Article contents

Developing fire-retardant and water-repellent bio-structural panels using nanocellulose

Published online by Cambridge University Press: 22 March 2018

Abstract

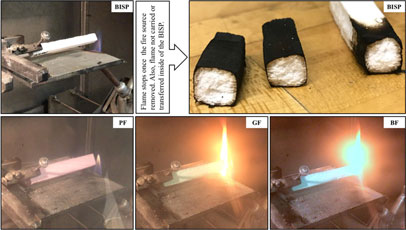

The fire-retardant and water-repellent bio-structural panels (BISPs) were successfully developed using cellulose nanofibrils, corn starch, boric acid, and n-dodecenyl succinic anhydride with adhesive-free character. Its performance properties were evaluated and compared with other well-known products on the market. The BISP's density (0.1 g/cm3) and permeance value [41.81 g/day/m2 with 5.76% coefficient of variation (CV)] were found higher than compared competitor products. The BISPs' contact angle was found 132.13° (1.59% CV) for BISP. The BISP was the only fire-retardant product, and the only one developed almost no smoke 2.20%.

- Type

- Research Letters

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

- 4

- Cited by