Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Mavridi-Printezi, Alexandra

Guernelli, Moreno

Menichetti, Arianna

and

Montalti, Marco

2020.

Bio-Applications of Multifunctional Melanin Nanoparticles: From Nanomedicine to Nanocosmetics.

Nanomaterials,

Vol. 10,

Issue. 11,

p.

2276.

Cuzzubbo, Stefania

and

Carpentier, Antoine F.

2021.

Applications of Melanin and Melanin-Like Nanoparticles in Cancer Therapy: A Review of Recent Advances.

Cancers,

Vol. 13,

Issue. 6,

p.

1463.

Lin, Lanlan

Li, Haiyang

Chen, Zekun

Wen, Xinyu

Yan, Rui

Liu, Lei

and

Tao, Caihong

2022.

Construction of MPDA@IR780 nano drug carriers and photothermal therapy of tumor cells.

Journal of Drug Delivery Science and Technology,

Vol. 76,

Issue. ,

p.

103819.

Tao, Caihong

Lin, Lanlan

Li, Haiyang

Chen, Zekun

Wen, Xinyu

Yan, Rui

and

Liu, Lei

2022.

Construction of Mpda@Ir780 Nano Drug Carriers and Photothermal Therapy of Tumor Cells.

SSRN Electronic Journal ,

Heidari, Samira

Akhlaghi, Mehdi

Sadeghi, Mahdi

Kheirabadi, Amin Mokhtari

Beiki, Davood

Ardekani, Alireza Emami

Rouhollah, Amir

Saeidzadeh, Parya

and

Soleyman, Rouhollah

2022.

Development of 64Cu-DOX/DOX-loaded chitosan-BSA multilayered hollow microcapsules for selective lung drug delivery.

Journal of Drug Delivery Science and Technology,

Vol. 73,

Issue. ,

p.

103477.

Lin, Lanlan

Li, Haiyang

Su, Sisi

Wen, Xinyu

Yan, Rui

and

Tao, Caihong

2022.

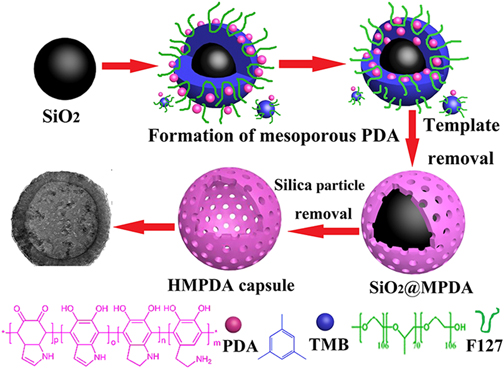

Study on the structure and properties of Fe3O4@HMPDA@HA magnetic hollow mesoporous submicron drug-carrying system.

Microporous and Mesoporous Materials,

Vol. 330,

Issue. ,

p.

111582.

Busa, Prabhakar

Koutavarapu, Ravindranadh

and

Kuthati, Yaswanth

2022.

Polydopamine-Coated Copper-Substituted Mesoporous Silica Nanoparticles for Dual Cancer Therapy.

Coatings,

Vol. 12,

Issue. 1,

p.

60.

Han, Zehua

Gao, Minjie

Wang, Zhihua

Peng, Lichao

Zhao, Yanbao

and

Sun, Lei

2022.

pH/NIR-responsive nanocarriers based on mesoporous polydopamine encapsulated gold nanorods for drug delivery and thermo-chemotherapy.

Journal of Drug Delivery Science and Technology,

Vol. 75,

Issue. ,

p.

103610.

Özcan, Sinem

Süngü Akdoğan, Çağıl Zeynep

Polat, Mustafa

Kip, Çiğdem

and

Tuncel, Ali

2023.

A new multimodal magnetic nanozyme and a reusable peroxymonosulfate oxidation catalyst: Manganese oxide coated-monodisperse-porous and magnetic core-shell microspheres.

Chemosphere,

Vol. 341,

Issue. ,

p.

140034.

Yi, Mingyuan

Xiong, Siwen

Zhang, Yuxuan

Wan, Lihong

Chen, Fanfan

Gong, He

Yan, Sitong

Fang, Lin

and

Wang, Zhifen

2023.

Antioxidating and reinforcing effect of polydopamine functionalized silica on natural rubber latex films.

Journal of Applied Polymer Science,

Vol. 140,

Issue. 12,

Zhang, Tingyu

Yu, Yaru

Han, Shuiquan

Cong, Hailin

Kang, Chuankui

Shen, Youqing

and

Yu, Bing

2024.

Preparation and application of UPLC silica microsphere stationary phase:A review.

Advances in Colloid and Interface Science,

Vol. 323,

Issue. ,

p.

103070.

Ain, Noor Ul

Khan, Bibimaryam

Zhu, Kehan

Ji, Wen

Tian, He

Yu, Xiaoxiao

Yi, Lin

Li, Duxin

and

Zhang, Zhenqing

2024.

Fabrication of mesoporous silica nanoparticles for releasable delivery of licorice polysaccharide at the acne site in topical application.

Carbohydrate Polymers,

Vol. 339,

Issue. ,

p.

122250.

Chen, Zekun

Yin, Qingyue

Xu, Liang

Guo, Wenwen

and

Tao, Caihong

2024.

Preparation and Photothermal Antimicrobial Performance of Triple Linkage Hydrogels.

Coatings,

Vol. 14,

Issue. 3,

p.

363.