Article contents

Phase separation and transformation of binary immiscible systems in molten core-derived optical fibers

Published online by Cambridge University Press: 31 March 2020

Abstract

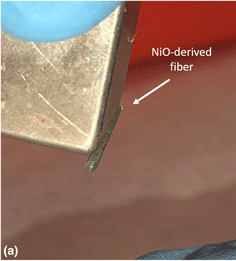

This work studies phase-separated fibers in the CaO–SiO2 and NiO–SiO2 systems. The nature of the phase-separated microstructures and underlying phase equilibria are discussed, including dimensionality, composition, and phase formation as well as the realization of ferrimagnetic behavior in the NiO–SiO2 fibers based on the formation of metallic Ni inclusions. In addition to understanding the composition/processing relationships in these systems, the work represents a step forward toward novel magneto-optic fibers. It is important to understand the underlying materials science in order to advance the properties of novel optical fibers possessing engineered heterogeneities in the core.

- Type

- Research Letters

- Information

- Copyright

- Copyright © Materials Research Society 2020

References

- 5

- Cited by