Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Sone, Masato

2020.

Mechanics of Metallic Materials in Micro-Scale ―IV. Tensile and Bending Deformation of Micro-size Metal and the Young Modulus Measurements―.

Materia Japan,

Vol. 59,

Issue. 12,

p.

669.

Watanabe, Hitomi

Chang, Tso-Fu Mark

Schneider, Michael

Schmid, Ulrich

Chen, Chun-Yi

Iida, Shinichi

Yamane, Daisuke

Ito, Hiroyuki

Machida, Katsuyuki

Masu, Kazuya

and

Sone, Masato

2021.

Effective Young’s Modulus of Complex Three Dimensional Multilayered Ti/Au Micro-Cantilevers Fabricated by Electrodeposition and the Temperature Dependency.

Electrochem,

Vol. 2,

Issue. 2,

p.

216.

Omura, Taro

Chen, Chun-Yi

Chang, Tso-Fu Mark

Yamane, Daisuke

Ito, Hiroyuki

Machida, Katsuyuki

Masu, Kazuya

and

Sone, Masato

2022.

Effect of current density on micro-mechanical property of electrodeposited gold film evaluated by micro-compression.

Surface and Coatings Technology,

Vol. 436,

Issue. ,

p.

128315.

Jiang, Yiming

Chen, Chun-Yi

Luo, Xun

Yamane, Daisuke

Mizoguchi, Masanori

Kudo, Osamu

Maeda, Ryu

Sone, Masato

and

Chang, Tso-Fu Mark

2022.

Electrodeposition and Micro-Mechanical Property Characterization of Nickel–Cobalt Alloys toward Design of MEMS Components.

Electrochem,

Vol. 3,

Issue. 2,

p.

198.

Suzuki, Kosuke

Jiang, Yiming

Hori, Ryohei

Hashigata, Ken

Kurioka, Tomoyuki

Chen, Chun-Yi

Chang, Tso-Fu Mark

Chakraborty, Parthojit

Machida, Katsuyuki

Ito, Hiroyuki

Miyake, Yoshihiro

and

Sone, Masato

2023.

Correlation of sample geometry and grain size in micro-bending of electrodeposited polycrystalline gold.

Materials Today Communications,

Vol. 35,

Issue. ,

p.

106072.

Kanno, Shota

Omura, Taro

Wu, Jhen-Yang

Kurioka, Tomoyuki

Chen, Chun-Yi

Chakraborty, Parthojit

Machida, Katsuyuki

Ito, Hiroyuki

Miyake, Yoshihiro

Sone, Masato

and

Chang, Tso-Fu Mark

2024.

Effects of the strain rate in compression of electrodeposited gold micro-pillars toward the design of MEMS components.

Micro and Nano Engineering,

Vol. 23,

Issue. ,

p.

100254.

Hori, Ryohei

Fujita, Kazuya

Chen, Chun Yi

Kurioka, Tomoyuki

Wu, Jhen-Yang

Chang, Tso-Fu Mark

Machida, Katsuyuki

Ito, Hiroyuki

Miyake, Yoshihiro

and

Sone, Masato

2024.

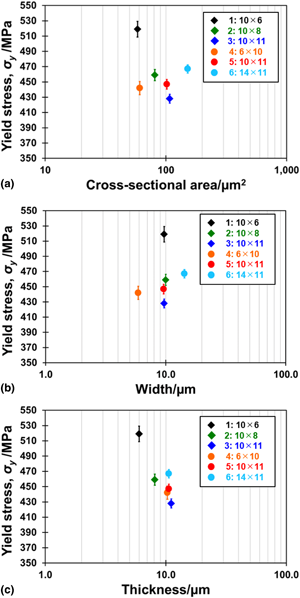

Cross-sectional geometry effect on bending strength of gold micro-cantilever with trapezoidal cross-section.

Micro and Nano Engineering,

Vol. 23,

Issue. ,

p.

100259.