Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

KALELİ CAN, Gizem

MUTLU, Selma

and

MUTLU, Mehmet

2019.

Plasma Polymerized Films for Mass Sensitive Biosensors.

Natural and Applied Sciences Journal,

Vol. 2,

Issue. 1,

p.

1.

Alshammari, Abeer

Aldosari, Fadwa

Bin Qarmalah, Najd

Lsloum, Ahoud

Muthuramamoorthy, Muthumareeswaran

and

Alodhayb, Abdullah

2020.

Detection of Chemical Host–Guest Interactions Using a Quartz Tuning Fork Sensing System.

IEEE Sensors Journal,

Vol. 20,

Issue. 21,

p.

12543.

Kaleli-Can, Gizem

Özgüzar, Hatice Ferda

and

Mutlu, Mehmet

2021.

Development of mass sensitive sensor platform based on plasma polymerization technique: Quartz tuning fork as transducer.

Applied Surface Science,

Vol. 540,

Issue. ,

p.

148360.

Demir, Derya

Gundogdu, Sude

Kilic, Seyda

Kartallioglu, Tugce

Alkan, Yusuf

Baysoy, Engin

and

Kaleli Can, Gizem

2021.

A Comparison of Different Strategies for The Modification of Quartz Tuning Forks Based Mass Sensitive Sensors Using Natural Melanin Nanoparticles.

Journal of Intelligent Systems with Applications,

p.

128.

Parmar, Saurabh

Ray, Bishakha

and

Datar, Suwarna

2021.

Detection of binary and ternary mixtures of volatile organic compounds using quartz tuning fork based sensor array.

Sensors and Actuators A: Physical,

Vol. 332,

Issue. ,

p.

113198.

Özgüzar, Hatice Ferda

Meydan, Ahmet Ersin

Göçmen, Jülide Sedef

and

Mutlu, Mehmet

2021.

Single-step amphoteric surface modification through plasma polymerization: Antifouling coating for titanium substrate.

MRS Communications,

Vol. 11,

Issue. 4,

p.

523.

Kaleli-Can, Gizem

Özgüzar, Hatice Ferda

and

Mutlu, Mehmet

2022.

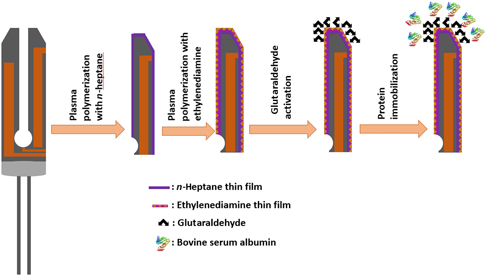

Development of QTF-based mass-sensitive immunosensor for phenylketonuria diagnosis.

Applied Physics A,

Vol. 128,

Issue. 4,

Özgüzar, Hatice Ferda

Evren, Ebru

Meydan, Ahmet Ersin

Kabay, Gozde

Göçmen, Julide Sedef

Buyukserin, Fatih

and

Erogul, Osman

2023.

Plasma‐Assisted Surface Modification and Heparin Immobilization: Dual‐Functionalized Blood‐Contacting Biomaterials with Improved Hemocompatibility and Antibacterial Features.

Advanced Materials Interfaces,

Vol. 10,

Issue. 6,

Erbaş, Kadir Can

Erdoğan, Mebrure

Çökeliler Serdaroğlu, Dilek

and

Koçum, İsmail Cengiz

2024.

A game-changing equation during the etching of tuning forks and its verification through experiments.

Measurement,

Vol. 237,

Issue. ,

p.

115135.

Gürcan, Dilhan

Baysoy, Engin

and

Kaleli-Can, Gizem

2024.

Anti-IgG Doped Melanin Nanoparticles Functionalized Quartz Tuning Fork Immunosensors for Immunoglobulin G Detection: In Vitro and In Silico Study.

Sensors,

Vol. 24,

Issue. 13,

p.

4319.

KALELİ CAN, Gizem

2024.

Molecularly Imprinted Chitosan Modified Quartz Tuning Fork Sensors for Real Time Biosensing in Liquid Environment.

Düzce Üniversitesi Bilim ve Teknoloji Dergisi,

Vol. 12,

Issue. 1,

p.

337.