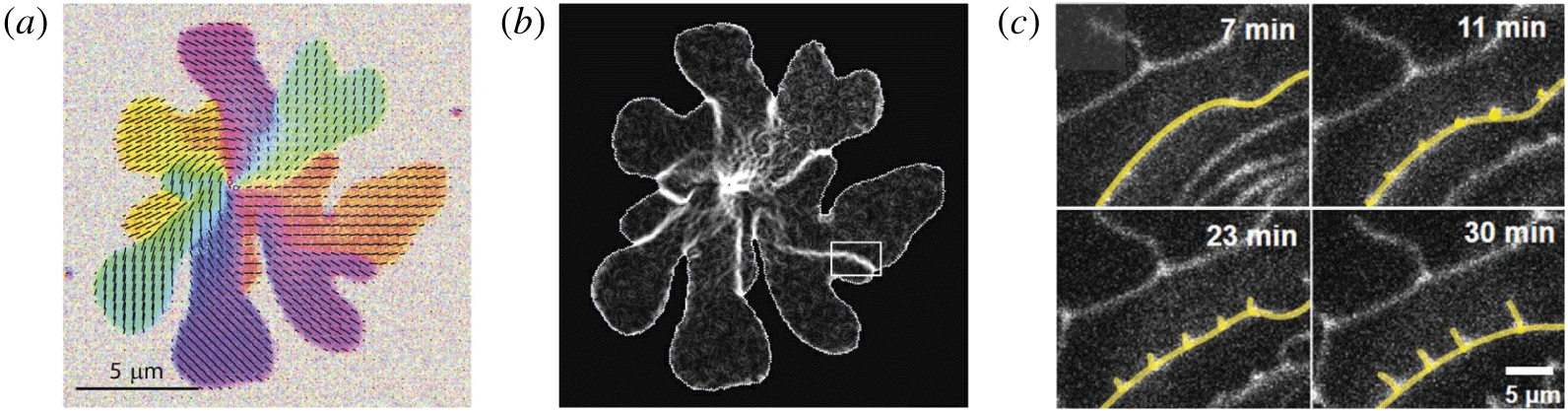

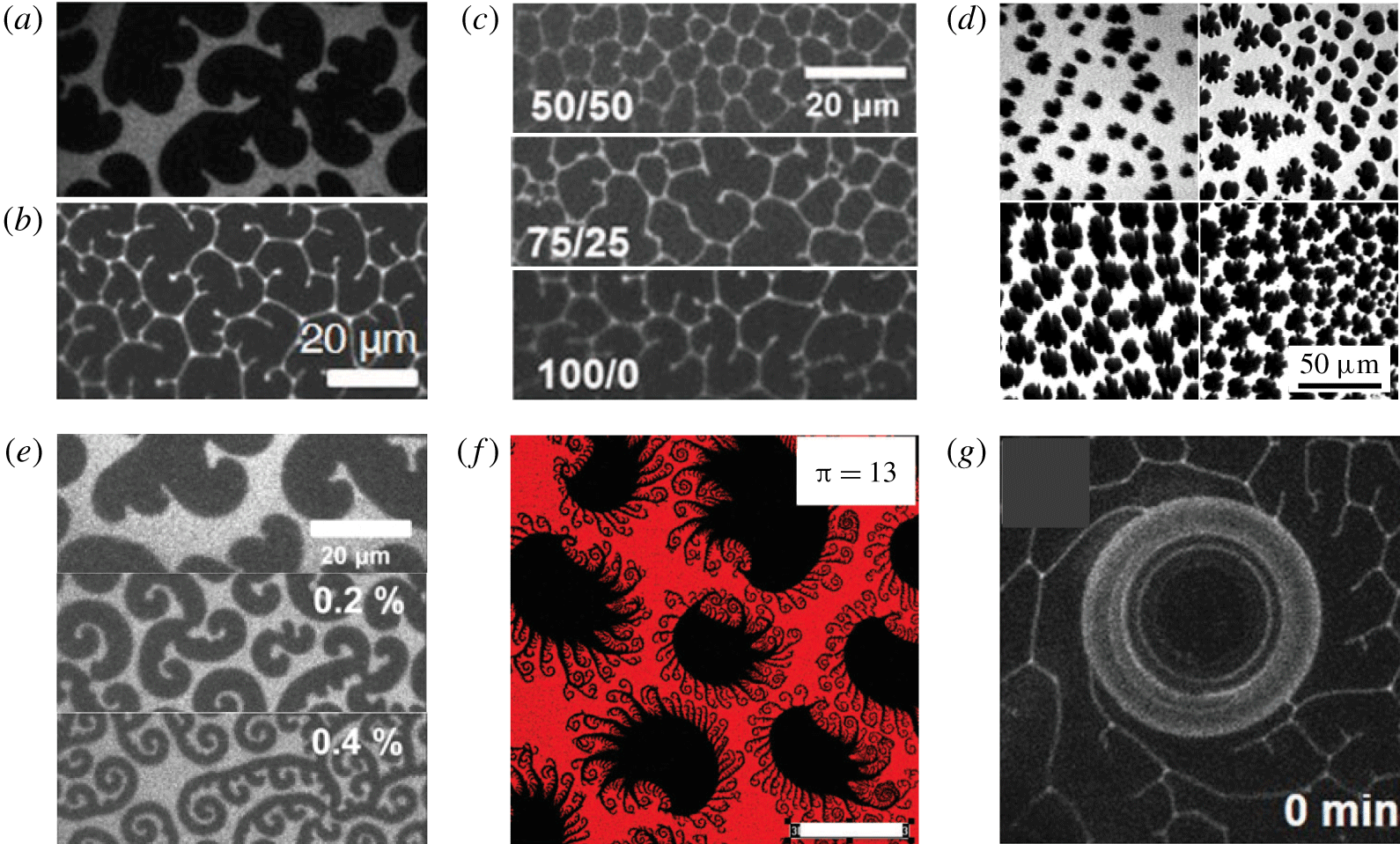

Any species (molecular or particulate) that has a positive surface excess is – by definition – a surfactant. And so – what are the options? How much do they reduce surface tension? What time scales emerge? The equilibrium properties of different classes of surfactants can differ substantially, as shown in figure 4. All cases depict a spherical liquid drop of surface area

![]() $A_{i}$

whose shape is deformed and held at a final surface area

$A_{i}$

whose shape is deformed and held at a final surface area

![]() $A_{f}$

, for an increase of

$A_{f}$

, for an increase of

![]() $\unicode[STIX]{x0394}A$

. The clean, surfactant-free drop (figure 4

a) serves as a base case: the extra surface area

$\unicode[STIX]{x0394}A$

. The clean, surfactant-free drop (figure 4

a) serves as a base case: the extra surface area

![]() $\unicode[STIX]{x0394}A$

created by deforming at the interface comes at the cost of the ‘clean’ surface tension

$\unicode[STIX]{x0394}A$

created by deforming at the interface comes at the cost of the ‘clean’ surface tension

![]() $\unicode[STIX]{x1D6FE}_{0}$

of the liquid/liquid interface, requiring an additional energy

$\unicode[STIX]{x1D6FE}_{0}$

of the liquid/liquid interface, requiring an additional energy

![]() $\unicode[STIX]{x0394}U=\unicode[STIX]{x1D6FE}_{0}\unicode[STIX]{x0394}A$

.

$\unicode[STIX]{x0394}U=\unicode[STIX]{x1D6FE}_{0}\unicode[STIX]{x0394}A$

.

Figure 4. Examples of change in surface energy upon deformation of a drop with surface-active molecules or particles.

Many surfactants are soluble, meaning that the surface excess concentration

![]() $\unicode[STIX]{x1D6E4}$

of adsorbed surfactant equilibrates with the dissolved concentration

$\unicode[STIX]{x1D6E4}$

of adsorbed surfactant equilibrates with the dissolved concentration

![]() $C$

according to an isotherm (table 1). When a drop is initially coated with soluble surfactant at surface coverage

$C$

according to an isotherm (table 1). When a drop is initially coated with soluble surfactant at surface coverage

![]() $\unicode[STIX]{x1D6E4}_{eq}$

and then deformed to create extra area

$\unicode[STIX]{x1D6E4}_{eq}$

and then deformed to create extra area

![]() $\unicode[STIX]{x0394}A$

, the interfacial concentration

$\unicode[STIX]{x0394}A$

, the interfacial concentration

![]() $\unicode[STIX]{x1D6E4}$

drops below its equilibrium with the bulk concentration

$\unicode[STIX]{x1D6E4}$

drops below its equilibrium with the bulk concentration

![]() $C$

. Bulk surfactant is then driven to adsorb to the interface, until the equilibrium surface coverage (

$C$

. Bulk surfactant is then driven to adsorb to the interface, until the equilibrium surface coverage (

![]() $\unicode[STIX]{x1D6E4}_{f}=\unicode[STIX]{x1D6E4}_{eq}$

) is restored (figure 4

b). At steady state, the surface tension of the drop is thus equal to the initial, equilibrium value

$\unicode[STIX]{x1D6E4}_{f}=\unicode[STIX]{x1D6E4}_{eq}$

) is restored (figure 4

b). At steady state, the surface tension of the drop is thus equal to the initial, equilibrium value

![]() $\unicode[STIX]{x1D6FE}_{eq}(C)$

, which is lower than the clean surface tension

$\unicode[STIX]{x1D6FE}_{eq}(C)$

, which is lower than the clean surface tension

![]() $\unicode[STIX]{x1D6FE}_{0}$

. The energetic cost of this deformation is thus reduced to

$\unicode[STIX]{x1D6FE}_{0}$

. The energetic cost of this deformation is thus reduced to

![]() $\unicode[STIX]{x0394}U=\unicode[STIX]{x1D6FE}_{eq}\unicode[STIX]{x0394}A$

.

$\unicode[STIX]{x0394}U=\unicode[STIX]{x1D6FE}_{eq}\unicode[STIX]{x0394}A$

.

Some surfactants are insoluble in the bulk solution, meaning that there are no surfactants dissolved in the ‘reservoir’, and the number

![]() $N$

of surfactants on an interface remains constant. Deforming a drop coated with insoluble surfactants (figure 4

c) decreases the surface concentration to

$N$

of surfactants on an interface remains constant. Deforming a drop coated with insoluble surfactants (figure 4

c) decreases the surface concentration to

![]() $\unicode[STIX]{x1D6E4}_{f}=\unicode[STIX]{x1D6E4}_{i}A/(A+\unicode[STIX]{x0394}A)$

, which typically increases the surface tension according to an equilibrium isotherm

$\unicode[STIX]{x1D6E4}_{f}=\unicode[STIX]{x1D6E4}_{i}A/(A+\unicode[STIX]{x0394}A)$

, which typically increases the surface tension according to an equilibrium isotherm

![]() $\unicode[STIX]{x1D6FE}(\unicode[STIX]{x1D6E4})$

(§ 2.3). The change in surface energy is then

$\unicode[STIX]{x1D6FE}(\unicode[STIX]{x1D6E4})$

(§ 2.3). The change in surface energy is then

![]() $\unicode[STIX]{x0394}U=\int \unicode[STIX]{x1D6FE}(\unicode[STIX]{x1D6E4})\,\text{d}A$

.

$\unicode[STIX]{x0394}U=\int \unicode[STIX]{x1D6FE}(\unicode[STIX]{x1D6E4})\,\text{d}A$

.

Small particles with intermediate wettability can also act like surfactants – forming the basis for so-called ‘Pickering’ emulsions (Binks Reference Binks2002). Nanoparticles often adsorb extremely strongly to fluid interfaces – with millions or billions of

![]() $k_{B}T$

in binding energy. However strong this binding energy may be, deforming a particle-laden drop creates ‘clean’ interface, at a cost given by the clean liquid surface tension

$k_{B}T$

in binding energy. However strong this binding energy may be, deforming a particle-laden drop creates ‘clean’ interface, at a cost given by the clean liquid surface tension

![]() $\unicode[STIX]{x1D6FE}_{0}$

(figure 4

d). Therefore, particles do not affect the surface tension in any appreciable way if they do not interact with each other. Mutually repulsive interfacial particles, for example, relax and separate when the drop is deformed (figure 4

e). Clean fluid interface is created at a cost

$\unicode[STIX]{x1D6FE}_{0}$

(figure 4

d). Therefore, particles do not affect the surface tension in any appreciable way if they do not interact with each other. Mutually repulsive interfacial particles, for example, relax and separate when the drop is deformed (figure 4

e). Clean fluid interface is created at a cost

![]() $\unicode[STIX]{x1D6FE}_{0}$

, but reducing interparticle repulsion ‘returns’ some energy per area

$\unicode[STIX]{x1D6FE}_{0}$

, but reducing interparticle repulsion ‘returns’ some energy per area

![]() $\unicode[STIX]{x1D6F1}_{int}(\unicode[STIX]{x1D6E4})$

, giving a net surface tension

$\unicode[STIX]{x1D6F1}_{int}(\unicode[STIX]{x1D6E4})$

, giving a net surface tension

![]() $\unicode[STIX]{x1D6FE}_{eff}(\unicode[STIX]{x1D6E4})=\unicode[STIX]{x1D6FE}_{0}-\unicode[STIX]{x1D6F1}_{int}(\unicode[STIX]{x1D6E4})$

, and the energetic cost of deformation takes the same form as for an insoluble surfactant.

$\unicode[STIX]{x1D6FE}_{eff}(\unicode[STIX]{x1D6E4})=\unicode[STIX]{x1D6FE}_{0}-\unicode[STIX]{x1D6F1}_{int}(\unicode[STIX]{x1D6E4})$

, and the energetic cost of deformation takes the same form as for an insoluble surfactant.

Table 1. Common adsorption isotherms, and corresponding expressions for surface pressure and the Marangoni modulus.

Figure 4 gives some sense for the diverse ways that surfactants behave when one waits ‘long enough’. In what follows (§§ 2.3–3), we address questions raised by this figure. What differentiates soluble surfactants from insoluble ones? What determines the surface tension

![]() $\unicode[STIX]{x1D6FE}(\unicode[STIX]{x1D6E4})$

or

$\unicode[STIX]{x1D6FE}(\unicode[STIX]{x1D6E4})$

or

![]() $\unicode[STIX]{x1D6FE}(C)$

? How long is ‘long enough’, and what happens ‘in between’?

$\unicode[STIX]{x1D6FE}(C)$

? How long is ‘long enough’, and what happens ‘in between’?

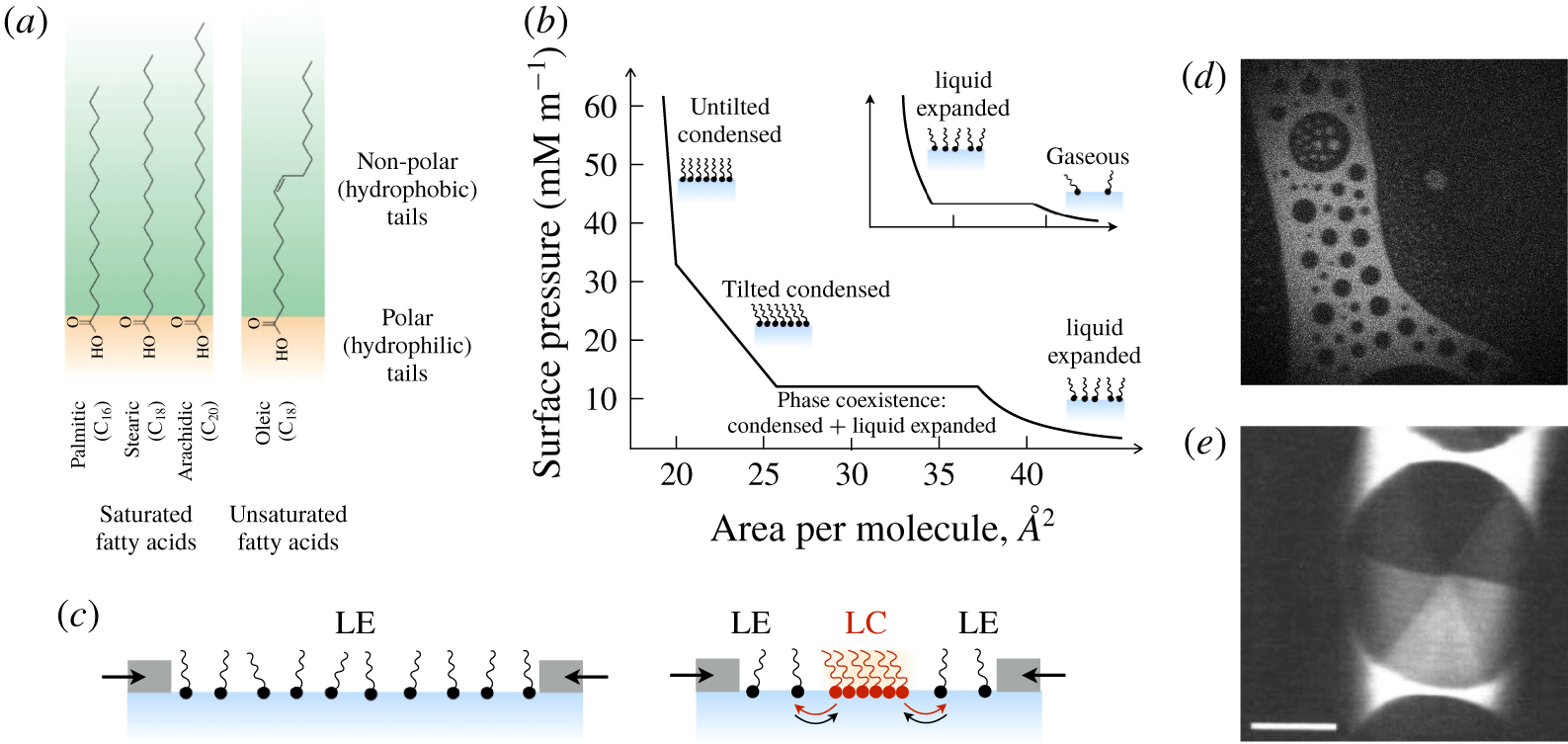

2.3 Insoluble surfactants: Langmuir monolayers

A lot of salt can be dissolved in water – but not an infinite amount. Above some solubility limit

![]() $C_{sol}$

, additional salt does not dissolve, but remains in solid form and sediments. Substances with extremely low solubility in a liquid – like wax in water – are said to be ‘insoluble’, meaning that the concentration of dissolved molecules is immeasurably small. Likewise, surfactants can be insoluble when the precipitated (aggregated) form is energetically so much more favourable than the dissolved form. Surfactants may gain entropy by dissolving, but this comes at the cost of disrupting attractive interactions between surfactants, and also entropic loss of solvent molecules. Crudely speaking, the larger the hydrophobic component, the lower the solubility of a surfactant in water. Phospholipids represent one class of surfactants that is frequently insoluble in water owing to the two (hydrophobic) hydrocarbon tails attached to each hydrophilic headgroup. The insolubility of phospholipids is essential for important biological functions: biological membranes typically consist of phospholipid bilayers – two ‘sheets’ of phospholipids, oppositely oriented, so that the hydrophilic heads face the water, and hydrophobic tails are buried internally.

$C_{sol}$

, additional salt does not dissolve, but remains in solid form and sediments. Substances with extremely low solubility in a liquid – like wax in water – are said to be ‘insoluble’, meaning that the concentration of dissolved molecules is immeasurably small. Likewise, surfactants can be insoluble when the precipitated (aggregated) form is energetically so much more favourable than the dissolved form. Surfactants may gain entropy by dissolving, but this comes at the cost of disrupting attractive interactions between surfactants, and also entropic loss of solvent molecules. Crudely speaking, the larger the hydrophobic component, the lower the solubility of a surfactant in water. Phospholipids represent one class of surfactants that is frequently insoluble in water owing to the two (hydrophobic) hydrocarbon tails attached to each hydrophilic headgroup. The insolubility of phospholipids is essential for important biological functions: biological membranes typically consist of phospholipid bilayers – two ‘sheets’ of phospholipids, oppositely oriented, so that the hydrophilic heads face the water, and hydrophobic tails are buried internally.

Monolayers formed by insoluble surfactants are called Langmuir monolayers, and can be prepared and controlled by literally spreading a known number

![]() $N$

of surfactant molecules onto a fluid surface of area

$N$

of surfactant molecules onto a fluid surface of area

![]() $A$

, to give a surface concentration

$A$

, to give a surface concentration

Langmuir troughs allow this surface concentration

![]() $\unicode[STIX]{x1D6E4}$

of insoluble surfactants to be controlled using mobile barriers to change the area

$\unicode[STIX]{x1D6E4}$

of insoluble surfactants to be controlled using mobile barriers to change the area

![]() $A$

available to the

$A$

available to the

![]() $N$

surfactants on the monolayer.

$N$

surfactants on the monolayer.

Any fluid mechanician should expect that spreading some number

![]() $N$

of insoluble surfactants onto a fluid interface of area

$N$

of insoluble surfactants onto a fluid interface of area

![]() $A$

will lower its surface tension. Real questions lie just beyond this qualitative, ‘binary’ expectation. How much does the surface tension change? Why do different surfactants behave differently, both in static and dynamic situations?

$A$

will lower its surface tension. Real questions lie just beyond this qualitative, ‘binary’ expectation. How much does the surface tension change? Why do different surfactants behave differently, both in static and dynamic situations?

The simplest Langmuir monolayer consists of ‘ideal’ surfactants that are so dilute that they behave as point-like and non-interacting. The free energy required to assemble such ideal monolayers reflects the contribution from mixing entropy alone

where

![]() $\unicode[STIX]{x1D707}_{s}^{0}$

is the free energy per surfactant (chemical potential) of a reference monolayer of surfactant concentration

$\unicode[STIX]{x1D707}_{s}^{0}$

is the free energy per surfactant (chemical potential) of a reference monolayer of surfactant concentration

![]() $\unicode[STIX]{x1D6E4}_{0}$

. Equation (2.8) represents the 2-D analogue of an (3-D) ideal gas.

$\unicode[STIX]{x1D6E4}_{0}$

. Equation (2.8) represents the 2-D analogue of an (3-D) ideal gas.

Just like the pressure of a 3-D material is defined by the energy required to compress it isothermally,

the surface pressure

![]() $\unicode[STIX]{x1D6F1}$

exerted by a species bound to a surface is determined by the energy required to compress it isothermally, in two dimensions

$\unicode[STIX]{x1D6F1}$

exerted by a species bound to a surface is determined by the energy required to compress it isothermally, in two dimensions

The surface pressure of an ideal Langmuir monolayer (2.8) can then be computed using (2.10) to give

as should be expected for an ideal, 2-D gas.

Despite its clear analogy to 3-D pressure, and its clear thermodynamic status, the surface pressure

![]() $\unicode[STIX]{x1D6F1}$

is largely unfamiliar to the fluid mechanics community. It can, however, be simply connected to more familiar terrain. Namely, the surface tension

$\unicode[STIX]{x1D6F1}$

is largely unfamiliar to the fluid mechanics community. It can, however, be simply connected to more familiar terrain. Namely, the surface tension

![]() $\unicode[STIX]{x1D6FE}_{0}$

of clean fluid interfaces pulls on interfaces, acting to reduce interfacial area. At the same time, the surface pressure

$\unicode[STIX]{x1D6FE}_{0}$

of clean fluid interfaces pulls on interfaces, acting to reduce interfacial area. At the same time, the surface pressure

![]() $\unicode[STIX]{x1D6F1}$

of adsorbed surfactant pushes outward on interfaces, acting to increase interfacial area. The net effect is what a fluid mechanician would simply call the surface tension

$\unicode[STIX]{x1D6F1}$

of adsorbed surfactant pushes outward on interfaces, acting to increase interfacial area. The net effect is what a fluid mechanician would simply call the surface tension

![]() $\unicode[STIX]{x1D6FE}(\unicode[STIX]{x1D6E4})$

:

$\unicode[STIX]{x1D6FE}(\unicode[STIX]{x1D6E4})$

:

In other words, the surface pressure

![]() $\unicode[STIX]{x1D6F1}(\unicode[STIX]{x1D6E4})$

exerted by a surfactant monolayer represents the reduction in surface tension caused by the surfactant.

$\unicode[STIX]{x1D6F1}(\unicode[STIX]{x1D6E4})$

exerted by a surfactant monolayer represents the reduction in surface tension caused by the surfactant.

Although intuitive and straightforward, the ideal gas model, (2.8) and (2.11), is almost never appropriate in describing real surfactants. This can be seen by evaluating (2.11) to determine the surface concentration

![]() $\unicode[STIX]{x1D6E4}_{1}$

required for an ideal gas surfactant to reduce surface tension by a nominal amount, e.g.

$\unicode[STIX]{x1D6E4}_{1}$

required for an ideal gas surfactant to reduce surface tension by a nominal amount, e.g.

![]() $\unicode[STIX]{x1D6F1}_{1}\sim 1~\text{mN}~\text{m}^{-1}$

, which is just over 1 % of the surface tension of clean water

$\unicode[STIX]{x1D6F1}_{1}\sim 1~\text{mN}~\text{m}^{-1}$

, which is just over 1 % of the surface tension of clean water

Ideal gas surfactants must be packed to surface concentrations of at least one per few square nanometres to exert even a small surface pressure, but must nonetheless obey the ideal gas conditions. First, each surfactant must behave as ‘point-like’, meaning that its molecular radius must be significantly smaller than 2 nm. This restriction effectively renders the ideal gas description invalid for proteins, nanoparticles and colloids. Second, intermolecular interactions must be negligible over

![]() ${\sim}\text{nm}$

length scales – also a rarity, given the strength of van der Waals interactions between hydrophobic tails, interfacial electrostatic dipoles and electrostatic repulsions between headgroups at nm length scales.

${\sim}\text{nm}$

length scales – also a rarity, given the strength of van der Waals interactions between hydrophobic tails, interfacial electrostatic dipoles and electrostatic repulsions between headgroups at nm length scales.

If surfactant monolayers cannot be described by ideal gas behaviour, then how can one describe them? In many cases,

![]() $\unicode[STIX]{x1D6F1}$

versus

$\unicode[STIX]{x1D6F1}$

versus

![]() $\unicode[STIX]{x1D6E4}$

isotherms are simply measured. However, ‘simple’ violations of the point-like and non-interacting assumptions in the ideal gas model can be accommodated analogous to treatments of 3-D gasses.

$\unicode[STIX]{x1D6E4}$

isotherms are simply measured. However, ‘simple’ violations of the point-like and non-interacting assumptions in the ideal gas model can be accommodated analogous to treatments of 3-D gasses.

For example, the Langmuir isotherm accounts for finite surfactant size

![]() $A_{0}\equiv 1/\unicode[STIX]{x1D6E4}_{\infty }$

by effectively allowing them to occupy sites on a lattice. Assuming

$A_{0}\equiv 1/\unicode[STIX]{x1D6E4}_{\infty }$

by effectively allowing them to occupy sites on a lattice. Assuming

![]() $N$

surfactants to occupy a fraction of

$N$

surfactants to occupy a fraction of

![]() $N_{\infty }=\unicode[STIX]{x1D6E4}_{\infty }A$

such sites, the free energy of the interface is (Diamant & Andelman Reference Diamant and Andelman1996; Kralchevsky, Danov & Denkov Reference Kralchevsky, Danov and Denkov2008)

$N_{\infty }=\unicode[STIX]{x1D6E4}_{\infty }A$

such sites, the free energy of the interface is (Diamant & Andelman Reference Diamant and Andelman1996; Kralchevsky, Danov & Denkov Reference Kralchevsky, Danov and Denkov2008)

where

![]() $\unicode[STIX]{x1D707}_{s}^{0}$

is the chemical potential at half-maximum packing (

$\unicode[STIX]{x1D707}_{s}^{0}$

is the chemical potential at half-maximum packing (

![]() $\unicode[STIX]{x1D6E4}_{\infty }/2$

). As with the ideal gas, (2.14) omits all interactions between surfactants, but instead accounts only for the free energy of mixing of both the occupied and unoccupied sites.

$\unicode[STIX]{x1D6E4}_{\infty }/2$

). As with the ideal gas, (2.14) omits all interactions between surfactants, but instead accounts only for the free energy of mixing of both the occupied and unoccupied sites.

Computing surface pressure using (2.10) for the lattice gas (2.14) gives the so-called Langmuir isotherm,

At low surfactant concentrations

![]() $\unicode[STIX]{x1D6E4}\ll \unicode[STIX]{x1D6E4}_{\infty }$

,

$\unicode[STIX]{x1D6E4}\ll \unicode[STIX]{x1D6E4}_{\infty }$

,

![]() $\unicode[STIX]{x1D6F1}^{L}$

reduces to

$\unicode[STIX]{x1D6F1}^{L}$

reduces to

![]() $\unicode[STIX]{x1D6F1}^{ideal}$

. As surfactant concentration

$\unicode[STIX]{x1D6F1}^{ideal}$

. As surfactant concentration

![]() $\unicode[STIX]{x1D6E4}$

approaches

$\unicode[STIX]{x1D6E4}$

approaches

![]() $\unicode[STIX]{x1D6E4}_{\infty }$

, however, the surface pressure diverges.

$\unicode[STIX]{x1D6E4}_{\infty }$

, however, the surface pressure diverges.

Rather than constraining surfactants to a lattice, surfactants with finite size might simply reduce the area available for surfactants to explore. Placing

![]() $N$

surfactants, each of area

$N$

surfactants, each of area

![]() $A_{0}\equiv 1/\unicode[STIX]{x1D6E4}_{\infty }$

, onto a surface of area

$A_{0}\equiv 1/\unicode[STIX]{x1D6E4}_{\infty }$

, onto a surface of area

![]() $A$

leaves an unoccupied area

$A$

leaves an unoccupied area

![]() $A^{\prime }=A-N/\unicode[STIX]{x1D6E4}_{\infty }$

. Replacing

$A^{\prime }=A-N/\unicode[STIX]{x1D6E4}_{\infty }$

. Replacing

![]() $A$

in the ideal gas expression

$A$

in the ideal gas expression

![]() ${\mathcal{F}}_{s}^{ideal}$

with

${\mathcal{F}}_{s}^{ideal}$

with

![]() $A^{\prime }$

,

$A^{\prime }$

,

gives the Volmer isotherm,

Like the Langmuir isotherm, the Volmer pressure recovers the ideal gas pressure as

![]() $\unicode[STIX]{x1D6E4}\ll \unicode[STIX]{x1D6E4}_{\infty }$

, and diverges as

$\unicode[STIX]{x1D6E4}\ll \unicode[STIX]{x1D6E4}_{\infty }$

, and diverges as

![]() $\unicode[STIX]{x1D6E4}\rightarrow \unicode[STIX]{x1D6E4}_{\infty }$

, but in a different way than

$\unicode[STIX]{x1D6E4}\rightarrow \unicode[STIX]{x1D6E4}_{\infty }$

, but in a different way than

![]() $\unicode[STIX]{x1D6F1}^{L}$

.

$\unicode[STIX]{x1D6F1}^{L}$

.

One might think it would be straightforward to distinguish between the Langmuir and Volmer forms for the divergence, but interactions between surfactants become significant and alter this form considerably.

The simplest way to include interactions between surfactants is perturbatively, i.e. adding a term to either the Langmuir (2.14) or Volmer (2.16) expressions

that reduces the free energy to assemble a monolayer of mutually attractive surfactants (when

![]() $\unicode[STIX]{x1D6FD}>0$

), or vice versa for repulsive interactions. For example, adding (2.18) to the Volmer free energy

$\unicode[STIX]{x1D6FD}>0$

), or vice versa for repulsive interactions. For example, adding (2.18) to the Volmer free energy

![]() ${\mathcal{F}}_{s}^{V}$

gives the van der Waals monolayer,

${\mathcal{F}}_{s}^{V}$

gives the van der Waals monolayer,

with surface pressure

Equation (2.20) is the precise two-dimensional analogue of the 3-D van der Waals equation of state. Similarly, adding the interaction term (2.18) to the Langmuir surface free energy

![]() ${\mathcal{F}}_{s}^{L}$

(2.14) gives the Frumkin isotherm (see table 1). Kralchevsky et al. (Reference Kralchevsky, Danov and Denkov2008) provide a detailed thermodynamic derivation of each of these commonly used models, the results of which are summarized in table 1 and illustrated in figure 5.

${\mathcal{F}}_{s}^{L}$

(2.14) gives the Frumkin isotherm (see table 1). Kralchevsky et al. (Reference Kralchevsky, Danov and Denkov2008) provide a detailed thermodynamic derivation of each of these commonly used models, the results of which are summarized in table 1 and illustrated in figure 5.

Figure 5. The (a)

![]() $\unicode[STIX]{x1D6E4}(C)$

and (b)

$\unicode[STIX]{x1D6E4}(C)$

and (b)

![]() $\unicode[STIX]{x1D6F1}(\unicode[STIX]{x1D6E4})$

relations corresponding to Frumkin adsorption from an ideal subphase. Intermolecular interactions are attractive when

$\unicode[STIX]{x1D6F1}(\unicode[STIX]{x1D6E4})$

relations corresponding to Frumkin adsorption from an ideal subphase. Intermolecular interactions are attractive when

![]() $\tilde{\unicode[STIX]{x1D6FD}}=\unicode[STIX]{x1D6FD}\unicode[STIX]{x1D6E4}_{\infty }/k_{B}T>0$

(blue lines), and repulsive when

$\tilde{\unicode[STIX]{x1D6FD}}=\unicode[STIX]{x1D6FD}\unicode[STIX]{x1D6E4}_{\infty }/k_{B}T>0$

(blue lines), and repulsive when

![]() $\tilde{\unicode[STIX]{x1D6FD}}<0$

(red lines). Here

$\tilde{\unicode[STIX]{x1D6FD}}<0$

(red lines). Here

![]() $\tilde{\unicode[STIX]{x1D6FD}}=0$

(grey solid lines) recovers Langmuir adsorption. The black line in each panel is the 2-D ideal gas limit (the Henry isotherm).

$\tilde{\unicode[STIX]{x1D6FD}}=0$

(grey solid lines) recovers Langmuir adsorption. The black line in each panel is the 2-D ideal gas limit (the Henry isotherm).

2.3.1 Compressibility: Gibbs (

$E$

) and Marangoni (

$E$

) and Marangoni (

$E_{0}$

) moduli

$E_{0}$

) moduli

The surface compressional (or dilatational) modulus,

measures the resistance of the surface to compression, completely analogous to 3-D materials. For insoluble surfactants, the number of surfactants in a monolayer does not change during compression, meaning

![]() $A$

can be replaced with

$A$

can be replaced with

![]() $N/\unicode[STIX]{x1D6E4}$

in (2.21) to give the insoluble dilatational modulus

$N/\unicode[STIX]{x1D6E4}$

in (2.21) to give the insoluble dilatational modulus

The nomenclature of (2.21) and (2.22) varies across the surfactant literature, with the names of Gibbs, Marangoni, Gibbs–Marangoni or simply dilatational modulus used for both

![]() $E$

and

$E$

and

![]() $E_{0}$

. For the purposes of this review, we will consistently call

$E_{0}$

. For the purposes of this review, we will consistently call

![]() $E$

the Gibbs modulus and

$E$

the Gibbs modulus and

![]() $E_{0}$

the Marangoni modulus.

$E_{0}$

the Marangoni modulus.

The Marangoni modulus

![]() $E_{0}$

measures the work done in squeezing surfactant molecules together, and generally increases with surfactant concentration. For example, ideal gas monolayers have Marangoni modulus

$E_{0}$

measures the work done in squeezing surfactant molecules together, and generally increases with surfactant concentration. For example, ideal gas monolayers have Marangoni modulus

with expressions for other isotherms given in table 1. Notably, the Marangoni modulus for the van der Waals isotherm,

becomes negative for a range of

![]() $\unicode[STIX]{x1D6E4}$

whenever

$\unicode[STIX]{x1D6E4}$

whenever

![]() $\unicode[STIX]{x1D6FD}\unicode[STIX]{x1D6E4}_{\infty }/k_{B}T>27/4$

. Just like in three dimensions, a monolayer with negative compressibility is mechanically unstable, and undergoes phase separation to a two-phase coexistence between a high-

$\unicode[STIX]{x1D6FD}\unicode[STIX]{x1D6E4}_{\infty }/k_{B}T>27/4$

. Just like in three dimensions, a monolayer with negative compressibility is mechanically unstable, and undergoes phase separation to a two-phase coexistence between a high-

![]() $\unicode[STIX]{x1D6E4}$

condensed phase, and a low-

$\unicode[STIX]{x1D6E4}$

condensed phase, and a low-

![]() $\unicode[STIX]{x1D6E4}$

expanded phase.

$\unicode[STIX]{x1D6E4}$

expanded phase.

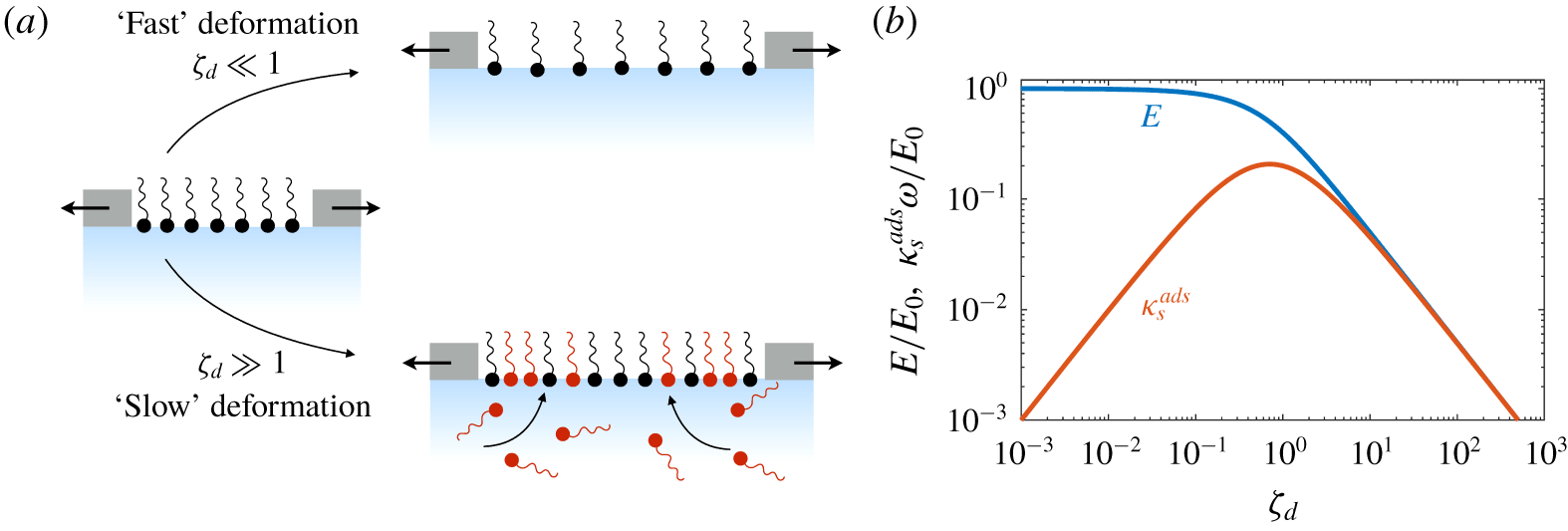

In what follows (§§ 2.4.2 and 3.2), we will find that monolayers (soluble or insoluble) do not always react instantaneously following compression – finite time scales are required for phase transitions to occur, for surfactants to adsorb or desorb to equilibrate with the surrounding bulk fluid, or for surfactant gradients in the surroundings to diffusively relax. In this regard, the Marangoni modulus

![]() $E_{0}$

reflects an intrinsic material property, whereas the Gibbs modulus

$E_{0}$

reflects an intrinsic material property, whereas the Gibbs modulus

![]() $E$

describes the dynamic response of a macroscopic interface, which additionally depends on the shape, size and time scales of the forcing.

$E$

describes the dynamic response of a macroscopic interface, which additionally depends on the shape, size and time scales of the forcing.

2.3.2 The chemical potential

In preparation for the upcoming transition to soluble surfactants, we discuss one final thermodynamic property of Langmuir monolayers. The chemical potential represents the free energy cost of adding one additional molecule to the monolayer, holding temperature and area constant

The chemical potential of a monolayer of ideal surfactants – as described by (2.8) – is

or, equivalently,

where

![]() $\unicode[STIX]{x1D707}_{s}^{0}$

is a reference chemical potential, valid at a particular concentration

$\unicode[STIX]{x1D707}_{s}^{0}$

is a reference chemical potential, valid at a particular concentration

![]() $\unicode[STIX]{x1D6E4}_{0}$

. In what follows, we will frequently use the Langmuir (lattice) isotherm as a model; its chemical potential is

$\unicode[STIX]{x1D6E4}_{0}$

. In what follows, we will frequently use the Langmuir (lattice) isotherm as a model; its chemical potential is

where

![]() $\unicode[STIX]{x1D707}_{s}^{0}$

is the chemical potential at

$\unicode[STIX]{x1D707}_{s}^{0}$

is the chemical potential at

![]() $\unicode[STIX]{x1D6E4}=\unicode[STIX]{x1D6E4}_{\infty }/2$

.

$\unicode[STIX]{x1D6E4}=\unicode[STIX]{x1D6E4}_{\infty }/2$

.

2.4 Soluble surfactants: Gibbs monolayers

We now turn to soluble surfactants, which can dissolve into the liquid below the interface. Monolayers of soluble surfactants – called Gibbs monolayers – represent an equilibrium between surfactants adsorbed at the interface (with surface concentration

![]() $\unicode[STIX]{x1D6E4}$

) and those dissolved in the bulk (with concentration

$\unicode[STIX]{x1D6E4}$

) and those dissolved in the bulk (with concentration

![]() $C$

).

$C$

).

Detailed balance must hold for adsorbed and dissolved surfactants to be in equilibrium: as many surfactants must adsorb to a surface as desorb in any given time. For this to happen spontaneously, the two states must be equivalent from a free energy standpoint. Adding one surfactant to the monolayer costs energy – the chemical potential

![]() $\unicode[STIX]{x1D707}_{s}(\unicode[STIX]{x1D6E4})$

of the adsorbed surfactant. This free energy cost must be identical to the free energy liberated by removing that surfactant from the subphase – represented by the chemical potential

$\unicode[STIX]{x1D707}_{s}(\unicode[STIX]{x1D6E4})$

of the adsorbed surfactant. This free energy cost must be identical to the free energy liberated by removing that surfactant from the subphase – represented by the chemical potential

![]() $\unicode[STIX]{x1D707}_{b}(C)$

of the surfactant in the bulk. In short, equilibrium between dissolved and adsorbed surfactant requires

$\unicode[STIX]{x1D707}_{b}(C)$

of the surfactant in the bulk. In short, equilibrium between dissolved and adsorbed surfactant requires

which defines the equilibrium isotherm

![]() $\unicode[STIX]{x1D6E4}(C)$

.

$\unicode[STIX]{x1D6E4}(C)$

.

For example, surfactants that are sufficiently dilute in solution have ‘ideal’ chemical potential

where

![]() $\unicode[STIX]{x1D707}_{b}^{0}$

is the chemical potential at a reference concentration

$\unicode[STIX]{x1D707}_{b}^{0}$

is the chemical potential at a reference concentration

![]() $C_{0}$

.

$C_{0}$

.

If adsorbed surfactants also form an ideal gas monolayer, with

![]() $\unicode[STIX]{x1D707}_{s}$

given by (2.27), then equating chemical potentials (2.29) reveals a linear relation between adsorbed and bulk concentrations

$\unicode[STIX]{x1D707}_{s}$

given by (2.27), then equating chemical potentials (2.29) reveals a linear relation between adsorbed and bulk concentrations

or

which is called the Henry isotherm (table 1). Here

is an equilibrium constant for adsorption. The adsorption free energy

![]() $\unicode[STIX]{x0394}\unicode[STIX]{x1D707}_{ads}^{0}=\unicode[STIX]{x1D707}_{b}^{0}-\unicode[STIX]{x1D707}_{s}^{0}$

indicates the drop in free energy when a surfactant (at reference concentrations) adsorbs to the interface. As expected from statistical mechanics, the equilibrium constant

$\unicode[STIX]{x0394}\unicode[STIX]{x1D707}_{ads}^{0}=\unicode[STIX]{x1D707}_{b}^{0}-\unicode[STIX]{x1D707}_{s}^{0}$

indicates the drop in free energy when a surfactant (at reference concentrations) adsorbs to the interface. As expected from statistical mechanics, the equilibrium constant

![]() $K$

grows exponentially with

$K$

grows exponentially with

![]() $\unicode[STIX]{x0394}\unicode[STIX]{x1D707}_{ads}^{0}$

. Different choices of either reference concentration (

$\unicode[STIX]{x0394}\unicode[STIX]{x1D707}_{ads}^{0}$

. Different choices of either reference concentration (

![]() $\unicode[STIX]{x1D6E4}_{0}$

or

$\unicode[STIX]{x1D6E4}_{0}$

or

![]() $C_{0}$

), both of which are chosen arbitrarily, would change the corresponding reference chemical potentials (

$C_{0}$

), both of which are chosen arbitrarily, would change the corresponding reference chemical potentials (

![]() $\unicode[STIX]{x1D707}_{s}^{0}$

or

$\unicode[STIX]{x1D707}_{s}^{0}$

or

![]() $\unicode[STIX]{x1D707}_{b}^{0}$

, respectively), giving the same adsorption constant

$\unicode[STIX]{x1D707}_{b}^{0}$

, respectively), giving the same adsorption constant

![]() $K$

.

$K$

.

Given

![]() $\unicode[STIX]{x1D6E4}(C)$

for a Gibbs monolayer of soluble surfactant, other monolayer properties like

$\unicode[STIX]{x1D6E4}(C)$

for a Gibbs monolayer of soluble surfactant, other monolayer properties like

![]() $\unicode[STIX]{x1D6F1}(C)$

and

$\unicode[STIX]{x1D6F1}(C)$

and

![]() $E_{0}(C)$

can be determined following the thermodynamic arguments for the insoluble surfactants given above. Surface pressure

$E_{0}(C)$

can be determined following the thermodynamic arguments for the insoluble surfactants given above. Surface pressure

![]() $\unicode[STIX]{x1D6F1}$

is still defined from the surface free energy via (2.10), so that the Gibbs monolayer defined by (2.32) has

$\unicode[STIX]{x1D6F1}$

is still defined from the surface free energy via (2.10), so that the Gibbs monolayer defined by (2.32) has

with

![]() $K^{ideal}$

defined by (2.33). The Marangoni modulus, defined by (2.22), is also

$K^{ideal}$

defined by (2.33). The Marangoni modulus, defined by (2.22), is also

![]() $E_{0}^{ideal}=k_{B}TK^{ideal}C$

.

$E_{0}^{ideal}=k_{B}TK^{ideal}C$

.

More complex isotherms arise for more complex monolayers or solutions. For example, soluble surfactants that adsorb to Langmuir (lattice) monolayers have surface chemical potentials of the Langmuir form (2.28), and equilibrate with an ideal bulk solution of surfactant (2.30) to give

where

is the equilibrium constant for Langmuir adsorption, with units of

![]() $[\text{concentration}]^{-1}$

. The surface pressure for the Langmuir isotherm then follows by inserting

$[\text{concentration}]^{-1}$

. The surface pressure for the Langmuir isotherm then follows by inserting

![]() $\unicode[STIX]{x1D6E4}^{L}$

from (2.35) into

$\unicode[STIX]{x1D6E4}^{L}$

from (2.35) into

![]() $\unicode[STIX]{x1D6F1}^{L}(\unicode[STIX]{x1D6E4})$

from (2.15) to give

$\unicode[STIX]{x1D6F1}^{L}(\unicode[STIX]{x1D6E4})$

from (2.15) to give

The desorption constant,

![]() $K_{D}^{L}=(K^{L})^{-1}$

, represents a characteristic subphase concentration, at which the interface is half-saturated. The Langmuir adsorption isotherm (2.35) reduces to the ideal gas isotherm (2.34) for concentrations significantly below

$K_{D}^{L}=(K^{L})^{-1}$

, represents a characteristic subphase concentration, at which the interface is half-saturated. The Langmuir adsorption isotherm (2.35) reduces to the ideal gas isotherm (2.34) for concentrations significantly below

![]() $K_{D}^{L}$

(i.e.

$K_{D}^{L}$

(i.e.

![]() $C\ll 1/K^{L}$

). Similar to insoluble monolayers, adding an interaction term to the surface chemical potential of the Langmuir form gives the Frumkin isotherm. Other models of monolayers that equilibrate with ideal surfactant solutions are reviewed by Kralchevsky et al. (Reference Kralchevsky, Danov and Denkov2008), summarized in table 1 and illustrated in figure 5. All but the (purely empirical) Freundlich isotherm reduce to ideal gas monolayers at sufficiently low

$C\ll 1/K^{L}$

). Similar to insoluble monolayers, adding an interaction term to the surface chemical potential of the Langmuir form gives the Frumkin isotherm. Other models of monolayers that equilibrate with ideal surfactant solutions are reviewed by Kralchevsky et al. (Reference Kralchevsky, Danov and Denkov2008), summarized in table 1 and illustrated in figure 5. All but the (purely empirical) Freundlich isotherm reduce to ideal gas monolayers at sufficiently low

![]() $C$

.

$C$

.

Alternatively, surfactants dissolved in solution may show non-ideal behaviour. The most common example is micellization: above a critical micelle concentration (CMC), some surfactants spontaneously aggregate to form micelles. Spherical micelles are most common, but cylinders (‘wormlike micelles’), lamellae and vesicles can also form, depending on molecular morphology and intermolecular forces (Myers Reference Myers2006; Israelachvili Reference Israelachvili2011). The energetics, kinetics, and morphology of micelles is a broad and well-studied topic that is beyond the scope of this review. We will merely point out that at equilibrium and above the CMC, the chemical potential of surfactant monomers,

![]() $\unicode[STIX]{x1D707}_{b}(C)$

, must equal the chemical potential of surfactant molecules in micelles,

$\unicode[STIX]{x1D707}_{b}(C)$

, must equal the chemical potential of surfactant molecules in micelles,

![]() $\unicode[STIX]{x1D707}_{mic}(C)$

, both of which in turn must equal the chemical potential

$\unicode[STIX]{x1D707}_{mic}(C)$

, both of which in turn must equal the chemical potential

![]() $\unicode[STIX]{x1D707}_{s}(\unicode[STIX]{x1D6E4})$

of adsorbed surfactant molecules. In other words, micellization provides an energetic alternative to further interfacial adsorption: once conditions favour micelle formation, adding further surfactant to solution tends to form additional micelles, rather than increase interfacial concentration. Indeed, identifying the bulk concentration at which the surface tension, and ostensibly the surface concentration, becomes approximately constant is a common method for measuring the CMC.

$\unicode[STIX]{x1D707}_{s}(\unicode[STIX]{x1D6E4})$

of adsorbed surfactant molecules. In other words, micellization provides an energetic alternative to further interfacial adsorption: once conditions favour micelle formation, adding further surfactant to solution tends to form additional micelles, rather than increase interfacial concentration. Indeed, identifying the bulk concentration at which the surface tension, and ostensibly the surface concentration, becomes approximately constant is a common method for measuring the CMC.

2.4.1 Gibbs isotherm

It is frequently difficult to measure the surface concentration

![]() $\unicode[STIX]{x1D6E4}$

of soluble surfactants; more common is to measure surface pressure

$\unicode[STIX]{x1D6E4}$

of soluble surfactants; more common is to measure surface pressure

![]() $\unicode[STIX]{x1D6F1}$

(or, equivalently, surface tension

$\unicode[STIX]{x1D6F1}$

(or, equivalently, surface tension

![]() $\unicode[STIX]{x1D6FE}$

) as a function of subphase concentration

$\unicode[STIX]{x1D6FE}$

) as a function of subphase concentration

![]() $C$

. In such cases, the Gibbs adsorption isotherm allows

$C$

. In such cases, the Gibbs adsorption isotherm allows

![]() $\unicode[STIX]{x1D6E4}$

to be derived from measured

$\unicode[STIX]{x1D6E4}$

to be derived from measured

![]() $\unicode[STIX]{x1D6F1}(C)$

relations (Martínez-Balbuena et al.

Reference Martínez-Balbuena, Arteaga-Jiménez, Hernández-Zapata and Márquez-Beltrán2017). The Gibbs relation connects changes in surface pressure

$\unicode[STIX]{x1D6F1}(C)$

relations (Martínez-Balbuena et al.

Reference Martínez-Balbuena, Arteaga-Jiménez, Hernández-Zapata and Márquez-Beltrán2017). The Gibbs relation connects changes in surface pressure

![]() $\unicode[STIX]{x1D6F1}$

to changes in the chemical potential

$\unicode[STIX]{x1D6F1}$

to changes in the chemical potential

![]() $\unicode[STIX]{x1D707}_{s}$

of adsorbed surfactants at concentration

$\unicode[STIX]{x1D707}_{s}$

of adsorbed surfactants at concentration

![]() $\unicode[STIX]{x1D6E4}$

, via (Adamson Reference Adamson1990; Myers Reference Myers2006; Kralchevsky et al.

Reference Kralchevsky, Danov and Denkov2008)

$\unicode[STIX]{x1D6E4}$

, via (Adamson Reference Adamson1990; Myers Reference Myers2006; Kralchevsky et al.

Reference Kralchevsky, Danov and Denkov2008)

The chemical potential of adsorbed surfactants

![]() $\unicode[STIX]{x1D707}_{s}$

is difficult to determine directly since

$\unicode[STIX]{x1D707}_{s}$

is difficult to determine directly since

![]() $\unicode[STIX]{x1D6E4}$

is unknown for soluble surfactants. However, when bulk and adsorbed surfactants are equilibrated,

$\unicode[STIX]{x1D6E4}$

is unknown for soluble surfactants. However, when bulk and adsorbed surfactants are equilibrated,

![]() $\unicode[STIX]{x1D707}_{s}$

must be equal to

$\unicode[STIX]{x1D707}_{s}$

must be equal to

![]() $\unicode[STIX]{x1D707}_{b}$

for the dissolved surfactants. In cases where the surfactant solution is dilute enough to behave as ideal,

$\unicode[STIX]{x1D707}_{b}$

for the dissolved surfactants. In cases where the surfactant solution is dilute enough to behave as ideal,

![]() $\unicode[STIX]{x1D707}_{b}(C)$

is given by (2.30), in which case

$\unicode[STIX]{x1D707}_{b}(C)$

is given by (2.30), in which case

The Gibbs relation (2.38) then gives

In other words, the adsorbed surfactant concentration

![]() $\unicode[STIX]{x1D6E4}$

can be determined from measurements of surface pressure

$\unicode[STIX]{x1D6E4}$

can be determined from measurements of surface pressure

![]() $\unicode[STIX]{x1D6F1}$

as a function of dissolved surfactant concentration

$\unicode[STIX]{x1D6F1}$

as a function of dissolved surfactant concentration

![]() $C$

, so long as the system has equilibrated, and the concentration is well below the CMC (Martínez-Balbuena et al.

Reference Martínez-Balbuena, Arteaga-Jiménez, Hernández-Zapata and Márquez-Beltrán2017).

$C$

, so long as the system has equilibrated, and the concentration is well below the CMC (Martínez-Balbuena et al.

Reference Martínez-Balbuena, Arteaga-Jiménez, Hernández-Zapata and Márquez-Beltrán2017).

2.4.2 Compressibility:

$E$

and

$E$

and

$E_{0}$

for soluble surfactants

$E_{0}$

for soluble surfactants

The distinction between the Gibbs and Marangoni moduli,

![]() $E$

and

$E$

and

![]() $E_{0}$

, defined by (2.21) and (2.22) respectively, becomes significant for soluble monolayers. Recall that

$E_{0}$

, defined by (2.21) and (2.22) respectively, becomes significant for soluble monolayers. Recall that

![]() $E$

tracks surface pressure changes when the monolayer area

$E$

tracks surface pressure changes when the monolayer area

![]() $A$

is changed, whereas

$A$

is changed, whereas

![]() $E_{0}$

additionally holds the number

$E_{0}$

additionally holds the number

![]() $N$

of adsorbed surfactant molecules fixed – meaning

$N$

of adsorbed surfactant molecules fixed – meaning

![]() $\unicode[STIX]{x1D6E4}$

changes when

$\unicode[STIX]{x1D6E4}$

changes when

![]() $A$

does. Compressing monolayers of soluble surfactants raises the chemical potential

$A$

does. Compressing monolayers of soluble surfactants raises the chemical potential

![]() $\unicode[STIX]{x1D707}_{s}$

of the adsorbed surfactants, without changing the concentration or chemical potential

$\unicode[STIX]{x1D707}_{s}$

of the adsorbed surfactants, without changing the concentration or chemical potential

![]() $\unicode[STIX]{x1D707}_{b}(C)$

of the dissolved surfactant. A thermodynamic force drives adsorbed surfactants to desorb, until

$\unicode[STIX]{x1D707}_{b}(C)$

of the dissolved surfactant. A thermodynamic force drives adsorbed surfactants to desorb, until

![]() $\unicode[STIX]{x1D6E4}$

returns to the value predicted by (2.29). Once equilibrium is re-established,

$\unicode[STIX]{x1D6E4}$

returns to the value predicted by (2.29). Once equilibrium is re-established,

![]() $\unicode[STIX]{x1D6E4}$

returns to its initial value, so that

$\unicode[STIX]{x1D6E4}$

returns to its initial value, so that

How quickly the interface re-equilibrates cannot be determined from thermodynamic properties alone, as discussed in § 3.2.

Soluble surfactant monolayers do have a non-zero Marangoni modulus

![]() $E_{0}$

, however. After all,

$E_{0}$

, however. After all,

![]() $\unicode[STIX]{x1D6E4}$

(and therefore

$\unicode[STIX]{x1D6E4}$

(and therefore

![]() $\unicode[STIX]{x1D6F1}$

) must increase during a rapid compression of a Gibbs monolayer, before the surfactants have had the chance to desorb. The Gibbs adsorption equation (2.40), however, offers a route to

$\unicode[STIX]{x1D6F1}$

) must increase during a rapid compression of a Gibbs monolayer, before the surfactants have had the chance to desorb. The Gibbs adsorption equation (2.40), however, offers a route to

![]() $E_{0}$

for soluble surfactant monolayers from measured

$E_{0}$

for soluble surfactant monolayers from measured

![]() $\unicode[STIX]{x1D6F1}(C)$

isotherms

$\unicode[STIX]{x1D6F1}(C)$

isotherms

Substituting

![]() $\unicode[STIX]{x1D6E4}$

and

$\unicode[STIX]{x1D6E4}$

and

![]() $\unicode[STIX]{x2202}\unicode[STIX]{x1D6E4}/\unicode[STIX]{x2202}\ln C$

using (2.40) gives

$\unicode[STIX]{x2202}\unicode[STIX]{x1D6E4}/\unicode[STIX]{x2202}\ln C$

using (2.40) gives

where primes denote differentiation with respect to

![]() $\ln C$

.

$\ln C$

.

While the Gibbs modulus

![]() $E$

describes the monolayer’s mechanical response to macroscopic compression or expansion

$E$

describes the monolayer’s mechanical response to macroscopic compression or expansion

![]() $(dA)$

, the Marangoni modulus

$(dA)$

, the Marangoni modulus

![]() $E_{0}$

reflects sensitivity to intrinsic molecular concentrations

$E_{0}$

reflects sensitivity to intrinsic molecular concentrations

![]() $\unicode[STIX]{x1D6E4}$

, and will play an important role in establishing an effective surface dilatational viscosity for surfactant monolayers, as shown in § 4.2.

$\unicode[STIX]{x1D6E4}$

, and will play an important role in establishing an effective surface dilatational viscosity for surfactant monolayers, as shown in § 4.2.

2.4.3 Soluble isotherms via dynamic equilibrium

Equilibrium between surfactants adsorbed at an interface and dissolved in the subphase can also be determined by explicitly balancing adsorption and desorption fluxes. This approach holds particular value to the fluid mechanics community, as it connects the equilibrium arguments and measurements made above to Marangoni stresses and dynamical processes in surfactant systems.

The simplest expressions for adsorption and desorption fluxes – which one should expect to hold for ideal mixtures in both the monolayer and in the bulk – is to take the adsorption flux,

![]() $j_{a}$

, to be proportional to the bulk concentration

$j_{a}$

, to be proportional to the bulk concentration

![]() $C$

, and the desorption flux

$C$

, and the desorption flux

![]() $j_{d}$

to be proportional to the adsorbed concentration

$j_{d}$

to be proportional to the adsorbed concentration

![]() $\unicode[STIX]{x1D6E4}$

:

$\unicode[STIX]{x1D6E4}$

:

These fluxes balance at equilibrium,

![]() $j_{a}=j_{d}$

, giving

$j_{a}=j_{d}$

, giving

reproducing the Henry isotherm (2.32). Previously, the adsorption constant

![]() $K^{ideal}$

was shown to depend upon the free energy of adsorption

$K^{ideal}$

was shown to depend upon the free energy of adsorption

![]() $\unicode[STIX]{x0394}\unicode[STIX]{x1D707}=\unicode[STIX]{x1D707}_{b}^{0}-\unicode[STIX]{x1D707}_{s}^{0}$

via (2.33). Equation (2.46) additionally relates

$\unicode[STIX]{x0394}\unicode[STIX]{x1D707}=\unicode[STIX]{x1D707}_{b}^{0}-\unicode[STIX]{x1D707}_{s}^{0}$

via (2.33). Equation (2.46) additionally relates

![]() $K^{ideal}$

to the ratio of adsorptive to desorptive rate constants

$K^{ideal}$

to the ratio of adsorptive to desorptive rate constants

![]() $k_{a}/k_{d}$

. Each individual rate constant

$k_{a}/k_{d}$

. Each individual rate constant

![]() $k_{a}$

and

$k_{a}$

and

![]() $k_{d}$

cannot be determined from an equilibrium quantity like

$k_{d}$

cannot be determined from an equilibrium quantity like

![]() $K$

; however, the ratio of the two is set by thermodynamics.

$K$

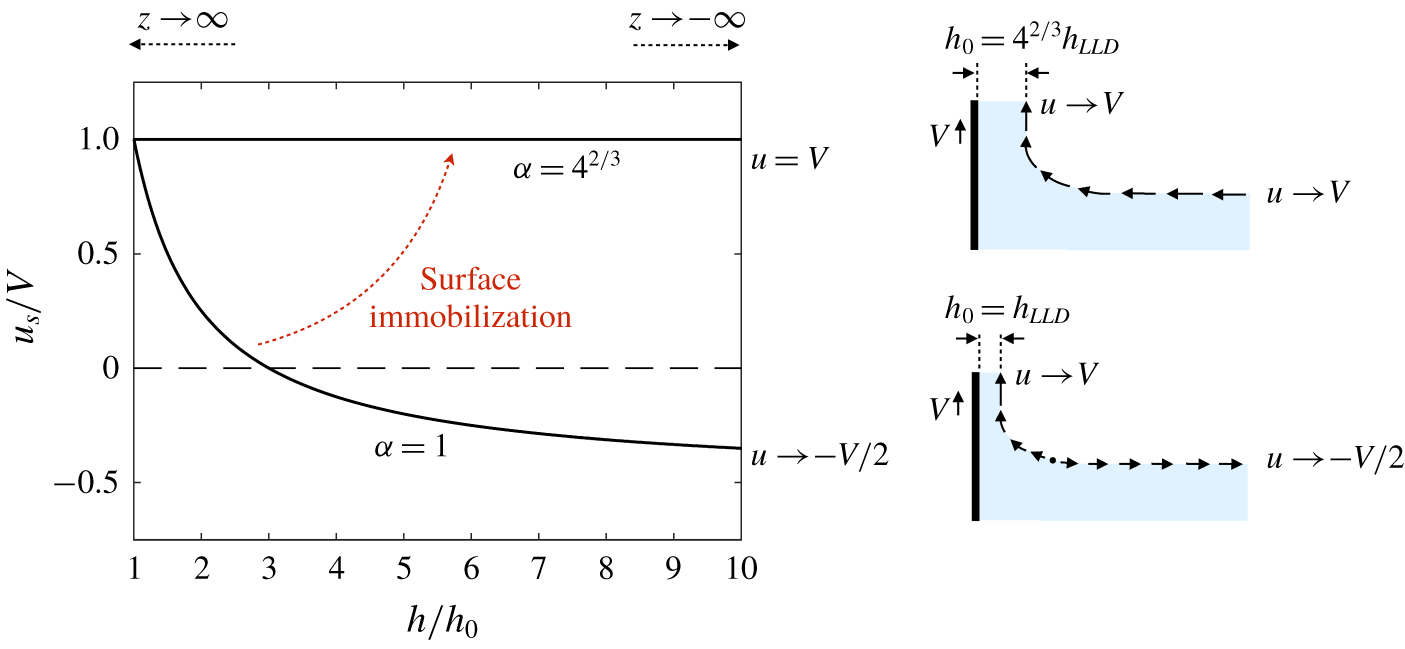

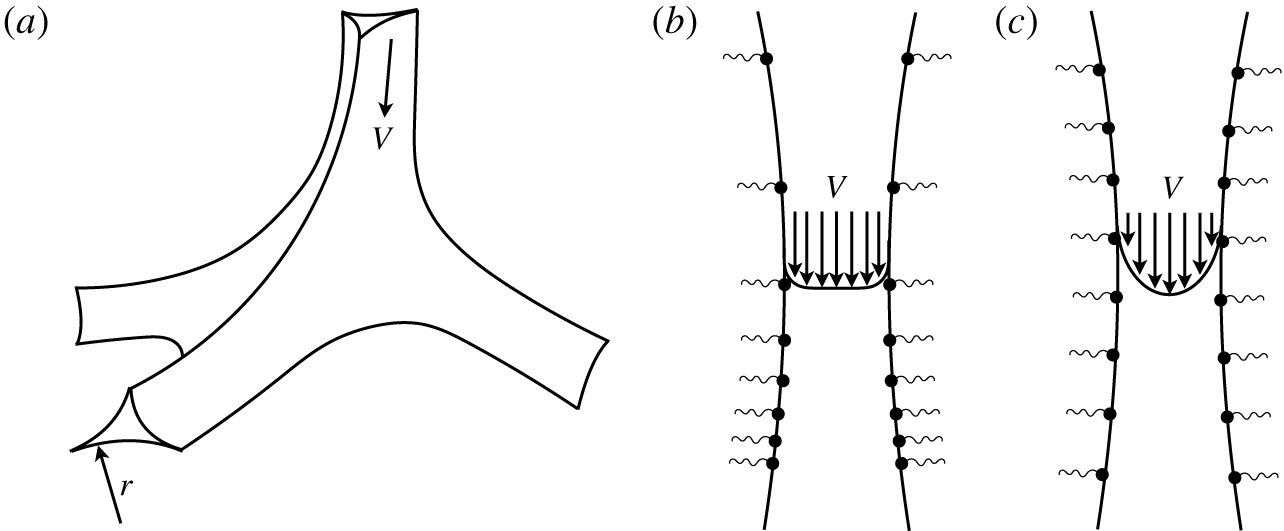

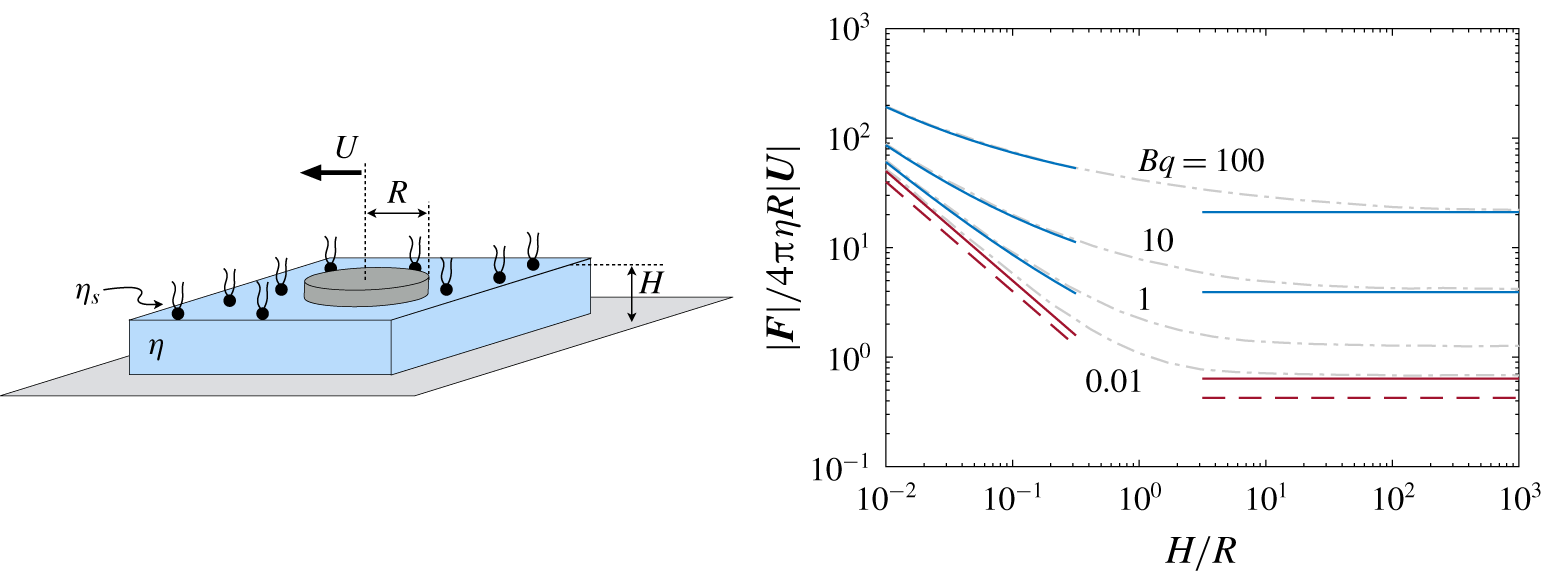

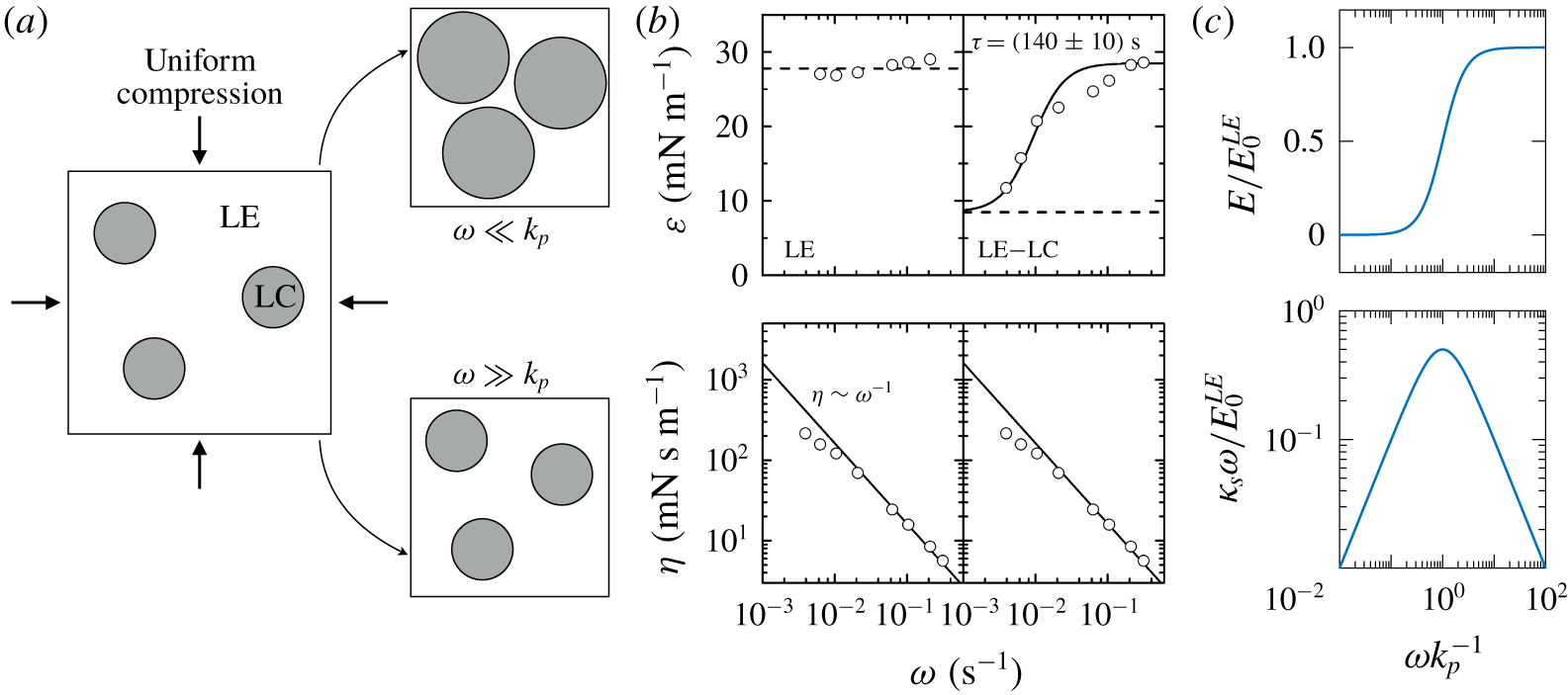

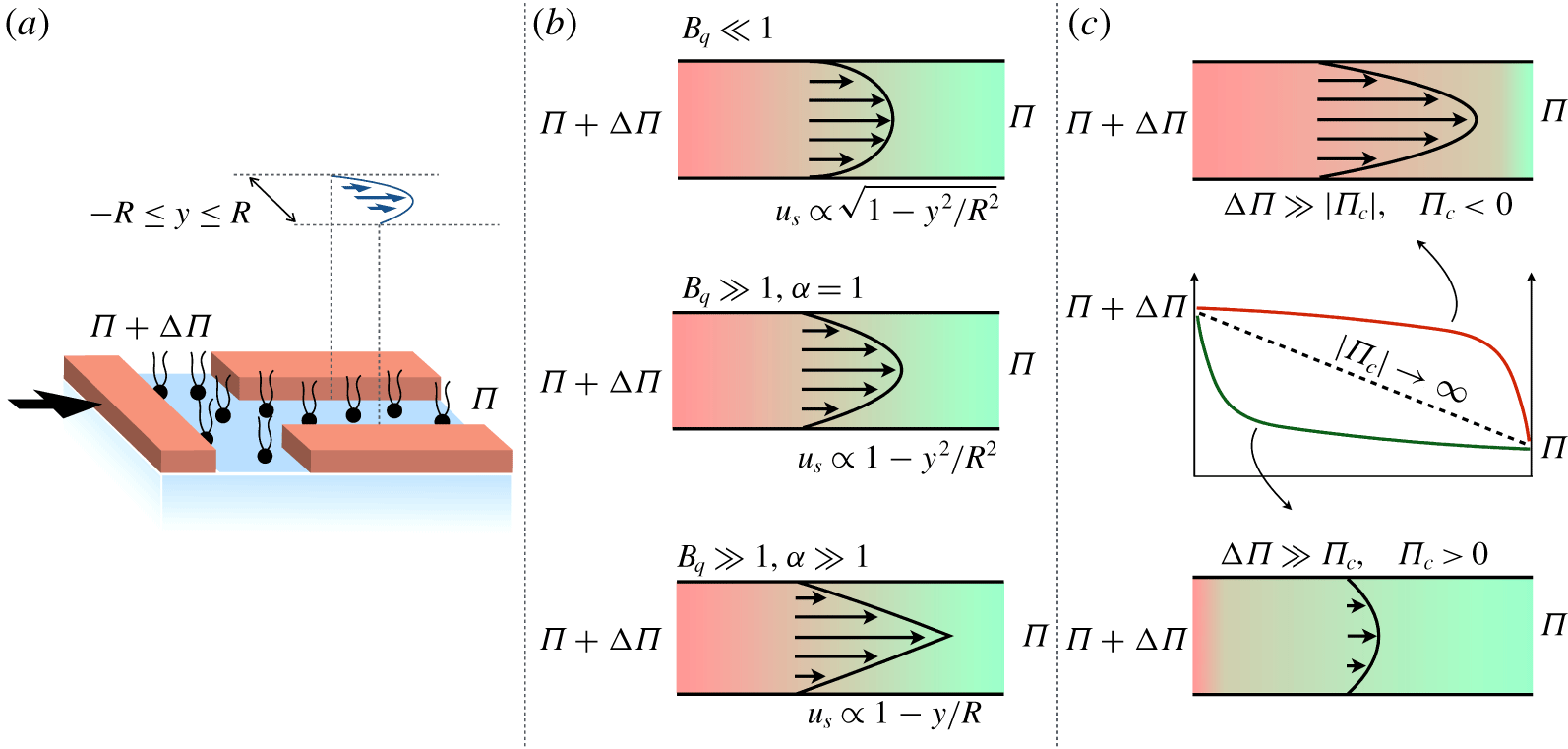

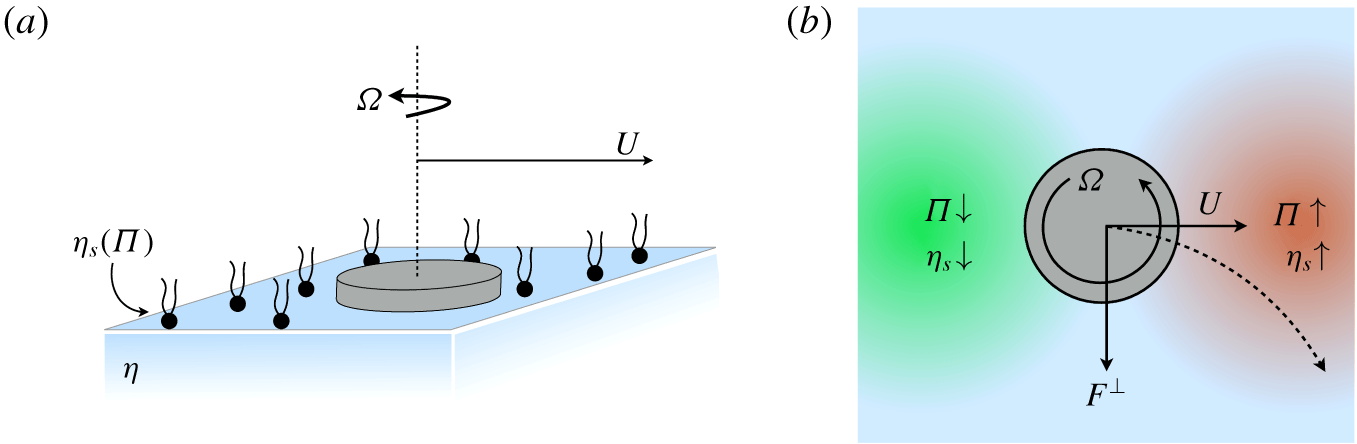

; however, the ratio of the two is set by thermodynamics.