Article contents

Platinum metallization on silicon and silicates

Published online by Cambridge University Press: 18 November 2020

Abstract

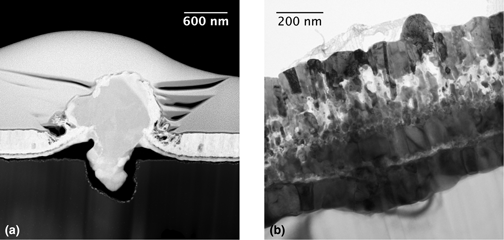

Thin films of platinum deposited by physical vapor deposition (PVD) processes such as evaporation and sputtering are used in many academic and industrial settings, for example to provide metallization when tolerance to corrosive thermal cycling is desired, or in electrocatalysis research. In this review, various practical considerations for platinum (Pt) metallization on both Si and SiO2 are placed in context with a comprehensive data review of diffusion measurements. The relevance of diffusion phenomena to the development of microstructure during deposition as well as the effect of microstructure on the properties of deposited films are discussed with respect to the Pt–Si system. Since Pt and Si readily form silicides, diffusion barriers are essential components of Pt metallization on Si, and various failure modes for diffusion barriers between Pt and Si are clarified with images obtained by electron microscopy. Adhesion layers for Pt films deposited on SiO2 are also considered.

- Type

- REVIEW

- Information

- Copyright

- Copyright © The Author(s), 2020, published on behalf of Materials Research Society by Cambridge University Press

Footnotes

Present address: Sandia National Laboratories, Albuquerque, New Mexico, USA.

References

- 7

- Cited by