Ceramics have many important high-temperature industrial applications but are exemplars of brittle failure. Yttria-stabilized zirconia (YSZ) is a ceramic that undergoes a stress-induced phase transformation that grants it limited ductility as crack propagation is slowed. However, further increases in ductility remain elusive as ceramics lack the ability to support a high-enough dislocation density. In a recent issue of Nature Communications (doi:10.1038/s41467-018-04333-2), Jaehun Cho, Qiang Li, Haiyan Wang, and Xinghang Zhang of Purdue University and their colleagues detail their study of flash-sintered YSZ with improved ductility.

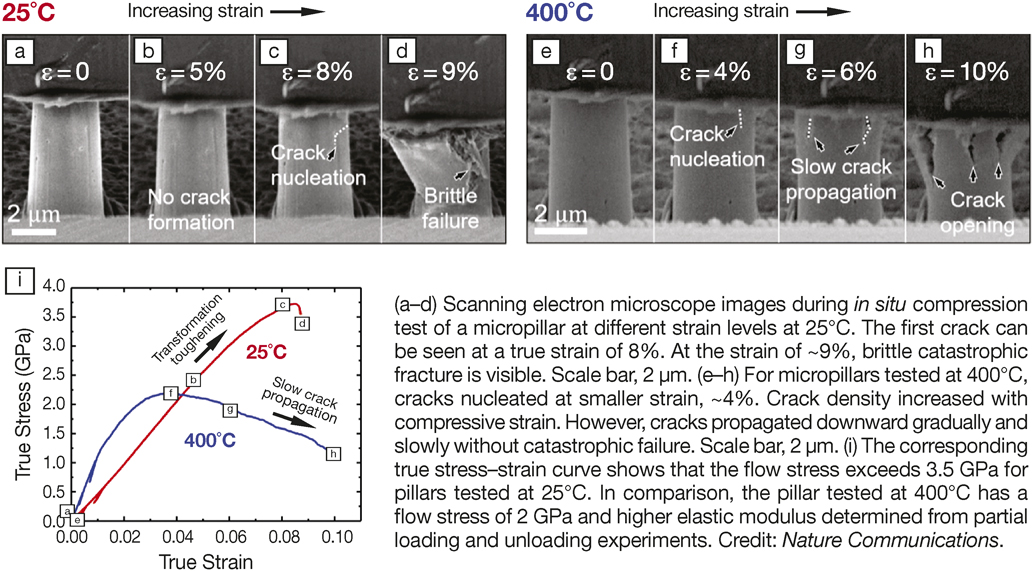

(a–d) Scanning electron microscope images during in situ compression test of a micropillar at different strain levels at 25°C. The first crack can be seen at a true strain of 8%. At the strain of ∼9%, brittle catastrophic fracture is visible. Scale bar, 2 μm. (e–h) For micropillars tested at 400°C, cracks nucleated at smaller strain, ∼4%. Crack density increased with compressive strain. However, cracks propagated downward gradually and slowly without catastrophic failure. Scale bar, 2 μm. (i) The corresponding true stress–strain curve shows that the flow stress exceeds 3.5 GPa for pillars tested at 25°C. In comparison, the pillar tested at 400°C has a flow stress of 2 GPa and higher elastic modulus determined from partial loading and unloading experiments. Credit: Nature Communications.

Flash sintering is a rapid densification process that results in nano-sized grains: heat is increasingly applied to a sample at a constant rate, under a moderate external electric field. When flash sintering was developed by Rishi Raj’s group at the University of Colorado Boulder a few years ago, this process seemed promising as a way to limit the grain growth of ceramics upon sintering, which is one of the standard ways of increasing ductility in metals—following the well-known Hall–Petch relation (doi:10.1111/j.1551-2916.2010.04089.x). Above the flash temperature, nanoparticles undergo densification within a few seconds. Once completed, the sample exhibits a significant and sudden increase in density and electrical conductivity. Haiyan Wang’s group began looking at flash-sintered ceramics and the fundamental sintering mechanisms.

The researchers studied the microstructure of flash-sintered YSZ using a transmission electron microscope. They observed dislocations (as multiple arrays of lines in the sample), which are only seen in metallic materials or ceramics deformed under extremely high temperatures. From there, the researchers began investigating the fundamental mechanism behind the ductility of flash-sintered YSZ: why does flash sintering result in high dislocation densities? They also measured the mechanical properties of flash-sintered YSZ using an in situ nanomechanical testing tool inside a scanning electron microscope. They found that while transformation toughening was the primary deformation mechanism at room temperature—with strains of 8% that led to brittle failure—at 400°C the mechanism changes and dislocations become the primary carriers of deformation—with strains of up to 10% leading to ductile failure.

B. Reeja Jayan of Carnegie Mellon University, not associated with this study, was impressed to see the high density of dislocations in flash-sintered YSZ. “Understanding such processing–structure–property relationships under external fields is exciting and will be an active area of research,” she says.

In future work, the research team hopes to generalize the results to other ceramic systems by understanding which are key in enabling the ceramics’ plastic deformation. This could lead to advances in engineering ceramics for many industrial applications.

Other members of the research team are affiliated with Oak Ridge National Laboratory, Colorado State University, and the University of California, Davis.